Method and device for producing hydrocarbons by connecting low-temperature Fischer-Tropsch section and high-temperature Fischer-Tropsch section in series

A low-temperature and high-temperature technology, applied in the field of Fischer-Tropsch synthesis, can solve the problems of low conversion rate of raw materials and low carbon utilization rate, and achieve the effects of improving economic benefits, improving utilization efficiency, and realizing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

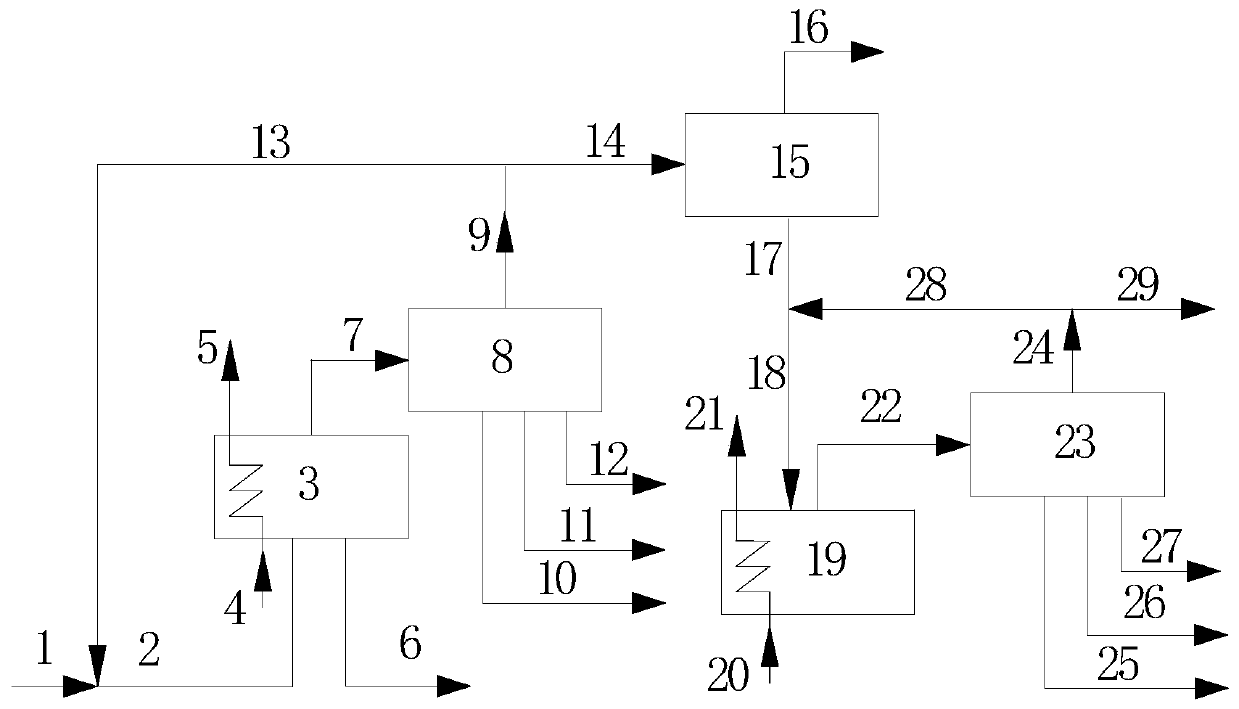

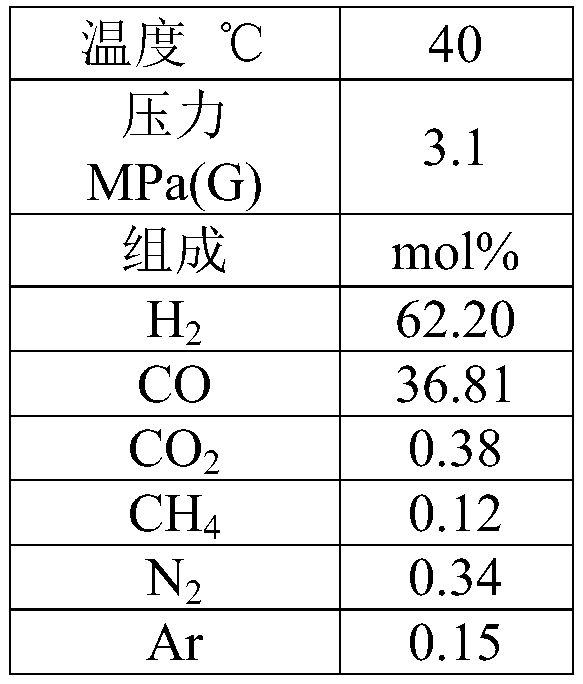

[0071] A kind of low-temperature Fischer-Tropsch and high-temperature Fischer-Tropsch two-stage method for producing hydrocarbons in series, adopting such as figure 1 The process flow shown, the raw material is fresh syngas from coal gasification, which has been transformed and purified, with a gas volume of 620,000 Nm 3 / h, H 2 / CO is 1.69, and the fresh gas composition is shown in Table 1.

[0072] Table 1 Composition of fresh air

[0073]

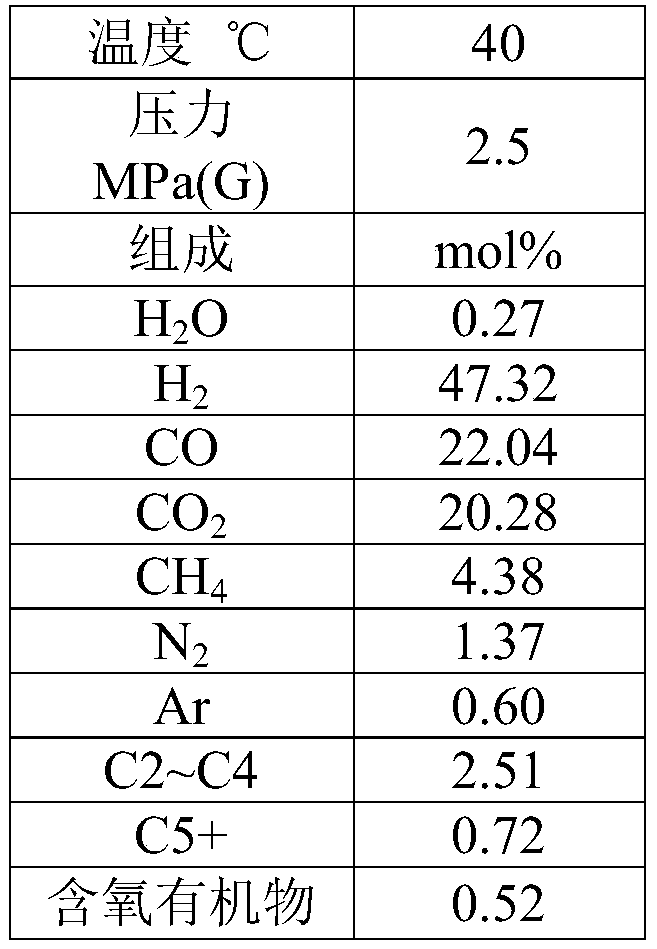

[0074] The first-stage low-temperature Fischer-Tropsch synthesis reactor is a slurry bed reactor, using precipitated iron catalyst, the reaction temperature is 240°C, the reaction pressure is 2.9MPa(G), the circulation ratio is 1, and the reactor inlet H 2 / CO is 1.86, and the Fischer-Tropsch synthesis reactor produces 494.46t / h of 1.6MPa(G) steam by-product. Reaction separation produces 50.63t / h of paraffin, 13.94t / h of low-temperature heavy oil, 21.85t / h of low-temperature light oil, 110.68t / h of low-temperature reaction water, a...

Embodiment 2

[0110] This embodiment adopts figure 1 Process flow shown, fresh synthesis gas from natural gas conversion and purification, gas volume 620,000 Nm 3 / h, H 2 / CO is 2.12, and the fresh gas composition is shown in Table 10.

[0111] Table 10 Fresh gas composition

[0112] temperature °C 40 Pressure MPa(G) 3.1 composition mol% H 2

67.37 CO 31.78 CO 2

0.10 CH 4

0.37 N 2

0.28 Ar 0.10

[0113] The first-stage low-temperature Fischer-Tropsch synthesis reactor is a slurry bed reactor, using a cobalt-based catalyst, the reaction temperature is 230°C, the reaction pressure is 2.9MPa(G), the circulation ratio is 1, and the reactor inlet H 2 / CO is 2.18, and the Fischer-Tropsch synthesis reactor produces 386.17t / h of 1.6MPa(G) steam by-product. Reaction separation produces 33.59t / h of paraffin, 15.13t / h of low-temperature heavy oil, 23.48t / h of low-temperature light oil, 113.26t / h of low-temperature reaction wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com