Wire rod rolled product surface processing device

A surface treatment device and steel technology, which is applied in the field of metal surface treatment, can solve the problems of affecting output, efficiency, increasing operating costs, and unsatisfactory results, and achieve the effects of improving efficiency, reducing working time, and smooth and easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

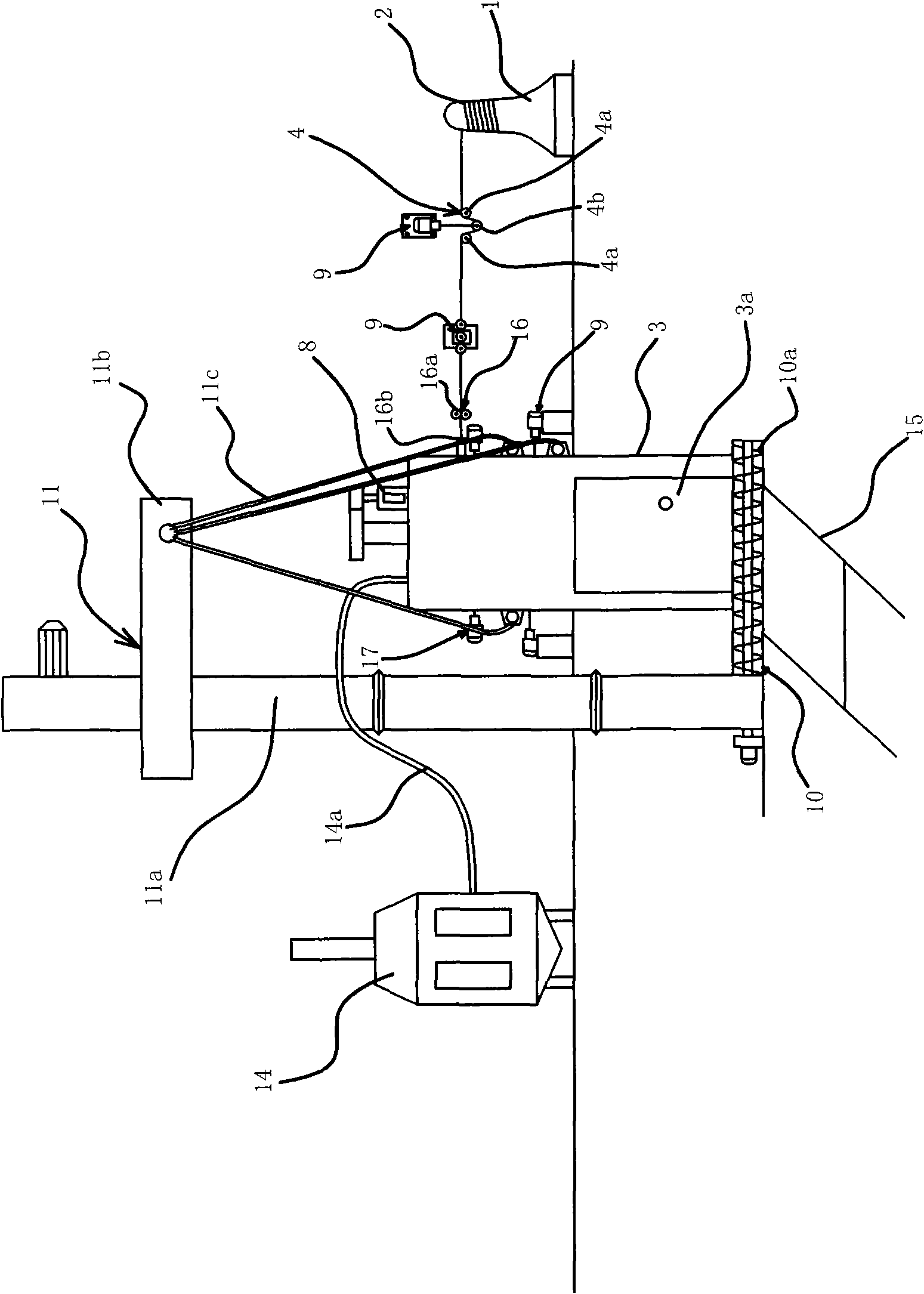

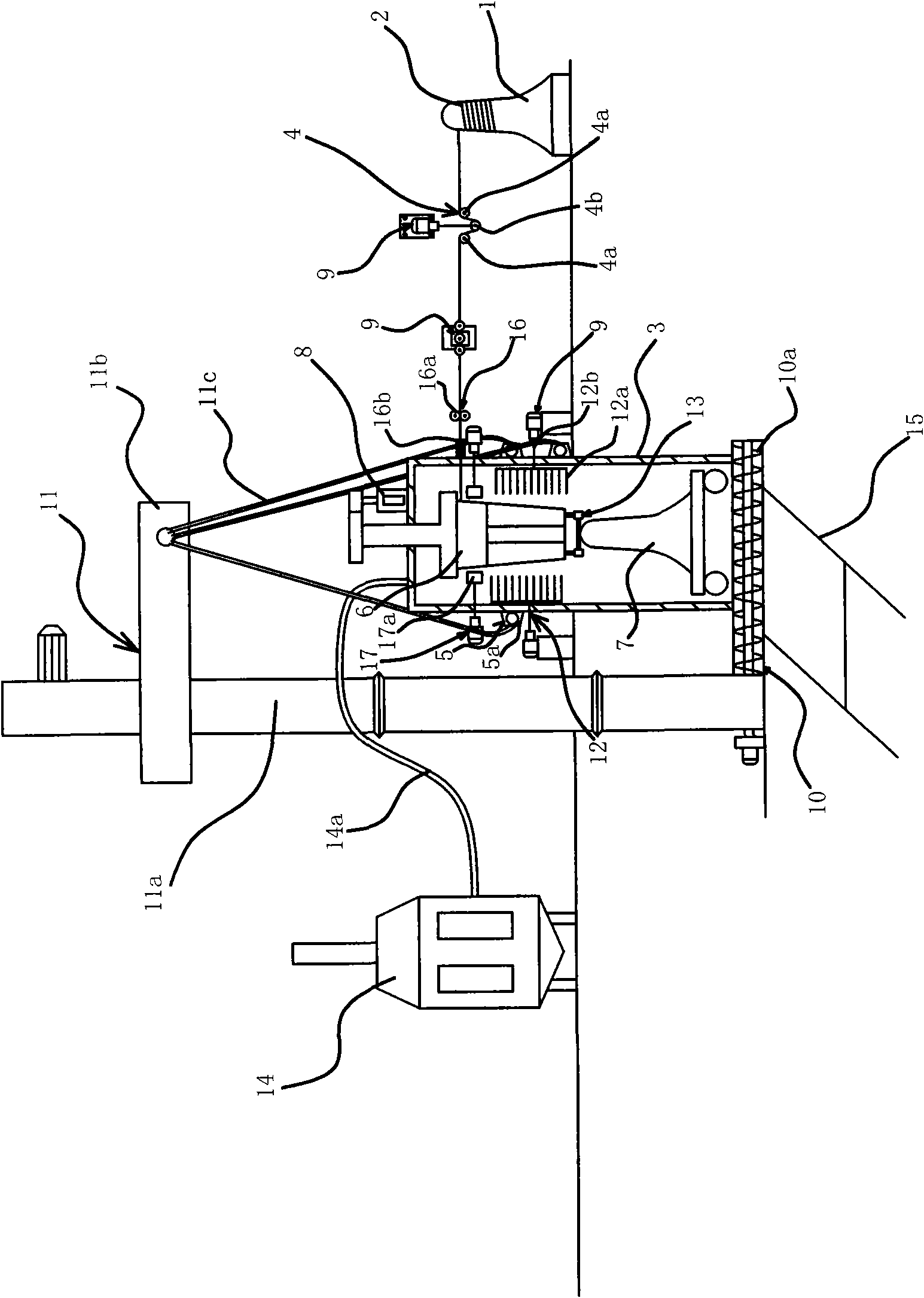

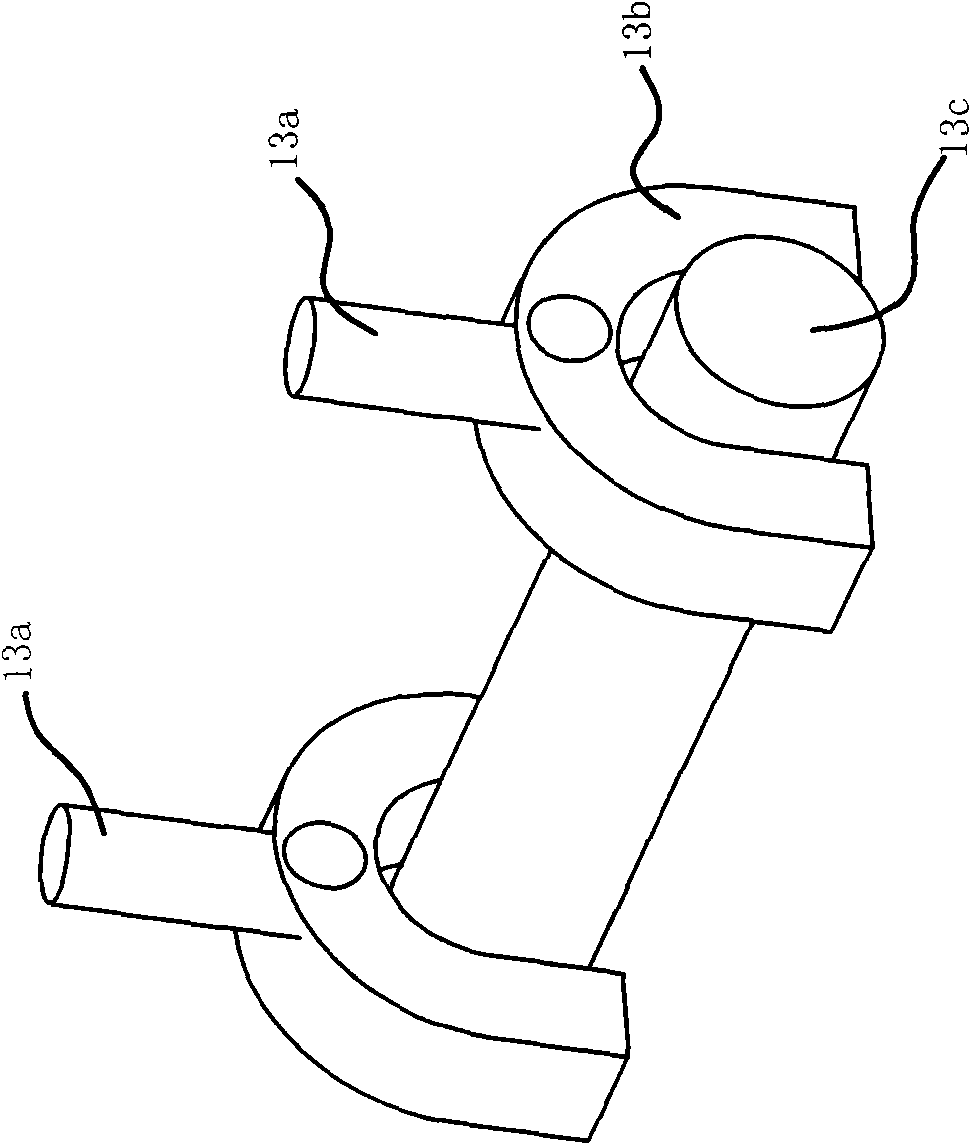

[0036] Such asfigure 1 , figure 2 As shown, the disc round steel surface treatment device includes a discharge drum 1 on which the disc round steel material 2 is placed, a casing 3 and a discharge door 3a located at the bottom of the casing 3 . The feeding drum 1 is placed on a rotating disk with bearings and can rotate. Between the discharge drum 1 and the casing 3, there are two twisting mechanisms 4 capable of bending and deforming the round steel material 2. The twisting mechanism 4 includes two parallel rollers 4a and a pressure roller between the two rollers 4a. 4b, the pressure roller 4b is connected with the power element 9 .

[0037] The entry end of the round steel material 2 enters the inner cavity of the casing 3 through the straightening guide mechanism 16 , and the entry end of the round steel material 2 is wound on the upright drum 6 by the pressing mechanism 17 . Straightening guide mechanism 16 comprises a group of straightening rollers 16a, a guide pipe 16...

Embodiment 2

[0047] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 4 As shown, the straightening guide mechanism 16 in this embodiment includes a fixed block 18 with a groove, a straightening roller 16a and a guide tube 16b arranged on the casing 3, and a disc circle is pierced in the groove of the fixed block 18. At the entry end of the steel material 2, the straightening roller 16a is located on the side of the fixed block 18 having a groove and is in contact with the groove, and the groove and the guide pipe 16b are in a position facing each other. The entry end of the round steel material 2 is located in the groove of the fixed block 18, rolled and straightened by the straightening roller 16a, and then enters the casing 3 through the guide pipe 16b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com