A method of manufacturing a chemically tempered thin glass using a full automated thin glass grinding machine with separated multi spindles and an apparatus for the same

A processing device and glass technology, applied in grinding drive devices, manufacturing tools, glass production, etc., can solve the problem of inability to ensure the continuity of workers and diamond blades, the overall strong enemy of the display window and the decline in quality, and the injury of the operator due to the grinding machine. and other problems, to achieve the effect of reducing production manpower, reducing uneven debris, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

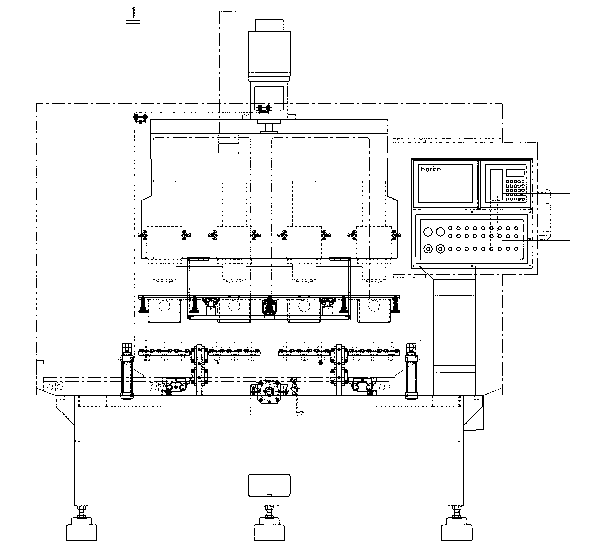

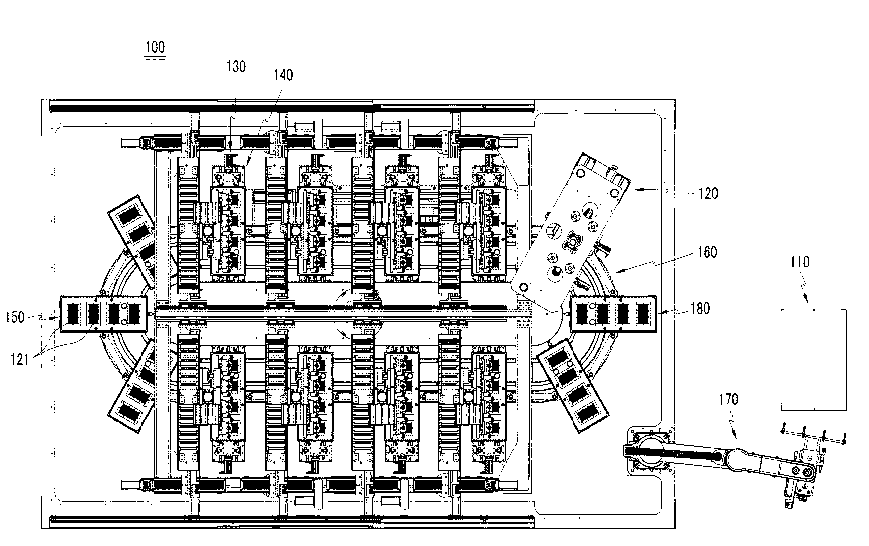

[0046] figure 2 It is a schematic diagram of a multi-axis separation automatic thin plate glass processing device in a preferred embodiment of the present invention.

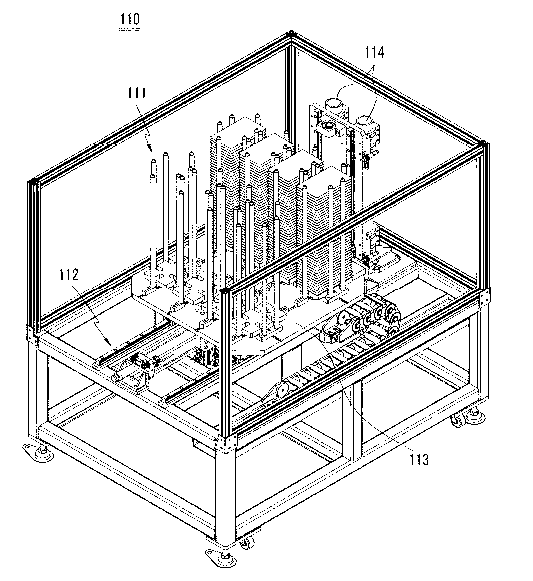

[0047] The inventive multi-separation automatic thin plate glass processing device 100 includes: a multi-shape supply device 110 that loads and supplies a plurality of glass to be processed; a multi-shape position determination device 120 that determines the glass to be processed and supplied for shape processing and grinding position; the automatic alignment device 130 is moved horizontally to automatically align the tray on which the glass to be processed is located; and the multi-axis grinding device 140 is composed of multiple processing axis assemblies.

[0048] In the above multi-axis separation automatic thin plate glass processing device 100, four processing fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com