Fan used for animal husbandry and production method of fan

A production method and animal husbandry technology, applied to parts, coatings, liquid fuel engines, etc. of pumping devices for elastic fluids, can solve problems such as insecurity, inability to bear forces at the same time, and increase the cost of raising cattle, and achieve Good impact strength, stable precision control, and good opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

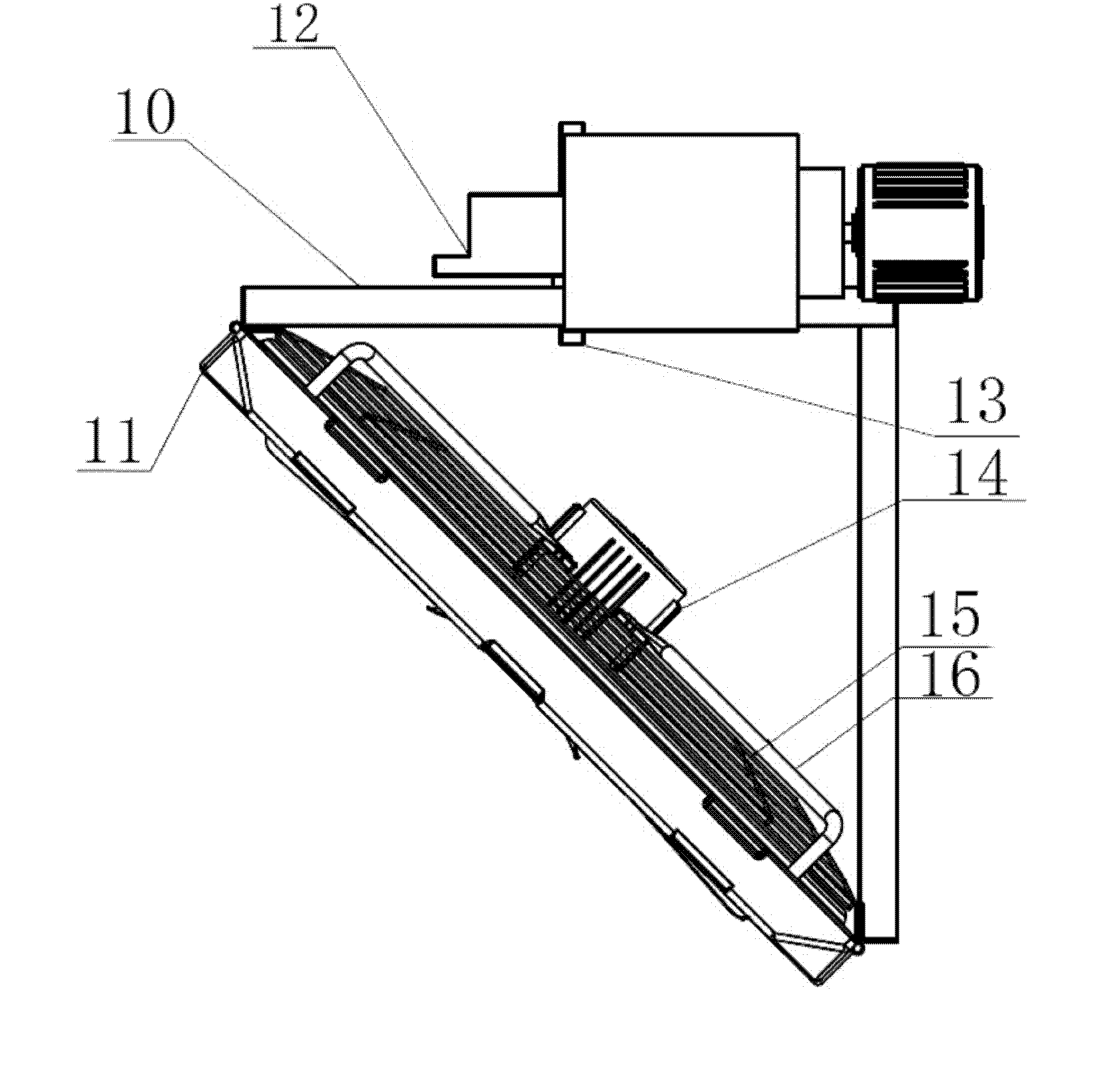

[0037] The present invention will be further described below with reference to the accompanying drawings, and the structure and principle of such a device will be very clear to those skilled in the art.

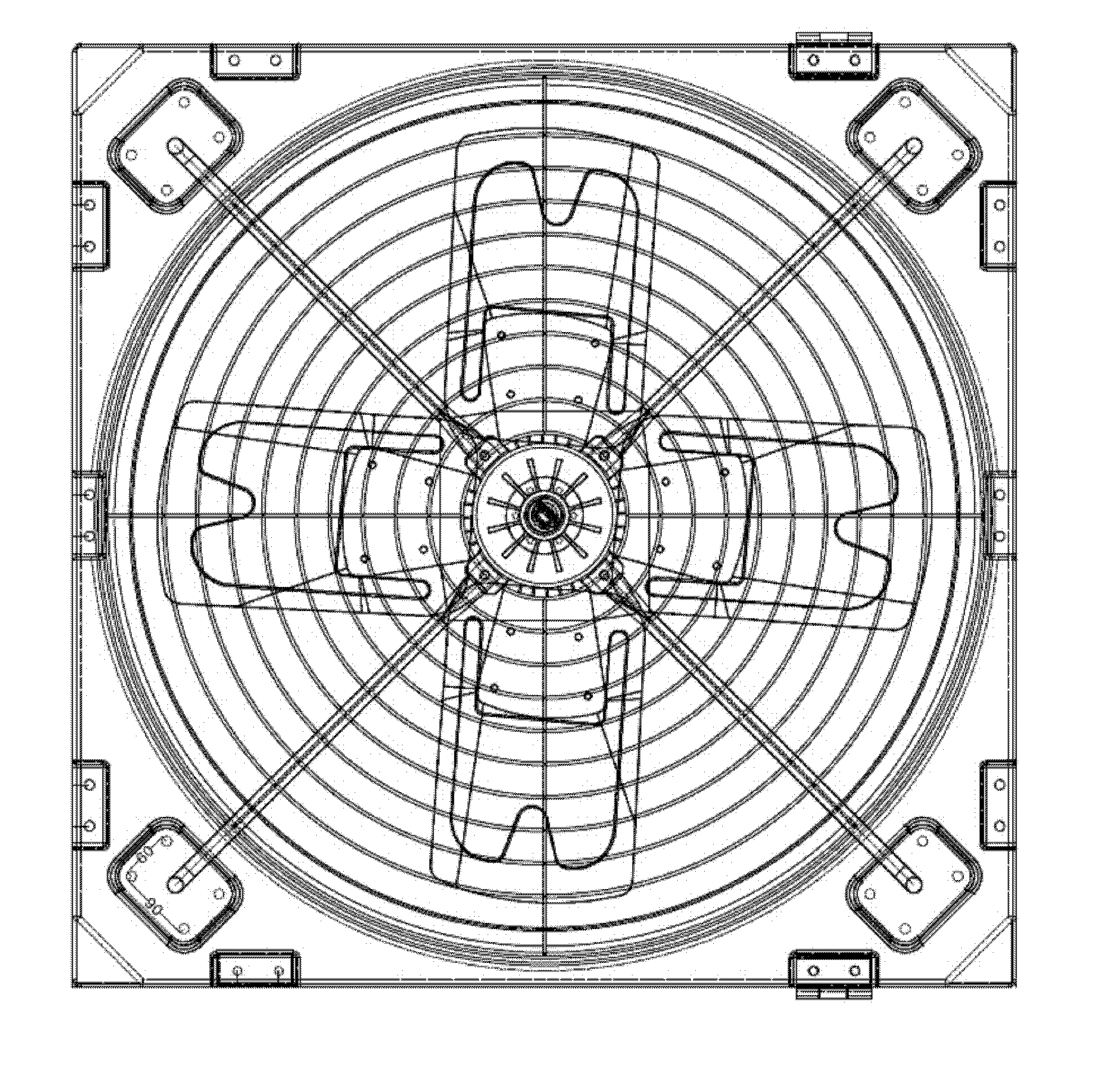

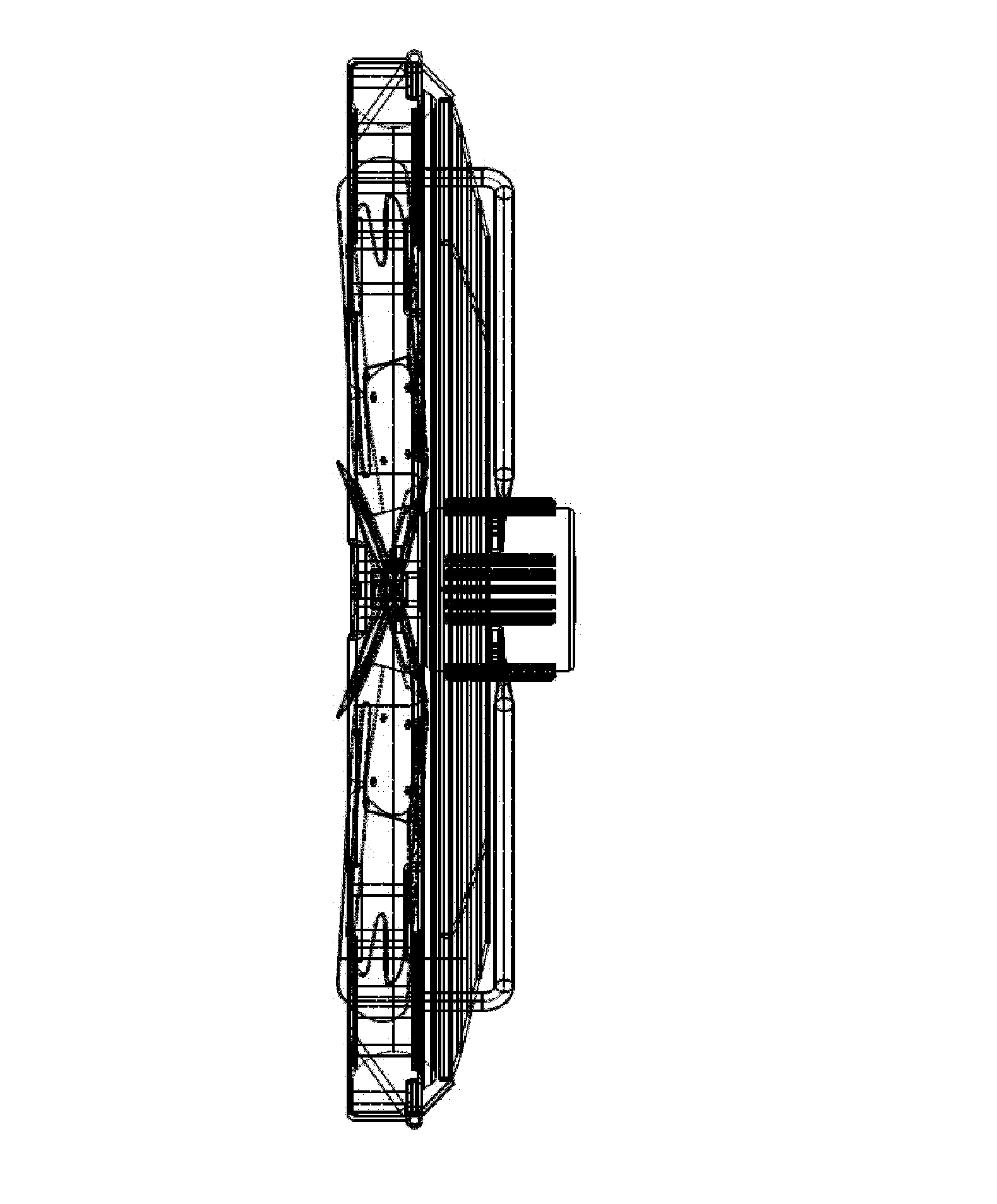

[0038]The overall structure of a fan related to animal husbandry in the present invention is mainly composed of a fan and a bracket, such as image 3 shown. The fan consists of plastic casing, motor, fan blade, fan blade holder, support tube, net cover, motor shaft flange, motor support tube, screws, nuts, rivets, pins, flat keys, gaskets, hoops, pads composition. The bracket is composed of a rotating system, a power system, and an electronic control system. The rotating system includes a bracket, a fan, a rotating shaft, a bearing, a plane bearing, a load-bearing nut, and a mounting plate. The power system consists of a coupling, a transmission shaft, a helical gear-turbine worm reducer, and an electric motor. The electronic control system includes contactors, time relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com