Metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel

A low-alloy, high-strength, metal powder core technology, applied in welding media, welding equipment, welding equipment, etc., can solve the problems of low production efficiency of low-hydrogen electrodes, unfused solid welding wire, low diffusible hydrogen content, etc., and achieve good The effect of welding operation process performance, reduction of welding defects, low content of diffusible hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The weight percent of each component in the metal powder core is: 8% low-carbon ferromanganese, 5% ferrosilicon, 1% ferrotitanium, 8% nickel powder, 1% ferromolybdenum, 4% ferroboron, 2% magnesium powder , rare earth fluoride 1%, iron powder 70%.

[0031] The mass of the metal powder core accounts for 12% of the total mass of the welding wire.

[0032] Metal powder cored flux cored wire welding conditions: the shielding gas is a mixed gas with a volume content of 80% Ar 2 and 20% CO 2 , current 260A, voltage 28V.

[0033] Metal powder cored flux cored wire deposited metal composition detection, its weight percentage is: carbon 0.035%, manganese 0.71%, silicon 0.16%, sulfur 0.007%, phosphorus 0.008%, nickel 0.81%, molybdenum 0.065, titanium 0.017, boron 0.015, The balance is iron.

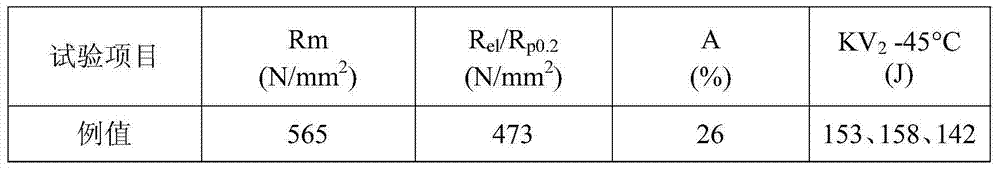

[0034] Metal powder cored flux cored wire deposited metal mechanical properties:

[0035]

[0036] Metal powder cored flux cored wire deposited metal diffusible hydrogen content: 3.8m...

Embodiment 2

[0038] The weight percent of each component in the metal powder core is: 15% low-carbon ferromanganese, 9% ferrosilicon, 3% ferrotitanium, 12% nickel powder, 3% ferromolybdenum, 8% ferroboron, 5% magnesium powder , rare earth fluoride 4%, iron powder 41%.

[0039] The mass of the metal powder core accounts for 17% of the total mass of the welding wire.

[0040] Metal powder cored flux cored wire welding conditions: the shielding gas is a mixed gas with a volume content of 80% Ar 2 and 20% CO 2 , current 260A, voltage 28V.

[0041] Metal powder cored flux cored wire deposited metal composition detection, its weight percentage is: carbon 0.058%, manganese 1.31%, silicon 0.34%, sulfur 0.004%, phosphorus 0.007%, nickel 1.05%, molybdenum 0.15, titanium 0.050, boron 0.035, The balance is iron.

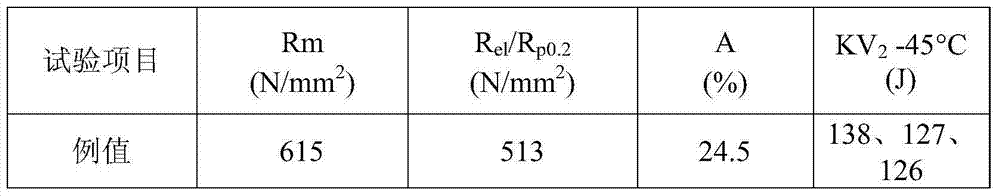

[0042] Metal powder cored flux cored wire deposited metal mechanical properties:

[0043]

[0044] Metal powder cored flux cored wire deposited metal diffusible hydrogen content: 3.5...

Embodiment 3

[0046] The weight percent of each component in the metal powder core is: 11.5% of low-carbon ferromanganese, 7% of ferrosilicon, 2% of ferrotitanium, 10% of nickel powder, 2% of ferromolybdenum, 6% of ferroboron, and 3.5% of magnesium powder , rare earth fluoride 2.5%, iron powder 55.5%.

[0047] The mass of the metal powder core accounts for 14.5% of the total mass of the welding wire.

[0048] Metal powder cored flux cored wire welding conditions: the shielding gas is a mixed gas with a volume content of 80% Ar 2 and 20% CO 2 , current 260A, voltage 28V.

[0049] Metal powder cored flux cored wire deposited metal composition detection, its weight percentage is: carbon 0.045%, manganese 1.02%, silicon 0.25%, sulfur 0.007%, phosphorus 0.007%, nickel 0.87%, molybdenum 0.10, titanium 0.030, boron 0.025, The balance is iron.

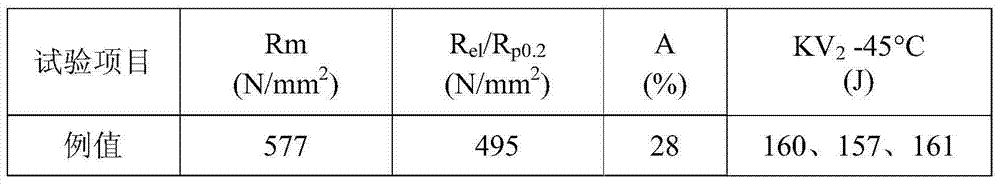

[0050] Metal powder cored flux cored wire deposited metal mechanical properties:

[0051]

[0052] Metal powder cored flux cored wire deposited metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com