A kind of autothermal pyrolysis method

A self-heating, pyrolysis technology, applied in special forms of dry distillation, direct heating dry distillation, gas dust removal, etc., can solve the problems of dangerous, high semi-coke temperature, spontaneous combustion in storage or transportation, etc., and achieve the effect of high-efficiency cascade utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

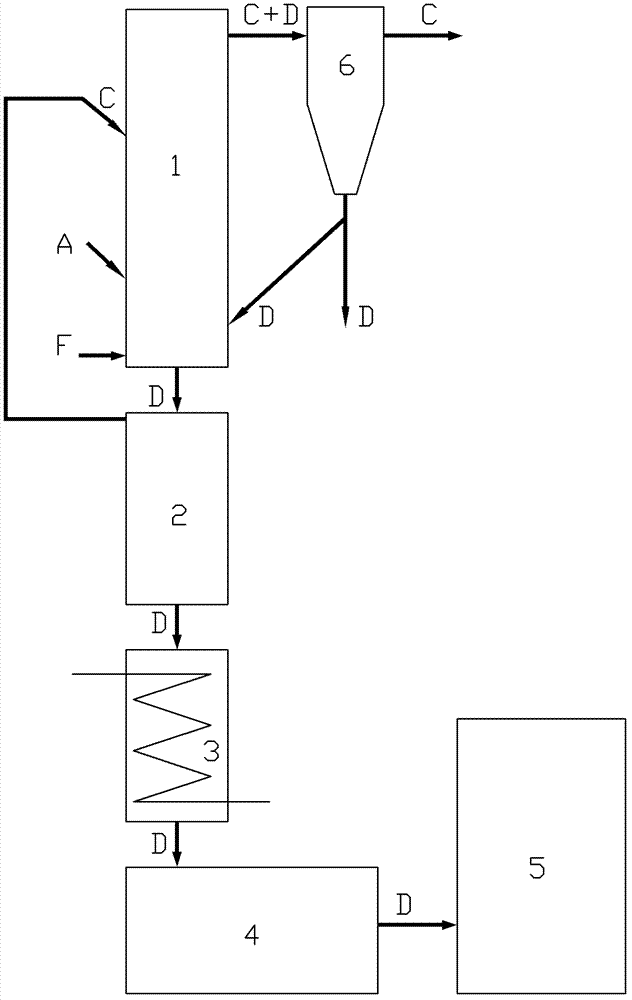

[0049] Such as figure 1 As shown, the fine coal A with a particle size ranging from 0 to 8mm is sent into the pyrolysis furnace 1 for pyrolysis, and the bottom of the pyrolysis furnace 1 is fed with air as a fluidizing gas. The fluidization velocity of the tower is 1.2-1.4m / s, and the ratio between the oxygen contained in the air and the coal is 0.05-0.15Nm 3 (oxygen) / kg (coal). The heat required for pyrolysis comes from the heat released from the combustion of part of the raw coal A; the reaction temperature in the pyrolysis furnace 1 is 700-750°C, and 60-75% of the volatiles in the coal are analyzed to produce gas C containing oil and gas and semi-coke D . Coal gas C entrains the fine powder of semi-coke D from the top of pyrolysis furnace 1 into the gas-solid separator 6, part of the separated semi-coke D returns to pyrolysis furnace 1, and the rest is discharged.

[0050] The high-temperature semi-coke D discharged from the bottom of the pyrolysis furnace 1 is sent into...

Embodiment 2

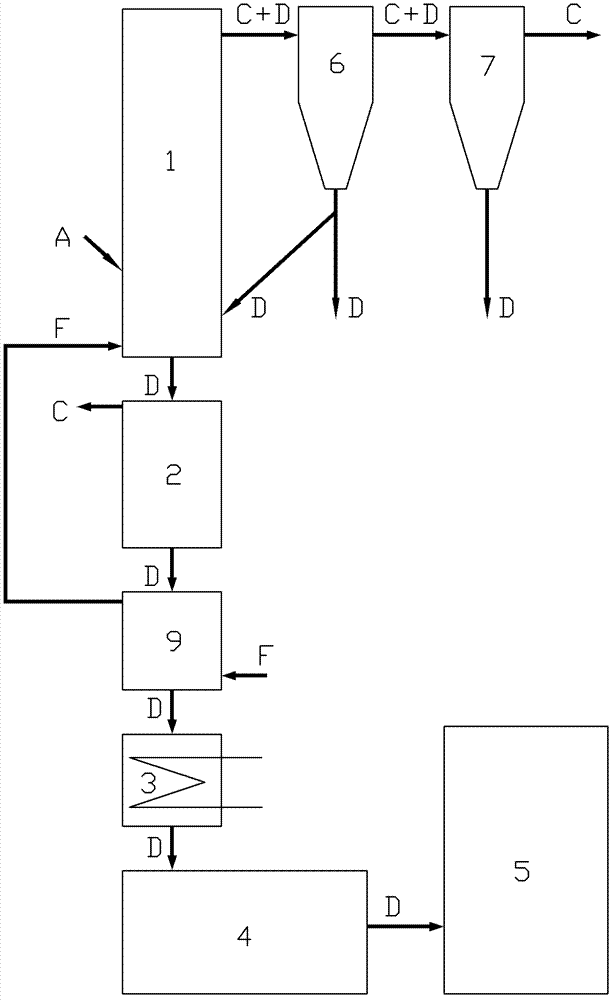

[0053] Such as figure 2 As shown, the fine coal A with a particle size ranging from 0 to 20 mm is sent into the pyrolysis furnace 1 for pyrolysis, and oxygen-enriched air and steam are fed into the bottom of the pyrolysis furnace 1 as fluidizing gas, and the fluidizing gas is heated The superficial fluidization velocity in the melting furnace 1 is 3.5-4.0m / s, and the ratio of the oxygen contained in the oxygen-enriched air to the coal is 0.2-0.35Nm 3 (oxygen) / kg (coal). The heat required for pyrolysis comes from the heat released from the combustion of part of the raw coal A; the reaction temperature in the pyrolysis furnace 1 is 1000-1050°C, and 80-95% of the volatiles in the coal are analyzed to produce gas C and semi-coke D. Coal gas C entrains the fine powder of semi-coke D from the top of pyrolysis furnace 1 into the gas-solid separator 6, part of the separated semi-coke D returns to pyrolysis furnace 1, and the rest is discharged. The separated coal gas C still entrai...

Embodiment 3

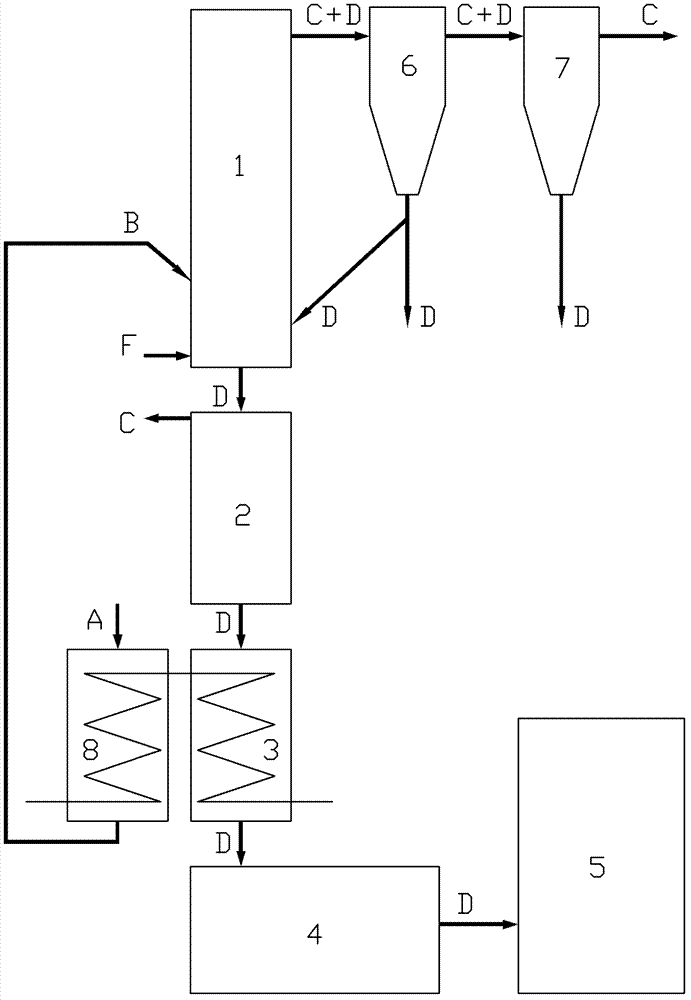

[0057] Such as image 3 As shown, the raw coal A of 0-15 mm is first sent into the drier 5 for drying. Then the dried fine coal B is sent into the pyrolysis furnace 1 for pyrolysis. The bottom of pyrolysis furnace 1 is fed with pure oxygen and steam as fluidization gas. The superficial fluidization velocity of fluidization gas in pyrolysis furnace 1 is 1.2-4.0m / s, and the ratio of oxygen to coal is 0.05-0.35Nm 3 (oxygen) / kg (coal). The heat required for pyrolysis comes from the heat released from the combustion of part of the coal; the reaction temperature in the pyrolysis furnace 1 is 700-1050°C, which can be realized by adjusting the amount of oxygen according to the requirements of the target product. Increasing the amount of oxygen can make the heat The temperature of the melting furnace 1 increases, and vice versa. 60-95% of the volatiles in the coal are analyzed to produce coal gas C and semi-coke D. Coal gas C entrains the fine powder of semi-coke D from the top of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com