Abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material and application thereof

A powder material and ferroalloy technology, which is applied in the field of rare earth-containing nickel-chromium-iron alloy powder materials, can solve the problems of high nickel content of precious metals, easy peeling of hard phases, and aggravated wear, so as to achieve uniform distribution, improve comprehensive performance, and reduce alloy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

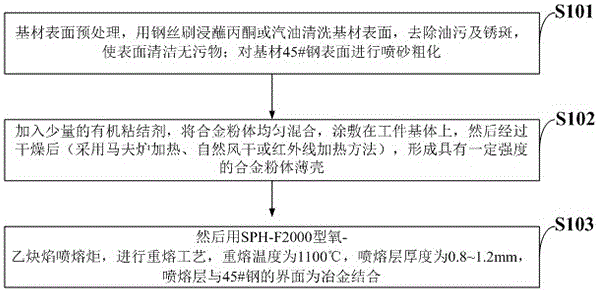

[0024] The application of the rare earth-containing nickel-chromium-iron alloy powder material used for wear-resistant grain wear in the embodiment of the present invention is the preparation of wear-resistant coating; as figure 1 As shown, the preparation method of the wear-resistant coating of the embodiment of the present invention comprises the following steps:

[0025] S101: Substrate surface pretreatment, use a steel wire brush dipped in acetone or gasoline to clean the surface of the substrate, remove oil and rust spots, and make the surface clean and free of dirt; sandblast and roughen the surface of the substrate 45# steel;

[0026] S102: Add a small amount of organic binder, mix the alloy powder evenly, coat it on the workpiece substrate, and then dry it (heating in a muffle furnace, natural air drying or infrared heating) to form an alloy powder with a certain strength thin shell;

[0027] S103: Then use the SPH-F2000 type oxygen-acetylene flame spraying torch to c...

Embodiment 1

[0030] In the embodiment of the present invention, ingredients are first prepared according to the determined chemical composition of the alloy, and the prepared materials are melted into molten metal in an induction furnace, and necessary refining treatment is carried out to obtain qualified molten metal. The alloy powder is prepared by an atomization method, and the powder is subjected to precipitation, drying, powder sieving, and inspection procedures to obtain qualified powder materials.

[0031] The SPH-F2000 oxygen-acetylene flame spraying torch produced by Shanghai Spraying Machinery Factory is used. The alloy powder is evenly coated on the end face of the 45# steel sample after cleaning, degreasing and sandblasting (20-40 mesh corundum sand) by the spray melting method. The thickness of the spray melting layer is 0.8~1.2mm. The interface with 45# steel is a metallurgical bond.

[0032] The technological process of spray melting mainly includes: base material surface p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com