Shot-blasting device for automatically recycling steel shots and metal surface processor using same

A technology of automatic recovery and shot blasting device, which is applied to used abrasive processing devices, metal processing equipment, abrasive jetting machine tools, etc., can solve the problems of waste, high energy consumption, low production efficiency, etc. The effect of uniform surface treatment and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

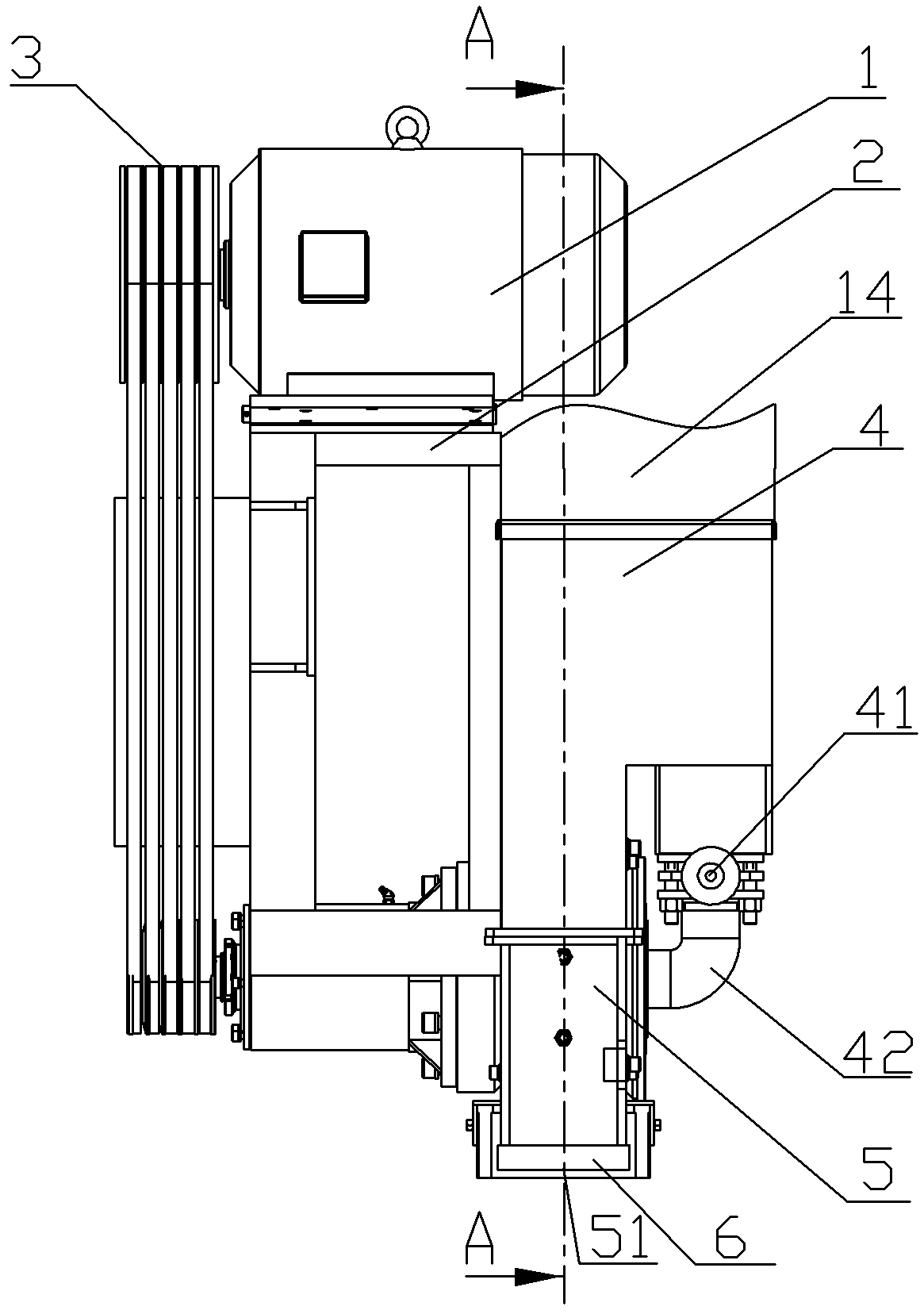

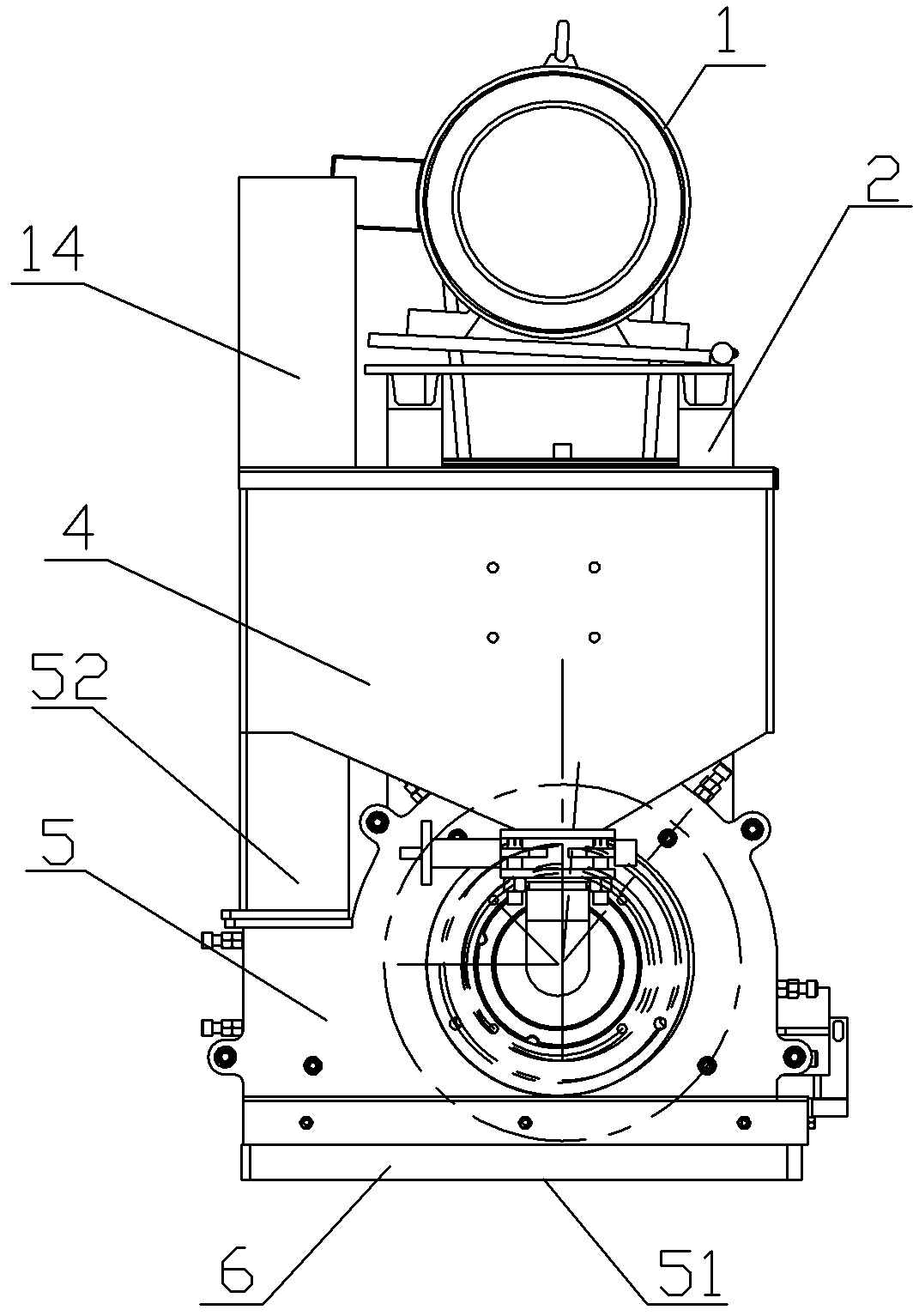

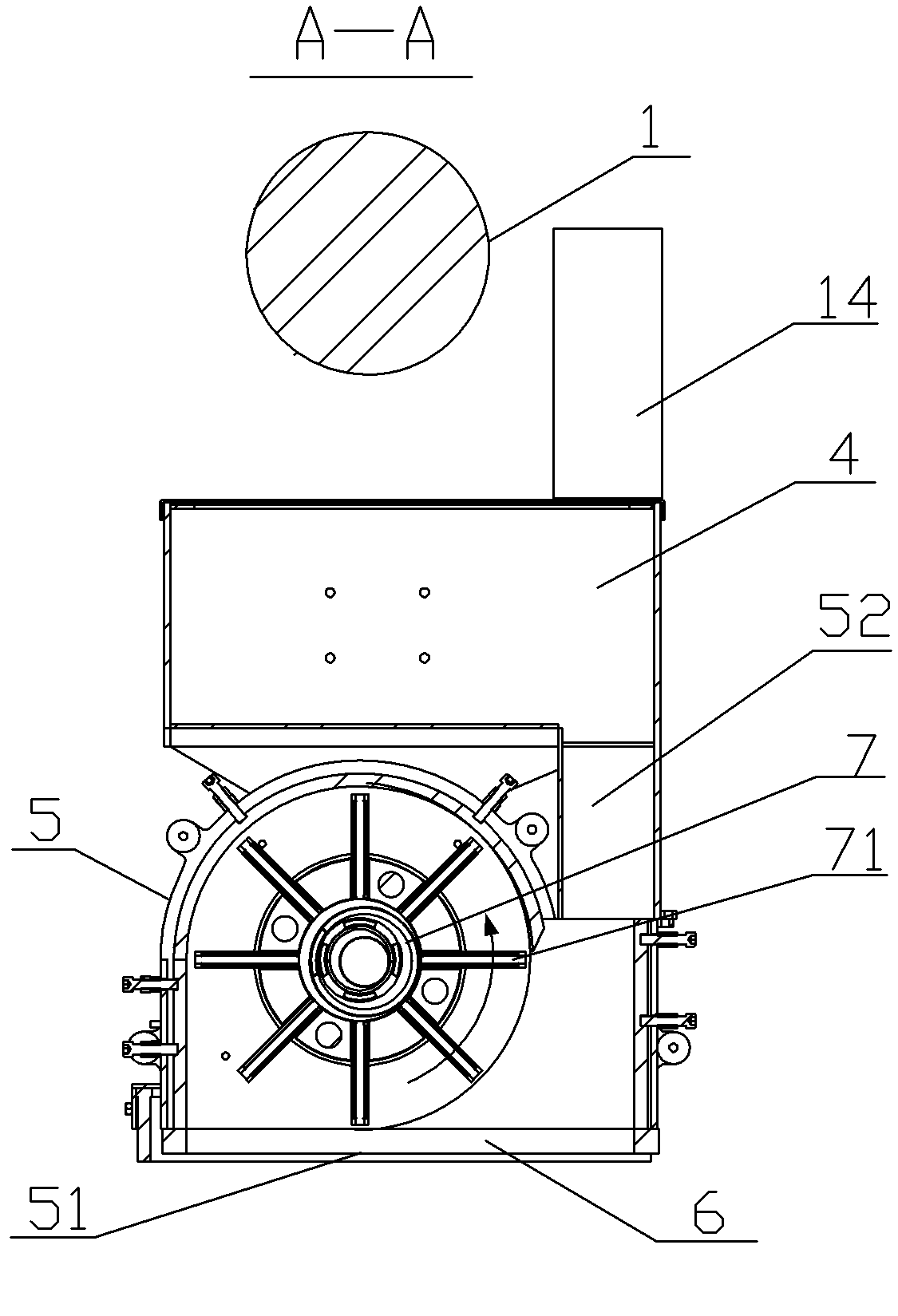

[0024] Figure 1 to Figure 4 A shot blasting device for automatic steel shot recovery is shown, which is characterized in that it includes a shot blasting impeller 7 driven by a drive motor 1, and a semi-dome surface sealing box 5 enclosing the shot blasting impeller 7 is provided, and the side of the box is vertical Face to face, a shot blasting window 51 sealingly connected to the workpiece processing surface is provided at the bottom of the above-mentioned box body 5. The specific sealing structure is to set a sealing brush 6 around the shot blasting window 51, and its function is to seal the box body and the workpiece to be processed. Seal between them to prevent the thrown steel shots from falling out.

[0025] Such as image 3 As shown by the middle arrow, the upper part of one side of the box body corresponding to the upward rotation direction of the shot blasting impeller is provided with a shot return channel 52 connected to the feed hopper 4 . The above-mentioned f...

Embodiment 2

[0028] Figure 5 ~ Figure 7 Show a kind of metal surface treatment machine that adopts the shot blasting device that the steel shot of embodiment 1 is automatically recovered, it is characterized in that also be provided with control box 10, dust collector 13, the driving wheel 91 that height is controlled by height adjustment mechanism, driven wheel 92. The above-mentioned dust collector 13 is connected to the top of the above-mentioned feed hopper 4 through the recovery pipe 11. In the actual equipment setting, the dust collector 13 can be used as a fixed connection device for the equipment, and can also be connected at any time on site through the dust collector connection port 14 on the top of the feed hopper. The function of the dust collector is to recover a large amount of dust generated in the shot blasting process to the filter cartridge in the dust collector 13 through the recovery pipe 11 through the negative pressure generated by the rotation of the dust removal fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com