Pre-treatment auxiliary agent for cotton knitted fabrics, preparation method and application thereof

A technology of cotton knitted fabrics and additives, applied in fiber treatment, bleached products, plant fibers, etc., can solve the problems of many types, long processing procedures, and inconvenience, and achieve the effects of simple operation, reduced overall cost, and relieved pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the formula of pretreatment auxiliary agent for cotton knitted fabrics:

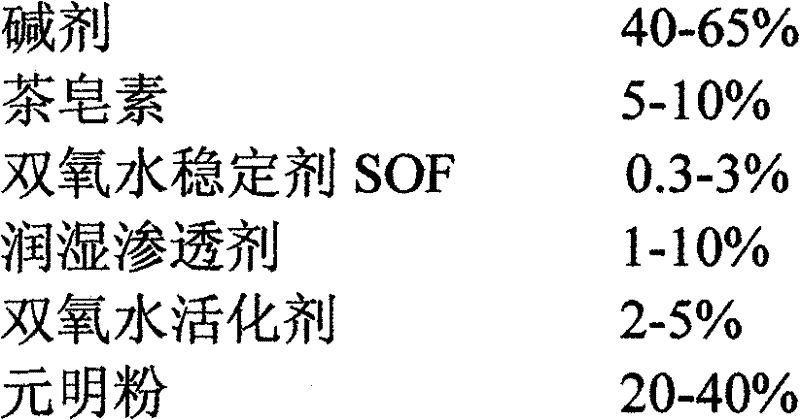

[0033] A kind of cotton knitted fabric pretreatment auxiliary agent, comprises the raw material composition of following percentage by weight:

[0034] Alkali 40-65%

[0035] Tea saponin 5-10%

[0036] Hydrogen peroxide stabilizer 0.3-3%

[0037] Wetting and penetrating agent 1-10%

[0038] Hydrogen peroxide activator 2-5%

[0039] Yuanming powder 20-40%

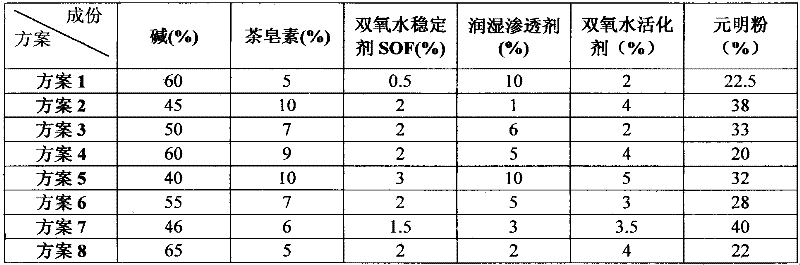

[0040] According to above-mentioned prescription of the present invention, preparation specific example is as shown in table 1.

[0041] Table 1: List of pretreatment additives for cotton knitted fabrics with different compositions

[0042]

[0043] Remarks for Table 1:

[0044] The alkaline agent in Scheme 1 is sodium silicate, and the wetting and penetrating agent is BASF’s nonionic surfactant XP-70

[0045] Alkaline agent in scheme 2 is the mixture ratio of sodium carbonate and sodium silicate is 2: 1; Wetting and pen...

Embodiment 2

[0049] Embodiment 2, the preparation of pretreatment auxiliary agent for cotton knitted fabric:

[0050] Add alkali agent, tea saponin, hydrogen peroxide activator, and sodium sulfate in sequence in the reaction kettle, stir evenly, slowly add hydrogen peroxide stabilizer, wetting and penetrating agent, mix and stir at room temperature for 60 minutes, and obtain a solid product.

Embodiment 3

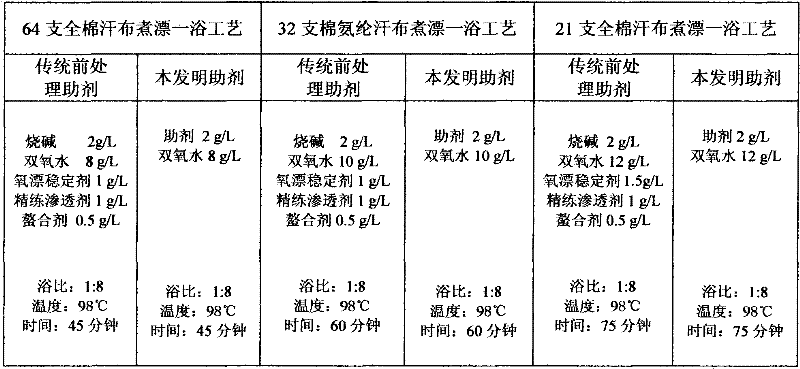

[0051] Example 3, the application of the pretreatment auxiliary agent for cotton knitted fabrics in the one-bath process of boiling and bleaching cotton knitted fabrics:

[0052]Adopt traditional pretreatment auxiliary agent as contrast, carry out one-bath process of boiling and bleaching to 64 cotton jerseys, 32 cotton spandex jerseys, and 21 cotton jerseys respectively with the cotton knitted fabric pretreatment auxiliary agent of the present invention As shown in Table 2, the comparative treatment results are shown in Tables 3-5.

[0053] Table 2, adopting traditional pretreatment auxiliary agent and auxiliary agent of the present invention to carry out one-bath process table of boiling and bleaching

[0054]

[0055] Remarks in Table 2: what the 64 cotton single jersey bleaching process used was the auxiliary agent formulated in the scheme 4 of the present invention;

[0056] 32 cotton spandex single jersey bleaching process used is the auxiliary agent of the scheme 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com