Method for sterilizing preform and resin container

A technology made of preform and resin, which is applied in the direction of packaging sterilization, packaging item types, liquid materials, etc., and can solve the problems of bactericide residue, bactericide not evenly attached, poor sterilization, etc., and achieve the effect of realizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

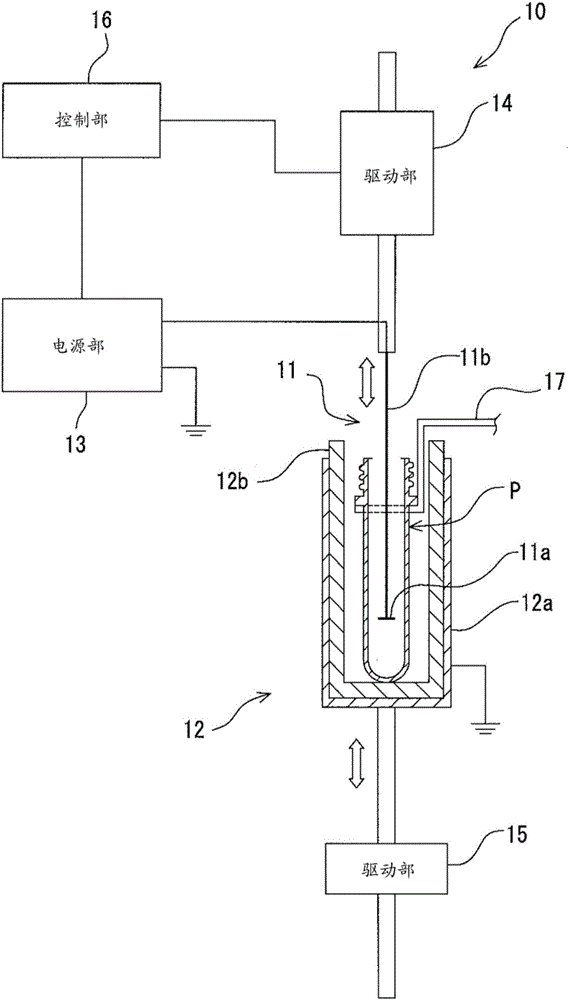

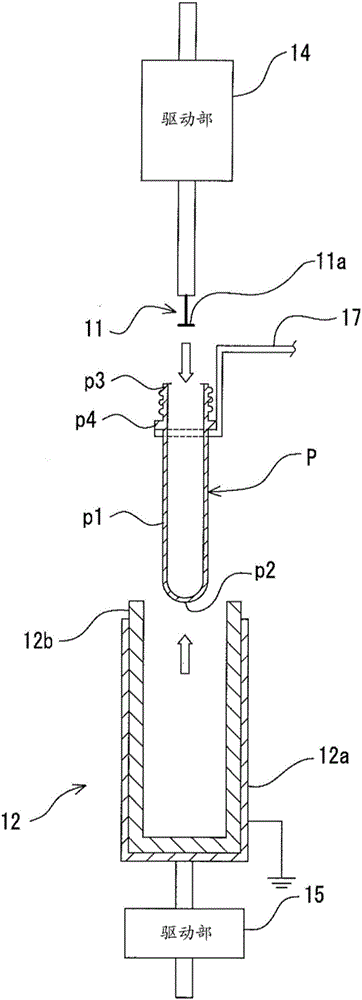

[0109] First, use Figure 1 ~ Figure 3 The configuration and general functions of an apparatus for performing corona discharge treatment on preforms before being molded into bottles will be described.

[0110] Here, the preform refers to a preform before being molded into a container, that is, a bottle.

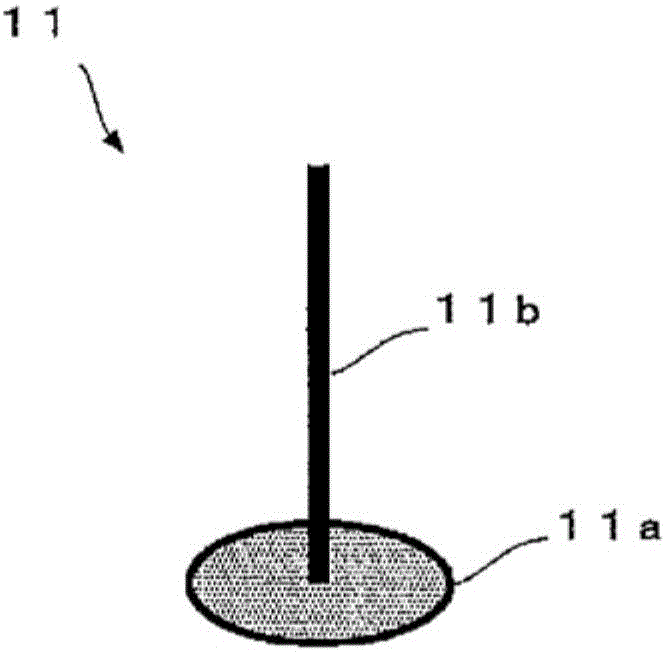

[0111] Such as figure 1 As shown, the corona discharge treatment device 10 has: an electrode 11, which can pass through the opening of the preform; a grounding part 12 for grounding; a power supply part 13, which applies a voltage to generate a corona discharge to the electrode 11; a driving part 14 , which inserts the electrode 11 into the preform P; the driving part 15, which makes the ground part 12 cover the preform P; the control part 16, which controls the operation of the driving part 14 and the driving part 15.

[0112] The corona discharge treatment device 10 modifies the inner surface of the preform P by corona discharge. For example, electrons emitted from the e...

Embodiment approach 2

[0198] In this Embodiment Mode 2, a conductor whose configuration is different from that in Embodiment Mode 1 is used for the corona discharge treatment.

[0199] Such as Image 6 As shown, the ground portion 42 (an example of a grounded conductor) does not have an insulating portion, and is composed of only a grounded conductor.

[0200] In this case, the preform P is installed so that the preform P does not come into contact with the ground portion 42 of the conductor. In addition, the opening p3 of the preform P slightly protrudes from the opening of the land portion 42 .

Embodiment approach 3

[0202] First, use Figure 11 , Figure 12 and image 3 The configuration and general functions of an apparatus for corona discharge treatment of bottles, which are one type of resin containers, will be described.

[0203] Such as Figure 11 As shown, the corona discharge treatment device 10 is equipped with: an electrode 11, which can pass through the opening of the resin container, that is, the bottle B; a grounding part 12 that is grounded; a power supply part 13 that applies a voltage that generates corona discharge to the electrode 11; The driving unit 14 is used to insert the electrode 11 into the bottle B; the driving unit 15 is used to cover the grounding unit 12 on the bottle B; the control unit 16 controls the operation of the driving unit 14 and the driving unit 15 .

[0204] The corona discharge treatment device 10 modifies the inner surface of the bottle B using corona discharge. For example, electrons emitted from the electrode 11 by corona discharge are acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com