Arc cutter for thermal shrinkage of packaging film

A technology of circular arc knife and packaging film, which is applied in packaging, transportation packaging, packaging protection, etc. It can solve the problems of packaging film not meeting standards, poor aesthetics, poor customer experience, and damaged products, and achieve rapid and accurate heat dissipation , improve the aesthetics and customer experience, and reduce the effect of contact objects stabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which presently preferred embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and will fully convey the scope of the invention. communicated to technical staff.

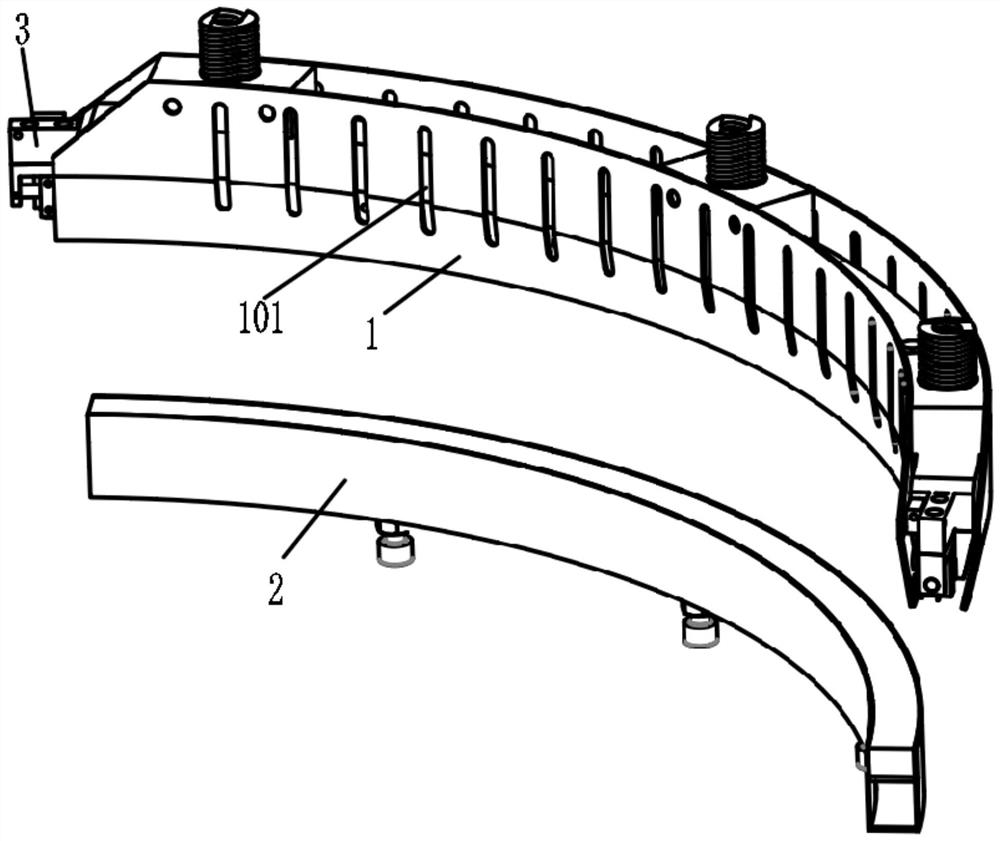

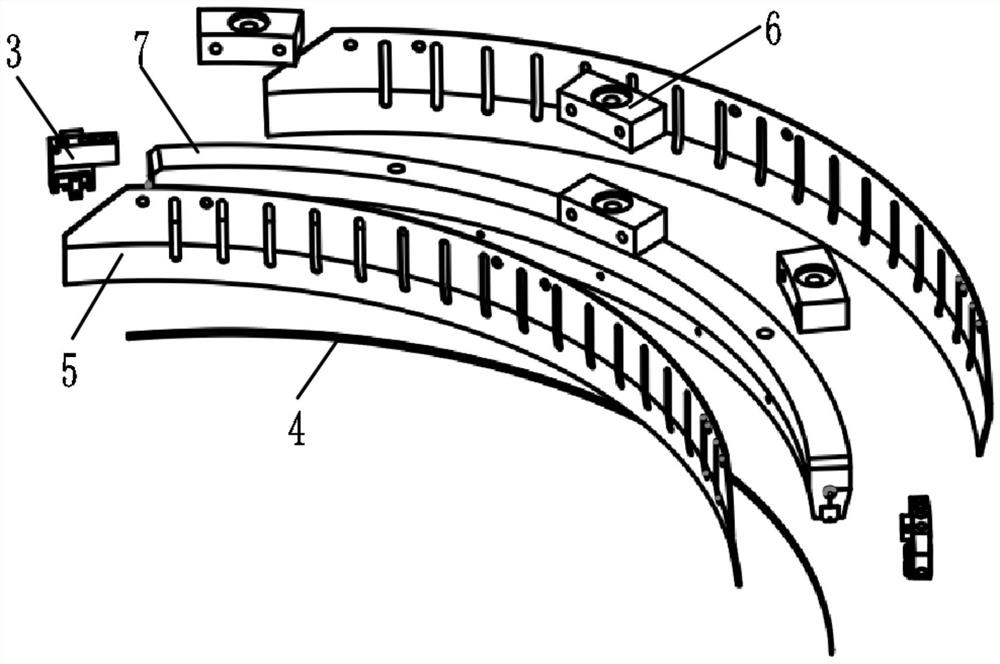

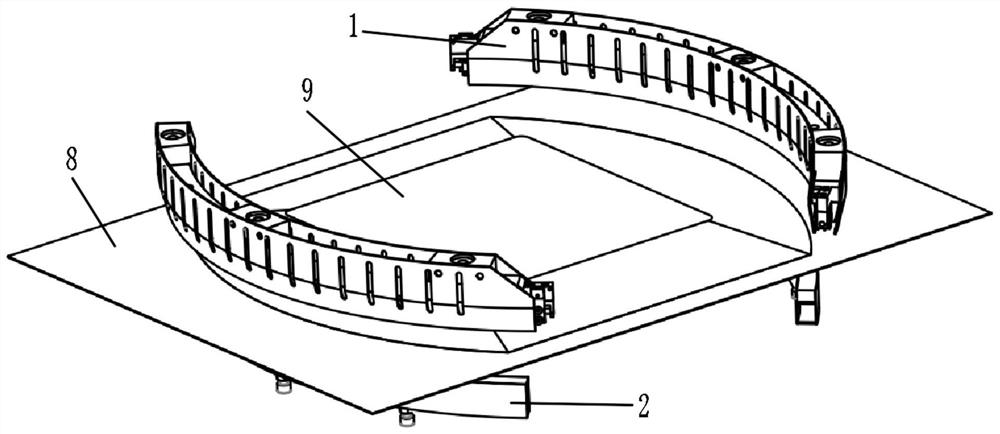

[0032] Such as Figure 1-5 As shown, an arc knife 4 for heat-shrinkable packaging film 8 includes an arc knife 4 module 1, a cutter pad 2, an overheating protection module 3 and an arc knife 4, and the lower side of the arc knife 4 module 1 A cutter spacer 2 is provided; both sides of the arc knife 4 module 1 are provided with an overheating protection module 3; an arc knife 4 is arranged between the overheating protection modules 3, and the arc knife 4 is located on the lower side of the arc knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com