Gun-barrel surface treatment process

A technology of surface treatment and gun barrel, which is applied in the direction of metal material coating process, etc., can solve the problems of large power consumption, complex and cumbersome structure, inconvenient operation, etc., and achieve the effect of simple structure, uniform temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

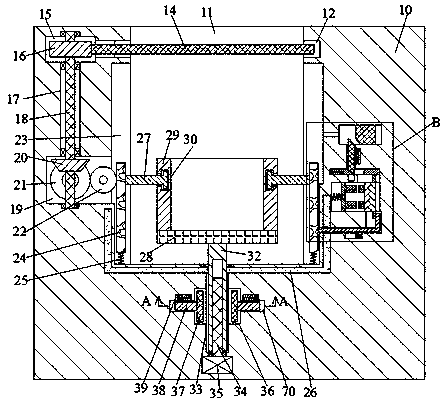

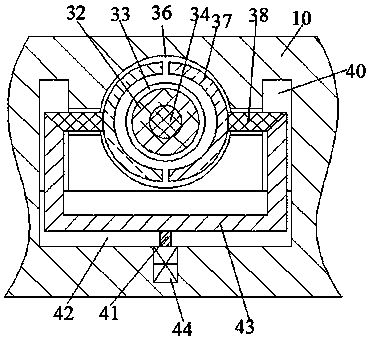

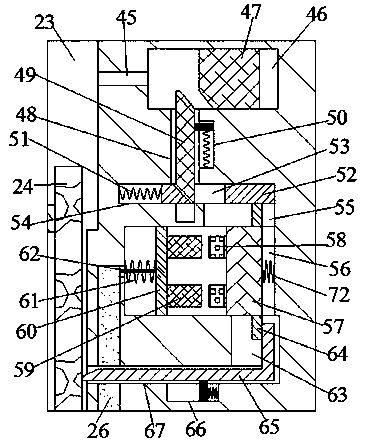

[0014] Combine below Figure 1-3 The present invention will be described in detail.

[0015] refer to Figure 1-3 , according to a gun barrel surface treatment process according to an embodiment of the present invention, the device used in the method includes a body 10, the body 10 is provided with a bluing treatment chamber 11 with an opening facing upwards, and the periphery of the treatment chamber 11 is communicated There is an arc-shaped empty slot 12 with an opening facing the processing chamber 11, a closed cover 14 is arranged in the empty slot 12, a rotating slot 15 is connected to the left side of the empty slot 12, and a rotating slot 15 is arranged in the rotating slot 15. There is a rotating wheel 16, the right end of the rotating wheel 16 is fixedly connected with the left end of the closure cover 14, and the rotating shaft 18 whose upper end is rotationally connected with the upper end wall of the rotating groove 15 is fixedly provided at the center of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com