Method and apparatus for treating oily sludge

A sludge treatment and drying device technology, which is applied in the field of comprehensive utilization of solid waste resources, can solve the problems of difficult oil recovery, difficult dehydration of oily sludge, high energy consumption, etc., and achieves significant energy saving and environmental protection benefits, and improves the level of resource utilization , solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

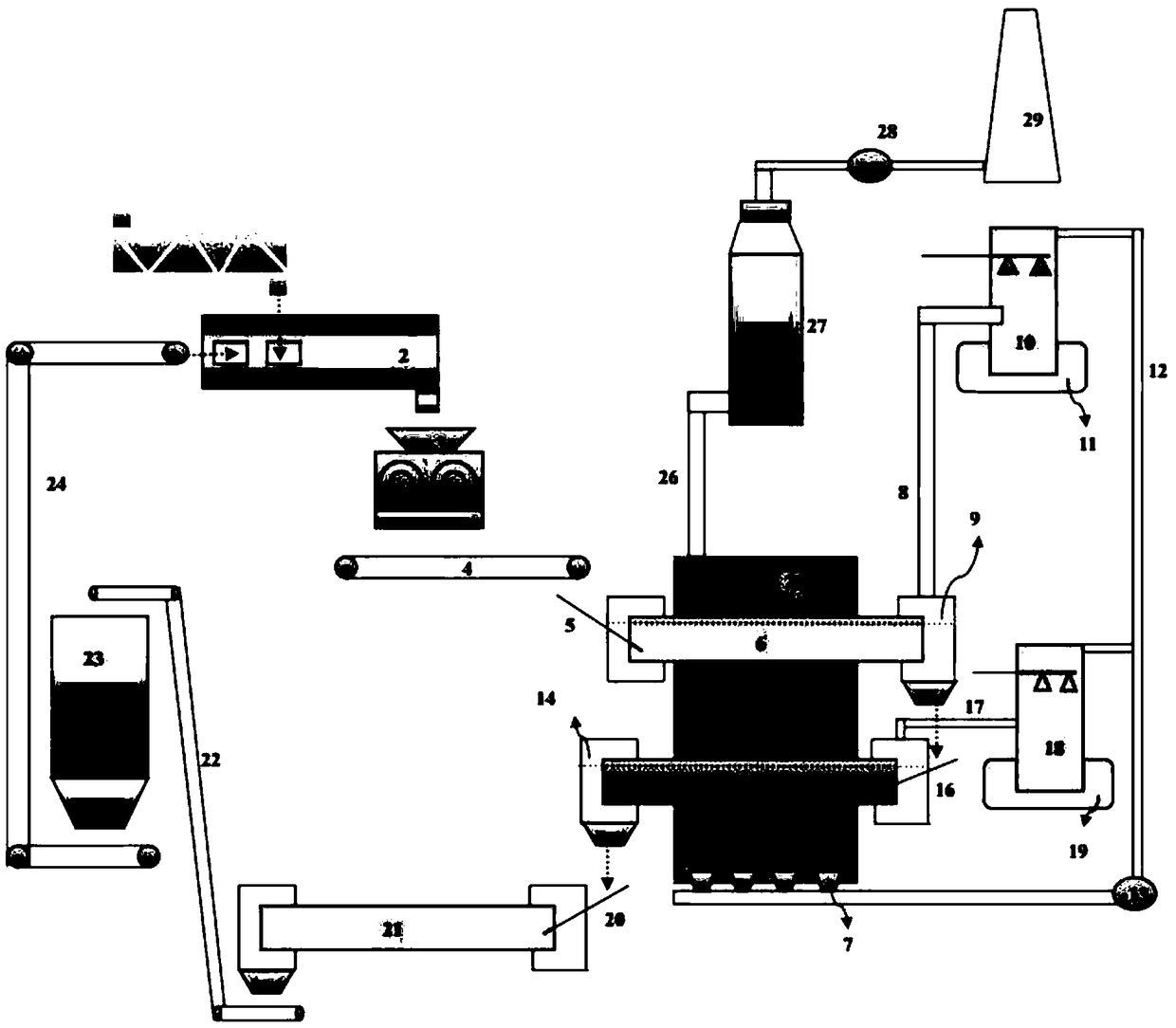

[0058] An oily sludge treatment device, such as figure 1 As shown, it includes: screw conveying device 1, mixing device 2, forming device 3, belt conveying device 4, 1# inclined chute 5, rotary drum indirect drying device 6, gas burner 7, steam pipe 8, 1# fixed scraper Plate dust removal device 9, steam condensing device 10, water treatment system 11, gas pipeline 12, gas fan 13, 2# fixed scraper dust removal device 14, rotary cylinder indirect thermal analysis device 15, 2# inclined chute 16, oil gas Conveying pipe 17, oil and gas condensing device 18, oil recovery storage device 19, 3# inclined chute 20, indirect cooling rotary drum 21, 2# belt conveyor 22, biochar storage bin 23, 3# belt conveyor 24, integrated heating Furnace 25, flue gas pipe 26, flue gas tail gas purification device 27, flue gas fan 28, chimney 29;

[0059] Wherein, the screw conveying device 1 is arranged above the mixing device 2, the mixing device 2 is connected to the forming device 3, the forming d...

Embodiment 2

[0077] A method for treating oily sludge, wherein the oily sludge is ground oil sludge, tank cleaning sludge and scum bottom sludge produced in an industrial production process, preferably ground oil sludge, tank cleaning sludge and scum bottom sludge produced by an oil refinery or an oil production plant Bottom mud. The processing method is as follows:

[0078] Using the oily sludge treatment device in Example 1, the oily sludge is transported into the mixing device 2 through the screw conveyor 1, and mixed with the biochar transported by the 3# belt conveyor 24; mixing Afterwards, the material directly enters the molding device 3 for high-pressure molding and granulation, and the obtained mud ball particles are transported by the 1# belt conveying device 4, and enter the rotary drum indirect drying device 6 through the 1# inclined chute 5 for drying and dehydration treatment; The dried mud ball particles are exported from the indirect drying device 6 of the rotary drum, dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com