Multistage heat supply back pressure type steam turbine, thermodynamic system and heat supply method of thermodynamic system

A thermal system, back pressure technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as the inability of heating back pressure machines to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At present, the back pressure steam turbine with multi-stage different heating parameters (such as industrial heating and heating heating), when the final heat supply is not continuous, the unit cannot continue to operate. In order to solve such problems, it is often necessary to configure multiple different back pressure machines. In this embodiment, a multi-stage heating back pressure steam turbine and its thermal system are specifically provided. This design is not simply based on high parameters Heat supply is used as the basis for the design parameters of the exhaust steam of the back-pressure steam turbine, and the heat supply demand of each level is met through traditional methods such as reducing the temperature and decompression outside the unit; Separate extraction can achieve more efficient and reasonable parameter matching, and when the final heat supply load is discontinuous, the unit can still operate.

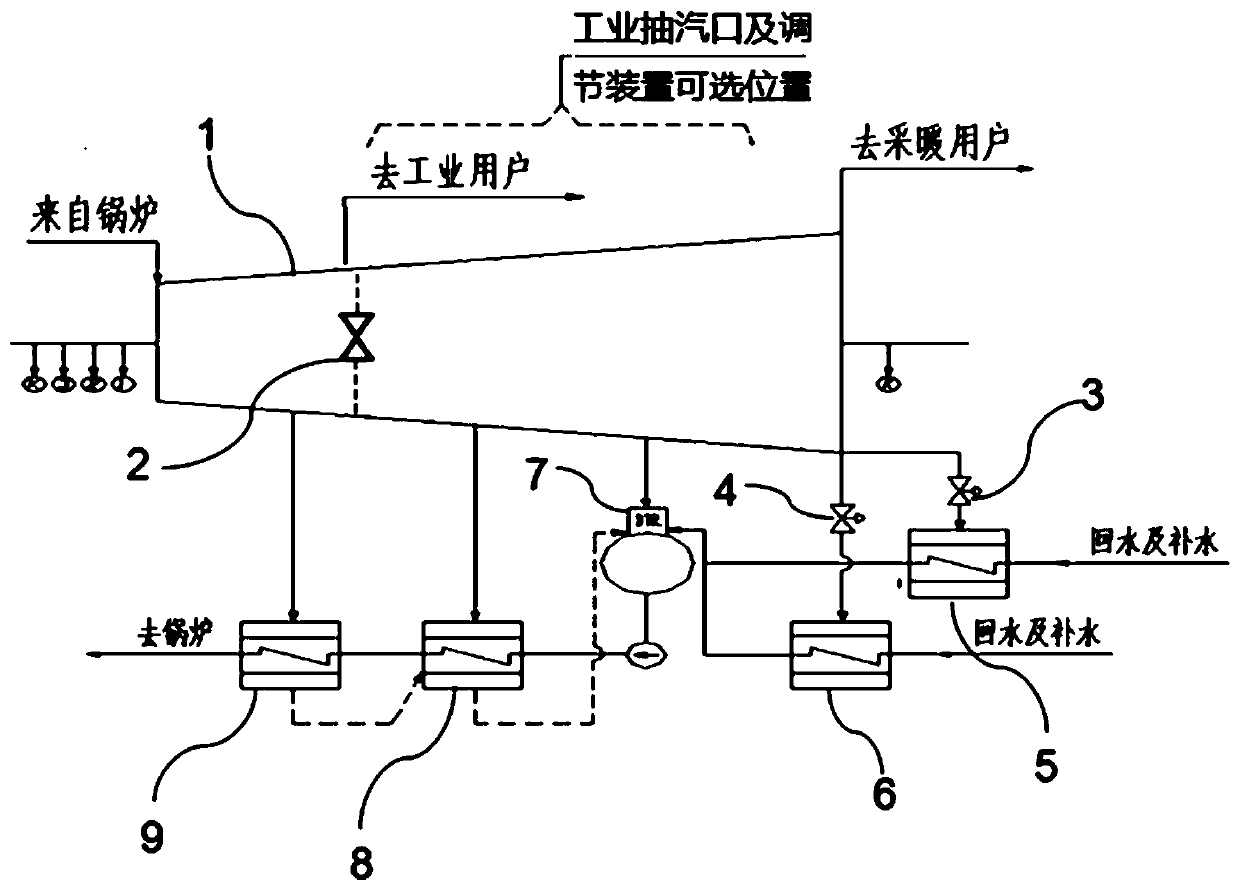

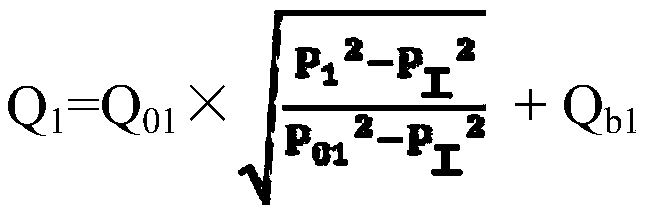

[0034] In this example, if figure 1 As shown, takin...

Embodiment 2

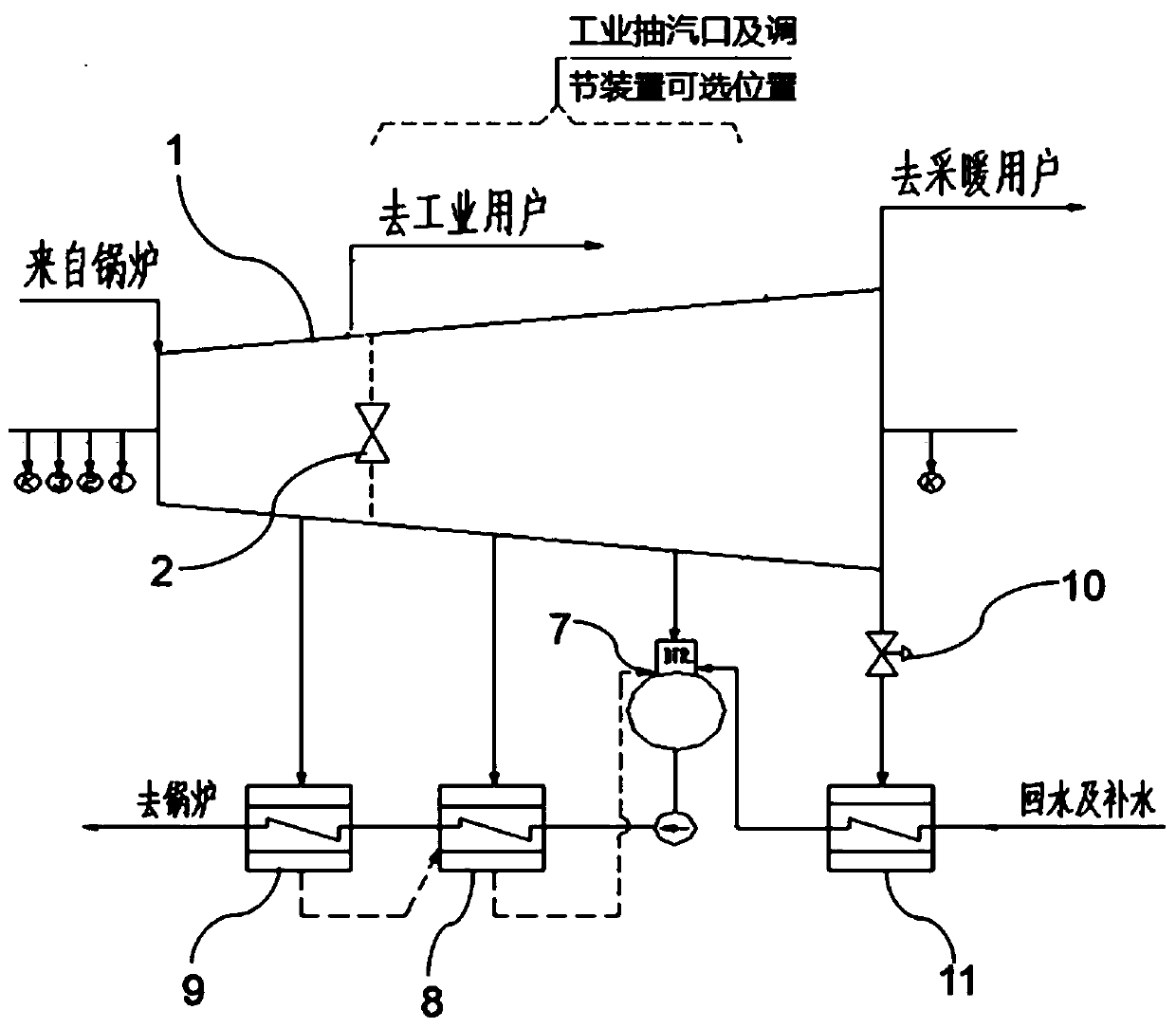

[0048] Such as figure 2 As shown, the variable heat recovery system configured in Embodiment 1 can also be designed in the following manner: the variable heat recovery system includes a low-pressure heater III, and the low-pressure heater III passes through the heat recovery pipeline It is connected to the final stage steam extraction port of the multi-stage heating back pressure steam turbine, and a regulating valve III is installed on the heat recovery pipeline to control the pressure at the exhaust end from dropping too much, and the throttling degree of the regulating valve III Change, adjust the heat extraction volume of the two adjacent stages and the temperature rise of the heater. As the load of the low-pressure heater III decreases, the pressure at the exhaust end increases, and the adjacent regenerative steam extraction volume is bound to increase, and the flow pressure at the corresponding extraction point decreases, thereby achieving the function of thrust adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com