Electric welding rod for welding large scale low temperature spherical tank steel

A welding rod, large-scale technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of low temperature impact toughness, low value, low temperature impact absorption energy can not meet the requirements, etc. Low temperature impact toughness and crack resistance, less spatter, good welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

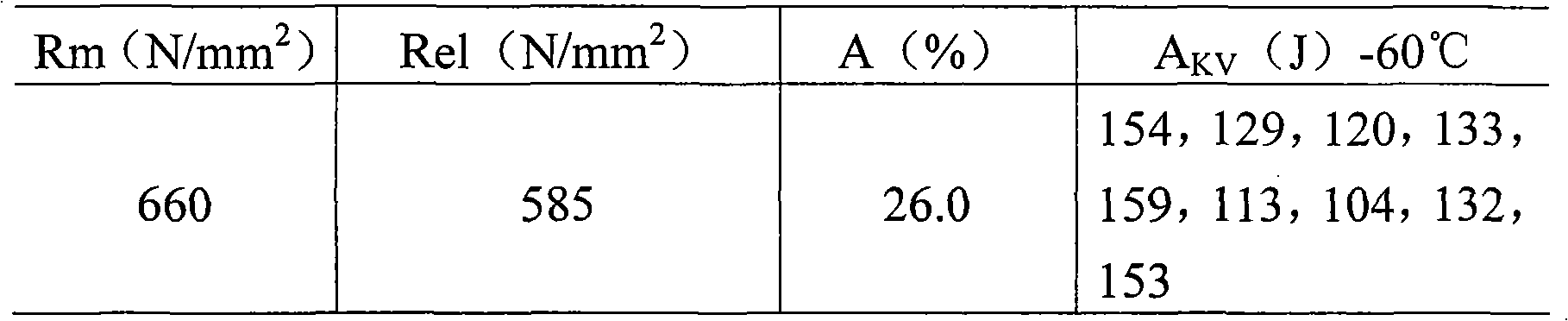

Embodiment 1

[0018] An electric welding rod used for welding large-scale low-temperature spherical tank steel, which is composed of welding core, electrode coating and adhesive, is manufactured according to the conventional welding rod production process, that is, the H08GX wire rod is cut into welding core; the welding rod coating is The auxiliary materials are prepared and mixed according to the proportion; the water glass binder is added into the auxiliary material mixed powder according to the weight ratio of 24%; the welding core and the mixed powder are made into welding rods with conventional welding rod production equipment and technology, and dried. Component situation is as follows in this embodiment:

[0019] 1) The welding core is wire rod for H08GX welding rod, and its chemical composition and weight percentage are as follows: (%)

[0020] C

S

mn

Si

P

Fe

0.054

0.003

0.45

0.027

0.006

margin

[0021]...

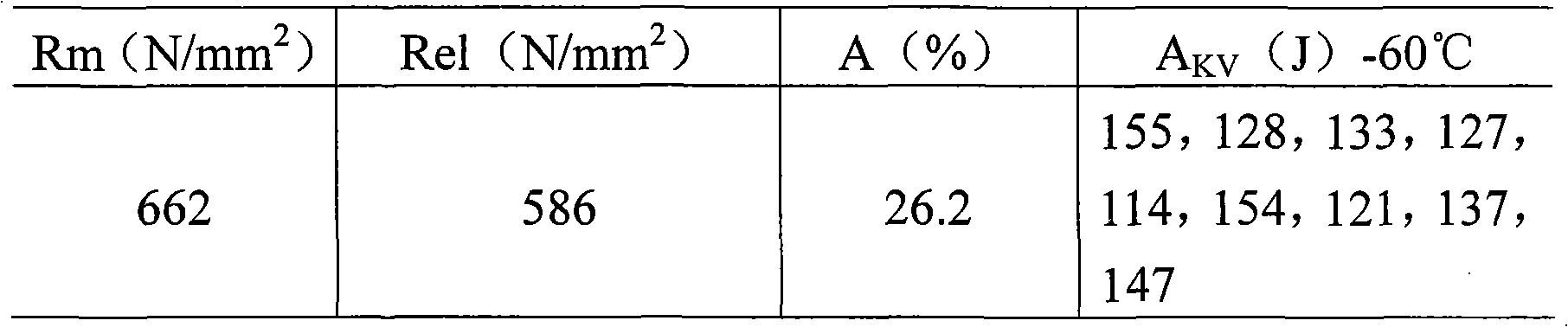

Embodiment 2

[0033] The manufacturing process and detection method of welding rod are identical with embodiment 1, and composition situation is as follows in this embodiment:

[0034] 1) The welding core is wire rod for H08GX welding rod, and its chemical composition and weight percentage are as follows: (%)

[0035] C

S

mn

Si

P

Fe

0.056

0.004

0.44

0.025

0.005

margin

[0036] 2) The electrode coating includes the following auxiliary materials and their weight percentages are as follows: (%)

[0037] Dali

stone

Jinhong

stone

silicon micro

pink

ferro-titanium

Ferroboron

33

17

7

5

5

3

8

10

1

0.5

10.5

[0038] , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com