Patents

Literature

36results about How to "Efficient cascade utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

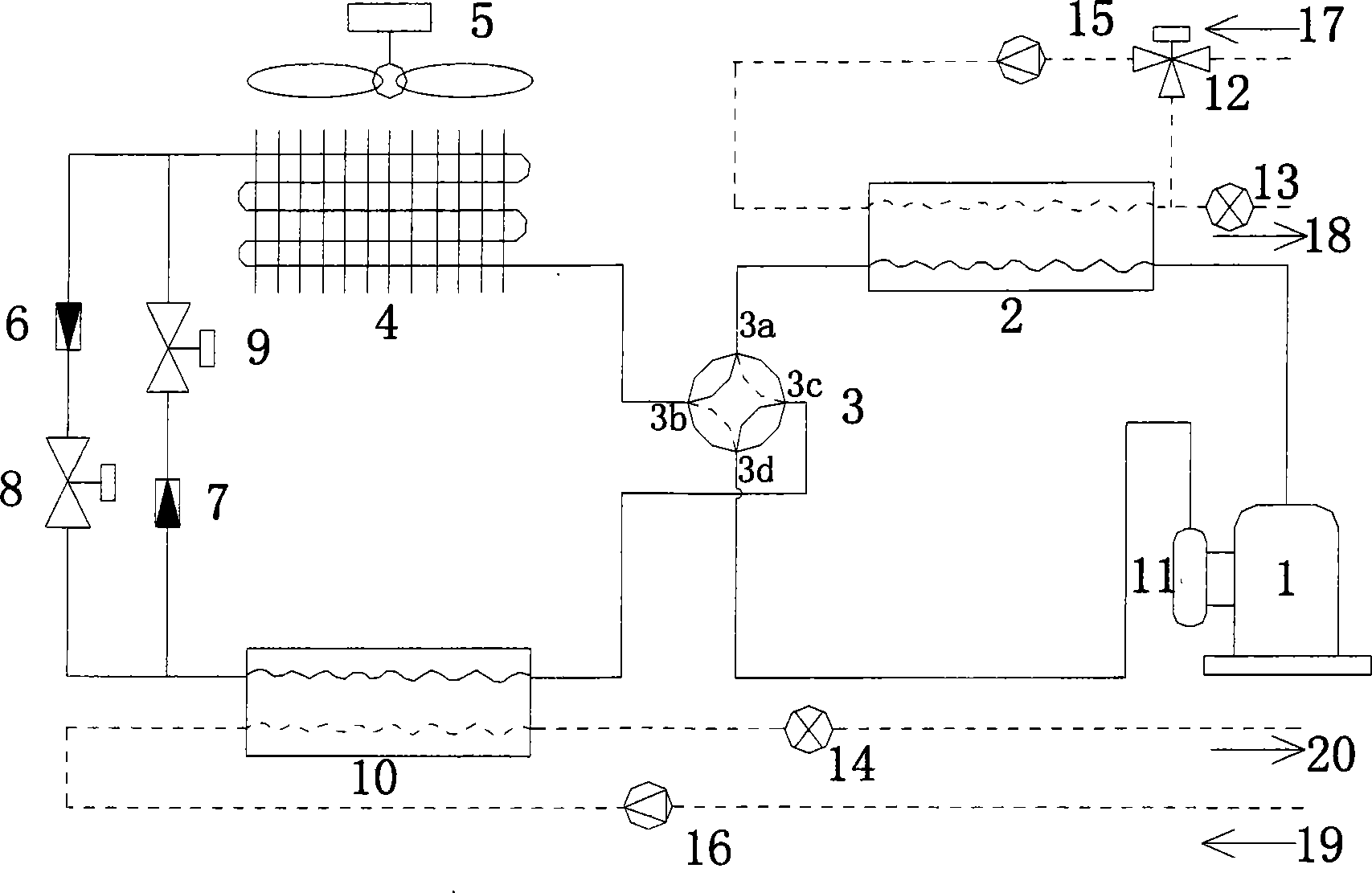

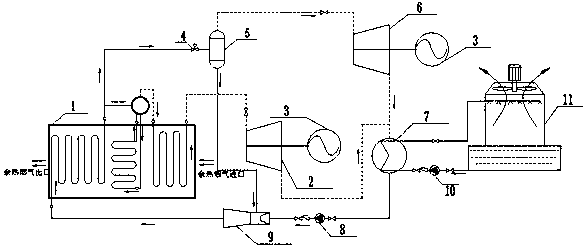

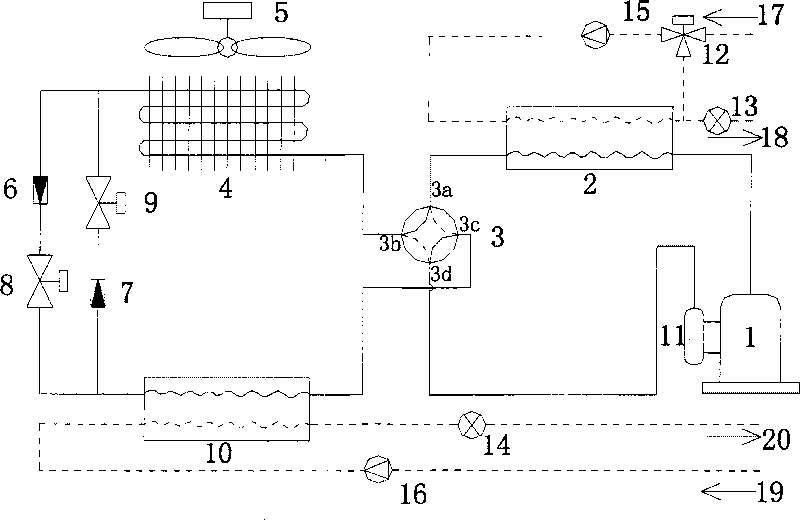

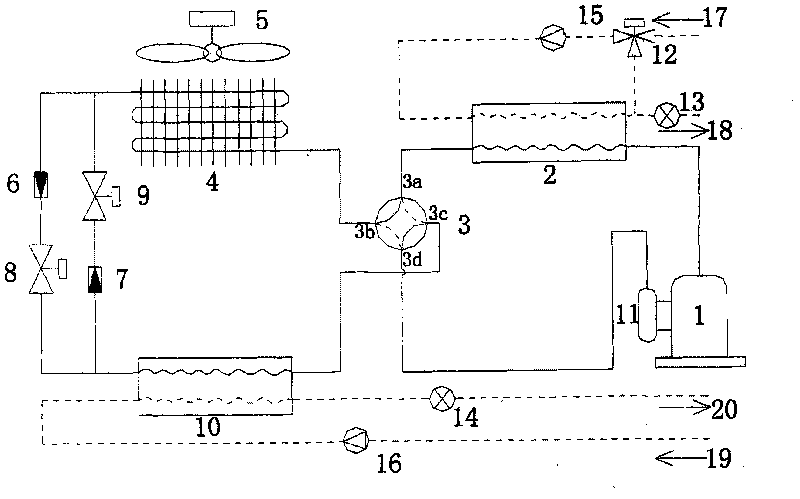

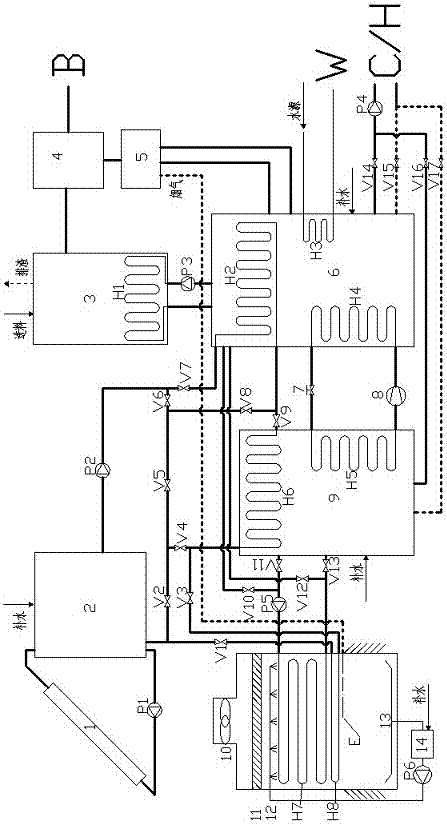

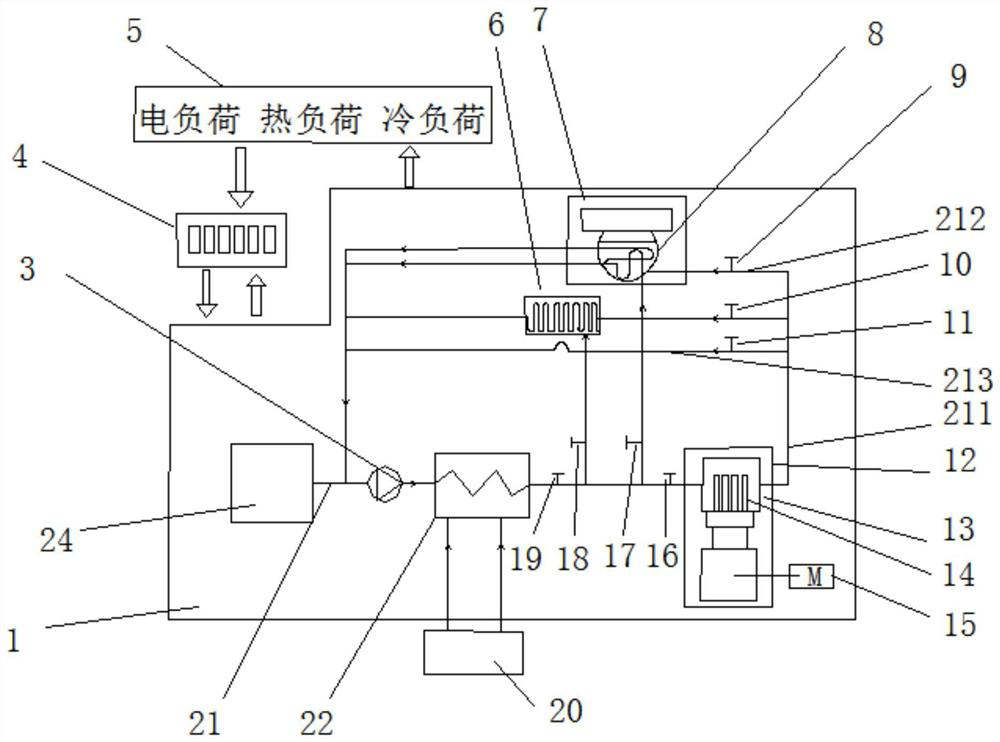

Cascade energy usable variable capacity family energy resource system

InactiveCN101240949AAvoid wet compressionRealize the supplyEnergy recovery in ventilation and heatingHeat pumpsSolenoid valveEngineering

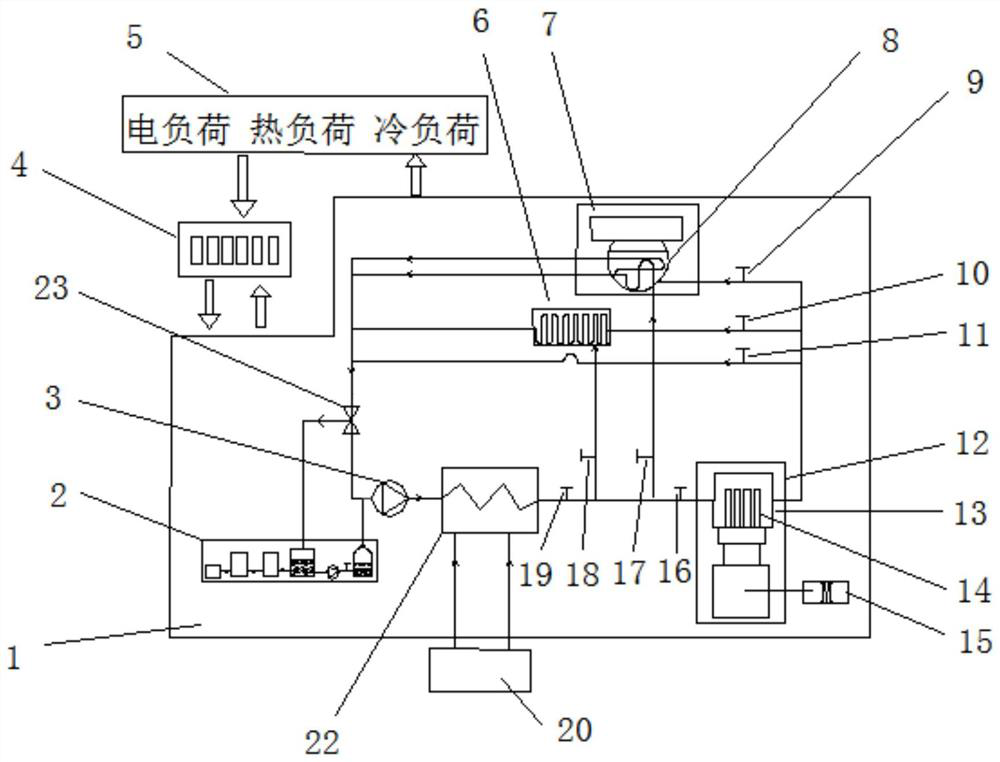

The present invention provides an adjustable volume family energy system utilized by step energy, the invention includes a compressor, a hot water heat exchanger, a four-way reversing valve, an outdoor wind cooling pipe coil, a first check valve, a second check valve, a first electronic expansion valve, a second electronic expansion valve, an air conditioning hot and cold heat exchanger, a gas-liquid separator, a water side electric three-way control way, a first solenoid valve, a second solenoid valve, a first water pump, a second water pump. These parts form a refrigerant loop, a domestic hot-cold water loop, realize refrigerating and hot water supplying, single refrigerating, single hot water supplying, single warm supplying, warm supplying and hot water supplying five modes. The control part of the refrigerant loop only has four-way reversing valve and electronic expansion valve in traditional air conditioning system, does not exist refrigerant potential safety hazard. The function of each system is mainly realized by switch and adjustment of the water side two solenoid valves and electric three-way control way, has a simple control, credible security.

Owner:SHANGHAI JIAO TONG UNIV

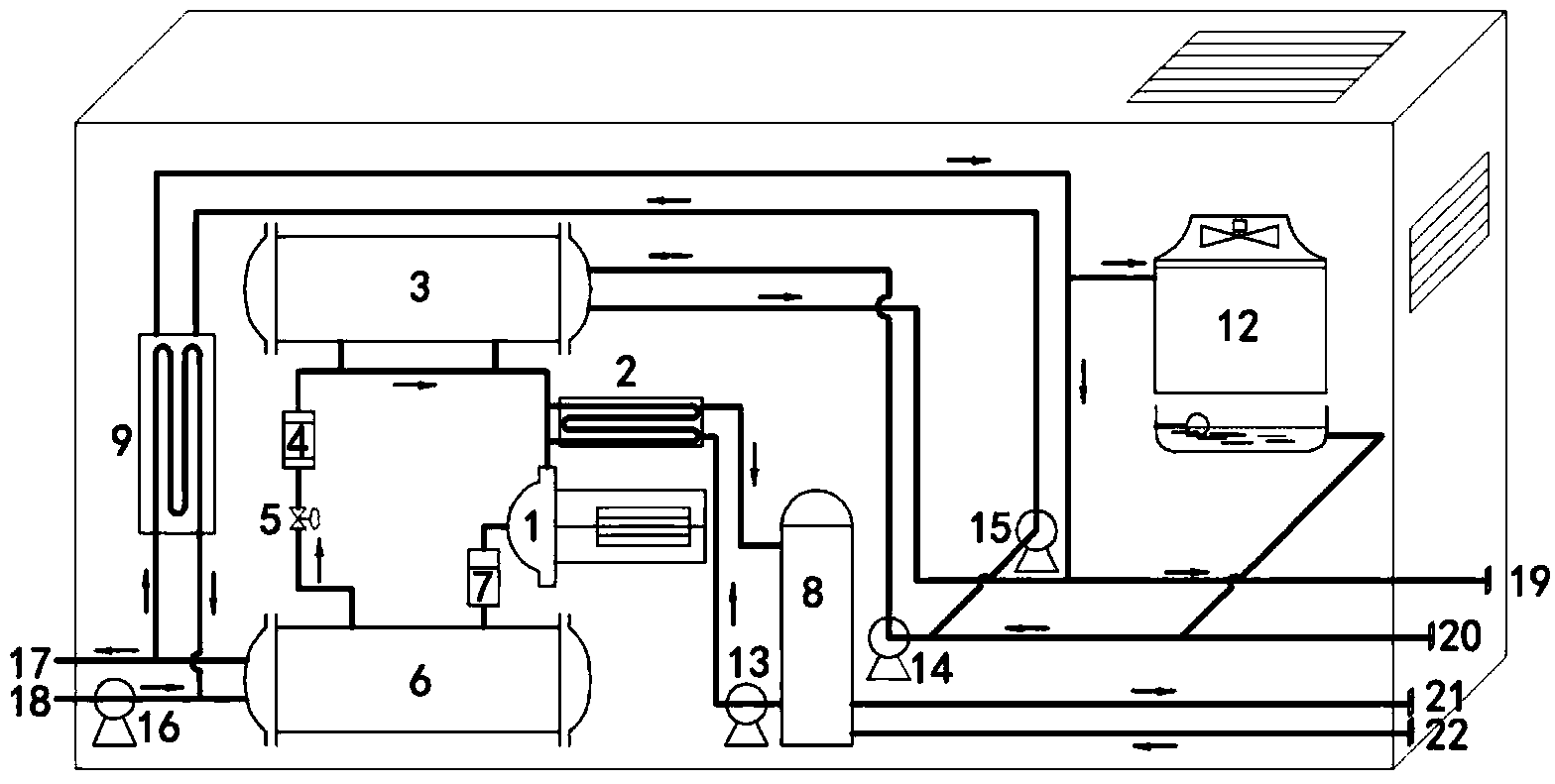

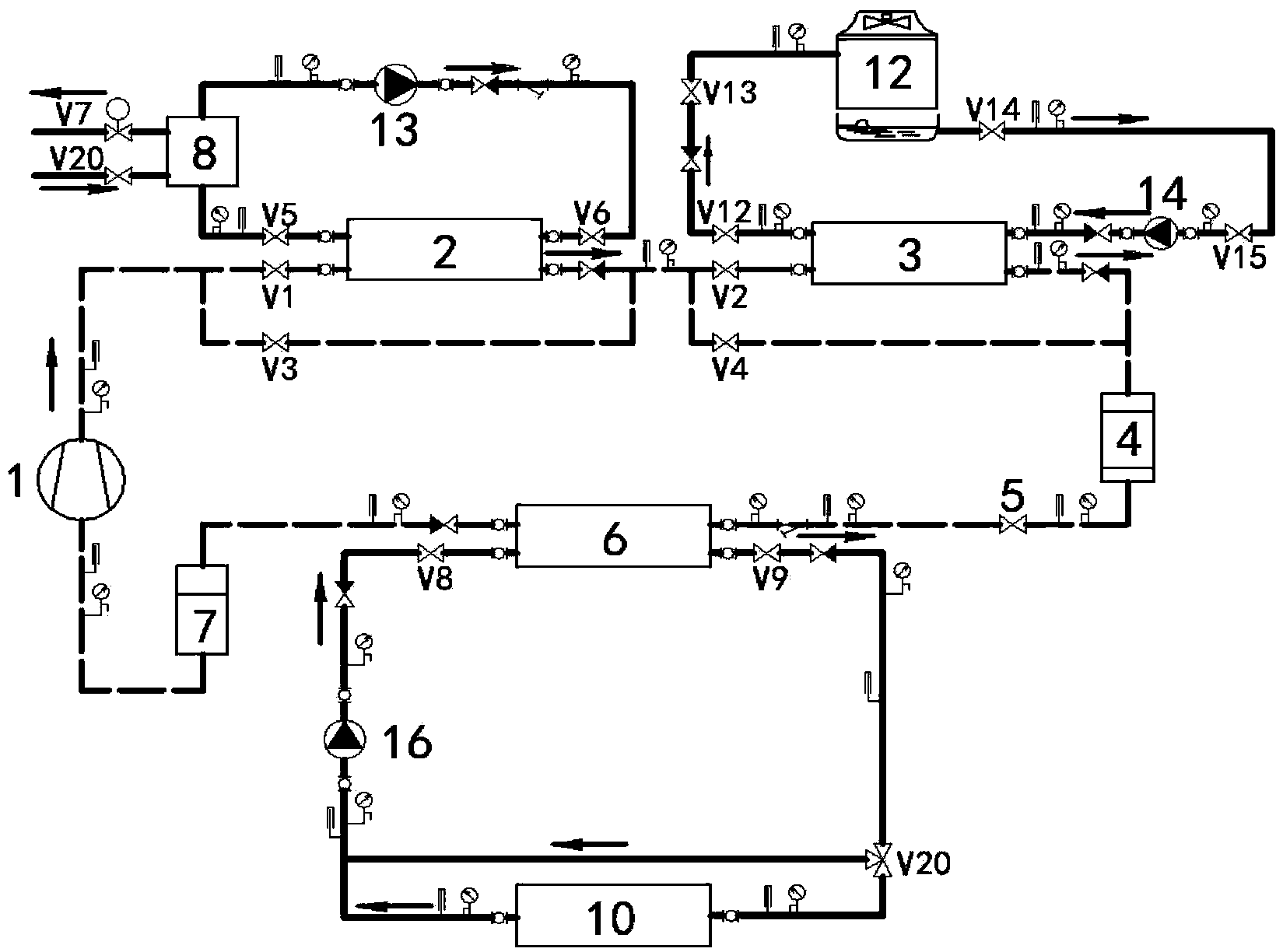

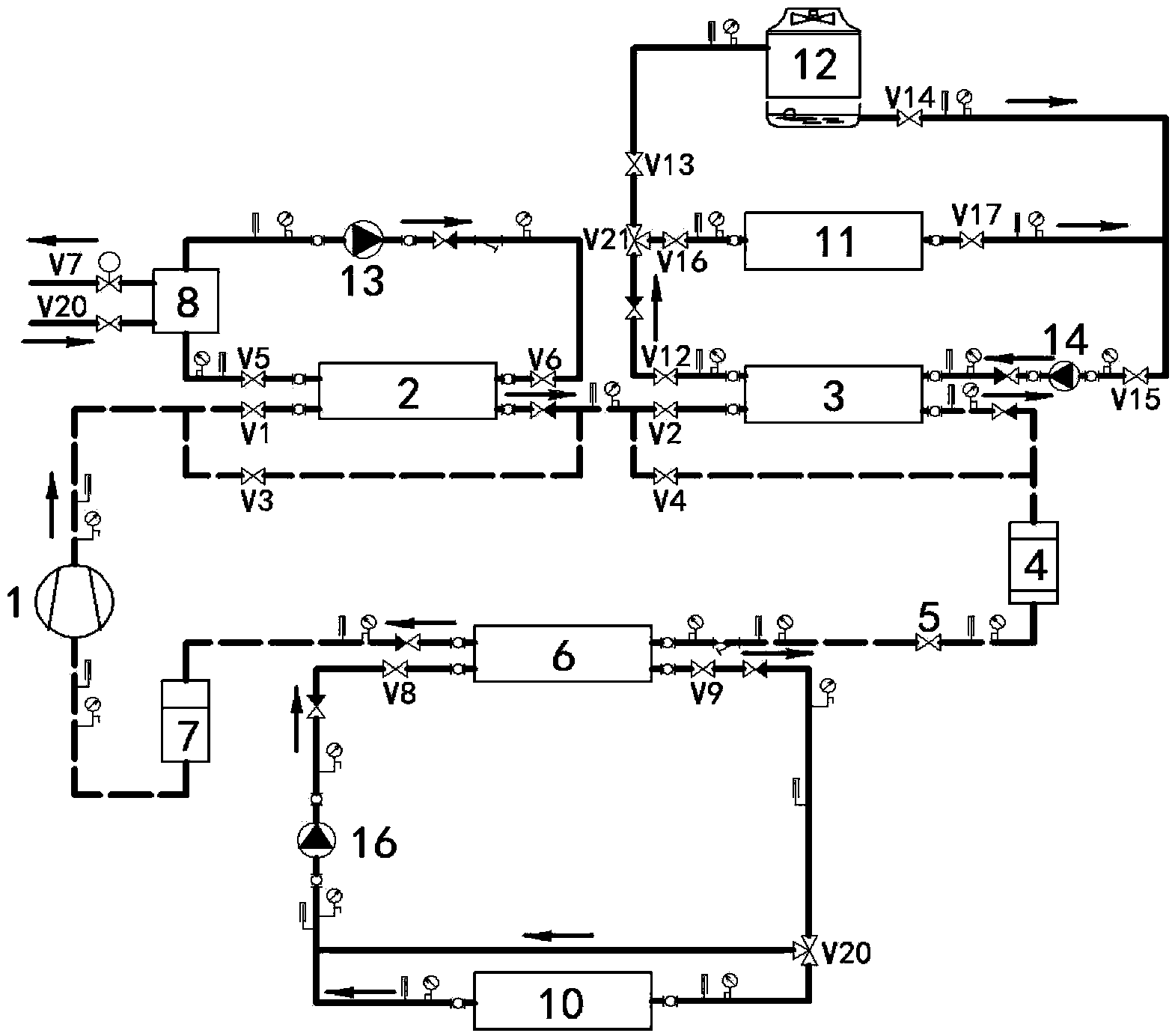

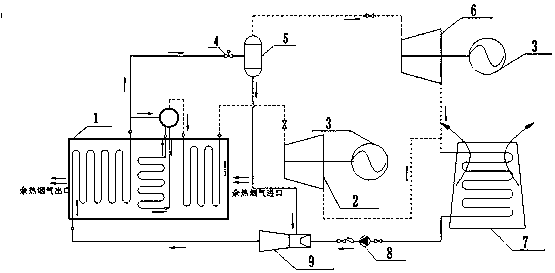

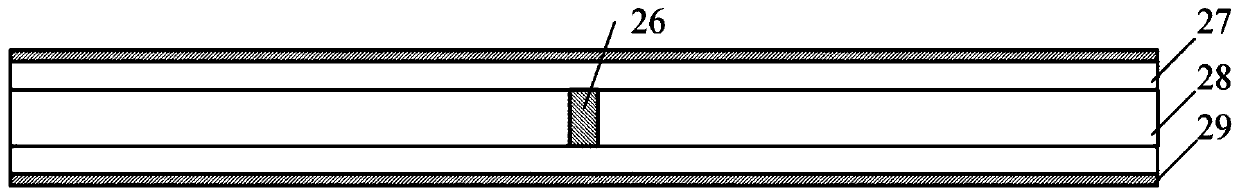

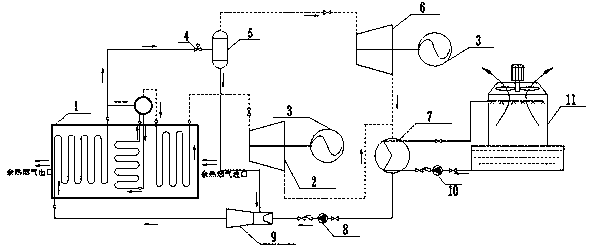

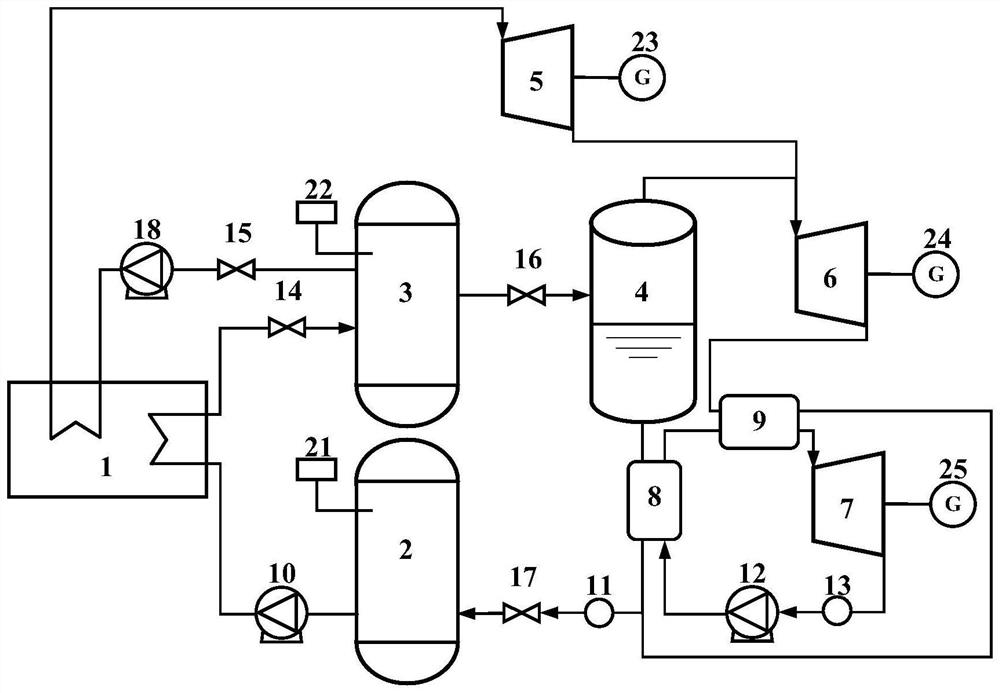

Multifunctional combined supply type integrated air conditioner unit for data rooms

InactiveCN103940145AReduce volumeImprove energy efficiencySpace heating and ventilation detailsHeating and refrigeration combinationsPlate heat exchangerCooling tower

The invention discloses a combined supply type air conditioner unit integrating the refrigerating function, the high-temperature hot water preparation function, the low-temperature hot water preparation function and the like. The air conditioner unit is mainly composed of a compressor 1, a high-temperature heat recovery device 2, a low-temperature heat recovery device 3, a dry filter 4, a throttling valve 5, an evaporator 6, a gas-liquid separator 7, a heat storage water tank 8, a plate heat exchanger 9, a cooling tower 12, a hot water circulating pump 13, a circulating pump 14, a cooling water pump 15, a chilled water pump 16, a chilled water outlet 17, a chilled water inlet 18, a low-temperature hot water outlet 19, a low-temperature hot water inlet 20, a high-temperature hot water outlet 21 and a heat storage water tank water adding opening 22, wherein all the components are connected through pipelines and are switched and adjusted through valves. According to the combined supply type air conditioner unit, circulated waste heat is refrigerated as a heat source by means of the high-temperature heat recovery device and the low-temperature heat recovery device, and user heat loads are borne through heat recovery. In addition, cooling free of charge can be achieved, and the combined supply type air conditioner unit has the good applicability and adaptability for the data room and the like needing perennial cooling.

Owner:CHONGQING UNIV

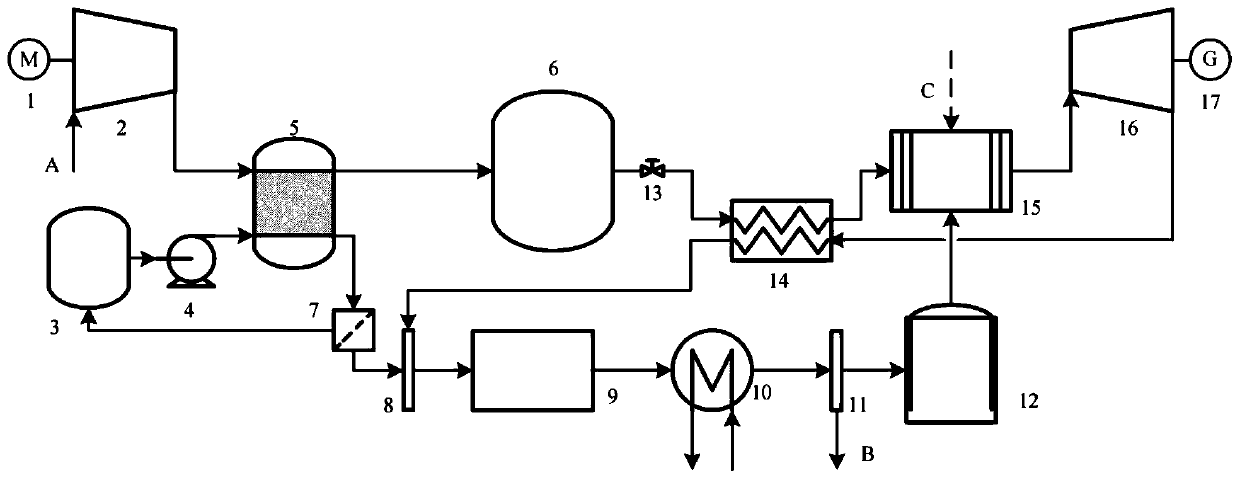

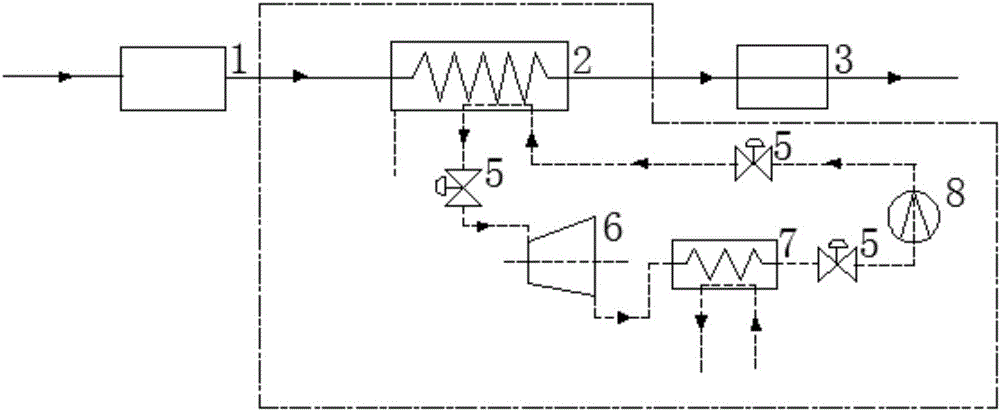

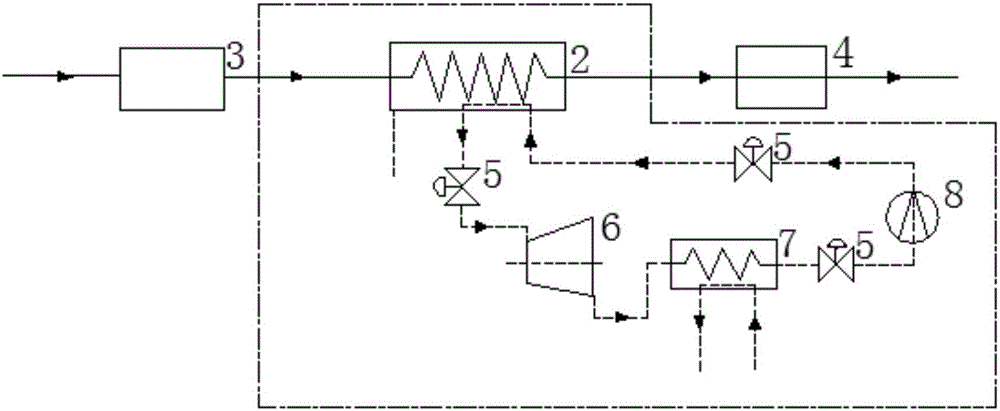

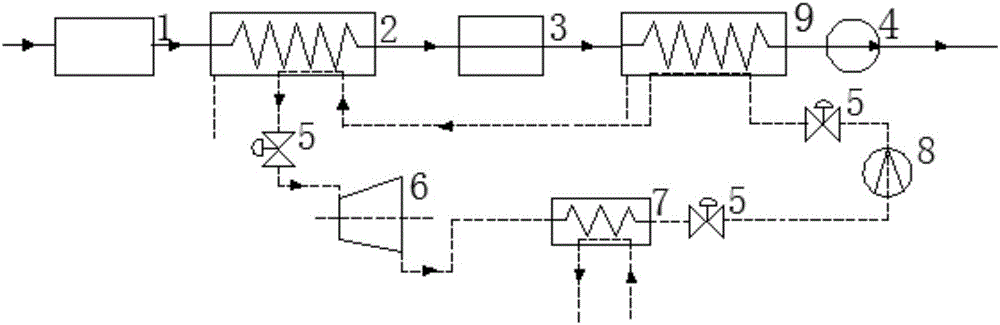

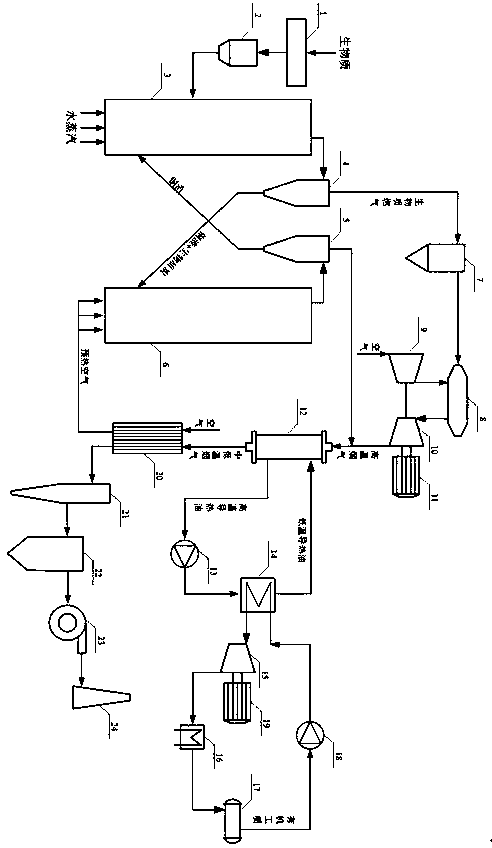

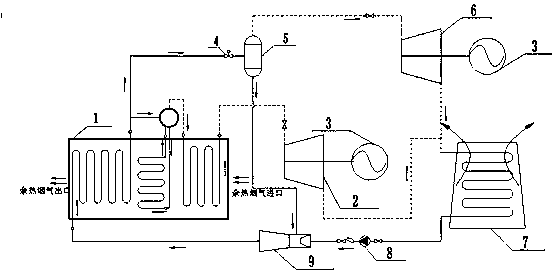

Dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system

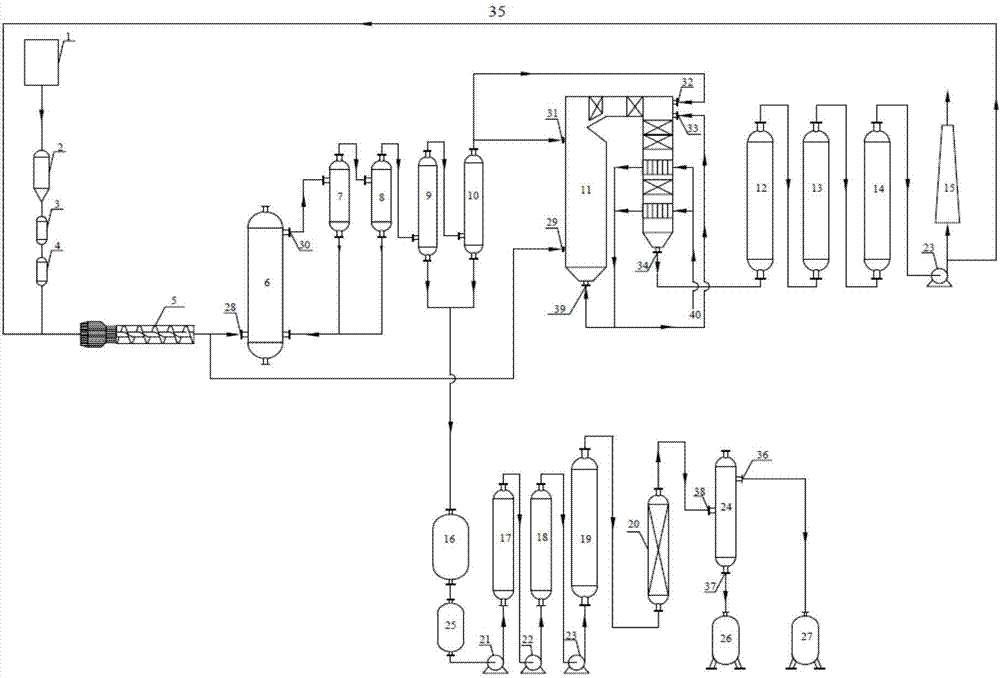

ActiveCN108167040AEfficient cascade utilizationEliminate cavitationSteam engine plantsCavitationOrganic Rankine cycle

The invention relates to a dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system and belongs to the technical field of energy and environments. According to the system, mid-low-temperature waste heat flue gas with the temperature being 200-350 DEG C is utilized as the driving heat source, organic working medium feeding liquid is preheated to be in a saturated liquid state in an ORC waste heat boiler preheating segment, then part of a saturated liquid organic working medium enters an evaporation segment and an superheating segment ofa waste heat boiler, generated saturated (or superheated) steam enters a radial-inward-flow turbine, and a high-pressure stage ORC expansion work doing process is completed; and the other part of thesaturated liquid organic working medium enters a flash vessel after being subjected to throttling and pressure reducing, saturated steam separated from the flash vessel enters a low-pressure stage screw expander, and a low-pressure stage ORC expansion work doing process is completed. An ejection compressor recovers the liquid-phase working medium separated out of the flash vessel, utilization ofliquid conveying pumps is reduced, the system is simplified, and the possibility of pump cavitation is eliminated.

Owner:KUNMING UNIV OF SCI & TECH

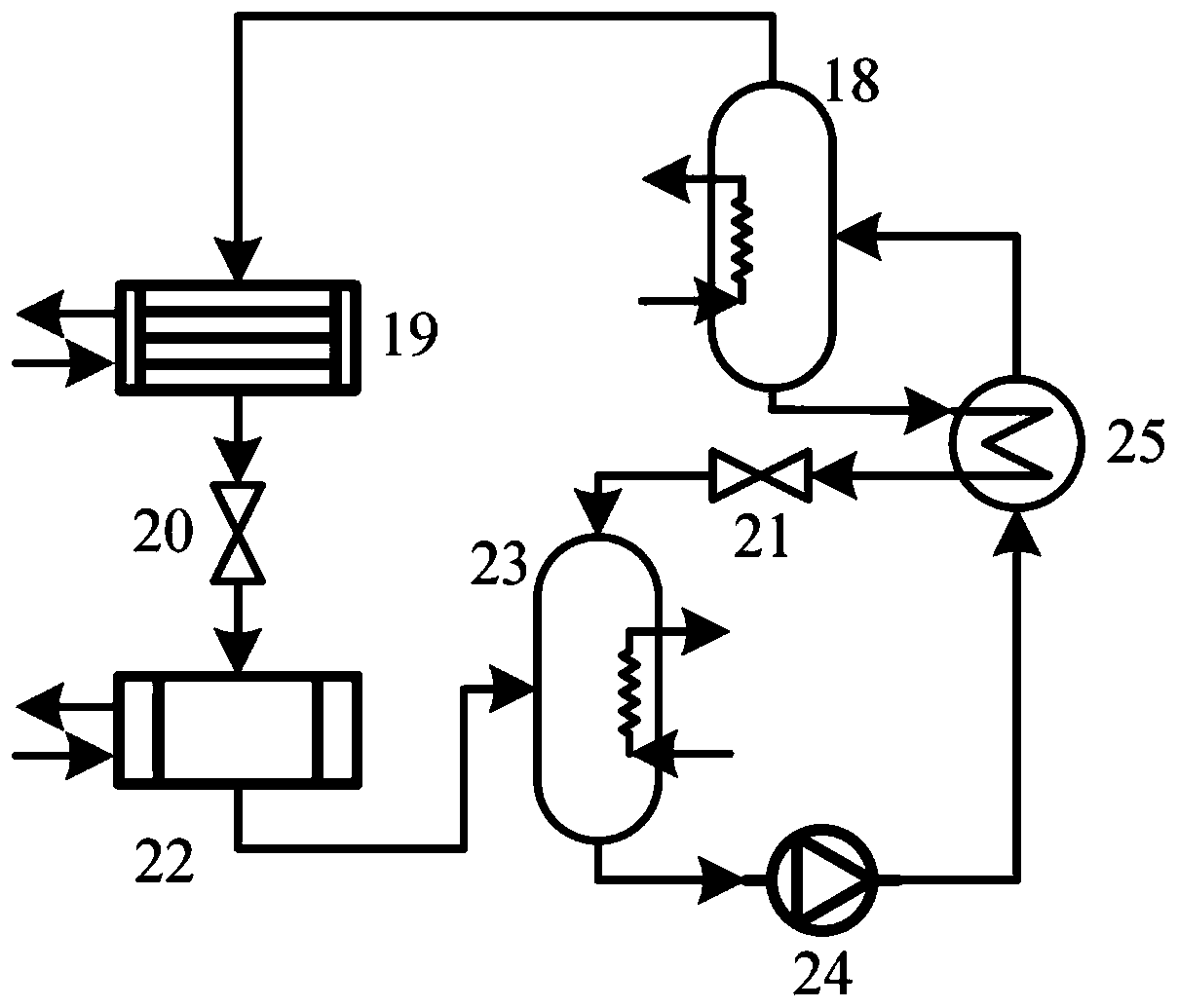

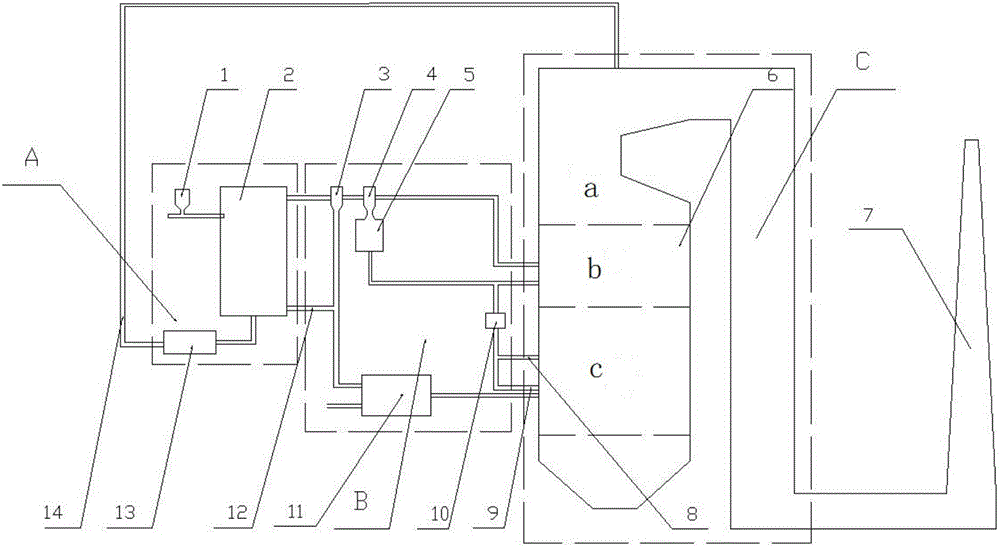

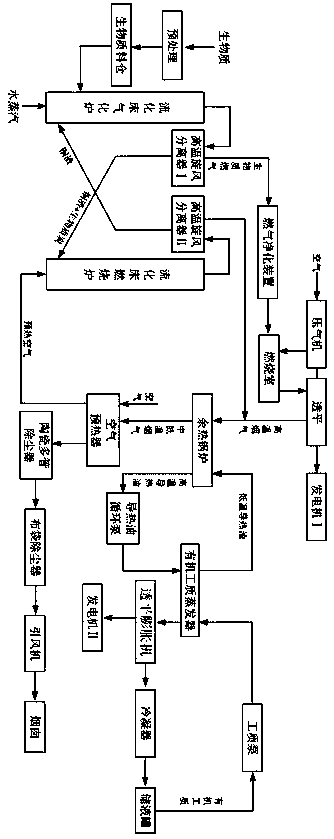

Combined cooling, heating and power system and method adopting compressed air and thermochemistry coupling for energy storage

ActiveCN110849023AMeet the power load demandStable power outputEnergy storageChemical/physical/physico-chemical stationary reactorsSyngasProcess engineering

The invention discloses a combined cooling, heating and power system and method adopting compressed air and thermochemistry coupling for energy storage. A compressed air energy storage unit is used for converting surplus power energy or surplus power energy generated by renewable energy sources into pressure potential energy and storing the pressure potential energy in a high-pressure gas storagedevice; a thermochemistry converting unit is used for converting compressed heat energy generated by the compressed air energy storage unit in the working process into chemical energy and storing thechemical energy into a synthetic gas storage tank; and a compressed air energy release unit is used for converting the pressure potential energy stored in the high-pressure gas storage device and thechemical energy in the synthetic gas storage tank into stable power energy to be output, and thus the energy converting process of inputting the surplus power energy to a system or outputting the stable power energy from the surplus power energy generated by the renewable energy sources to the system is completed. According to the combined cooling, heating and power system and method, the renewable energy sources are efficiently utilized, and diversification of the system function is achieved.

Owner:XI AN JIAOTONG UNIV

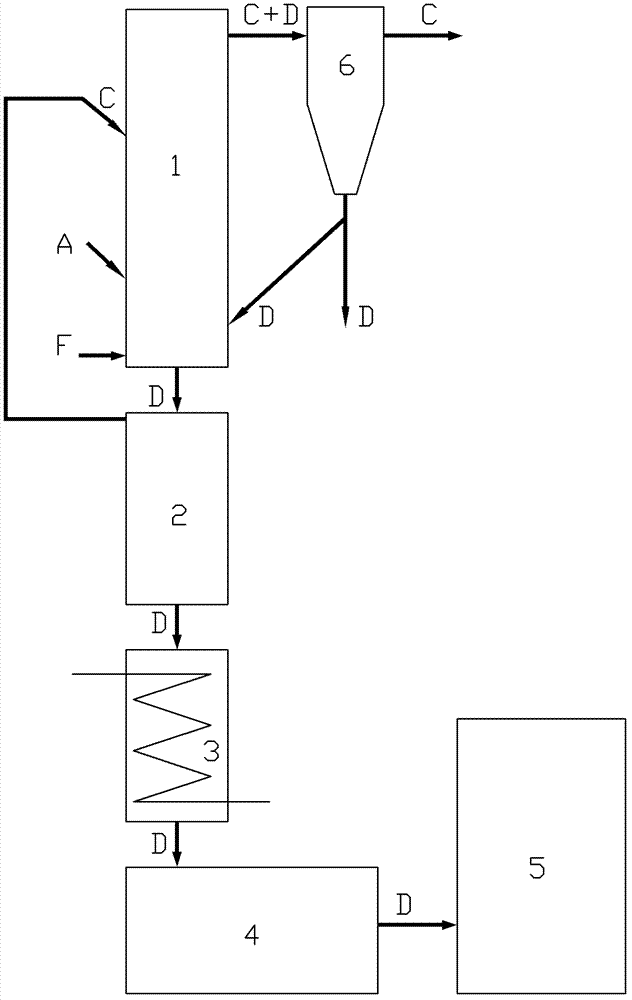

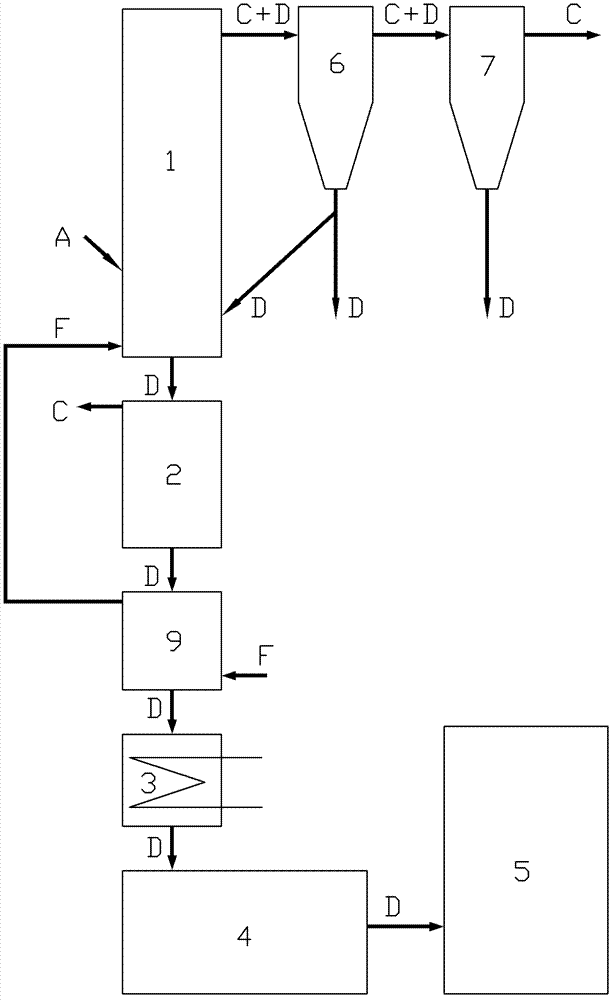

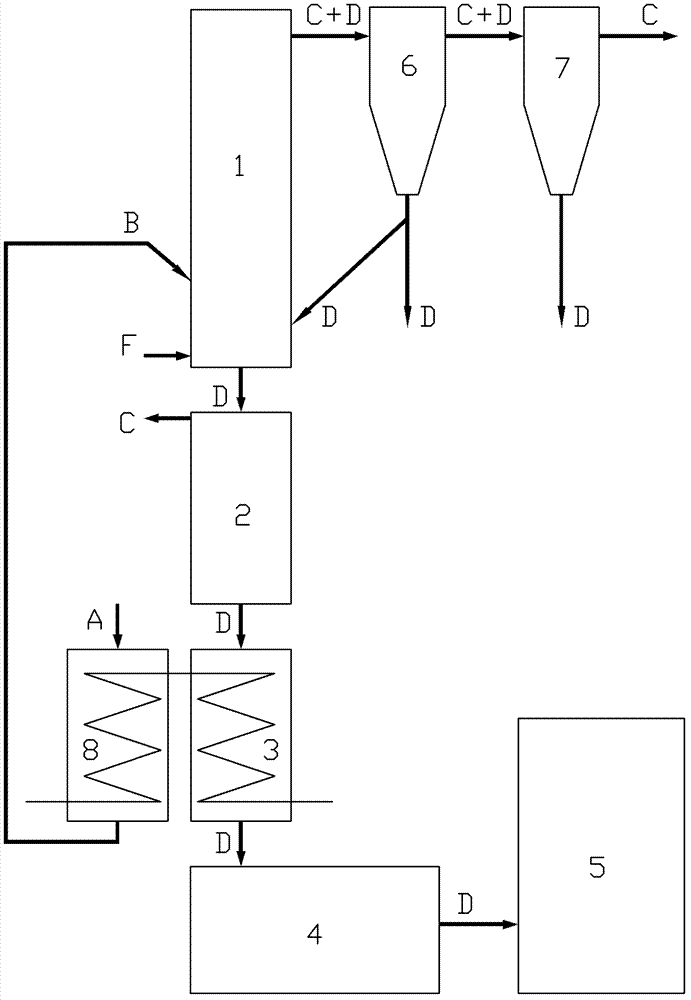

Self-heating pyrolysis method

ActiveCN103045275AFlexible adjustment indexEfficient cascade utilizationCoke quenchingDirect heating destructive distillationCombustionFluidized bed

The invention relates to a self-heating pyrolysis method. The self-heating pyrolysis method comprises the following steps of: feeding coal into a fluidized bed type pyrolysis furnace; introducing fluidifying gas at the bottom of the pyrolysis furnace, wherein the fluidifying gas contains oxygen, the oxygen content is sufficient for combustion of part of coal only, part of coal is combusted in the pyrolysis furnace and the oxygen is consumed while heat capable of heating the coal to a pyrolysis temperature is released, and the coal is pyrolyzed to produce semicoke and coal gas.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

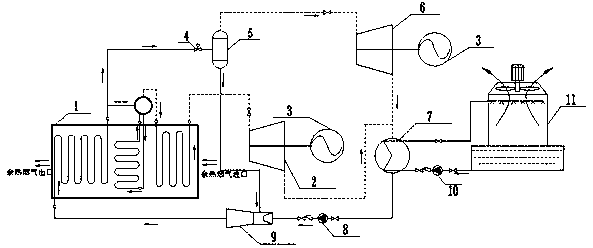

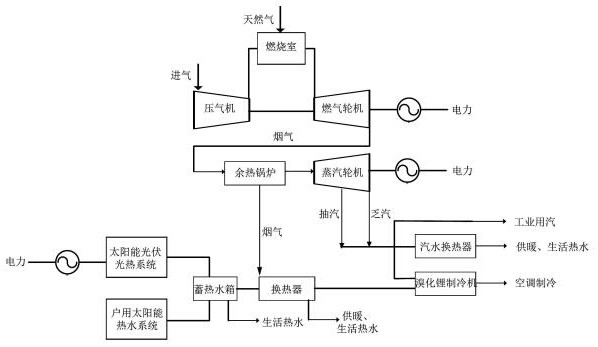

Distributed fuel gas type complementary solar energy utilization combined cooling heating and power system

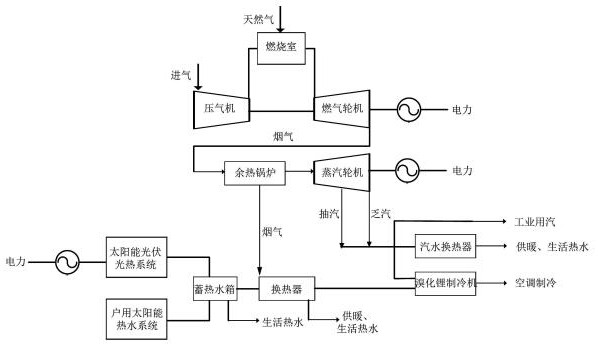

ActiveCN111928219AStrong Use ProspectsImprove efficiencySolar heating energyCombustion technology mitigationLithium bromideEnvironmental geology

The invention relates to a distributed fuel gas type complementary solar energy utilization combined cooling heating and power system. The system comprises a distributed fuel gas system, a solar photovoltaic photo-thermal system, a household solar water heating system and a lithium bromide absorption type refrigerating system, wherein the solar photovoltaic photo-thermal system and the household solar water heating system are connected with inlet water of a heat storage water tank, the heat storage water tank is connected with a cold water inlet of a heat exchanger, a hot water outlet of the heat exchanger is connected with a lithium bromide refrigerator, and a hot air inlet of the heat exchanger is connected with a fume exhaust pipeline of a waste heat boiler in the distributed fuel gas system. Hot water generated by a photo-thermal system in the solar photovoltaic photo-thermal system and the household solar water heating system flows into the heat storage water tank and is stored inthe heat storage water tank, and the hot water flows into the heat exchanger and is heated by exhaust fume of the distributed fuel gas waste heat boiler to reach the heat source temperature of the lithium bromide refrigerator, so that refrigeration is realized; and the system makes full use of heat generated by the system, the electric quantity generated by the system can be used by the system orconnected to a grid, efficient gradient utilization of clean energy is truly realized, and the system has a very strong utilization prospect.

Owner:国网(天津)综合能源服务有限公司 +5

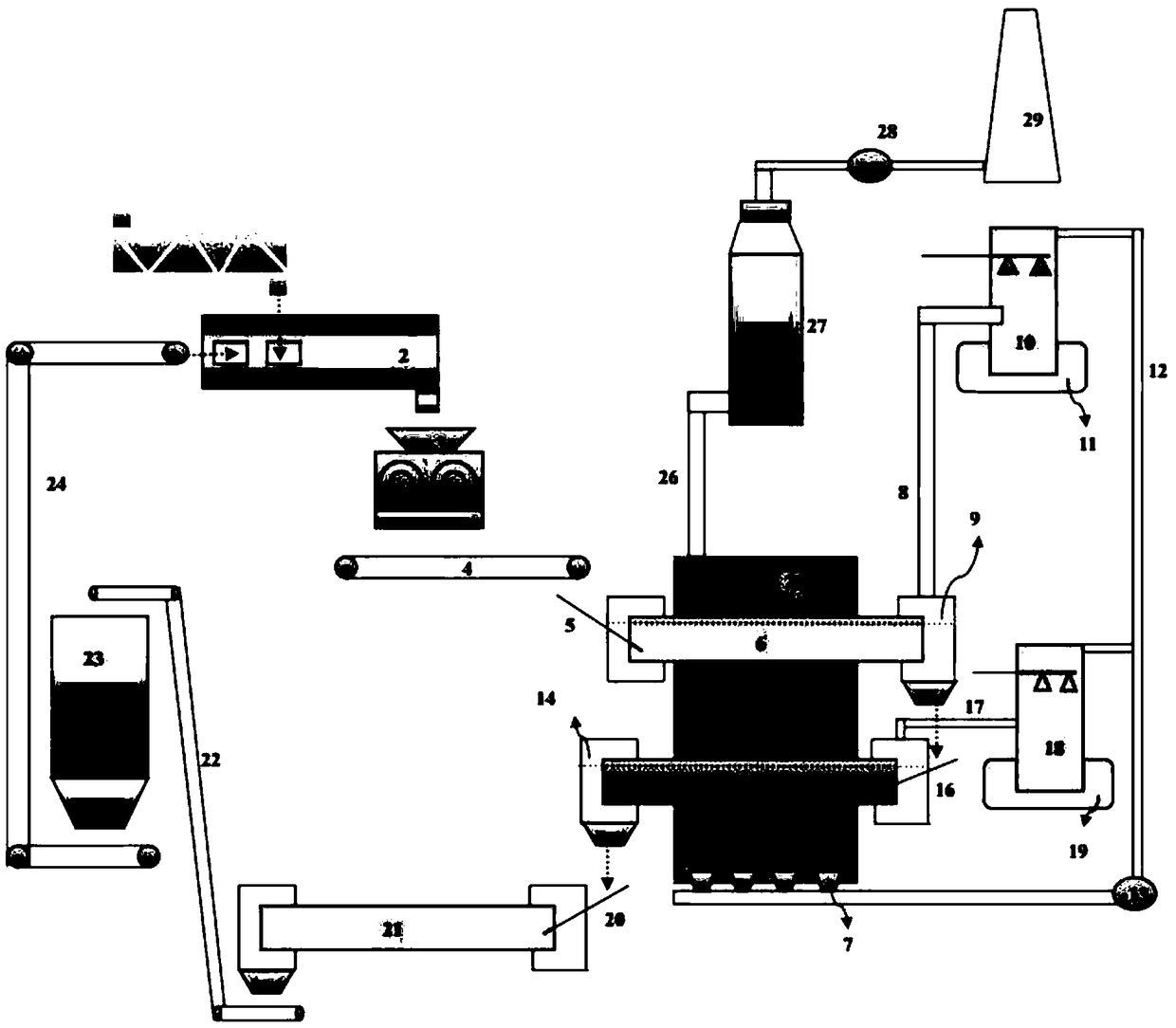

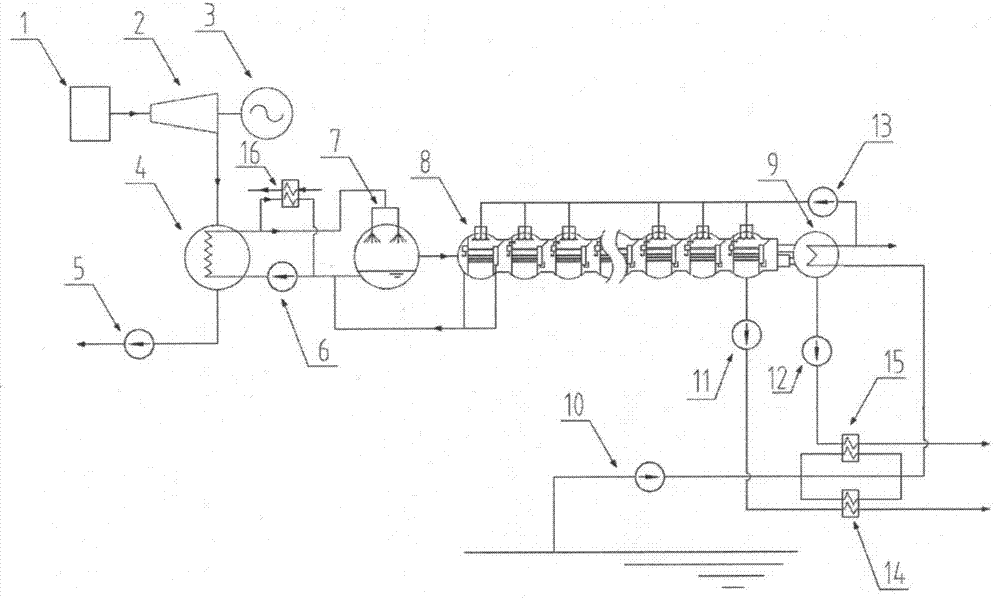

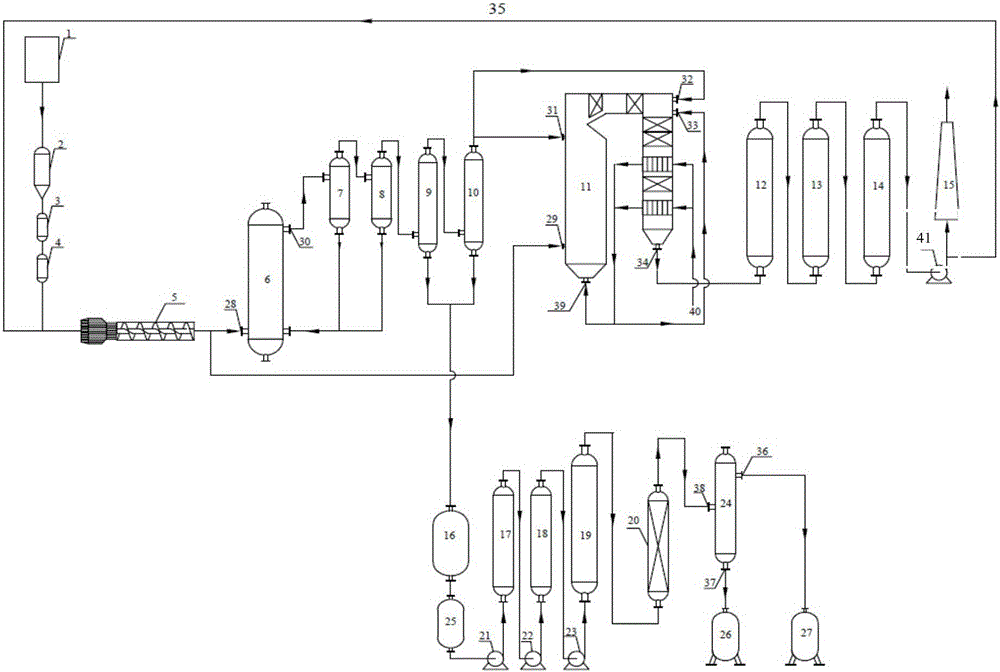

Device and method for synchronous power generation and multi-generation of coal gas and powdered coal

ActiveCN104776426AClean Cascade UtilizationEfficient cascade utilizationCombustion using gaseous and pulverulent fuelEnergy inputTarCirculating fluidized bed boiler

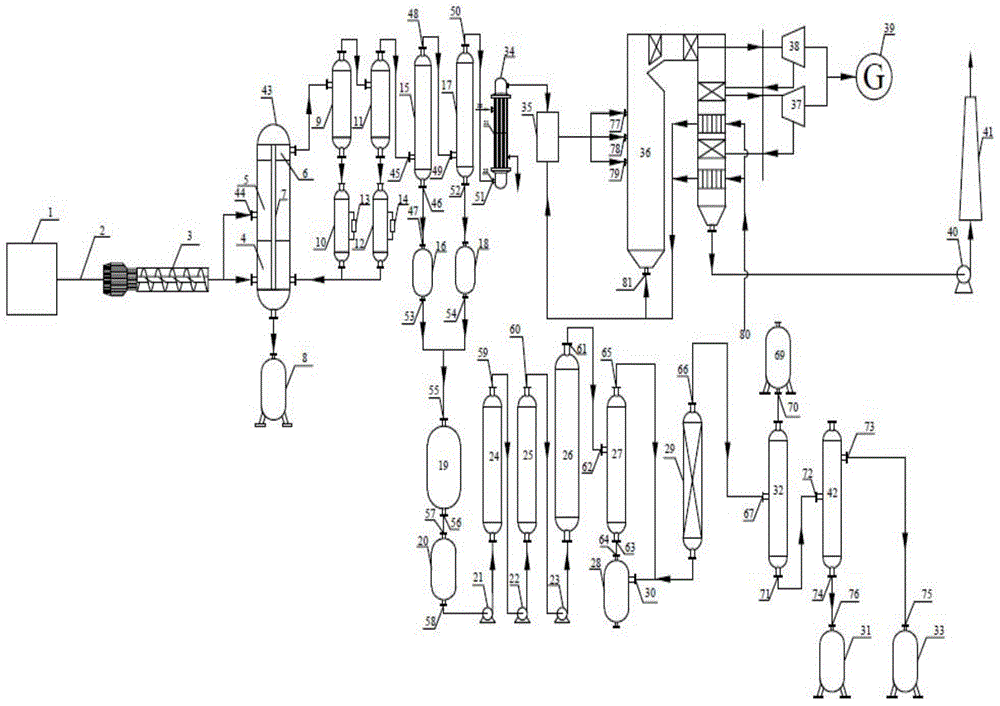

The invention relates to a device and a method for synchronous power generation and multi-generation of coal gas and powdered coal. High-volatile constituent faulty coal lignite, jet coal, non-caking coal, weakly caking coal, bottle coal are taken as feed coal, and enter a gasification-thermal dissociation coupled reactor by pressurizing a feeder so as to be subjected to high-efficiency and rapid pyrolysis reaction. the tar recovered from crude gas is pyrolyzed, the pyrolyzed tar is purified, then the purified tar is subjected to deep processing and transforming, finally, the tar is transformed into clean fuels such as liquefied gas, gasoline and diesel oil, the coal gas and bunker coal powder obtained by separation are subjected to blending combustion in a pulverized fuel boiler or a circulating fluid bed boiler, and thus steam is generated to drive a steam turbine so as to generate electricity. According to the invention, the preparation of coal-based clean fuels and fuel gas electricity generation technology are highly integrated; the coal gas and the coal dust are subjected to blending combustion in the boiler, so that the quantity of flue gas is deeply reduced; the concentration of PM2.5 and PM10 in flue gas is extremely low, the light-concentration emission of SO2, NOX, and heavy metals such as lead, chromium, cadmium, arsenic, mercury is realized, and the multi-generation of coal base energy source and gradient high efficiency utilization are realized.

Owner:李大鹏

Method and apparatus for treating oily sludge

PendingCN109179939ASolve the problem of energy consumptionSolve complexitySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeHigh energy

The invention relates to a method and an apparatus for treating oily sludge. The method comprises the following steps: mixing of biochar produced by pyrolysis of oily sludge with the oily sludge, molding, pyrolysis treatment, and drying and oil desorption in the same hearth in order to achieve efficient integrated gradient utilization of energy. The apparatus comprises a screw conveying device, amixing device, a shaping device, a belt conveying device, a revolving cylinder indirect drying device, a revolving cylinder indirect thermal desorption device, the integrated heating furnace, gas burners and the like. The method and the apparatus have the advantages of small investment, quick effect, simple and flexible process, low running cost, high practicability, large treatment scale, complete harmlessness, high recycling rate, high energy utilization rate, full embodiment of the concepts of circular economy and low-carbon economy, and significant social, economic and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Biomass gasification product and coal co-firing system and method

InactiveCN105841140AImprove adaptabilityReduce usageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLiquid productGreenhouse

The invention discloses a biomass gasification product and coal co-firing system and method. The biomass gasification product and coal combined burning system comprises a biomass gasification device, a biomass gasification product separation and conveying device and a boiler co-firing device. The biomass gasification device takes biomass as a raw material, and a biomass gasification product is obtained through the biomass raw material. The biomass gasification product comprises biomass char and a gaseous product body. The biomass gasification product separation and conveying device is used for separating the biomass gasification product and conveying the biomass gasification product into the boiler co-firing device to be fired with coal. The boiler co-firing device is used for enabling the biomass gasification product obtained in the biomass gasification device and the coal to be co-fired in a boiler. The biomass gasification product and coal co-firing method achieves co-firing of the biomass gasification product and the coal through the biomass gasification product and coal co-firing system. According to the biomass gasification product and coal co-firing system and method, by separating solid, gaseous and liquid products which are obtained through biomass gasification, all the products obtained through biomass raw material gasification are fully utilized, the generating efficiency of a conventional biomass and coal co-firing boiler is improved, and emissions of pollutants and greenhouse gases are decreased.

Owner:HUAZHONG UNIV OF SCI & TECH

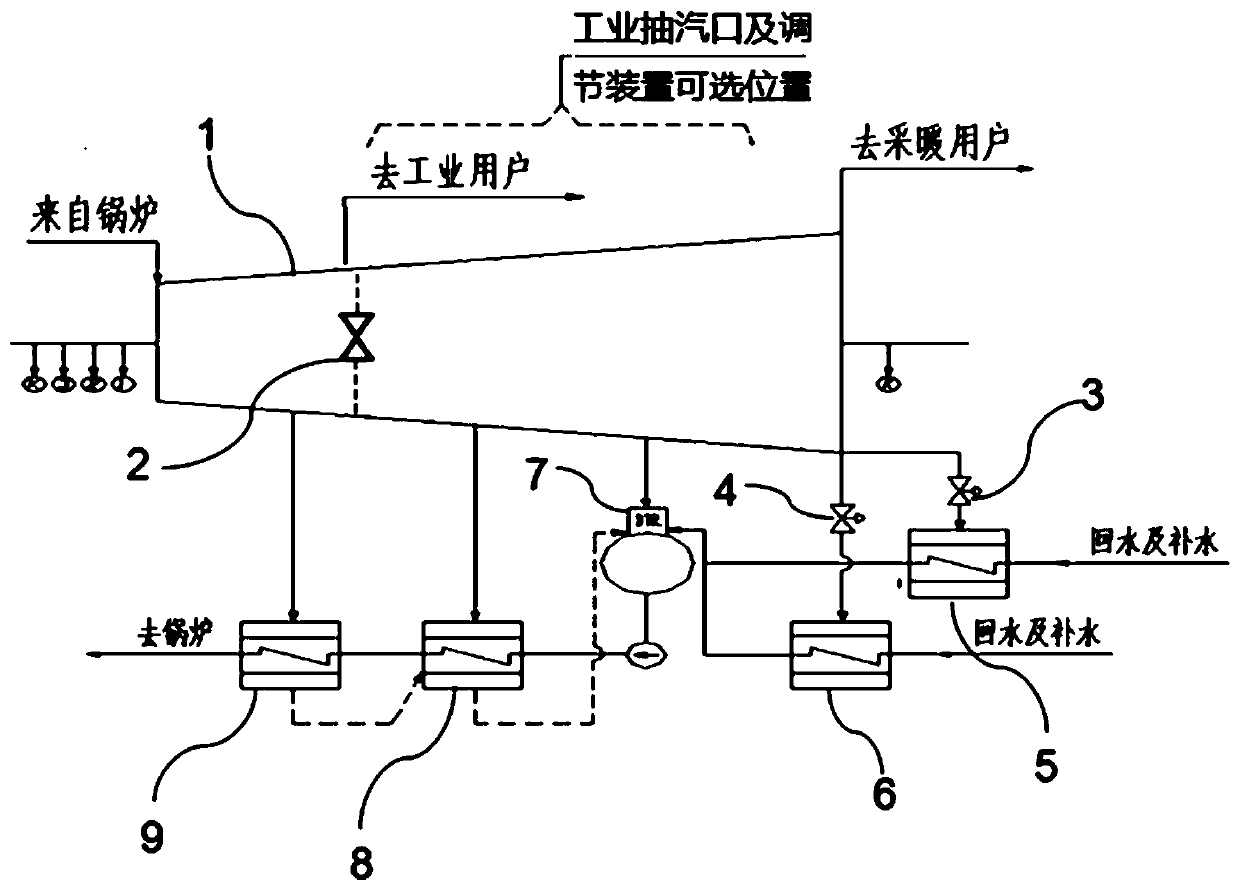

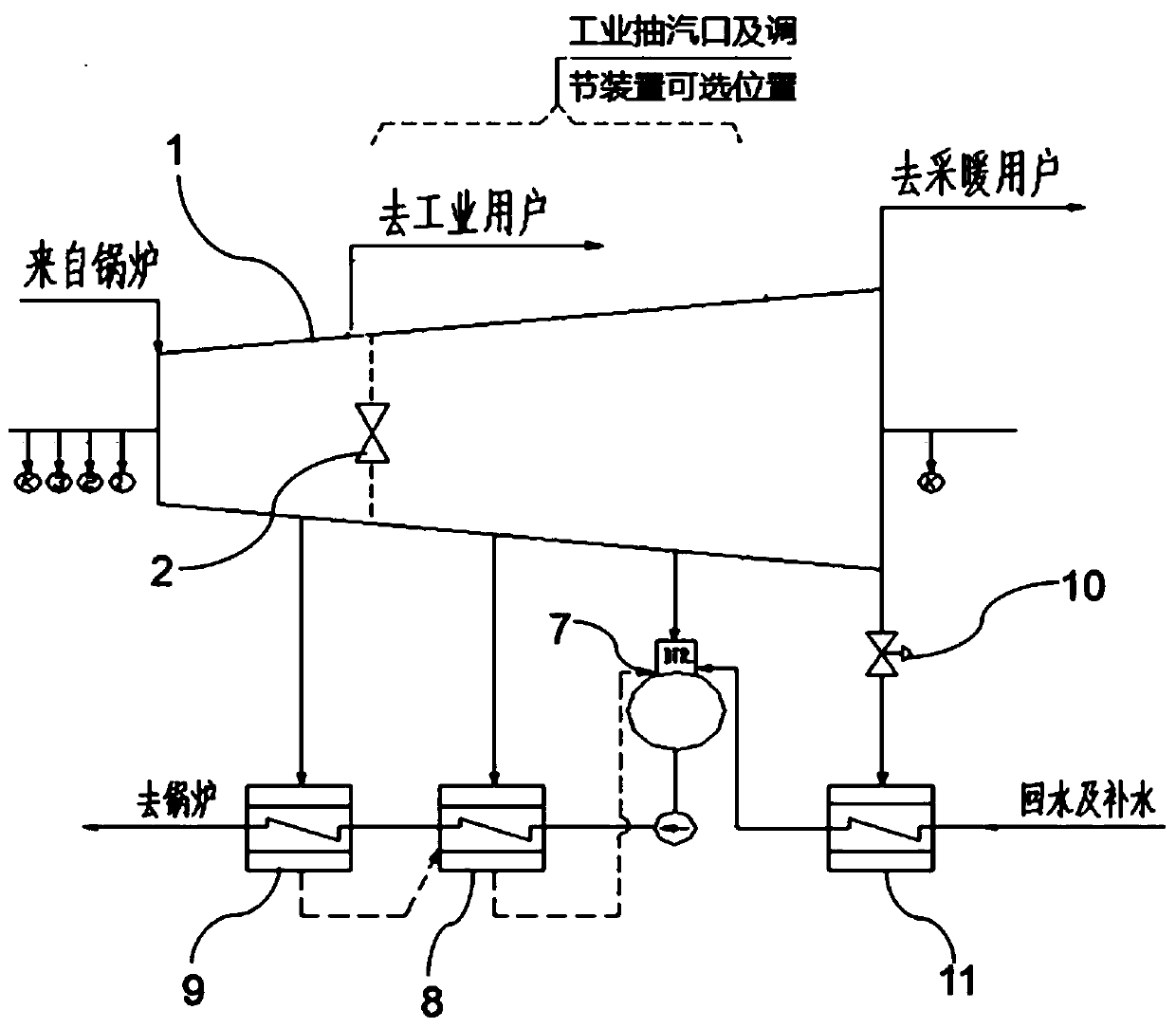

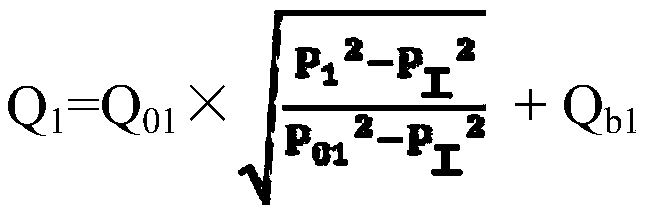

Multistage heat supply back pressure type steam turbine, thermodynamic system and heat supply method of thermodynamic system

PendingCN111379604AEfficient cascade utilizationMeet heating needsLighting and heating apparatusSteam useThermal forceCogeneration

The invention discloses a multistage heat supply back pressure type steam turbine, a thermodynamic system and a heat supply method of the thermodynamic system, and belongs to the field of combined heat and power generation equipment. The multistage heat supply back pressure type steam turbine comprises a back pressure type steam turbine body, a steam inlet end and a steam exhaust end, at least onesteam extraction adjusting device is arranged in a through flow between the steam inlet end and the steam exhaust end, heat supply steam extraction openings of all levels are formed between the steamextraction adjusting devices and the steam inlet end and between every two adjacent steam extraction adjusting devices correspondingly, and the steam exhaust end serves as the last-level heat supplysteam extraction opening; the steam flow and the pressure of the corresponding heat supply steam extraction opening are adjusted through each steam extraction adjusting device, so that multiple stagesof heat supply steam with different parameters are provided at the same time; the heat supply steam of each stage is extracted as required after expanding and acting in the back pressure type steam turbine so that more reasonable parameter matching can be realized, and energy gradient utilization is more sufficient; and after the multi-stage heat supply back pressure type steam turbine and a variable heat regenerative system matched with the multi-stage heat supply back pressure type steam turbine are adopted, the multi-stage heat supply back pressure type steam turbine can still continuouslyoperate when the last-stage heat supply load of the steam exhaust end is free of existence.

Owner:DONGFANG TURBINE CO LTD

A kind of autothermal pyrolysis method

ActiveCN103045275BFlexible adjustment indexEfficient cascade utilizationCoke quenchingDirect heating destructive distillationCombustionFluidized bed

The invention relates to a self-heating pyrolysis method. The self-heating pyrolysis method comprises the following steps of: feeding coal into a fluidized bed type pyrolysis furnace; introducing fluidifying gas at the bottom of the pyrolysis furnace, wherein the fluidifying gas contains oxygen, the oxygen content is sufficient for combustion of part of coal only, part of coal is combusted in the pyrolysis furnace and the oxygen is consumed while heat capable of heating the coal to a pyrolysis temperature is released, and the coal is pyrolyzed to produce semicoke and coal gas.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Cascade energy usable variable capacity family energy resource system

InactiveCN101240949BAvoid wet compressionRealize the supplyEnergy recovery in ventilation and heatingHeat pumpsSolenoid valveEngineering

The present invention provides an adjustable volume family energy system utilized by step energy, the invention includes a compressor, a hot water heat exchanger, a four-way reversing valve, an outdoor wind cooling pipe coil, a first check valve, a second check valve, a first electronic expansion valve, a second electronic expansion valve, an air conditioning hot and cold heat exchanger, a gas-liquid separator, a water side electric three-way control way, a first solenoid valve, a second solenoid valve, a first water pump, a second water pump. These parts form a refrigerant loop, a domestic hot-cold water loop, realize refrigerating and hot water supplying, single refrigerating, single hot water supplying, single warm supplying, warm supplying and hot water supplying five modes. The control part of the refrigerant loop only has four-way reversing valve and electronic expansion valve in traditional air conditioning system, does not exist refrigerant potential safety hazard. The functionof each system is mainly realized by switch and adjustment of the water side two solenoid valves and electric three-way control way, has a simple control, credible security.

Owner:SHANGHAI JIAOTONG UNIV

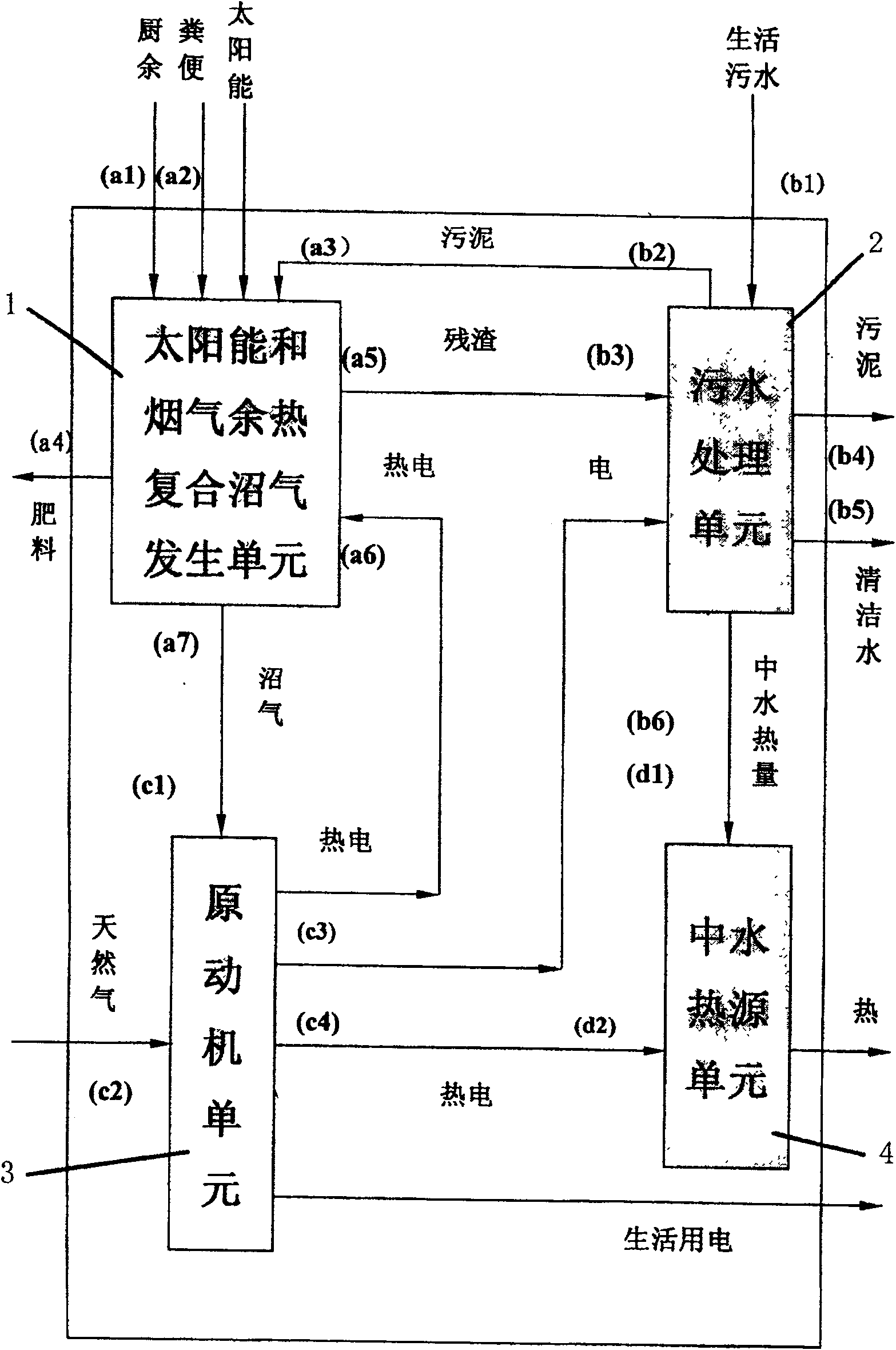

Distributed energy system for energy and resource integrated circulating utilization

InactiveCN100584473CEfficient cascade utilizationImprove recycling ratesBio-organic fraction processingWaste processingNew energyEngineering

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

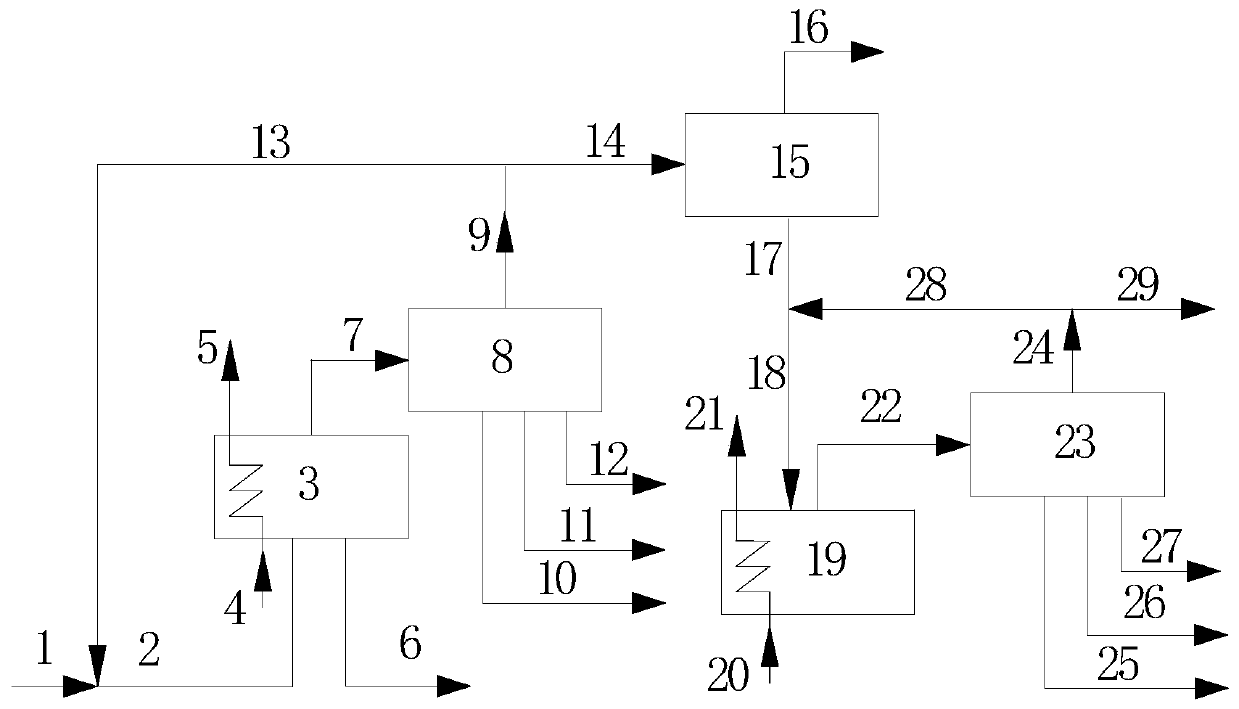

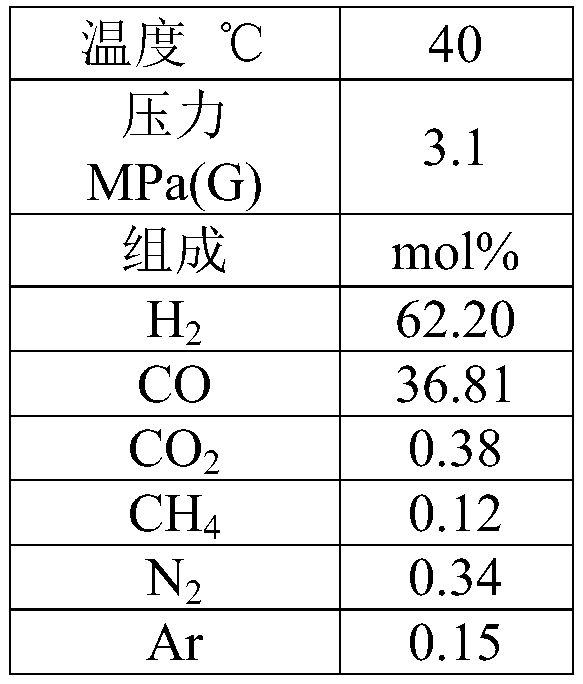

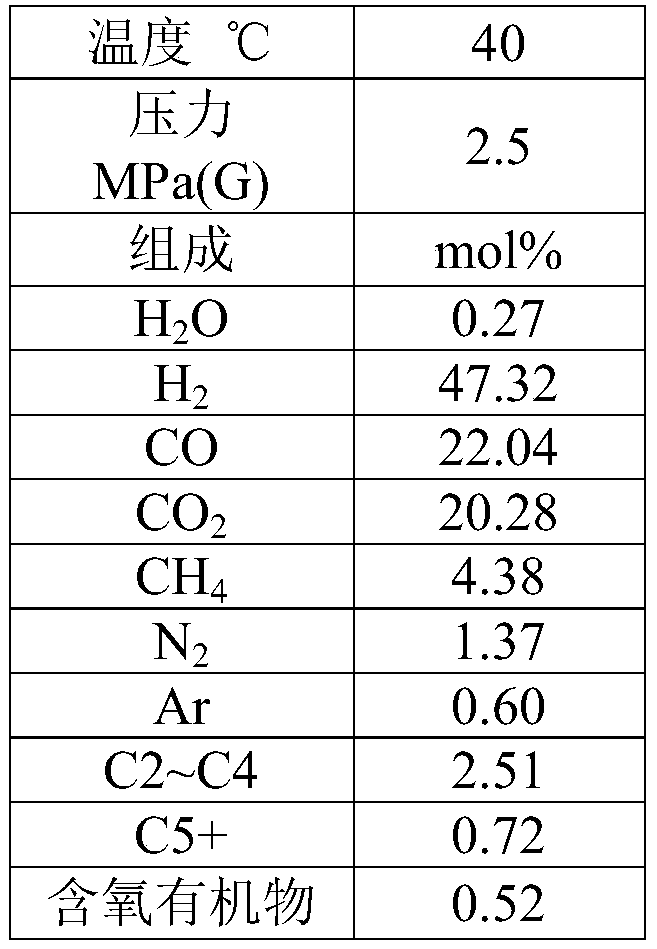

Method and device for producing hydrocarbons by connecting low-temperature Fischer-Tropsch section and high-temperature Fischer-Tropsch section in series

InactiveCN111286354ALow phase yieldHigh phase yieldLiquid hydrocarbon mixture productionPhysical chemistryLiquid hydrocarbons

The invention relates to a method for producing hydrocarbons by connecting a low-temperature Fischer-Tropsch section and a high-temperature Fischer-Tropsch section in series, wherein the method comprises the following steps: (1) introducing synthesis gas into a low-temperature Fischer-Tropsch synthesis reactor, carrying out a reaction, and separating reaction products to obtain high-carbon-numberhard paraffin, a low-temperature liquid hydrocarbon product, low-temperature reaction water and low-temperature Fischer-Tropsch tail gas; (2) feeding the low-temperature Fischer-Tropsch tail gas intoa decarburization device to completely or partially remove CO2, feeding the CO2-removed gas as a high-temperature Fischer-Tropsch raw material gas into a high-temperature Fischer-Tropsch synthesis reaction for reaction, and separating reaction products to obtain a high-temperature liquid hydrocarbon product, high-temperature reaction water and high-temperature Fischer-Tropsch tail gas; and (3) carrying out separation treatment on the low-temperature liquid hydrocarbon product and the high-temperature liquid hydrocarbon product to obtain the product. Compared with the prior art, efficient conversion of raw material gas and gradient utilization of energy are realized, the utilization efficiency of carbon is improved, the diversity of coal chemical products is realized, and the risk resistance of the Fischer-Tropsch synthesis device is improved.

Owner:YANKUANG ENERGY R&D CO LTD

Water and power cogeneration system matched with high back pressure unit for low-temperature multi-effect seawater desalination

ActiveCN107381688AEfficient cascade utilizationGood economic benefitsGeneral water supply conservationSeawater treatmentCogenerationSeawater

Owner:SHANGHAI POWER STATION ACCESSORY MACHINERY PLANT CO LTD

Boiler step energy using system and method

InactiveCN105840260AEfficient cascade utilizationEfficient use ofLighting and heating apparatusCombustion technology mitigationGas compressorEngineering

The invention discloses a boiler step energy using system and method. According to the boiler step energy using system and method, boiler tail fume and supercritical CO2 are subjected to heat exchange in a first heat exchanger, so that the temperature of the supercritical CO2 is raised; the warmed supercritical CO2 works outwards through a steam turbine and then is led into a second heat exchanger; and the supercritical CO2 is cooled after subjected to heat exchange with water in the second heat exchanger, and the cooled supercritical CO2 is subjected to isothermal compression in a gas compressor, and then led into the first heat exchanger or led into a third heat exchanger and then led into the first heat exchanger for circulation so as to achieve utilization of waste heat of the smoke. According to the boiler step energy using system and method, efficient and step utilization of the waste heat of the boiler tail fume can be achieved, and the boiler step energy using system and method have the advantages of being environmentally friendly, efficient, simple, low in cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

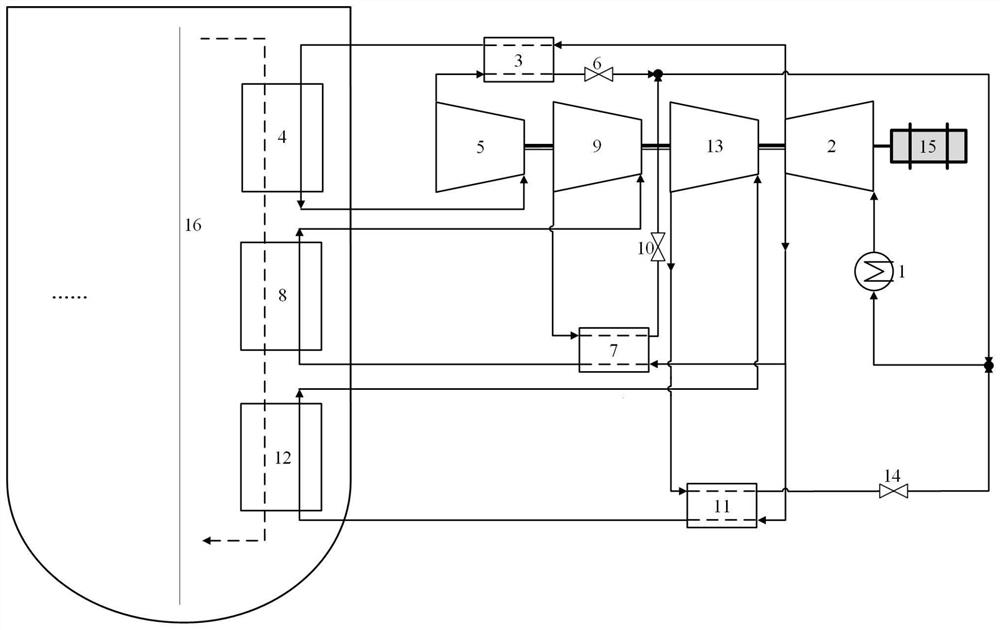

Multi-stage shunting flexible and efficient supercritical carbon dioxide lead-bismuth reactor system and method

InactiveCN114005562ASolve poor matchingEfficient and flexible power generationNuclear energy generationSteam engine plantsProcess engineeringElectric generator

The invention discloses a multi-stage shunting flexible and efficient supercritical carbon dioxide lead bismuth reactor system and method. The system comprises a precooler, a compressor, a high-temperature regenerator, a high-temperature main heat exchanger, a high-temperature turbine, a high-temperature flow regulating valve, a medium-temperature regenerator, a medium-temperature main heat exchanger, a medium-temperature turbine, a medium-temperature flow regulating valve, a low-temperature regenerator, a low-temperature main heat exchanger, a low-temperature turbine, a low-temperature flow regulating valve, a generator and a reactor. According to the multi-stage shunting supercritical carbon dioxide cycle power generation system comprising a high-temperature circulation loop, a medium-temperature circulation loop and a low-temperature circulation loop, efficient gradient utilization of heat in different temperature intervals of a lead-bismuth loop is realized, and the problem that the matching degree of the heat absorption temperature of supercritical carbon dioxide power circulation and a heat exchange window of liquid metal lead bismuth is poor is solved. According to the system, through flow distribution adjustment of different temperature loops, efficient gradient utilization of heat under the variable working conditions of the supercritical carbon dioxide lead bismuth reactor system is ensured, and efficient and flexible power generation is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

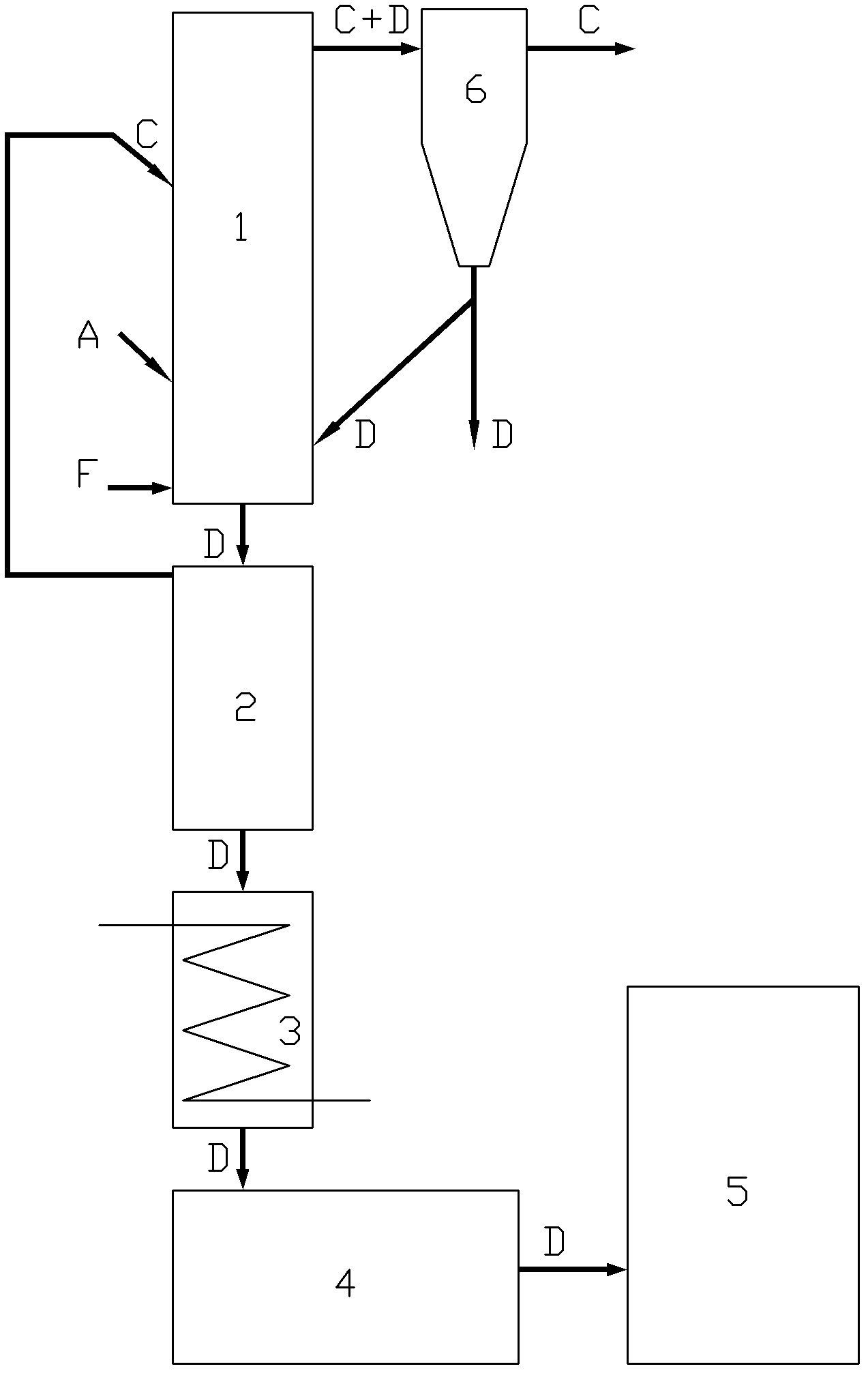

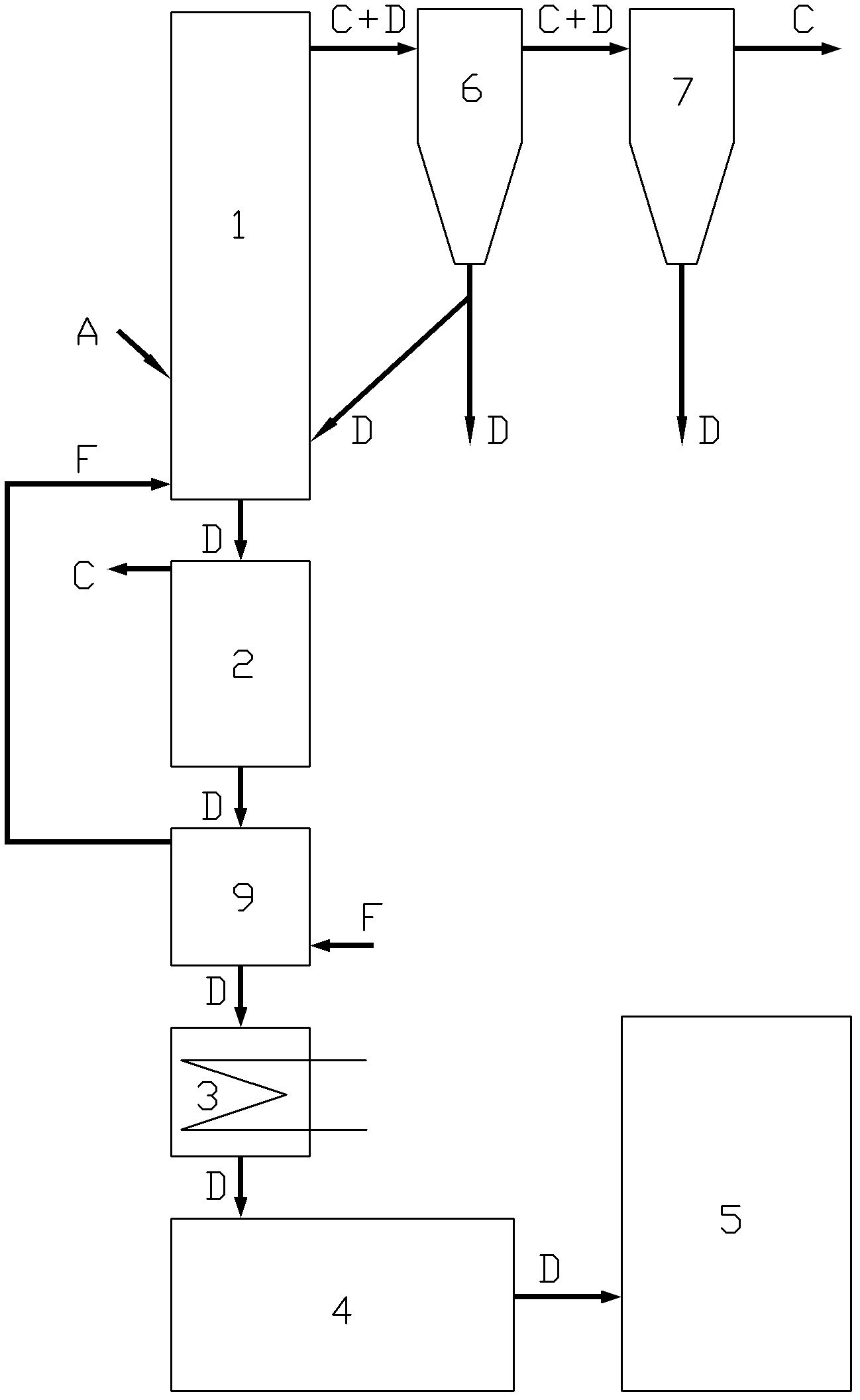

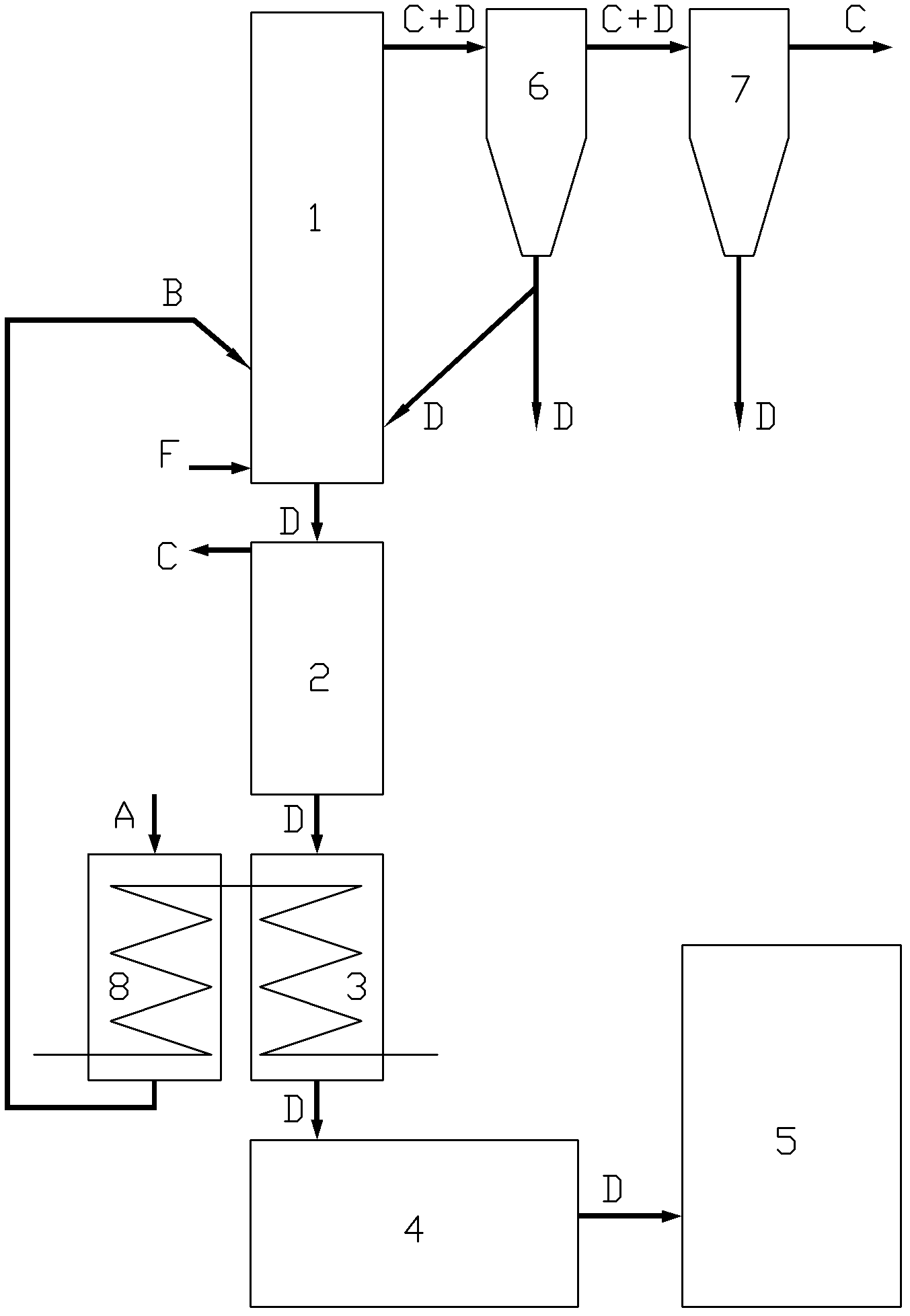

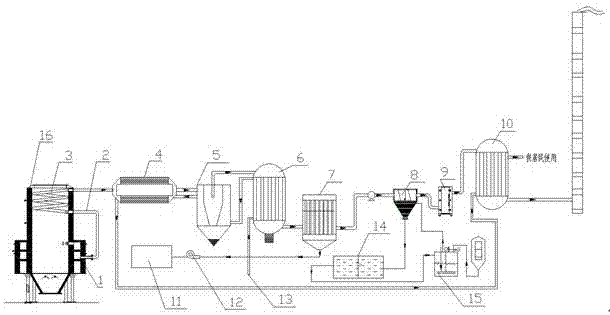

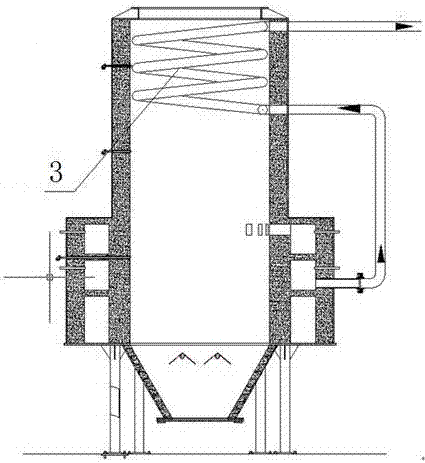

Exhaust gas waste heat gradient utilization system for small-sized living garbage pyrolysis and gasification

ActiveCN107477602AFast dryingClose to drying speedCombustion technology mitigationIncinerator apparatusTarProcess engineering

The invention discloses an exhaust gas waste heat gradient utilization system for small-sized living garbage pyrolysis and gasification. The exhaust gas waste heat gradient utilization system comprises a pyrolysis furnace, an exhaust gas cooling casing pipe, a cyclone dust removing and cooling device, a heat exchanger, a biomass filler tar-removal device, an alkali liquor water-washing device, a smoke remover, a tube type exhaust gas reheater, a chimney discharging unit and the like, wherein a garbage drying pipeline is arranged in the pyrolysis furnace. Through full utilization of applicability of exhaust gas of different temperatures and cooling water, effective combination of exhaust gas reheat utilization and living application is achieved, the heating efficiency is improved, meanwhile, the temperature and diffusion capacity of discharged exhaust gas are improved, the risk of haze is effectively reduced, and the environment benefits are remarkable.

Owner:湖南省环境保护科学研究院

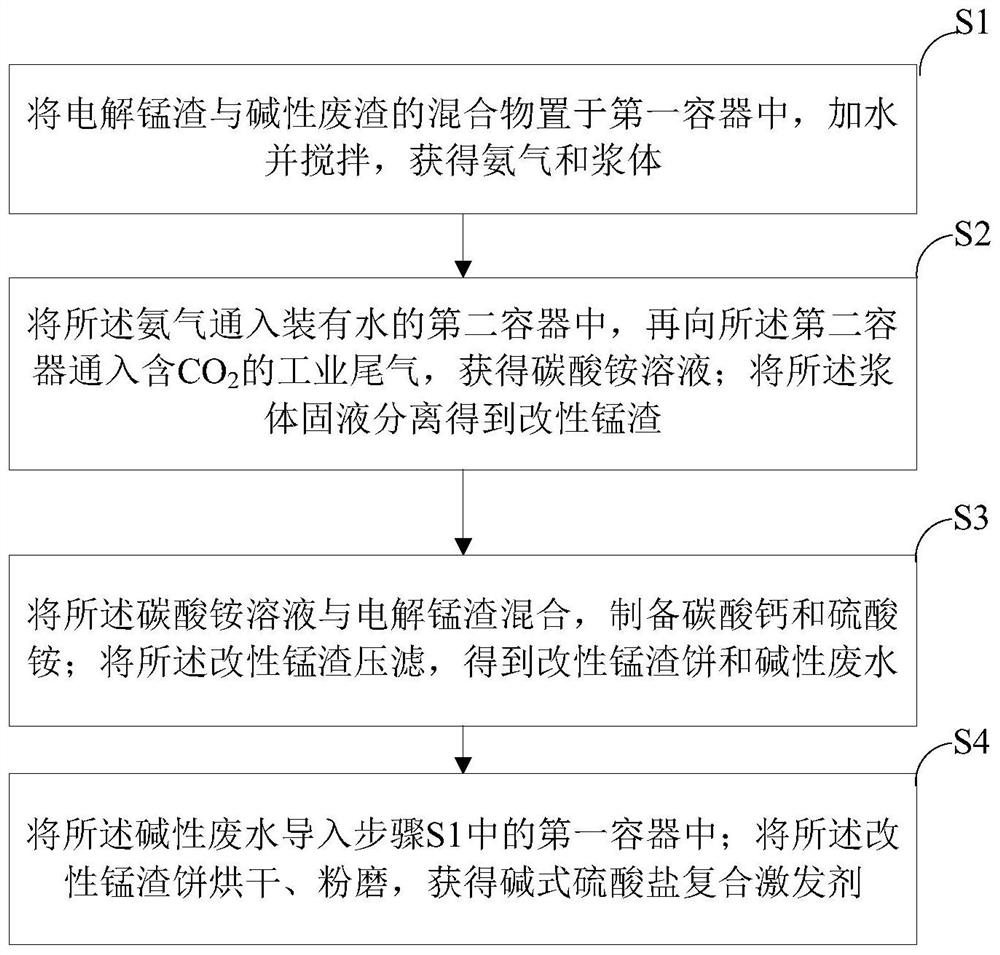

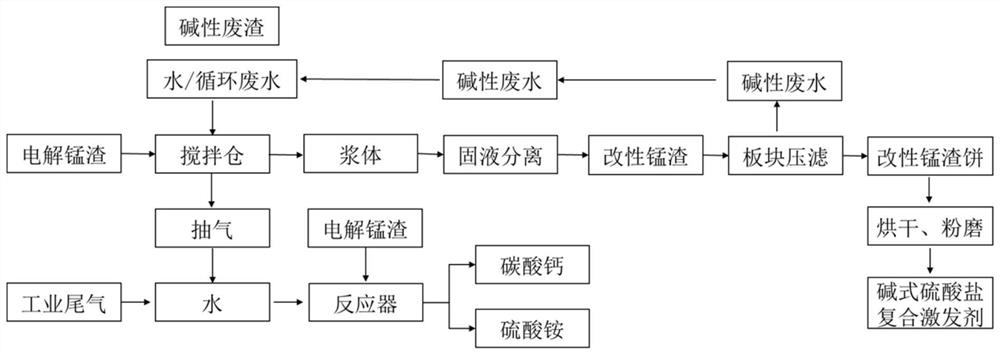

Industrial solid waste electrolytic manganese residue mineralization CO2 resource utilization method

ActiveCN114804177AEfficient cascade utilizationIncrease profitCalcium/strontium/barium carbonatesAmmonium salt fertilisersManganeseWastewater

The invention provides an industrial solid waste electrolytic manganese residue mineralization CO2 resource utilization method, which comprises: placing a mixture of electrolytic manganese residue and alkaline waste residue in a first container, adding water, and stirring to obtain ammonia gas and slurry; secondly, introducing ammonia gas into a second container filled with water, and introducing industrial tail gas containing CO2 into the second container to obtain an ammonium carbonate solution; carrying out solid-liquid separation on the slurry to obtain modified manganese slag; thirdly, mixing the ammonium carbonate solution with the electrolytic manganese residues to prepare calcium carbonate and ammonium sulfate; carrying out filter pressing on the modified manganese slag to obtain a modified manganese slag cake and alkaline wastewater; finally, introducing the alkaline wastewater into a first container; and drying and grinding the modified manganese slag cake to obtain the basic sulfate composite exciting agent. According to the method, efficient and gradient utilization of the electrolytic manganese residues is achieved, high-added-value utilization of the electrolytic manganese residues is achieved, the mineralized CO2 treatment cost is reduced, and the method has good application prospects and popularization value and has important significance in achieving carbon peak reaching and carbon neutralization.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

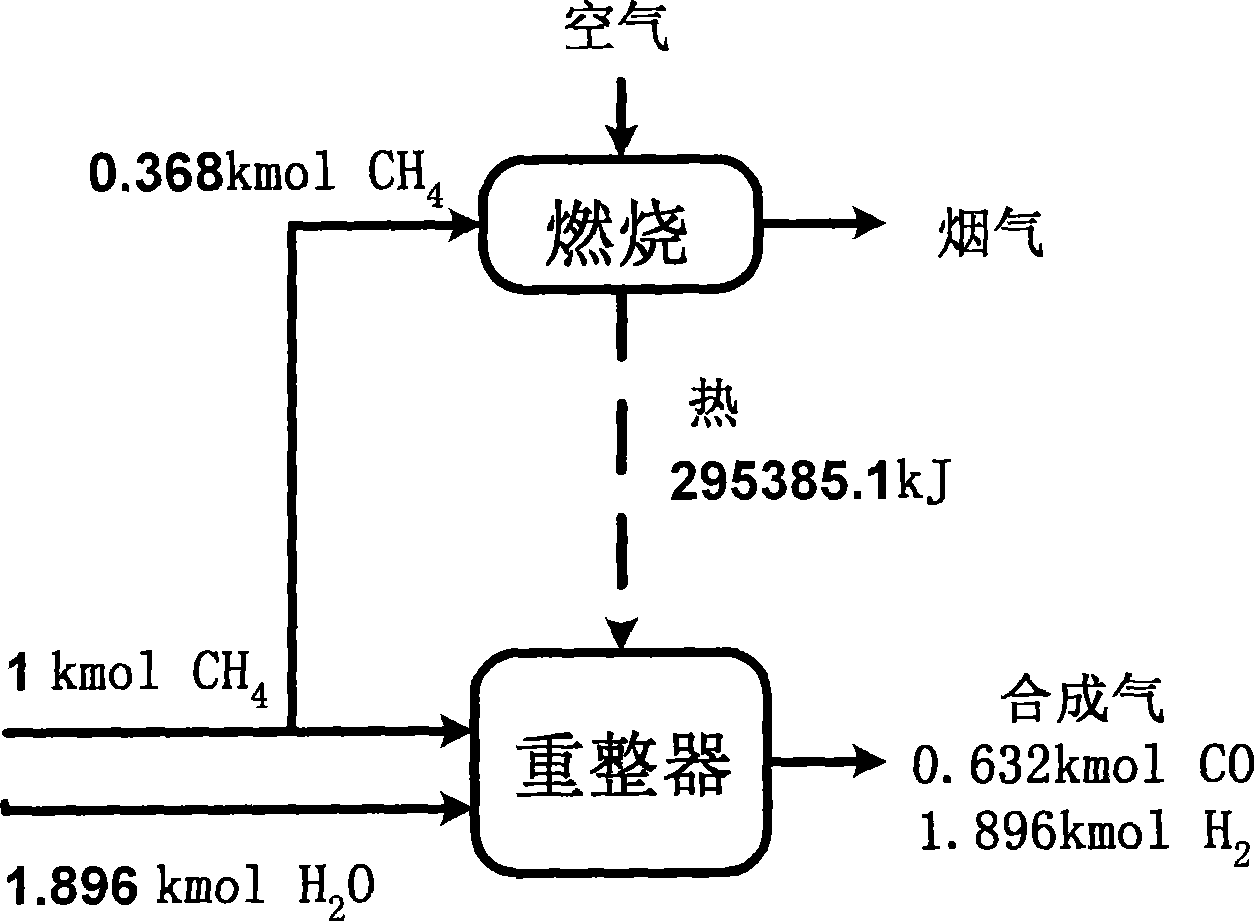

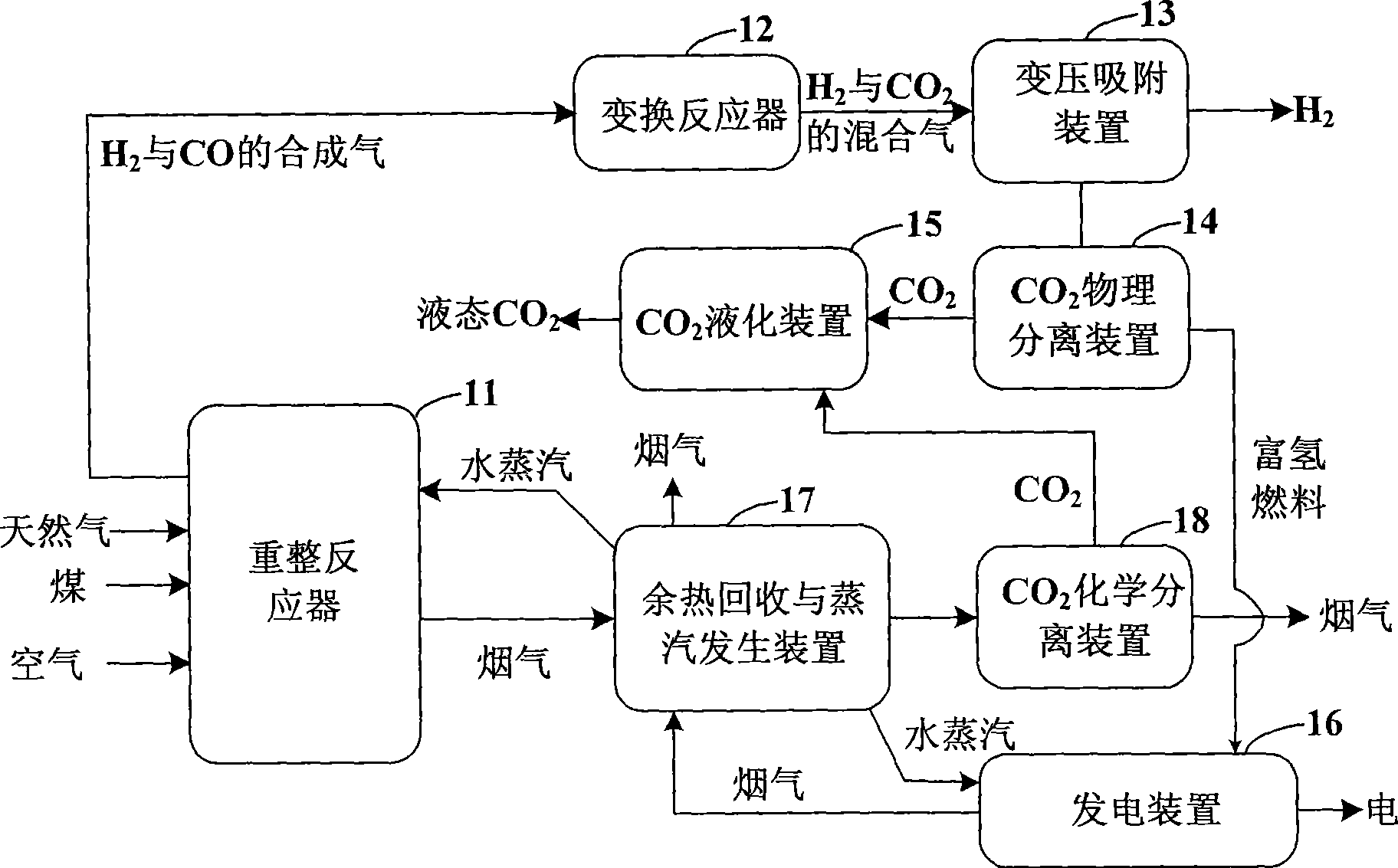

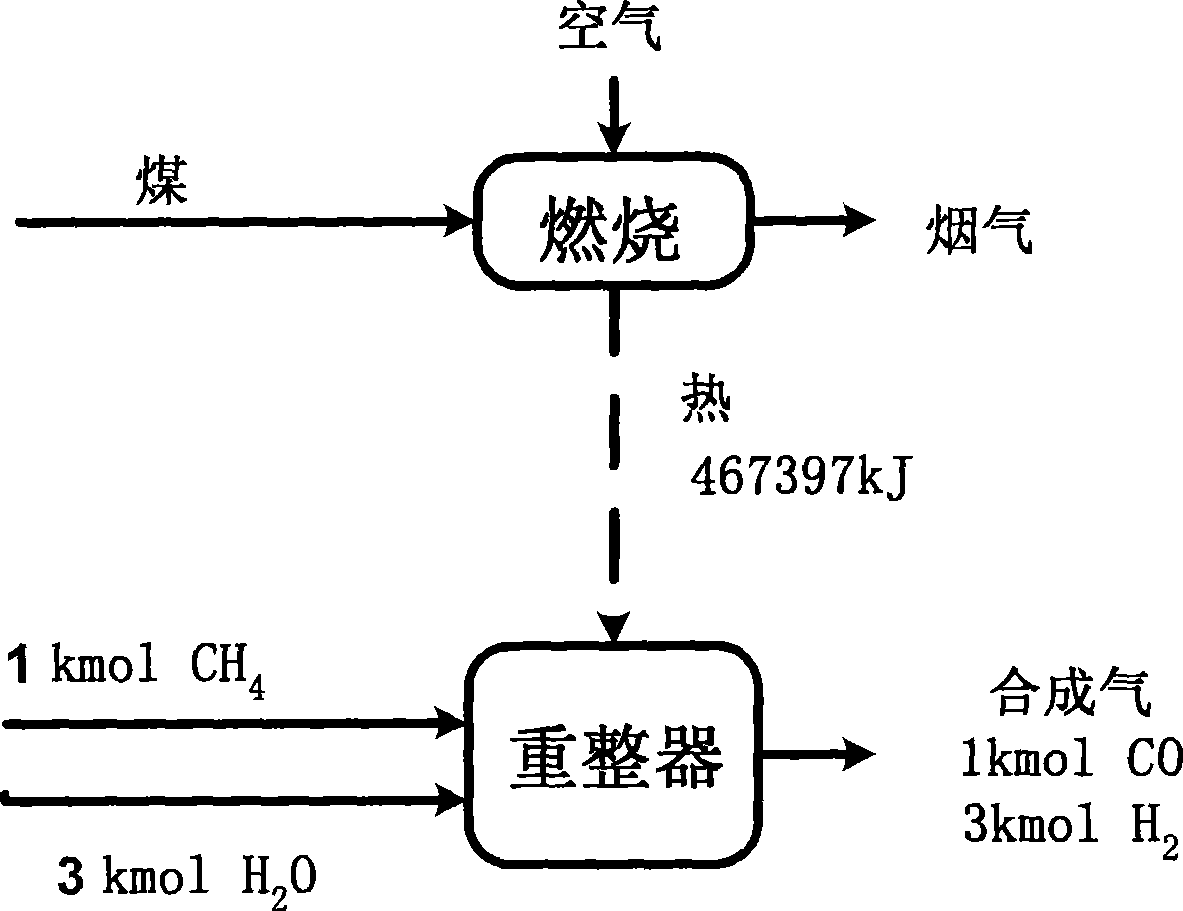

Multifunctional energy resource system

ActiveCN101285004BHuge lossReasonable useCombustible gas chemical modificationEnergy inputAtmospheric airNatural gas

Owner:中科思道(南京)储能技术有限公司

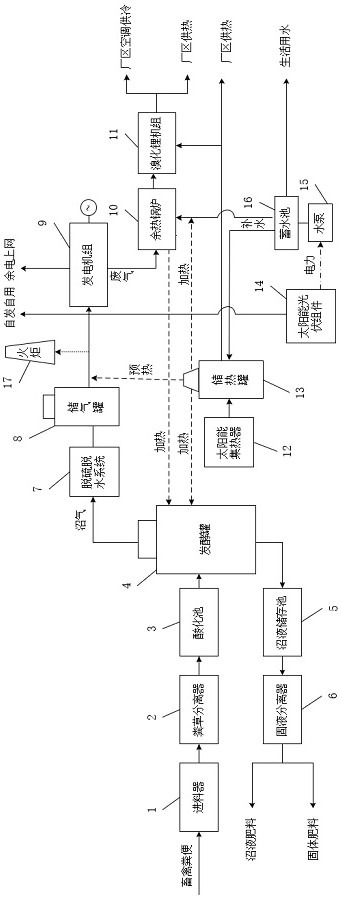

Multi-energy complementary cold and hot biogas co-supply system

ActiveCN107129928AEfficient cascade utilizationImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsAir preheaterFlue gas

The invention relates to a multi-energy complementary cold and hot biogas co-supply system. The system comprises a solar energy utilization device, a biogas production and utilization device, a heat pump device, an energy tower, a heat exchanger and the like. The solar energy utilization device comprises a solar heat collector, a heat storage water tank and a circulating pump; the biogas production and utilization device comprises a constant-temperature biogas generator, a biogas water heater and a biogas purification and storage device; the heat pump device comprises a high-temperature water tank, a low-temperature water tank, a throttle valve, a compressor, an evaporator and a condenser; the energy tower comprises a fan, a water retaining board, a sprayer, a heat exchanger, an air preheater, a water receiving plate, a spraying water tank and a spraying pump; the heat exchanger is arranged in the high-temperature water tank and used for production of domestic hot water. The high-temperature water tank is connected with the constant-temperature biogas generator, the energy tower is connected with the high-temperature water tank and the low-temperature water tank, and discharged flue gas is discharged from the lower portion of the air preheater by guidance of a pipeline. The system has the advantage that efficient cascaded utilization of energy is realized during stable supply of hot and cold biogas.

Owner:SHAANXI SCI TECH UNIV

Biomass double fluidized bed catalytic gasification combined cycle power generation method using copper slag as circulating bed material and system thereof

InactiveCN110564452AStable in natureHigh mechanical strengthEnergy inputGasification processes detailsCycloneHeat carrier

The invention relates to a biomass double-fluidized-bed catalytic gasification combined cycle power generation method taking copper slag as a circulating bed material and a system thereof, and belongsto the technical field of energy and environment. According to the method and system, biomass is heated by a high-temperature copper slag bed material in a fluidized bed gasification furnace to be pyrolyzed and gasified to generate biomass gas, biomass charcoal and tar, the tar is catalyzed by the copper slag bed material to be cracked, and the biomass gas containing a small amount of tar is purified and then utilized in a gas turbine power generation mode; the copper slag bed material and the biomass charcoal from a high-temperature cyclone separator enter a fluidized bed combustion furnace,and the high-temperature copper slag bed material heated by biomass charcoal combustion heat release returns to the fluidized bed gasification furnace; a turbine of a gas turbine is combined with high-temperature flue gas discharged by high-temperature cyclone separation, and then waste heat is recycled by adopting a waste heat boiler and an organic Rankine cycle power generation mode; in the whole process, the copper slag bed material has double functions of a heat carrier and tar catalyzing cracking, and heat energy is utilized step by step in a gas-organic working medium combined cycle power generation mode.

Owner:KUNMING UNIV OF SCI & TECH

Coal gas and pulverized coal synergistic power generation and polygeneration device and method

ActiveCN104776426BEfficient cascade utilizationReduce productionCombustion using gaseous and pulverulent fuelEnergy inputCogenerationBottle

Owner:李大鹏

A dual-pressure expansion organic Rankine cycle recovery system for low-temperature waste heat power generation

ActiveCN108167040BEfficient cascade utilizationEliminate cavitationSteam engine plantsFluid phaseOrganic Rankine cycle

The invention relates to a dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system and belongs to the technical field of energy and environments. According to the system, mid-low-temperature waste heat flue gas with the temperature being 200-350 DEG C is utilized as the driving heat source, organic working medium feeding liquid is preheated to be in a saturated liquid state in an ORC waste heat boiler preheating segment, then part of a saturated liquid organic working medium enters an evaporation segment and an superheating segment ofa waste heat boiler, generated saturated (or superheated) steam enters a radial-inward-flow turbine, and a high-pressure stage ORC expansion work doing process is completed; and the other part of thesaturated liquid organic working medium enters a flash vessel after being subjected to throttling and pressure reducing, saturated steam separated from the flash vessel enters a low-pressure stage screw expander, and a low-pressure stage ORC expansion work doing process is completed. An ejection compressor recovers the liquid-phase working medium separated out of the flash vessel, utilization ofliquid conveying pumps is reduced, the system is simplified, and the possibility of pump cavitation is eliminated.

Owner:KUNMING UNIV OF SCI & TECH

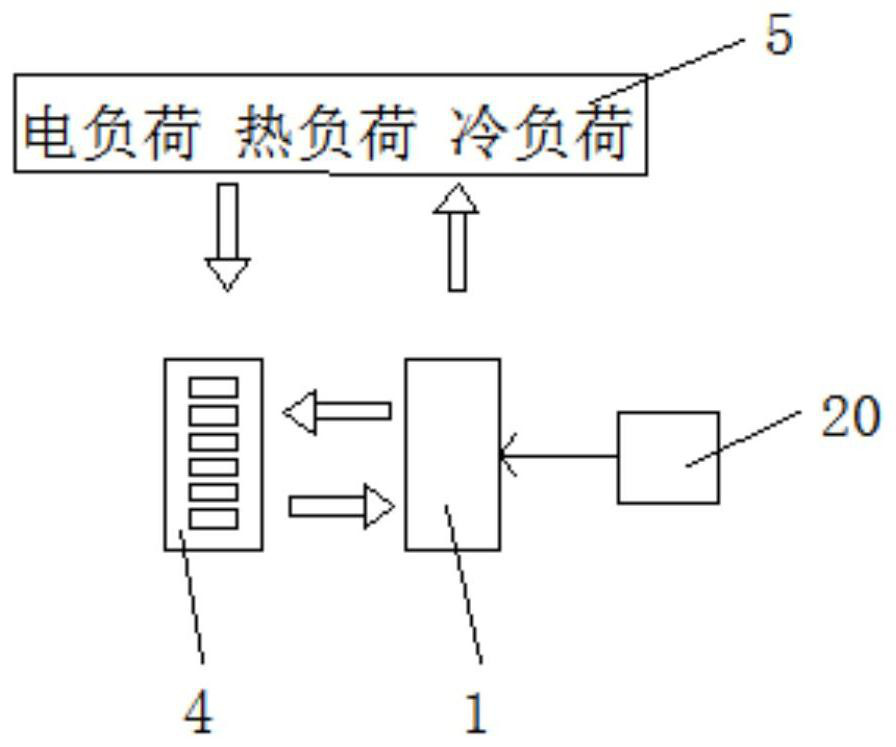

Energy supply system and control method thereof

PendingCN113513426AGuaranteed uptimeRuns evenly and smoothlyHot gas positive displacement engine plantsEngineeringEnergy supply

The invention provides an energy supply system and a control method thereof. The energy supply system comprises a medium flow path, a heat source, an external heating type engine and a hot / cold load, wherein the medium flow path is provided with a heat transfer medium capable of flowing in the medium flow path; the heat source is used for heating the heat transfer medium in the medium flow path, and the medium flow path located at the downstream of the heat source is provided with a first branch and a second branch; the external heating type engine is arranged on the first branch, and the heat transfer medium, heated by the heat source, in the first branch supplies heat to the external heating type engine; and the hot / cold load is arranged on the second branch, and the heat transfer medium, heated by the heat source, in the second branch supplies heat to the hot / cold load. The heat transfer medium heated by the heat source flows in the medium flow path, the heat transfer medium supplies heat to the external heating type engine of the first branch and the hot / cold load of the second branch, the external heating type engine absorbs heat to achieve heat-work conversion, the external heating type engine operates stably, the hot / cold load absorbs heat to generate a heat load or a cold load, the problem of energy waste is relieved, and the multi-combined supply requirement is met.

Owner:ZHEJIANG UNIV

Coal-to-oil and gas-to-power cogeneration device and method

ActiveCN104832226BEfficient cascade utilizationSmall excess coefficientHeat-exchange elementsGas purification with selectively adsorptive solidsCogenerationVolumetric Mass Density

Owner:李大鹏

A comprehensive energy utilization system for farms

ActiveCN110465534BReduce pollutionImprove securityInternal combustion piston enginesWaste processingLithium bromidePoultry manure

The invention discloses a comprehensive energy utilization system for a farm, and belongs to the technical field of distributed energy application. The system comprises a feeder, a manure-grass separator, an acidification pool, a fermentation tank, a biogas slurry storage pool, a solid-liquid separator, a desulfurization and dehydration system, a gas storage tank, a generator set, a waste heat boiler, a lithium bromide unit, a solar collector, a hot storage tank, a solar photovoltaic module, a water pump, a reservoir and a torch, wherein the livestock and poultry manure is treated intensively,the biogas and solar energy are combined organically to produce cold, heat and electricity and meet farm electricity, production heat, domestic water, domestic heating, air conditioning refrigerationand other demands, the biogas slurry and a solid organic fertilizer can produce to replace the use of pesticides and fertilizers, so that livestock and poultry manure can be turned into wealth.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Double-working-medium circulating pressurized water energy storage system and control method

ActiveCN114198167ASimple structureGet rid of poor terrain requirementsSteam useWater storage tankWater circulation

The invention discloses a double-working-medium circulating pressurized water energy storage system and a control method. The system comprises a heater, a normal-temperature and normal-pressure water storage tank, a high-temperature and high-pressure water storage tank, a flash tank, a steam turbine, a circulating water booster pump, a circulating water cooler, a machine working medium turbine, an organic working medium booster pump and an organic working medium cooler. According to the control method, a normal-temperature and normal-pressure water storage tank is adopted to store normal-temperature and normal-pressure water, the water is heated and pressurized through a booster pump and a heater, and a high-temperature and high-pressure water storage tank is adopted as an energy storage container to store internal energy of high-temperature and high-pressure water; when surplus heat energy exists in the energy releasing process, the water circulation system adopts flash evaporation-Rankine coupling circulation, part of high-temperature and high-pressure saturated water is further pressurized and heated through a second circulation water pump and a heater, and generated superheated steam is used for driving a first steam turbine; saturated steam generated by flash evaporation of high-temperature and high-pressure saturated water and exhaust steam of the high-pressure stage turbine are used for driving the second steam turbine, and efficient gradient utilization of waste heat resources is fully achieved.

Owner:XI AN JIAOTONG UNIV

A distributed gas-complementary solar energy combined cooling, heating and power system

ActiveCN111928219BReach heat source temperatureEfficient cascade utilizationSolar heating energyCombustion technology mitigationSolar water heating systemLithium bromide

The invention relates to a distributed gas-complementary solar energy combined cooling, heating and power supply system, which includes a distributed gas system, a solar photovoltaic photothermal system, a household solar hot water system, and a lithium bromide absorption refrigeration system. The system and the household solar water heating system are connected to the water inlet of the heat storage tank, the heat storage tank is connected to the cold water inlet of the heat exchanger, the hot water outlet of the heat exchanger is connected to the lithium bromide refrigerator, and the hot gas inlet of the heat exchanger is connected to the The flue gas discharge pipeline of the waste heat boiler in the distributed gas system. The hot water generated by the photothermal system in the solar photovoltaic photothermal system and the household solar hot water system flows into the hot water storage tank, and the hot water flows into the heat exchanger and is heated by the exhaust gas of the distributed gas waste heat boiler. Reach the temperature of the heat source of the lithium bromide refrigerator to realize refrigeration. The system makes full use of the heat generated by the system, and the electricity generated by the system can be used for self-use or connected to the grid. It truly realizes the efficient cascade utilization of clean energy and has a strong utilization prospect.

Owner:国网(天津)综合能源服务有限公司 +5

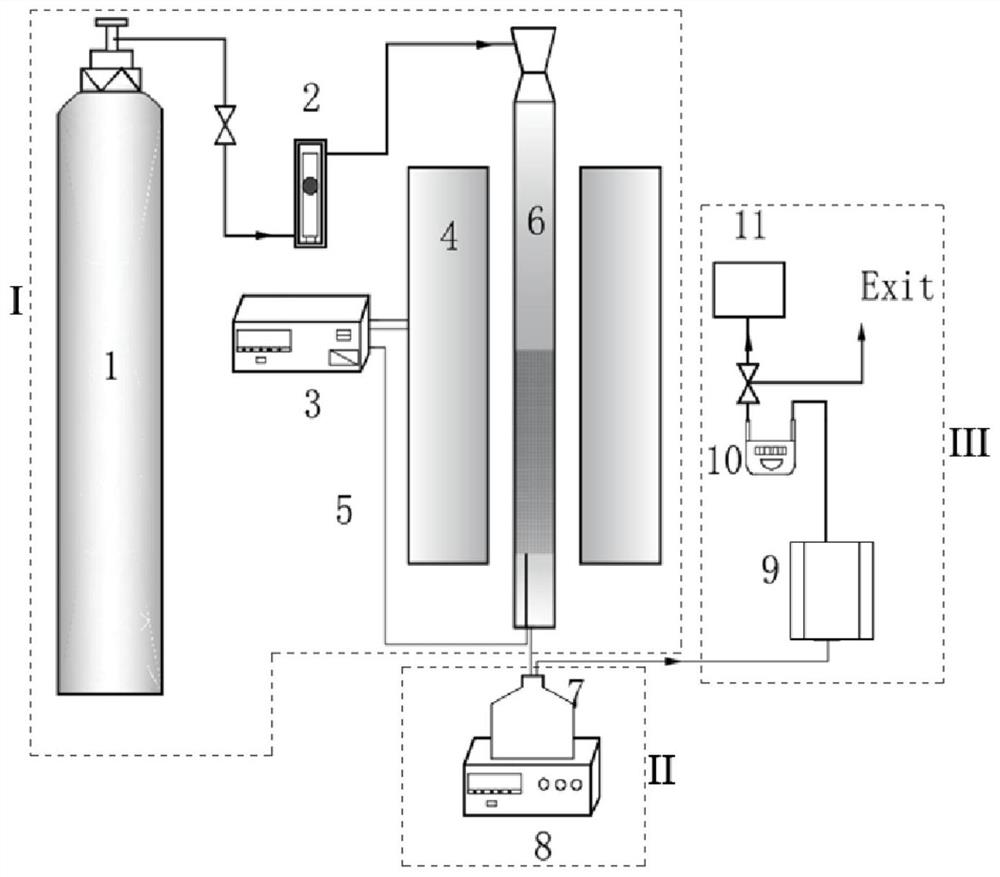

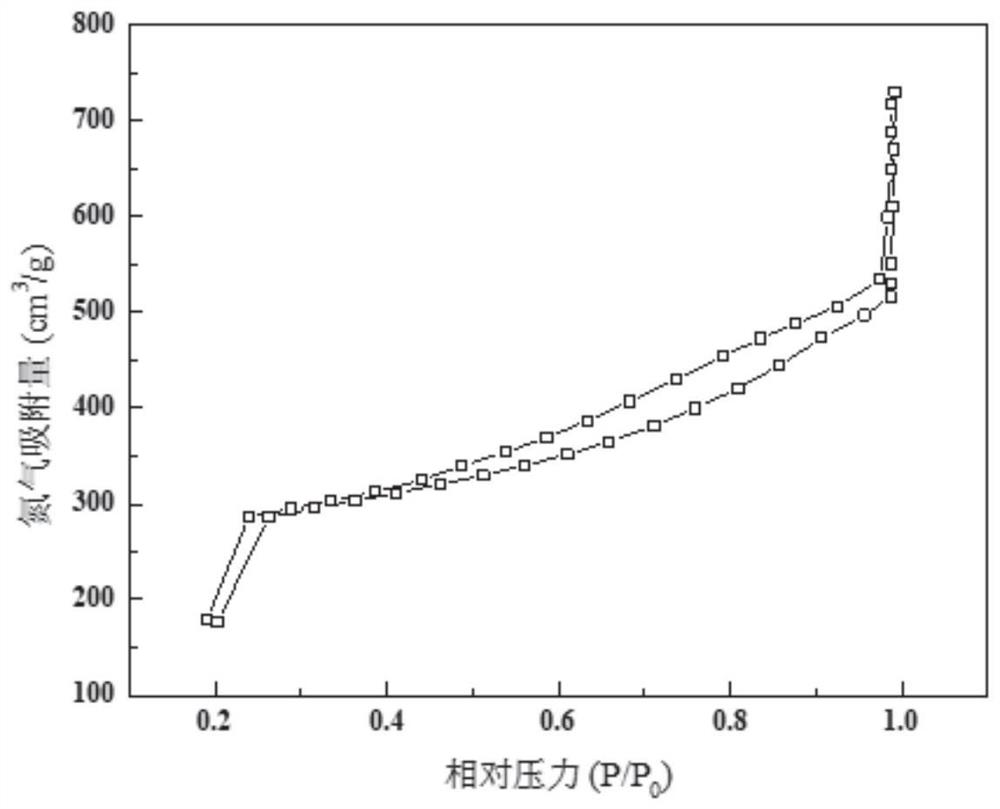

Device and method for preparing hydrogen storage carbon material by adopting biomass pyrolysis gas

ActiveCN112694088APrecise control of shapeFine-tuned structureHydrogenCarbon compoundsFiltrationFixed bed

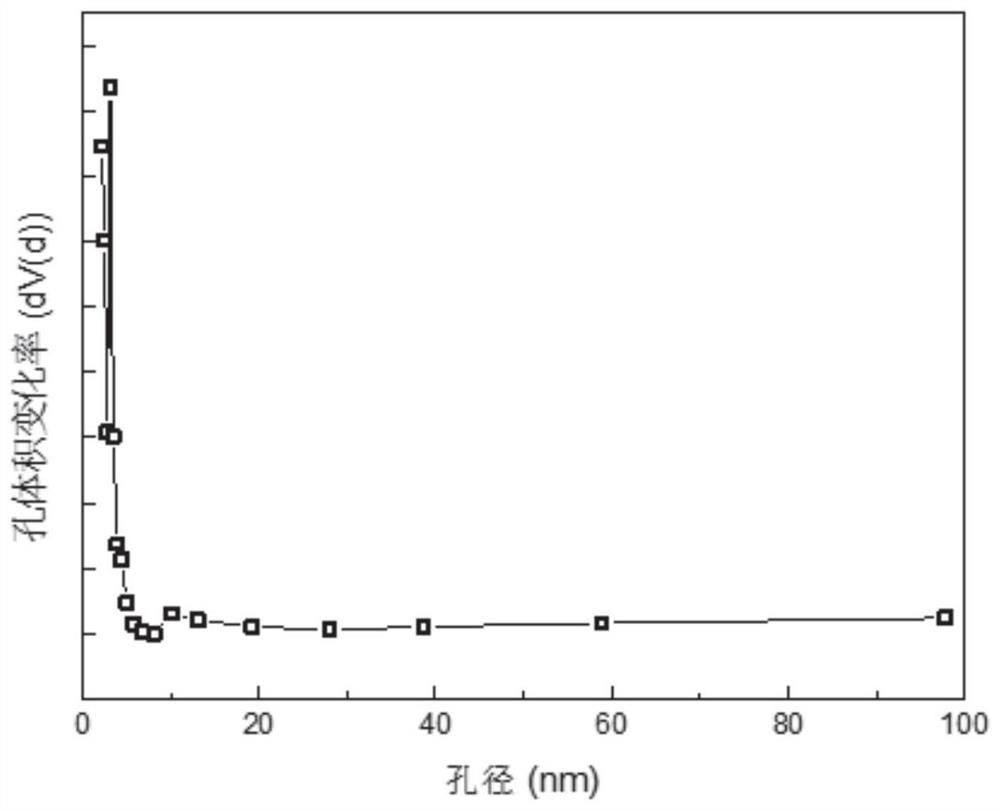

The invention relates to a device and a method for preparing a hydrogen storage carbon material by adopting biomass macromolecular pyrolysis gas. Granular biomass raw materials are added into a fixed bed or a fluidized bed for pyrolysis, and the macromolecular pyrolysis gas is uniformly mixed with a template agent calcium citrate ethanol solution at a gas outlet, heated and polymerized to prepare a carbon-containing precursor; the micromolecular pyrolysis gas which does not participate in the reaction enters a condensing device to be condensed to prepare light bio-oil; high-temperature carbonization is performed on the mixture in an inert gas atmosphere to obtain a C / CaO mixture, and acid pickling, suction filtration, washing and drying are performed to obtain the mesoporous carbon material with uniform pore size. Under normal pressure, the hydrogen absorption amount of the prepared carbon material at 77K is up to 1.8 wt%. The device is reasonable in structural design, the problem that macromolecules are coked to block a pipeline in the traditional pyrolysis oil production process while the hydrogen storage carbon material is prepared is solved, and high-value gradient utilization of pyrolysis gas is achieved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com