A system and application method for efficient and uniform processing of various profiles by ultrasonic shot peening

An ultrasonic shot peening and shot peening technology, used in metal processing equipment, manufacturing tools, abrasive jetting machine tools, etc., can solve the problem of difficult to process concave surfaces, low processing speed, shot peening speed, and precision control of processing areas. The uniformity of processing is difficult to control. and other problems to achieve the effect of avoiding acute angles and uniform surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

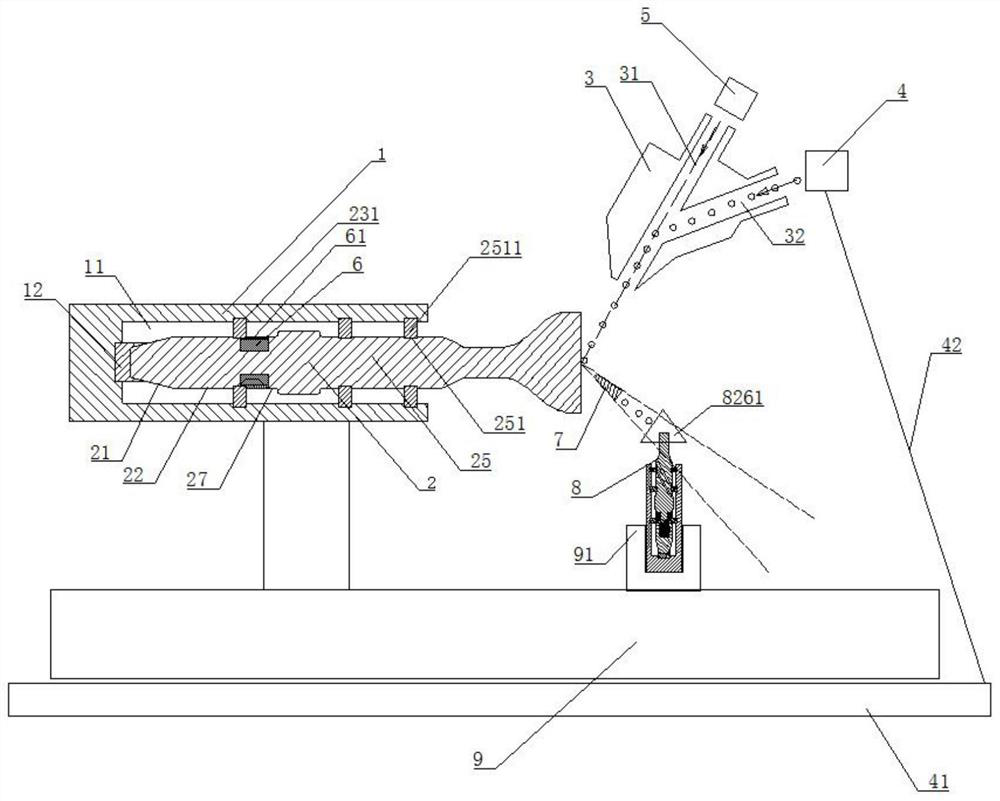

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] refer to image 3 , a system for ultrasonic shot peening of the present invention to efficiently and uniformly process various profiles, including a workpiece clamping mechanism 8, a workbench 9, and a first connecting piece 1 and a first vibration horn 2 arranged on the workbench 9 , mixer 3, shot blasting filling device 4, air injection mechanism 5, drive mechanism 91, control system; one end of the first vibration horn 2 is embedded in the first connector 1, and the other end is provided with an end face for rebound shot peening , the first vibration horn 2 is equipped with a pair of first piezoelectric actuators 6 opposite to each other. The direction is arranged at intervals, the first piezoelectric actuator 6 is connected with the ultrasonic generator; the gas injection mechanism 5 is used to rush the compressed gas into the mixer 3; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com