Anticorrosion lead-acid battery fiberglass diaphragm

A lead-acid battery and glass fiber technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve the problem of affecting the cycle life of the battery, the poor gas permeability of the polyolefin diaphragm, and the inability to meet the rapid charging of the battery. Discharge and other problems, to achieve the effect of low oxidation resistance, good hydrophilicity, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

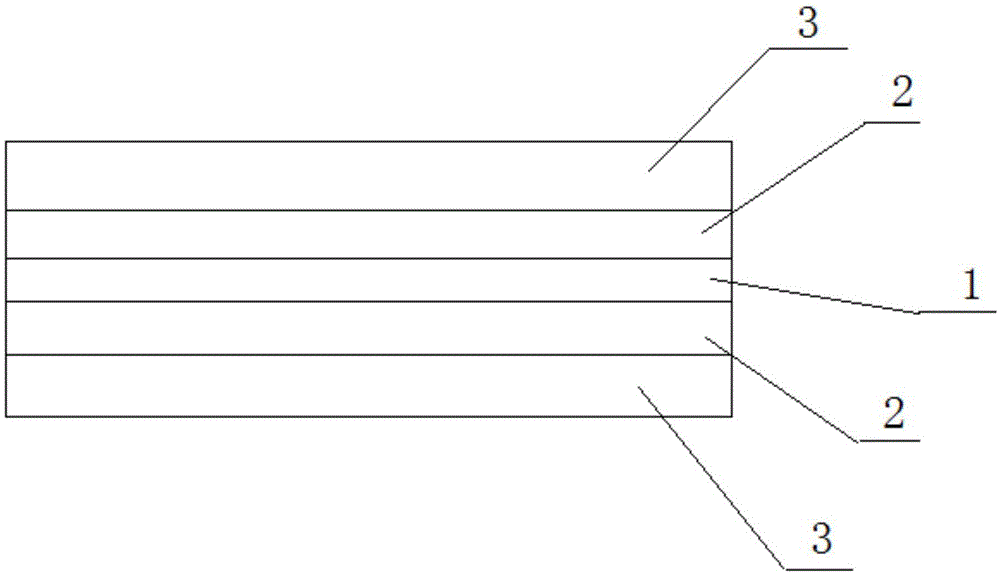

[0017] Corrosion-resistant lead-acid battery fiberglass separator, see figure 1 , including glass fiber composite corrosion resistance, 1. Polymer and water-soluble resin composite layer on both surfaces of glass fiber and polyvinyl alcohol fiber composite layer 2. Nanoparticles on the outer surface of polymer and water-soluble resin composite layer Particle Coating3.

[0018] The corrosion-resistant layer includes the following components by weight: 80 parts of glass fiber, 3 parts of magnesium hydroxide, 15 parts of acetyl tributyl citrate, 6 parts of styrene, 10 parts of graphite fluoride, and 10 parts of tricresyl phosphate , 30 parts of fatty acid amide, 20 parts of nitrile rubber, 2 parts of potassium dichromate.

[0019] In the composite layer of polymer and water-soluble resin, the polymer is polypropylene and polyethylene terephthalate with a mass ratio of 1:1, and the water-soluble resin is polyethylene with a mass ratio of 1:2:1. Alcohol, polyvinylpyrrolidone, pol...

Embodiment 2

[0026] Corrosion-resistant lead-acid battery fiberglass separator, see figure 1 , including glass fiber composite corrosion resistance, 1. Polymer and water-soluble resin composite layer on both surfaces of glass fiber and polyvinyl alcohol fiber composite layer 2. Nanoparticles on the outer surface of polymer and water-soluble resin composite layer Particle Coating3.

[0027] The corrosion-resistant layer includes the following components by weight: 80 parts of glass fiber, 1 part of magnesium hydroxide, 20 parts of acetyl tributyl citrate, 5 parts of styrene, 15 parts of graphite fluoride, and 5 parts of tricresyl phosphate , 35 parts of fatty acid amide, 15 parts of nitrile rubber, 3 parts of potassium dichromate.

[0028] In the composite layer of polymer and water-soluble resin, the polymer is a mixture of one or several kinds of polyethylene, and the water-soluble resin is hydroxymethyl cellulose and cellulose acetate with a mass ratio of 1:1:2 , A mixture of cellulose...

Embodiment 3

[0032] Corrosion-resistant lead-acid battery fiberglass separator, see figure 1 , including glass fiber composite corrosion resistance, 1. Polymer and water-soluble resin composite layer on both surfaces of glass fiber and polyvinyl alcohol fiber composite layer 2. Nanoparticles on the outer surface of polymer and water-soluble resin composite layer Particle Coating3.

[0033] The corrosion-resistant layer includes the following components by weight: 80 parts of glass fiber, 5 parts of magnesium hydroxide, 10 parts of acetyl tributyl citrate, 7 parts of styrene, 5 parts of graphite fluoride, and 15 parts of tricresyl phosphate , 25 parts of fatty acid amide, 25 parts of nitrile rubber, 1 part of potassium dichromate.

[0034] In the composite layer of polymer and water-soluble resin, the polymer is polyimide, and the water-soluble resin is cellulose acetate butyrate, cellulose acetate propionate, and pullulan at a mass ratio of 1:1:1. mixture.

[0035] The nanoparticle coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com