Surface processing apparatus

a surface processing and apparatus technology, applied in the direction of electrical apparatus, thin material processing, electric discharge tubes, etc., can solve the problems of non-uniform magnetic field, non-uniform density and diffusion direction of ions and electrons in the plasma, and non-uniform surface processing of the substrate b>14/b> by the plasma, etc., to achieve shorten the length of some of the magnets arranged at the outermost region, reduce the magnetic force of the magn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

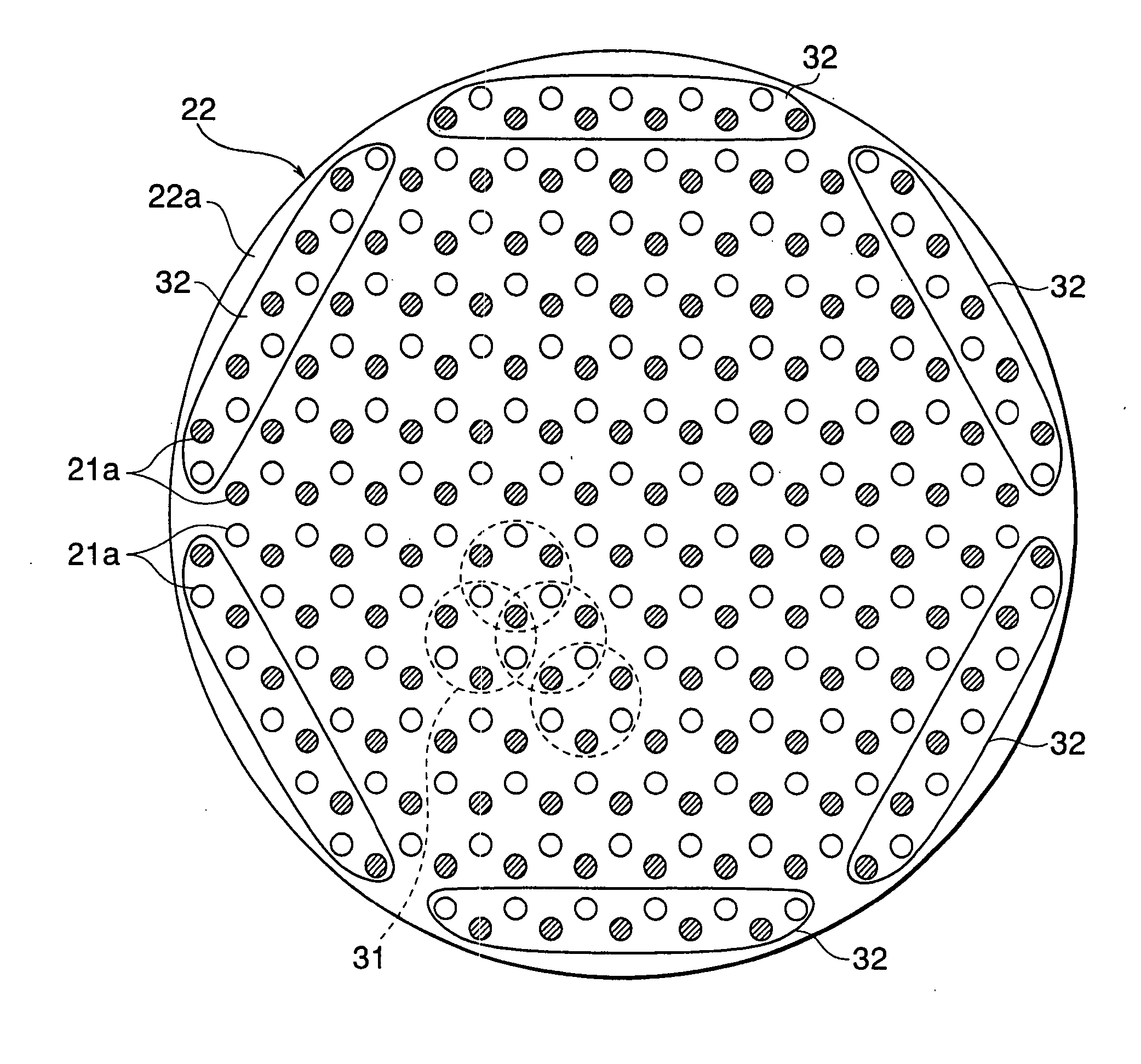

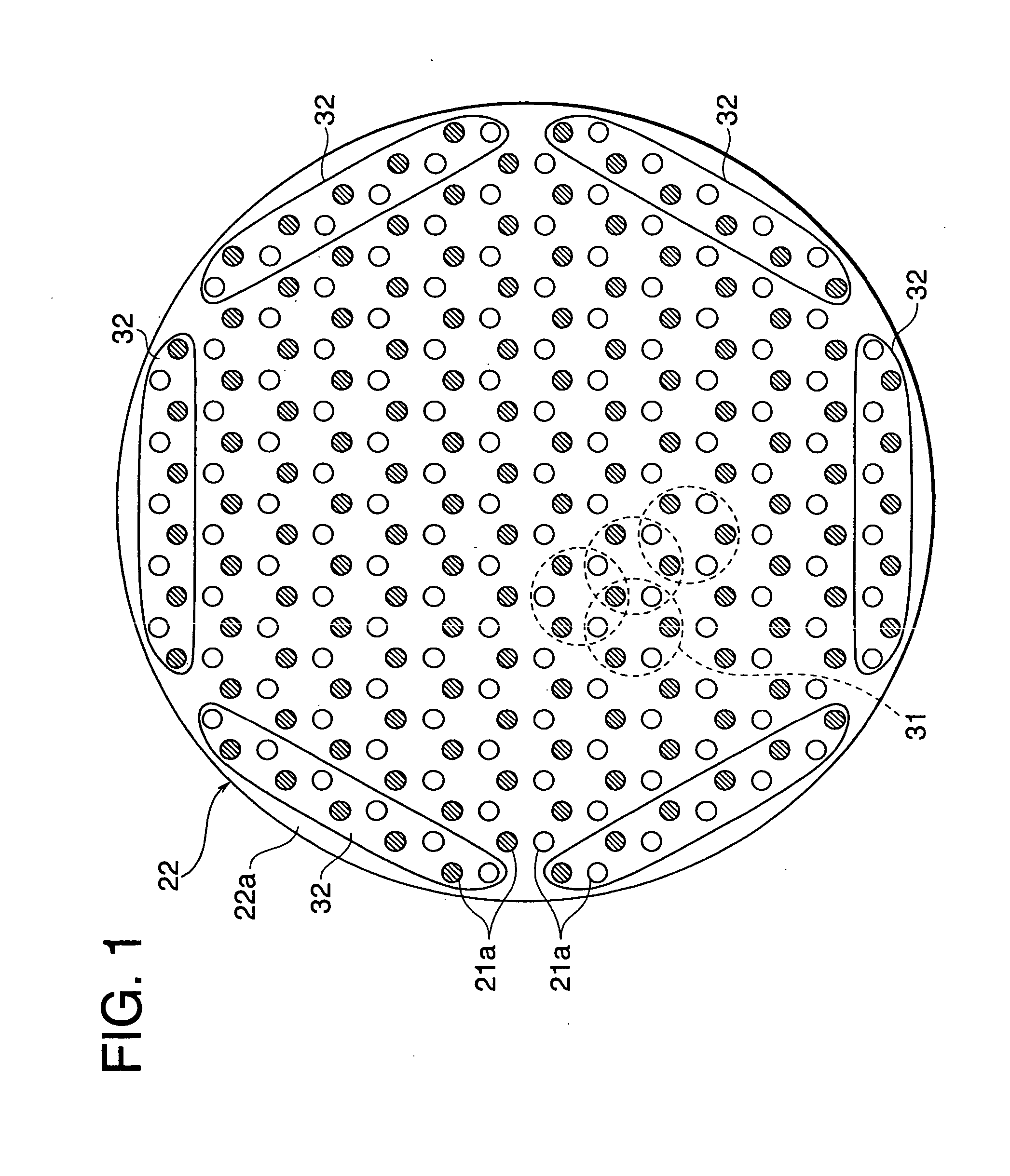

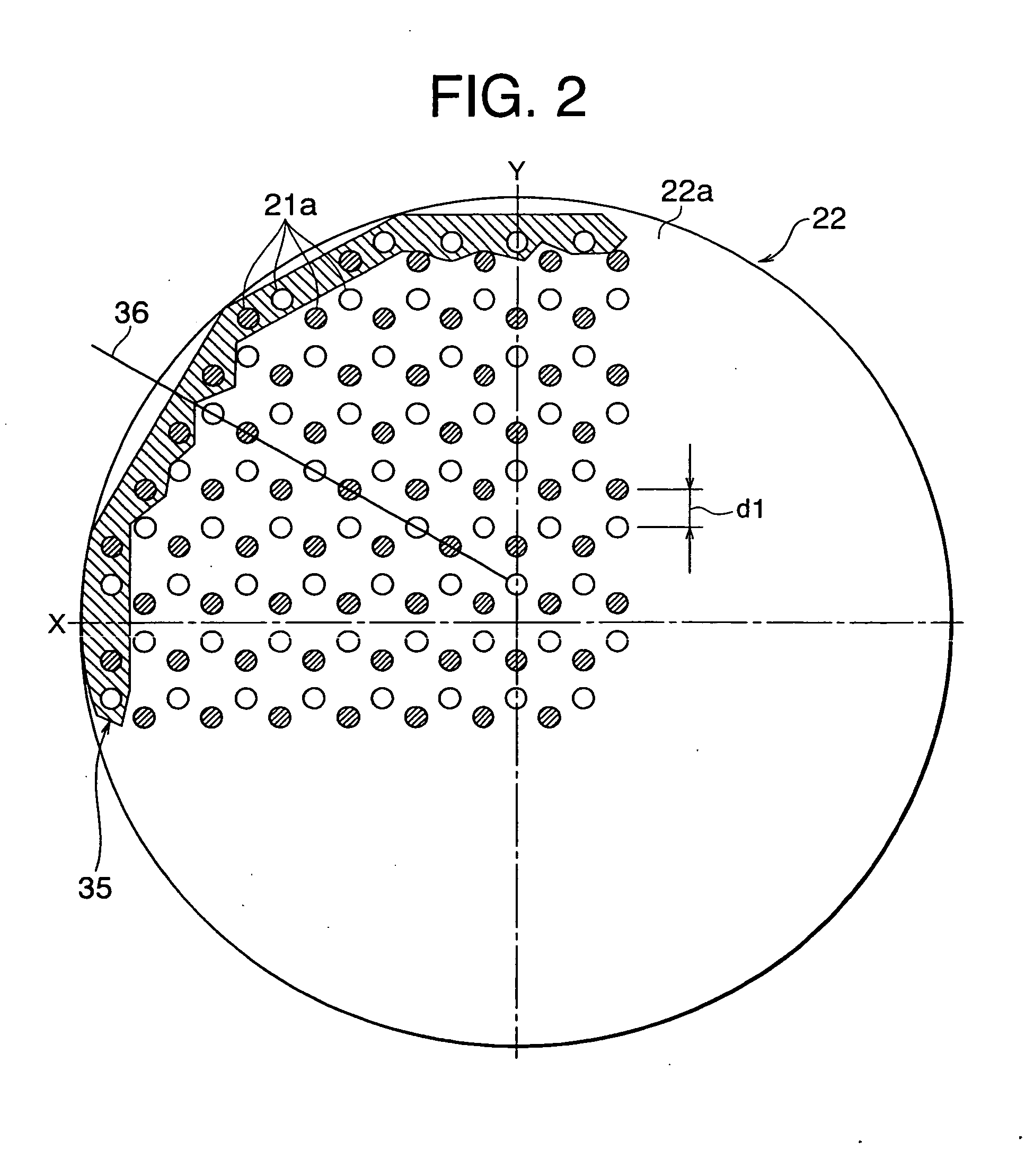

[0053]FIG. 1 shows the magnet array structure in a surface processing apparatus according to the present invention. FIG. 1 is similar to FIG. 19 and is a plan view of the magnet plate 22. In the magnet plate 22, the array structure of the large number of magnets 21 having the same shapes and same magnetic strengths is, if deeming the positions of arrangement of magnets as lattice points, a honeycomb lattice structure comprised of a large number of unit honeycomb lattices 31 forming regular hexagonal shapes by six lattice points. As explained above, the magnet plate 22 has a disk shape, so the magnets 21 attached to the surface of the disk-shaped plate member 22a are laid and fastened in unit honeycomb lattices 31 on the circular surface of the plate member 22a without gaps and without sticking out.

[0054] The magnet plate 22 has a circular plate member 22a used for fastening the magnets of the magnet plate 22. The arrangement of magnets 21 of the above honeycomb lattice structure, as...

fourth embodiment

[0064] In the fourth embodiment, the distribution of the magnetic field strength at the required locations was controlled by preferably halving the outermost magnets 61 of the one-half length, but the plane 34 of the region where the distribution of the magnetic field strength is measured is preferably made the same height, so it is also possible to provide a support base 62 as shown in FIG. 11 to make the plane 34 a constant height.

fifth embodiment

[0065] Next, the magnet array structure will be explained with reference to FIG. 12 and FIG. 13. FIG. 12 is a plan view of the magnet plate 22, while FIG. 13 is a partial side view of part of the magnet plate 22 in section.

[0066] The magnet plate 22 according to the present embodiment has, as its basic configuration, a magnet array of the square lattice structure explained as the prior art. A large number of magnets 21 are arranged based on the square lattice structure explained above in the region from the center of the magnet plate 22 to near the peripheral edge. In this region, a large number of square lattices 131 are arranged with periodicity. In an array of magnets 21 according to this square lattice structure, the polarities of the magnetic poles of any two nearest adjoining magnets 21 are opposite and therefore N poles and S poles are alternately arranged. A point-cusp magnetic field is formed by this square lattice structure. In FIG. 12, the large number of magnets 21 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com