Terylene half speed blended spinning-type ammonia-substituted fiber blended spinning method and its apparatus

A medium-speed, polyester technology, used in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problem of inability to produce composite yarns in the spinning position, achieve uniform waste water shrinkage, high economic benefits, and influencing factors less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

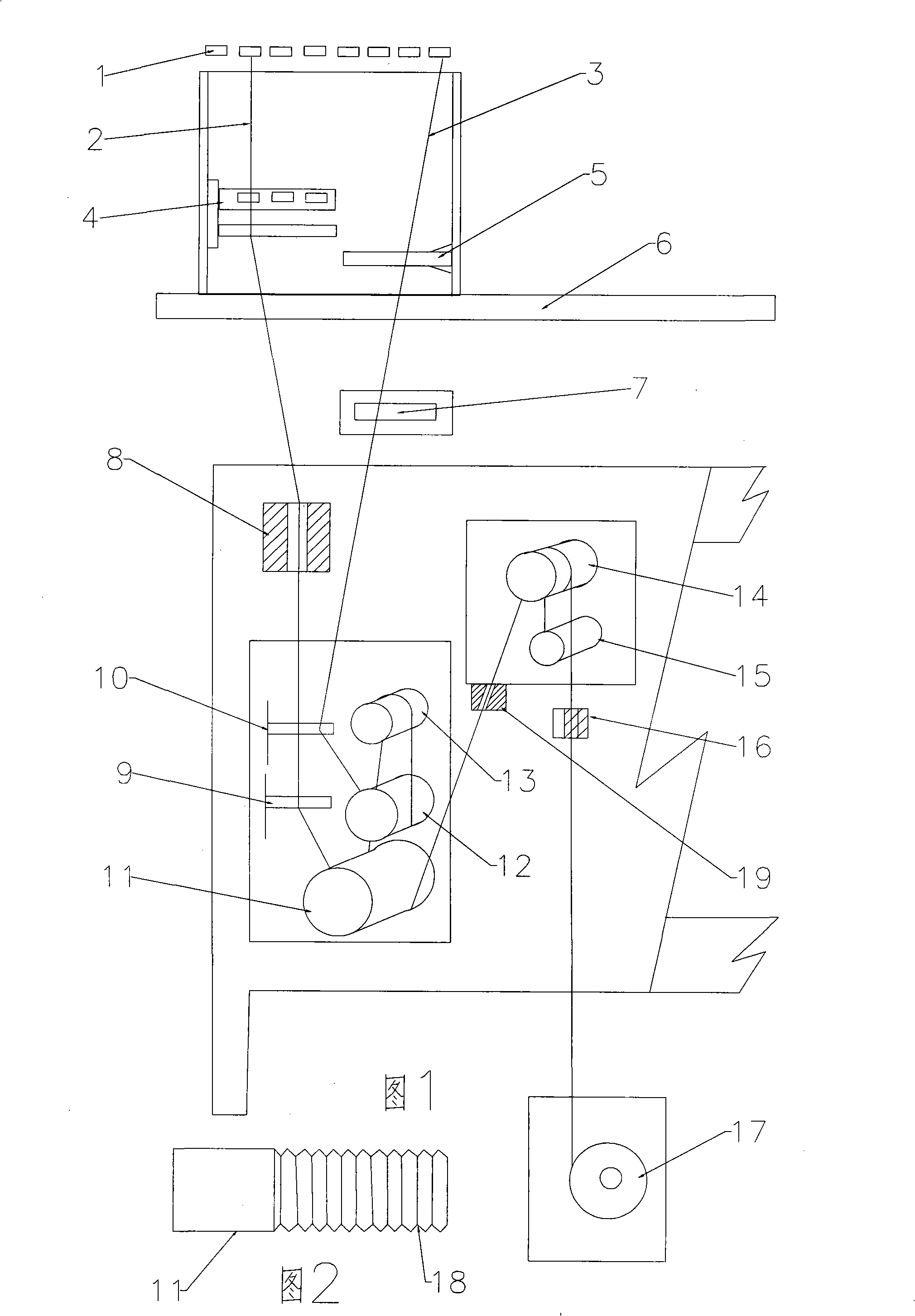

[0016] The blending method of a kind of polyester medium-speed blending type ammonia fiber that the present invention designs, comprises slice conveying screening, slice drying, screw extruding, melt spinning, blowing cooling, it is characterized in that: after cooling, enter POY spinning and spinning respectively FDY spinning, after POY spinning, enters the nozzle for oiling, and then enters the pre-internet; after FDY spinning, enters the tanker for oiling, then enters the pre-internet, then enters the hot roller for drafting, and then enters the POY and FDY filaments into the guide groove The type godets are merged and compounded, and after compounding, they enter the intermediate network, are reheated to shape the roll, and then enter the main network to be wound and formed. During the production process, the winding speed is 3000 m / min, the hot roller GR 1 Temperature: 85°C; Number of coils: 7.5 to 10 coils; Hot roller GR 2 Temperature: 100°C Number of coils: 4 to 5.5 co...

Embodiment approach 1

[0041] Embodiment 1: If the FDY spinning hot roll is a double hot roll (two hot rolls), then change one of the hot rolls, and install a splitting roll next to the other hot roll, then the first The set of double heat rolls is changed to a set of single heat rolls with splitting rolls. In addition, in order to produce POY at the same time, a grooved godet is installed behind the FDY spinning heat roll to make the POY tow and FDY tow separate for merger purposes.

Embodiment approach 2

[0042] Embodiment 2: If the first heat roll group is a single heat roll (one heat roll, one splitting roll), then it can be connected to install a grooved godet behind the first set of heat rolls, so that the POY tow and FDY tows are used for merging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com