Steel pipe hot galvanizing device

A technology of hot-dip galvanizing and steel pipe, applied in hot-dip plating process, coating, metal material coating process and other directions, can solve problems such as affecting the hardness and stability of steel pipe, affecting surface finish, etc., to achieve the effect of ensuring the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

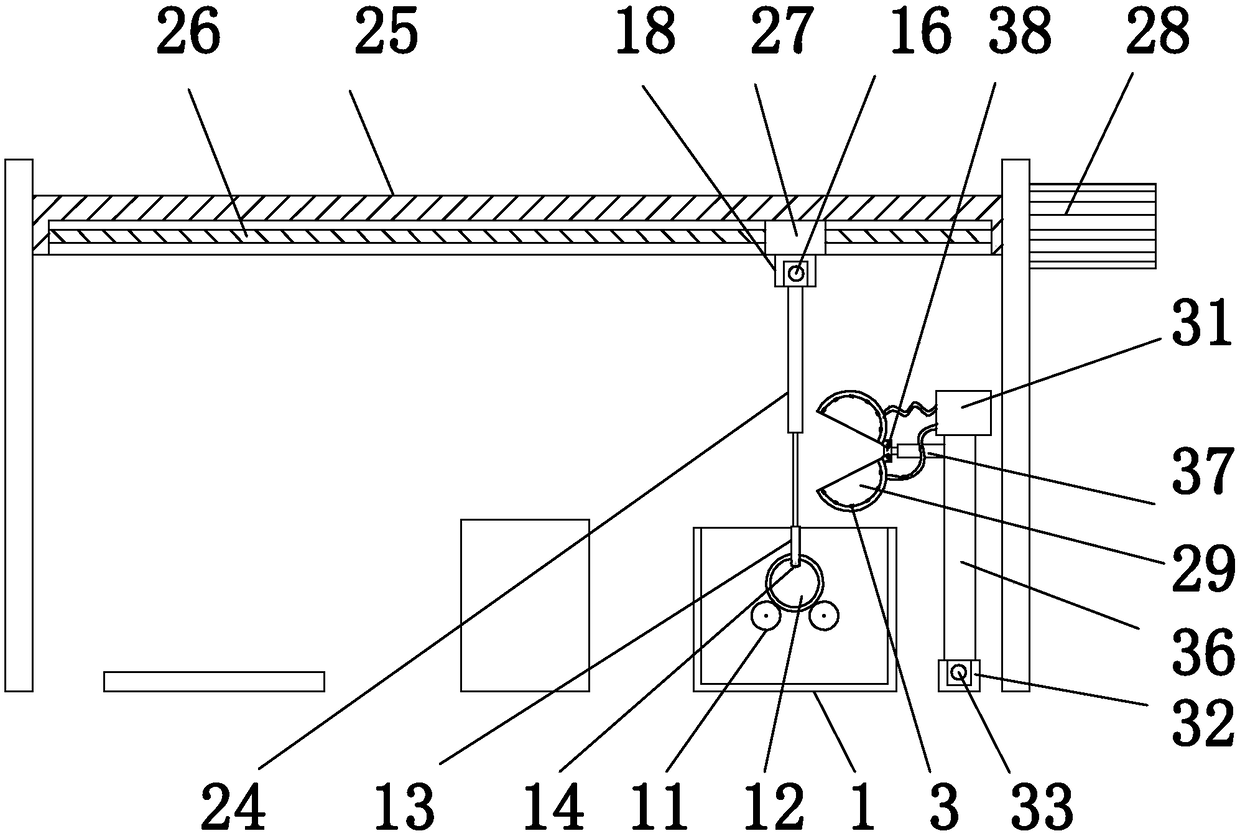

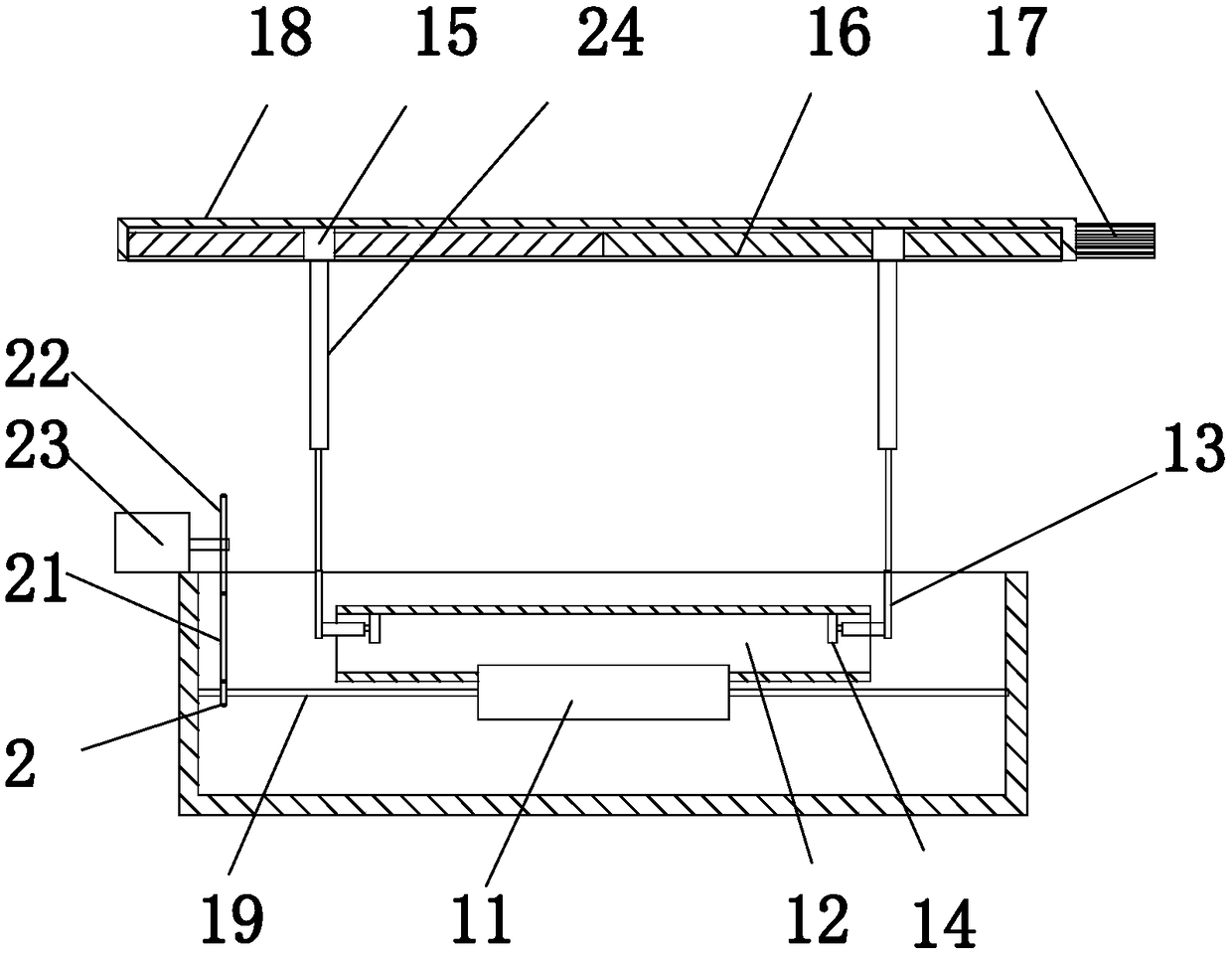

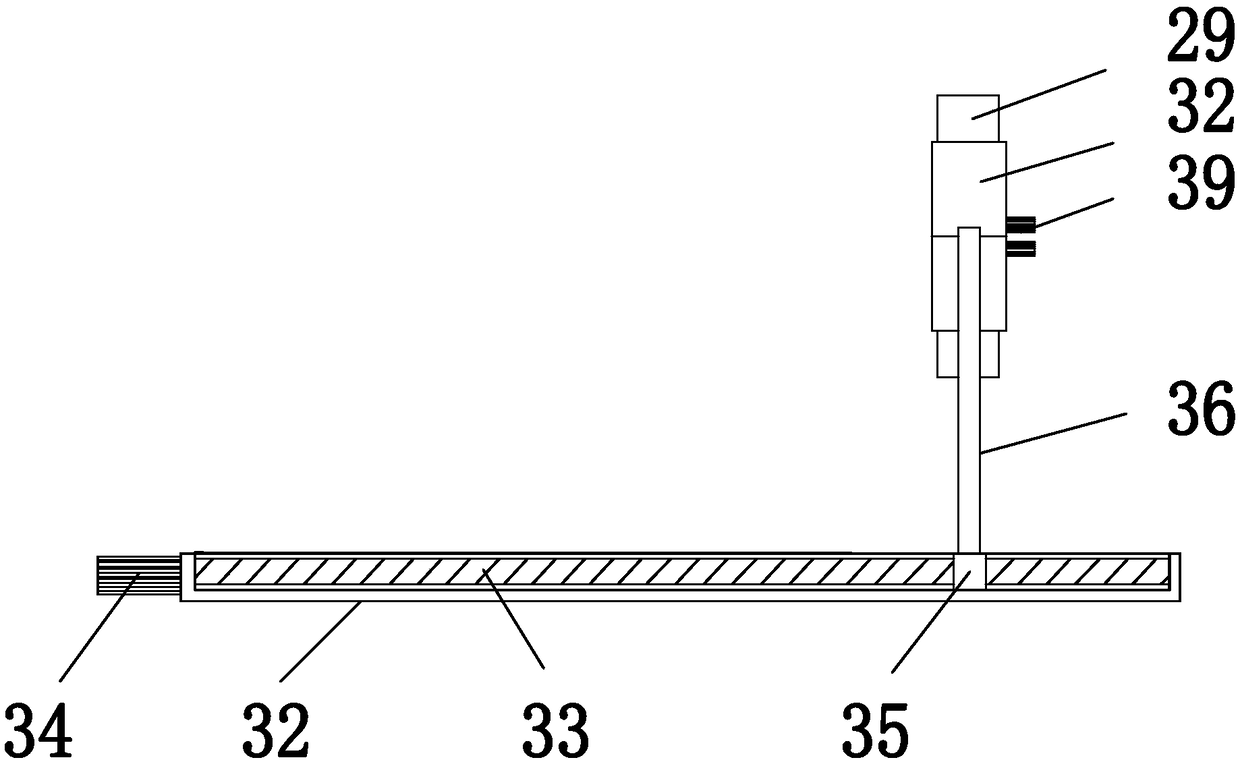

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] In specific implementation, such as Figure 1-3 As shown, a hot-dip tank 1 is included, and opposite rollers 11 are horizontally arranged in the hot-dip tank 1, each of which is rotatably connected with the hot-dip tank 1 through a power input mechanism, and the two The cylinders 11 are all tangent to the steel pipe 12 to be plated, and the inner diameters of the two ends of the steel pipe 12 to be plated are connected to the horizontal movement mechanism arranged outside the hot-dip tank 1 through a clamping mechanism, and the clamping mechanism includes oppositely arranged Vertical plate 13, rollers 14 are arranged oppositely on the opposite face of vertical plate 13, the axis of said roller 14 is parallel to the axis of said steel pipe 12 to be plated, said vertical plate 13 is connected with a height adjustment mechanism upwards, said height One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com