Technology for binding fish-culturing net

A technology and net cage technology, applied in the field of mariculture net cage production, can solve the problems of poor wind and wave resistance, damaged mesh bars and net clothing, and uneven force on the net clothing, so as to improve the ability to resist wind and waves and prevent nets from being damaged. Broken, avoid fraying or hanging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] see Figure 1-Figure 8 , using the binding process of the present invention to make a Figure 8 The circular cage shown.

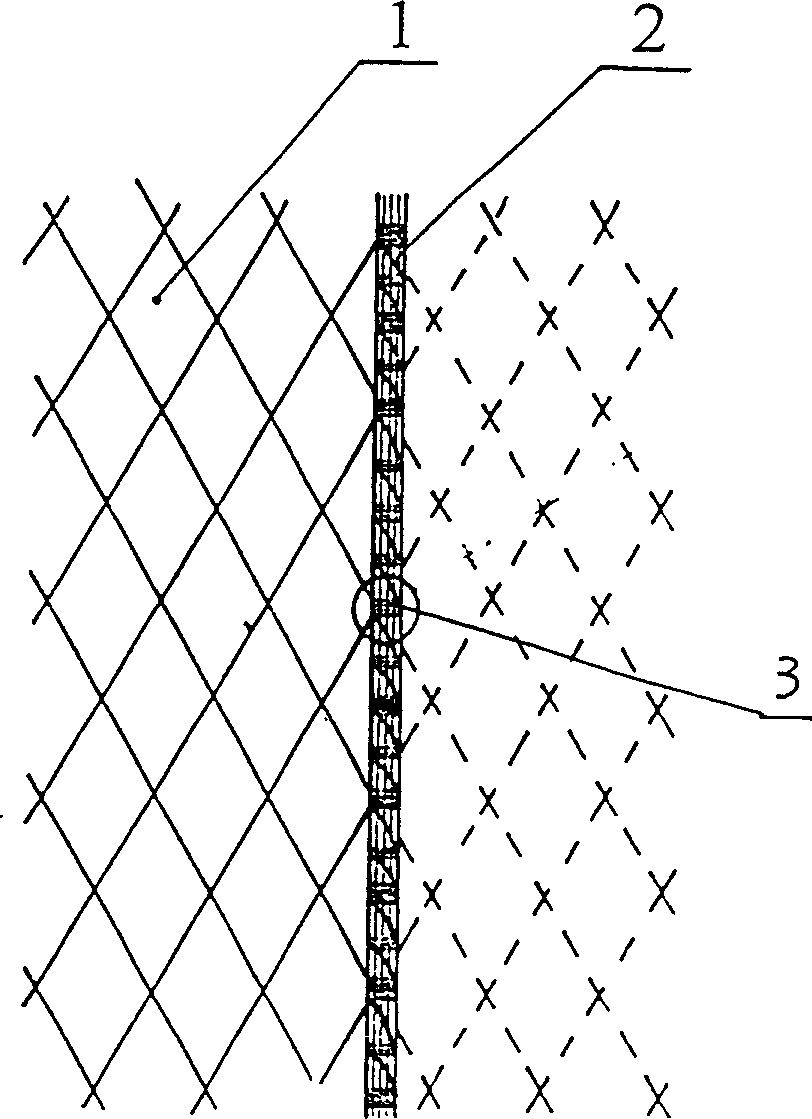

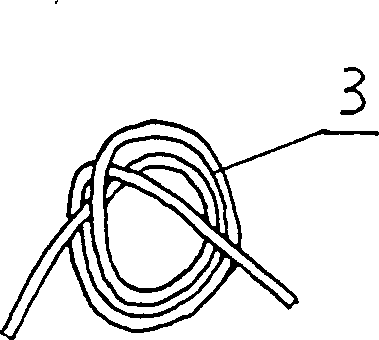

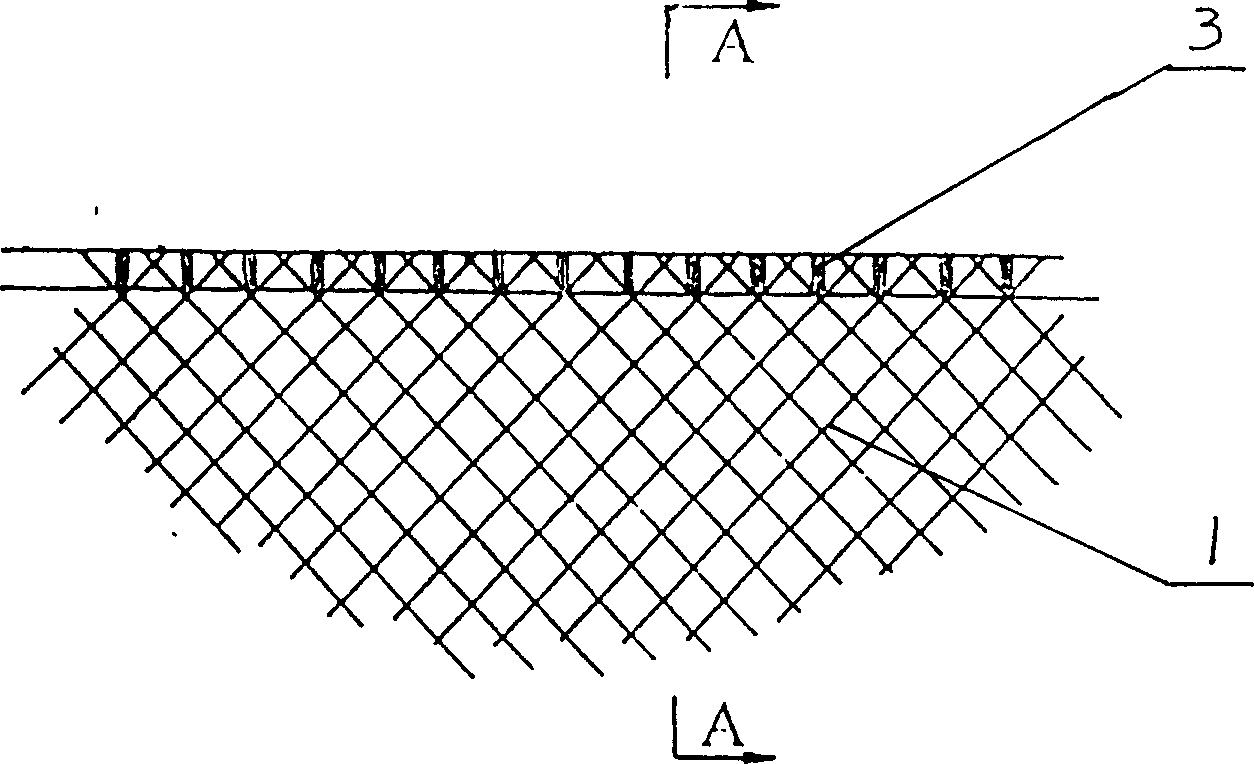

[0020] The mesh used in net clothing 1 is PA mesh, which is cut and cut by electric soldering iron. Sew the cut spare mesh vertically and horizontally on each side with 2-4 mesh binding (piping) 2, and tie it tightly with "double tack" 3 knots ( figure 1 , figure 2 ); the seaming process of the netting 1 is as follows: fasten the opposite binding edges or edges 2 of the two nettings 1 or every 20 mm with "double-tack knots" knots to form a large seam 5, binding the edges or edges There is no obvious gap after seaming of edge 2 ( Figure 5 , Figure 6 ). According to the cage net clothing size, some small net sheets are sewed together into 8 large main nets 1, two bottom nets 13 and a block net 9.

[0021] And then tie it with a special edge-gang process: sew the 2-4 mesh net 1 around the rope 4 (diameter 4-10mm) that is as long as the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com