A kind of welding strip for surfacing welding of nickel-saving and high-nitrogen austenitic stainless steel strip and supporting flux and preparation method thereof

A high nitrogen austenite, stainless steel strip technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of low corrosion resistance and hydrogen stripping resistance of the surfacing layer metal, and achieve excellent slag removal performance, The effect of reducing production costs and reducing harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

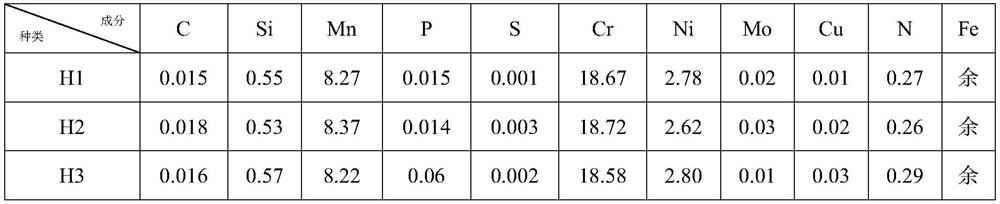

[0026] Example 1: According to the components of the welding strip designed according to the present invention, three types of welding strips were prepared, denoted as H1-H3, and their chemical compositions are shown in Table 1.

Embodiment 2

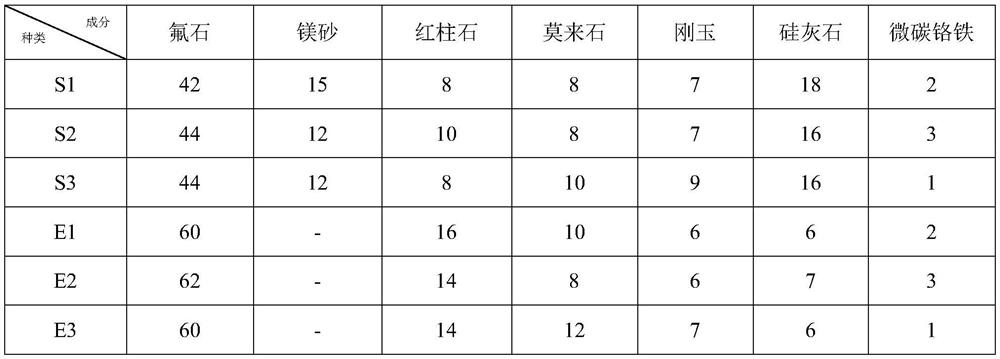

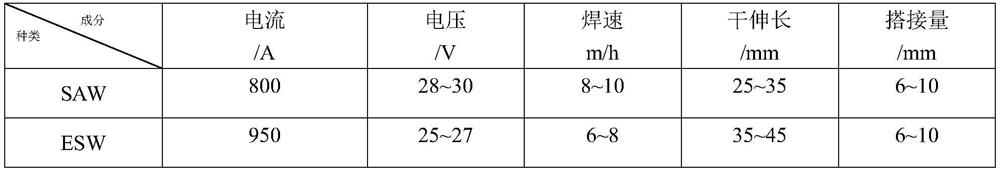

[0027] Example 2: According to the flux components designed in the present invention, three fluxes for submerged arc surfacing (SAW) with electrodes were designed, which are denoted as S1-S3, and the components and mass fractions of the components are shown in Table 2.

Embodiment 3

[0028] Example 3: According to the flux components designed in the present invention, three fluxes for electroslag surfacing (ESW) with electrodes were designed, which are denoted as E1-E3. The components and mass fractions of the components are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com