Exhaust gas waste heat gradient utilization system for small-sized living garbage pyrolysis and gasification

A technology for domestic waste, pyrolysis and gasification, applied in incinerators, combustion types, reduction of greenhouse gases, etc., can solve the problems of low exhaust gas temperature, uneven heating, white fog phenomenon, etc. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

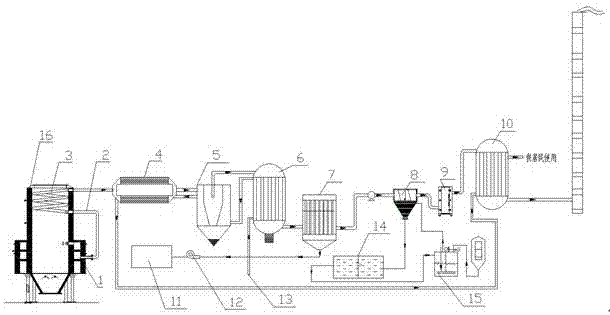

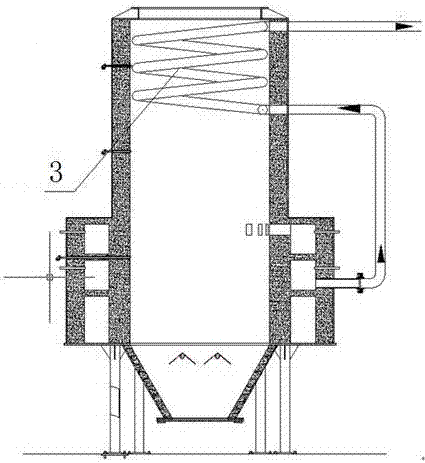

[0028] see figure 1 and figure 2 , the cascade utilization system for waste heat of flue gas from pyrolysis and gasification of small-scale domestic waste includes a pyrolysis furnace 16, and a garbage drying pipeline 3 is arranged in the pyrolysis furnace 16; The outlet of the flue gas pipeline 2 is connected, and the inlet of the flue gas pipeline 2 is communicated with the second combustion chamber 1 of the pyrolysis furnace 16; the flue gas outlet of the garbage drying pipeline 3 is connected with the flue gas inlet of the cooling pipe sleeve 4; The flue gas outlet of the cooling pipe sleeve 4 is connected with the flue gas inlet of the cyclone dust removal cooling device 5; the flue gas outlet of the cyclone dust removal cooling device 5 is connected with the flue gas inlet of the heat exchanger 6; the flue gas inlet of the heat exchanger 6 The gas outlet is connected with the flue gas inlet of the biomass filler detarring device 7; the flue gas outlet of the biomass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com