Coal gas and pulverized coal synergistic power generation and polygeneration device and method

A polygeneration and coal gas technology, which is applied to the combustion of gaseous fuel and powder fuel, joint combustion mitigation, and the production of combustible gas, can solve the problem of not really realizing the efficient utilization of coal resources in polygeneration of coal-based energy. Achieve the effect of clean cascade utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

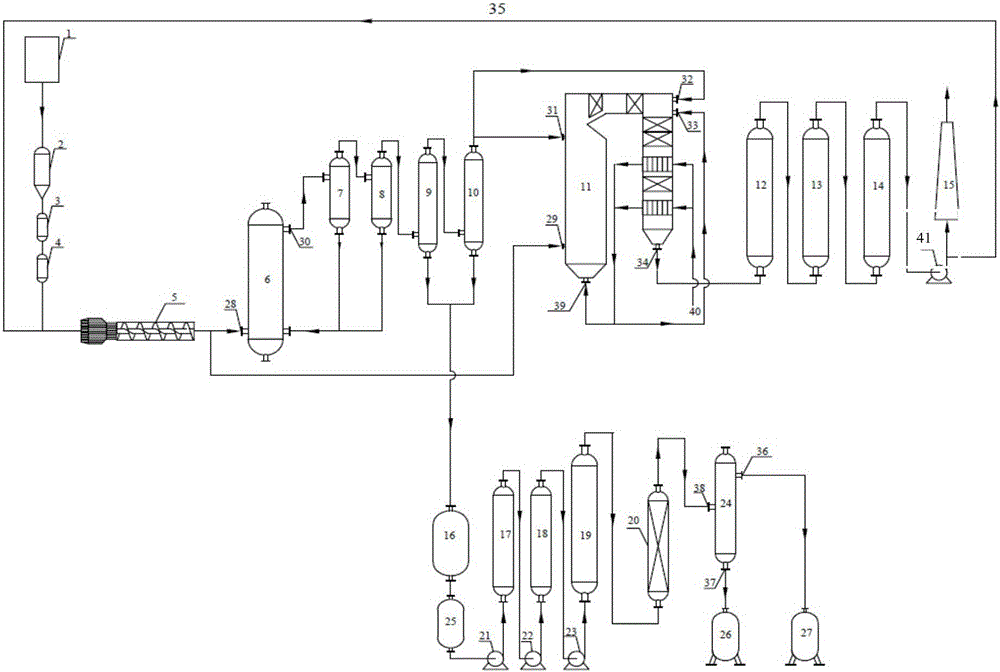

[0032] see figure 1 , the device of the present invention includes a pulverized coal feed device and a gasification-pyrolysis coupling reactor 6 and a boiler 11 connected to the pulverized coal feed device; the crude oil containing tar and ash output from the gasification-pyrolysis coupling reactor 6 The coal gas is connected with the dust removal and separation device, and the tar in the crude gas recovered by the dust removal and separation device is sent to the subsequent tar processing device to obtain naphtha and diesel oil. The crude gas containing tar and ash is divided into two after the dust removal and separation device. The branch path enters the boiler 11 for combustion, and the gas of one branch path enters the boiler 11 through the burner no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com