Energy supply system and control method thereof

A control method and energy supply technology, applied in the field of multi-generation, can solve problems such as molten salt is easy to solidify, block pipelines, limit the continuous, stable and efficient operation of externally heated engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

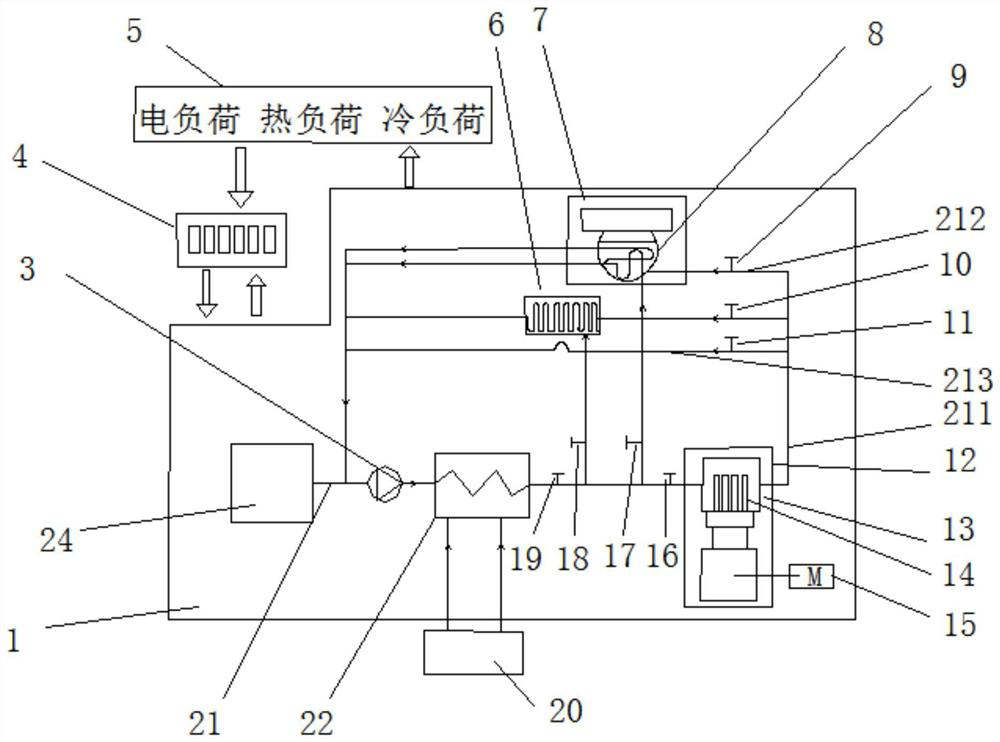

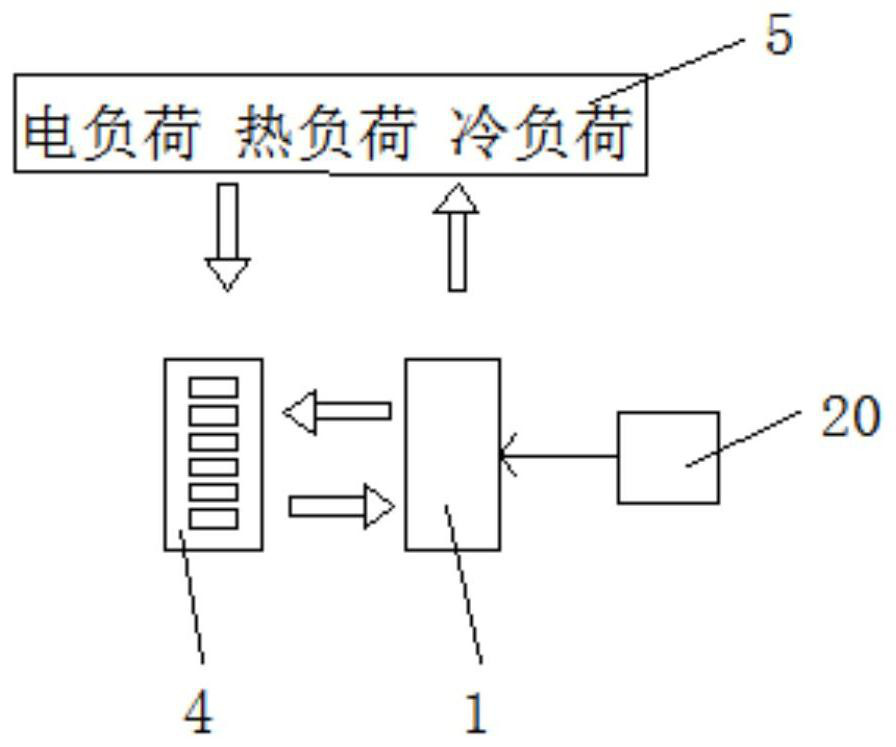

[0048] combine figure 1 with image 3 , an embodiment of the present invention is as follows:

[0049] An energy supply system, comprising an energy co-supply system body unit 1, a control unit 4, an adjustable load 5, and a heat source 20;

[0050] Among them, the main body unit 1 of the energy cogeneration system includes:

[0051] a medium flow path 21 having a heat transfer medium 24 capable of flowing therein;

[0052] The heat source 20 heats the heat transfer medium 24 in the medium flow path 21, and the medium flow path 21 located downstream of the heat source 20 has a first branch 211 and a second branch 212;

[0053] The external heat engine 12 is arranged in the first branch 211, and the heat transfer medium 24 in the first branch 211 heated by the heat source 20 supplies heat to the external heat engine 12;

[0054] The heat / cool load is arranged in the second branch 212, and the heat transfer medium 24 in the second branch 212 heated by the heat source 20 supp...

Embodiment 2

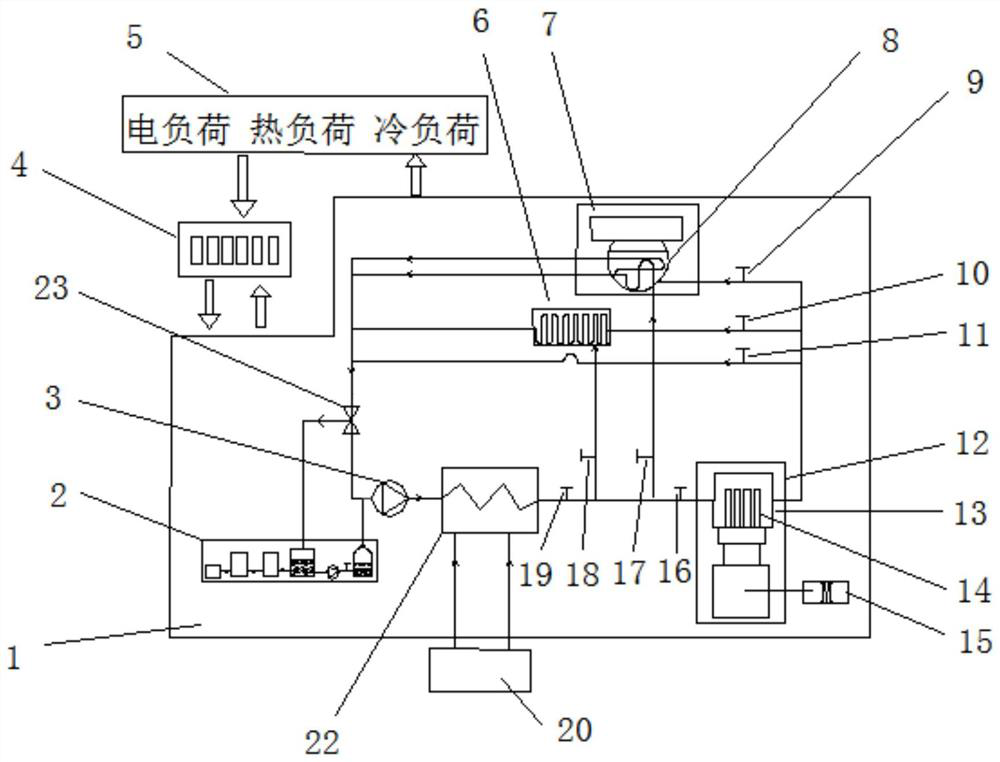

[0091] combine figure 2 , image 3 with Figure 4 , other embodiments of the present invention are as follows:

[0092] The main difference between the second embodiment and the first embodiment is that the heat transfer medium 24 used in this technical solution is water vapor.

[0093] Another difference between Embodiment 2 and Embodiment 1 is that a steam trap 23 and a working medium purification device 2 are added in the main unit 1 of the energy cogeneration system.

[0094] The working medium purification device 2 includes a water source 2a, a desalination device 2b, an oxygen removal device 2c, a water storage tank 2d, a feed water pump 2e, a feed water valve 2f, and a steam generator 2g.

[0095] The supply water from the water source 2a first passes through the desalination device 2b to remove salt impurities in the water; then passes through the deoxygenation device 2c to remove oxygen and other gases in the water to avoid slagging and corrosion in the circulatio...

Embodiment 3

[0104] combine figure 2 , Figure 4 with Figure 5 , other embodiments of the present invention are as follows: on the basis of embodiment two, the main heat source is solar energy, the sunlight heats the medium heater 22 after being concentrated by the secondary dish-type condenser heating unit, and the auxiliary heat source is natural gas.

[0105] In summer or when the temperature is high, the control unit 4 adjusts the medium circulation pump 3, the medium main valve 19, the external heat engine medium inlet valve 16, the cold load medium inlet valve one 9, the cold load medium inlet valve two 17 and the bypass Valve 11 closes heat load medium inlet valve one 10 and heat load medium inlet valve two 18, heat transfer medium 24 heats cold load generator 8 to generate cold energy while heating external heat engine heater 14 to generate electric energy, and realizes Cooling and electricity co-supply and coordination and matching of cooling and electricity loads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com