TIG brazing process for copper-aluminum dissimilar metal

A technology for dissimilar metals and brazing processes, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as performance degradation of brazed joints, achieve low production cost, simple operation, and solve performance degradation of brazed joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

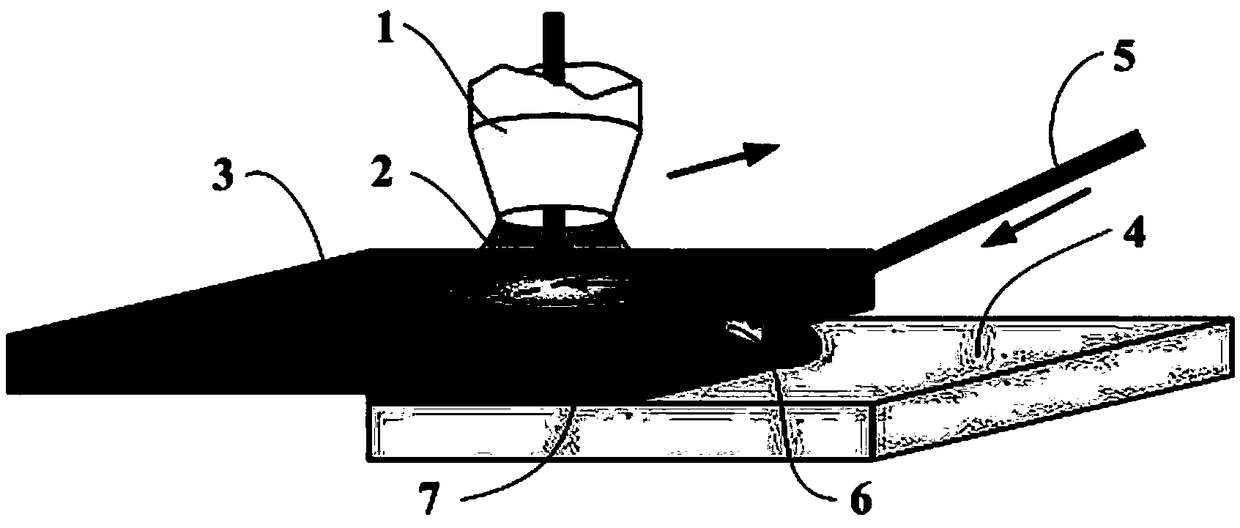

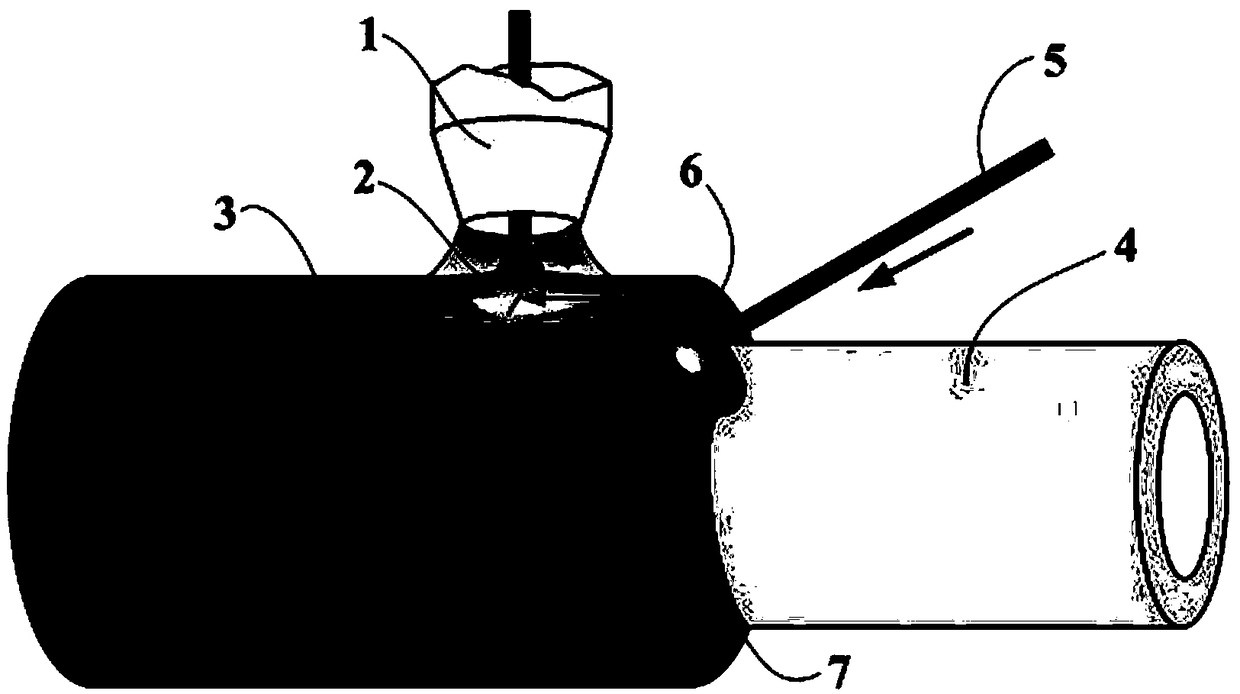

[0041] A copper-aluminum dissimilar metal TIG brazing process, the steps are as follows:

[0042] (1) Preparatory work: first polish the overlapping parts of copper 3 and aluminum 4 with fine sandpaper, and clean them with a brush; fix aluminum 4 on the water-cooled tooling; It needs to be adjusted (such as 10mm); connect the positive cable of the TIG welding machine to the tooling, and the nozzle 1 of the TIG welding torch is 5-8mm away from the surface of the copper 3 and is perpendicular to the copper 3.

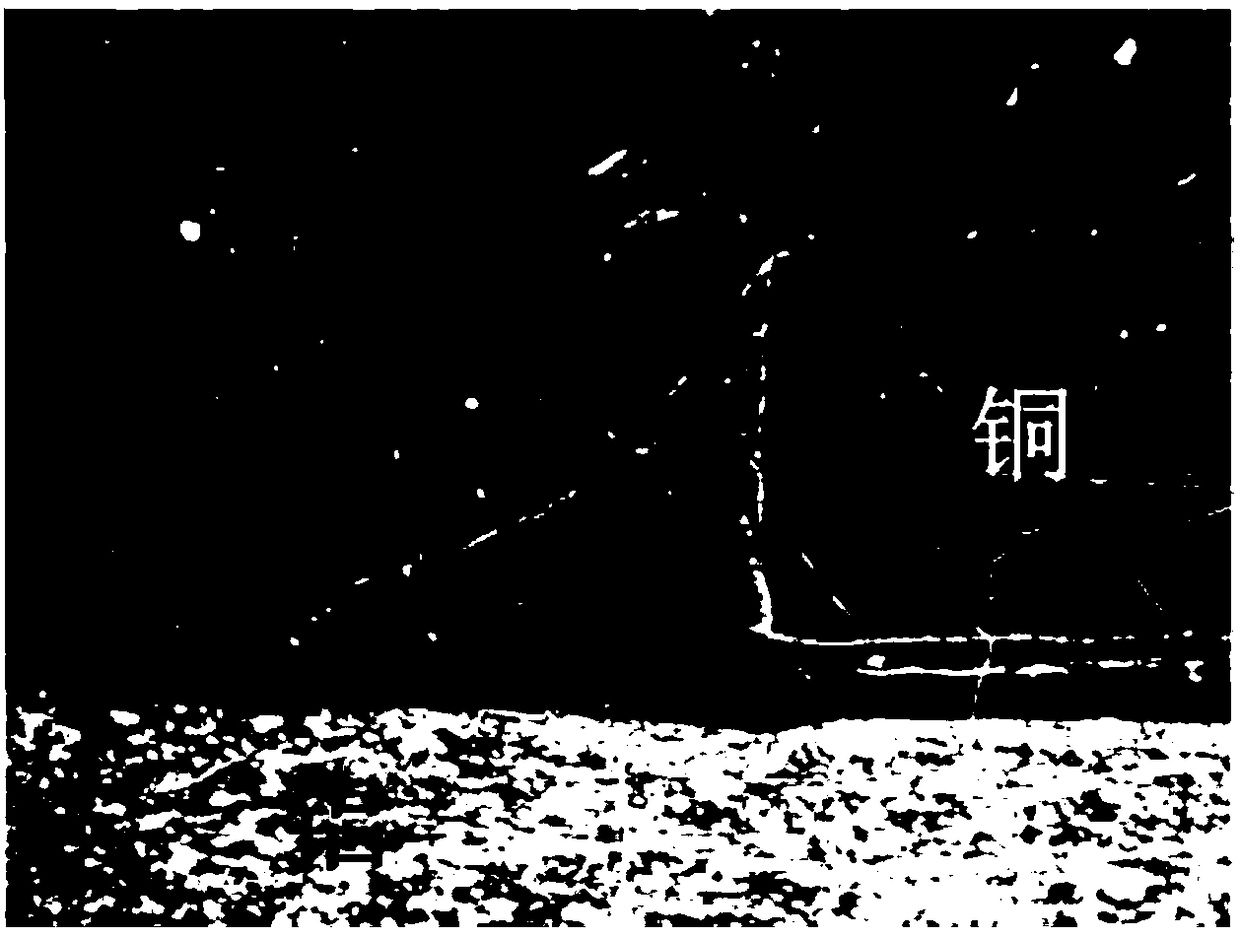

[0043] (2) Process parameter adjustment: according to the size and thickness of copper 3 and aluminum 4, adjust the distance from TIG torch nozzle 1 to the overlapping edge of copper 3 (plate or pipe) and the TIG current. Ignite the TIG electric arc 2 and heat it for 3-5 seconds. At this time, the welding wire 5 is fed into the welding area on the side of the copper 3 at a certain angle (30°-50° with the plane of the aluminum 4). Both copper 3 and aluminum 4 form a wetti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com