Coal-to-oil and gas-to-power cogeneration device and method

A coal-to-oil and gas technology, which is applied in the direction of steam engine equipment, manufacturing combustible gas, chemical instruments and methods, etc., can solve the problems of low resource utilization efficiency and achieve the effect of clean and cascaded utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

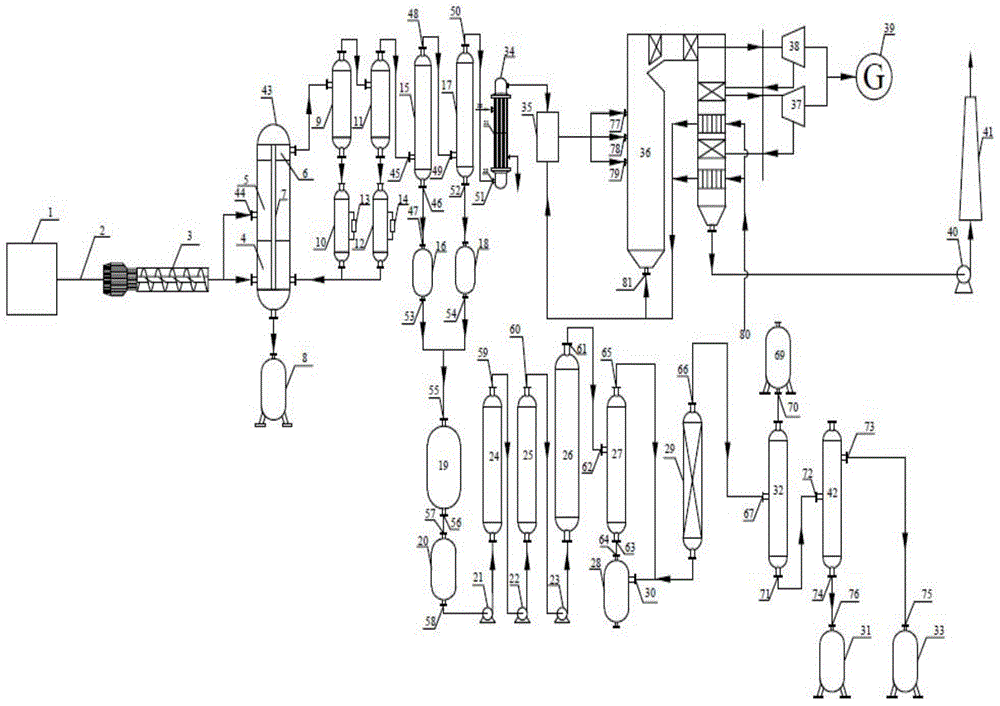

[0039] In order to make the technical solution and advantages of the present invention clearer, the following is a further detailed description of a coal-to-oil and gas-to-power cogeneration device and method disclosed in the present invention with reference to the accompanying drawings and embodiments.

[0040] see figure 1 , including coal extraction coal tar and coal gas integrated device subsystem, coal tar production clean fuel subsystem, gas combustion power generation subsystem;

[0041] The subsystem of the coal extraction coal tar and coal gas production integrated device includes a feed unit, a raw coal upgrading and conversion unit, and a raw coal upgrading and conversion reaction product separation and purification unit connected in sequence;

[0042] The subsystem for producing clean fuel from coal tar includes a coal tar pretreatment unit, a coal tar hydrogenation unit, and a coal tar hydrogenation product separation and purification unit connected in sequence; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com