Electrostatic vapor deposition method and device for OEL (organic electroluminescence) display materials

An electroluminescence display and luminescence technology, which is applied in the direction of vacuum evaporation plating, metal material coating process, circuit, etc., can solve the problems of not being able to be used, deformed, and affecting the shape accuracy of the pattern formed by evaporation, so as to achieve the goal of evaporation deposition The effect of high accuracy of position and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] According to a specific embodiment, when the red light emitting layer, the green light emitting layer and the blue light emitting layer need to be evaporated sequentially,

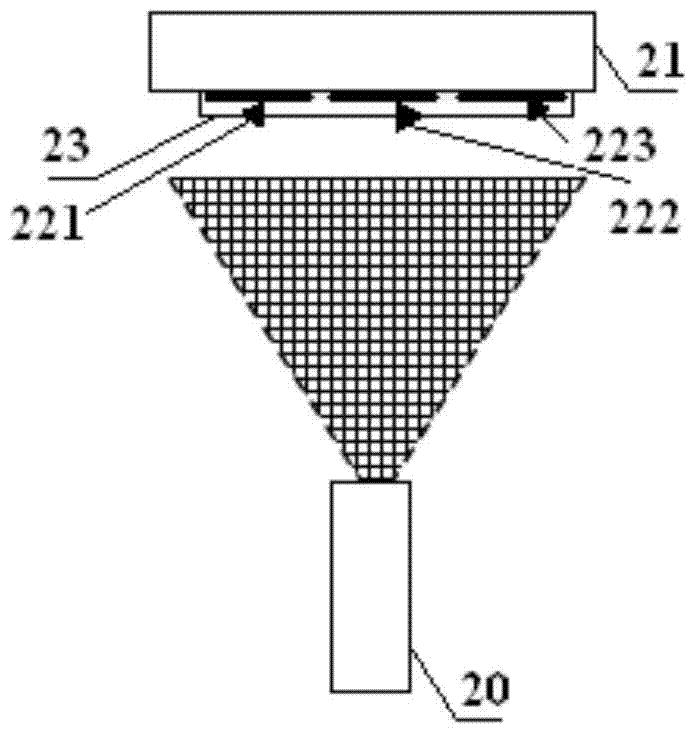

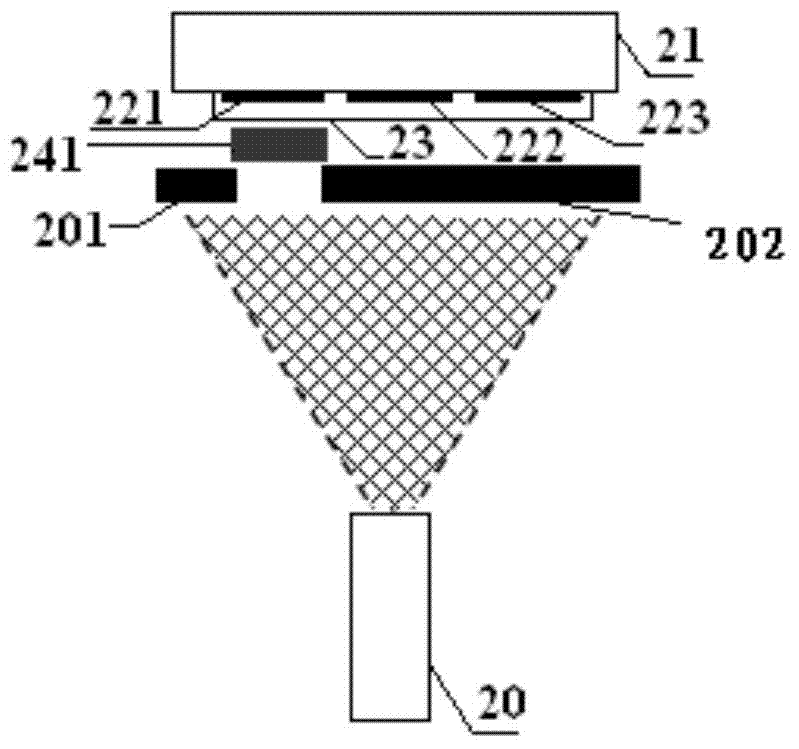

[0055] like Figure 4A As shown, first, the OEL material evaporation source 40 performs evaporation of the light-emitting layer lower structure 43 on the OLED display backplane 42 provided with the red sub-pixel electrode 411, the green sub-pixel electrode 412 and the blue sub-pixel electrode 413;

[0056] like Figure 4B As shown, the evaporation of the red light-emitting layer is carried out again: the OEL material evaporation source 40 outputs red OEL material particles;

[0057] Particle Charging and Transport Module ( Figure 4B not shown in the figure) to control the red OEL material particles to be positively charged, and make the positively charged red OEL material particles directional transport or scatter toward the OLED display backplane 42;

[0058] Particle speed control module (incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com