Mold case for producing high-temperature alloy single crystal blades

A high-temperature alloy and single-crystal blade technology, which is applied in the field of a heat-conducting formwork for the manufacture of high-temperature alloy single-crystal blades, can solve problems such as high production costs, cumbersome operations, and difficult production, and achieve improved thermal conductivity, faster cooling speed, Improving the effect of heat and temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the method of using silicon carbide as a whole to make a heat-conducting formwork

[0022] Preparation: use silicon carbide powder as powder, silica sol as binder, add other auxiliary materials (such as wetting agent and defoamer) to mix slurry, and use silicon carbide particles as sand material.

[0023] Production Method:

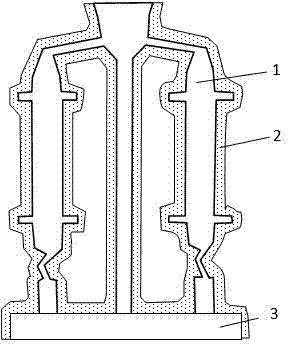

[0024] 1) Assemble the blade wax mold 1 according to the usual method to form the inner cavity of the mold shell.

[0025] 2) The surface layer and the back layer of the silicon carbide mold shell 2 are made by using the ordinary investment casting method on the outer surface of the blade wax mold 1 by using the method of sanding with slurry.

[0026] 3) After the silicon carbide mold shell 2 is dried, dewaxing and burning of residual wax are carried out by the usual method, and the calcination strengthening is carried out in an air atmosphere.

[0027] 4) The silicon carbide mold shell 2 is preheated and kept warm in a vacuum furna...

Embodiment 2

[0029] Embodiment two, use graphite and pottery to make the method for heat conduction formwork

[0030] Use ceramics to make the surface layer of the thermally conductive formwork:

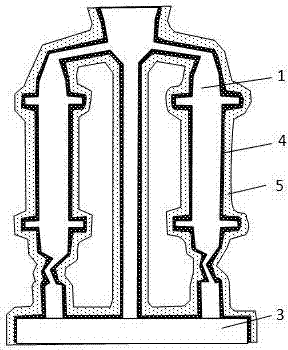

[0031] 1) Assemble the blade wax mold 1 according to the usual method to form the inner cavity of the mold shell.

[0032] 2) The ceramic surface layer 4 is made on the outer surface of the blade wax mold 1 by using a common precision casting method, using corundum powder slurry and sand material, and adopting the method of sticking slurry and pouring sand.

[0033] Use graphite to make the back layer of the thermally conductive formwork:

[0034] 3) Use graphite as powder, silica sol as binder, add other auxiliary materials (such as wetting agent and defoamer) to mix slurry, and use graphite particles as sand material.

[0035] 4) Use the ordinary precision casting method on the outer surface of the ceramic surface layer 4, use the slurry and sand material in step 3), and use the method of sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com