Equipment capable of tightly pasting polyethylene film to anti-corrosion pipeline

A polyethylene film and pipe technology, which is applied to the equipment field for sticking polyethylene film, can solve the problems that the polyethylene film and the anti-corrosion pipe are not tightly attached, the polyethylene film falls off, etc., and achieve the effect of facilitating stable movement and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

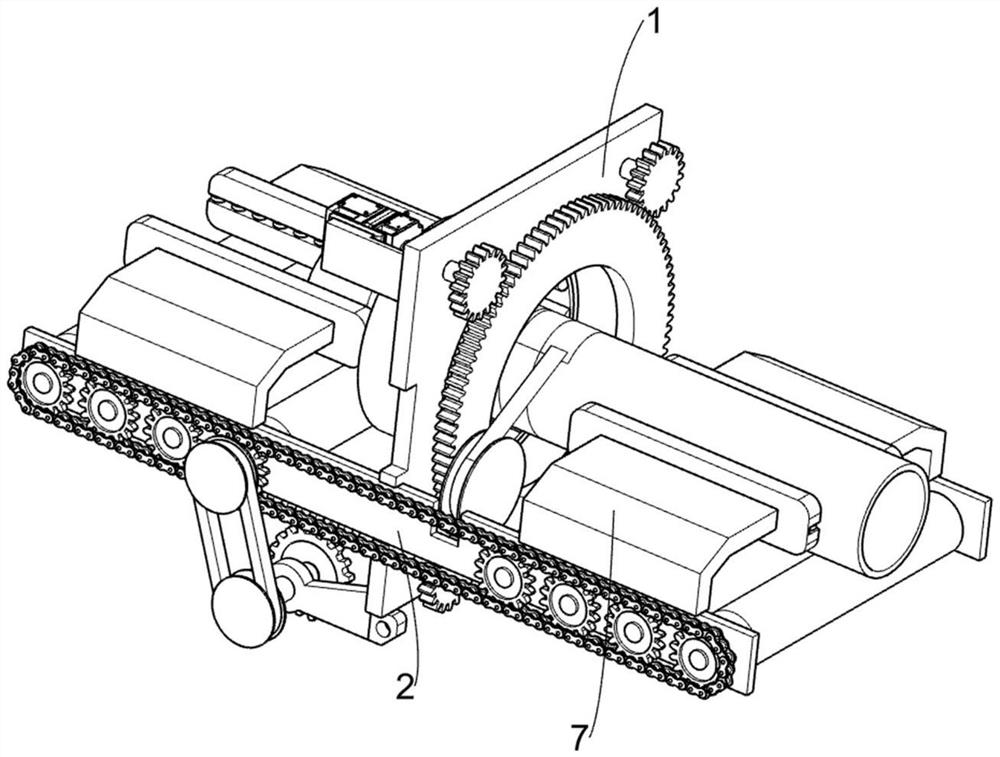

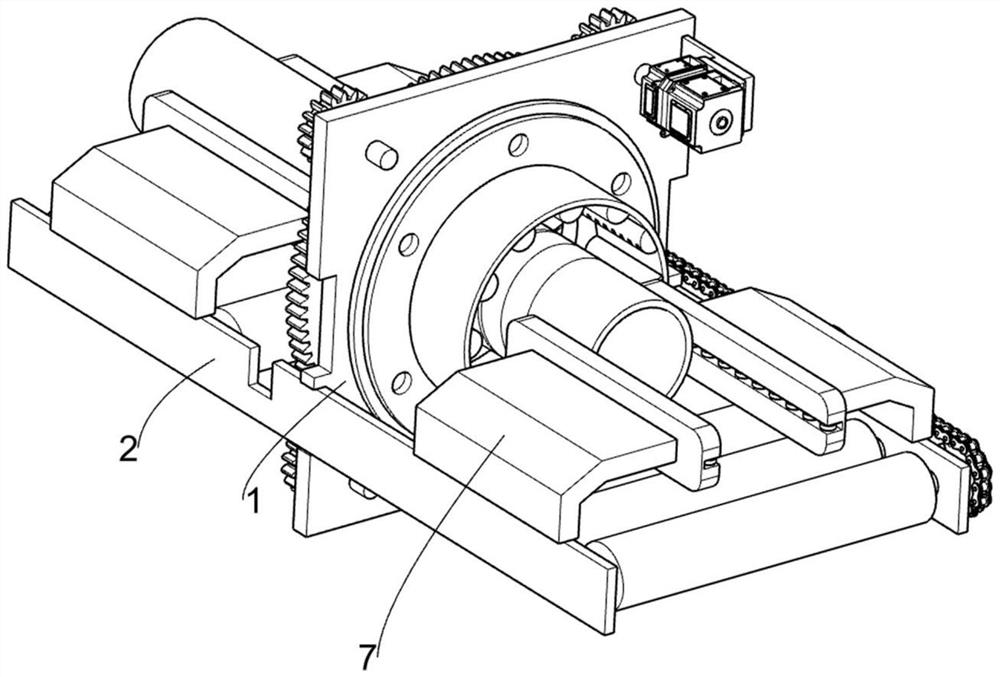

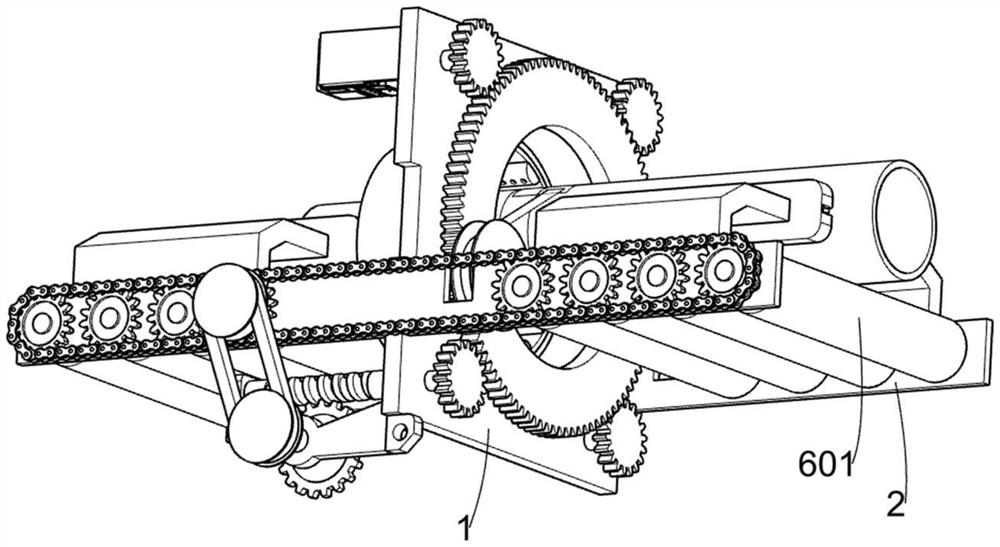

[0027] A device that can tightly paste polyethylene film on anti-corrosion pipelines, such as Figure 1-8 As shown, it includes a square mounting plate 1, a long plate 2, a polyethylene film pasting mechanism 3, a polyethylene film shrinking mechanism 4, a deceleration drive mechanism 5 and an anti-corrosion pipeline drive mechanism 6. The square mounting plate 1 is symmetrically installed with long Plate 2, polyethylene film posting mechanism 3 is rotatably connected to the square mounting plate 1, and the side of the square mounting plate 1 away from the polyethylene film posting mechanism 3 is equipped with a polyethylene film shrinking mechanism 4, a polyethylene film shrinking mechanism 4 It is used to evenly shrink the surface of the polyethylene film pasted on the anti-corrosion pipeline. The deceleration drive mechanism 5 is installed on the lower part of the square mounting plate 1. The deceleration drive mechanism 5 is used to make the rotating drive roller move slowl...

Embodiment 2

[0034] On the basis of Example 1, such as figure 2 As shown, it also includes a guide plate 7, and the top surface of the long plate 2 on both sides of the square mounting plate 1 is symmetrically fixed with the guide plate 7, and the guide plate 7 is used to limit the anti-corrosion pipeline.

[0035] When the anti-corrosion pipeline moves slowly towards the direction of the worm wheel 503, the guide plate 7 on the long plate 2 is used to limit the position of the anti-corrosion pipeline, so as to avoid the position deviation caused by the external force, resulting in incomplete and irregular pasting of the polyethylene film on the anti-corrosion pipeline .

Embodiment 3

[0037] On the basis of Example 2, such as Figure 8 As shown, guide wheels 8 are also included, and there is a draw-in groove on the guide plate 7 away from the long plate 2, and guide wheels 8 are distributed in the draw-in groove. The friction between the wheels 8 is reduced.

[0038] When the anti-corrosion pipeline moves slowly towards the direction of the worm wheel 503, there is a slot on the guide plate 7, and the guide wheel 8 in the slot is in contact with the anti-corrosion pipeline, so that the friction between the anti-corrosion pipeline and the guide wheel 8 is reduced, so that the anti-corrosion pipeline can rotate the driving roller Driven by 601, it moves stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com