Device for air cleaning

A technology of air purification equipment and filters, applied in the direction of steam flow control, chemical instruments and methods, external electrostatic separators, etc., can solve the problems of reduced overall efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

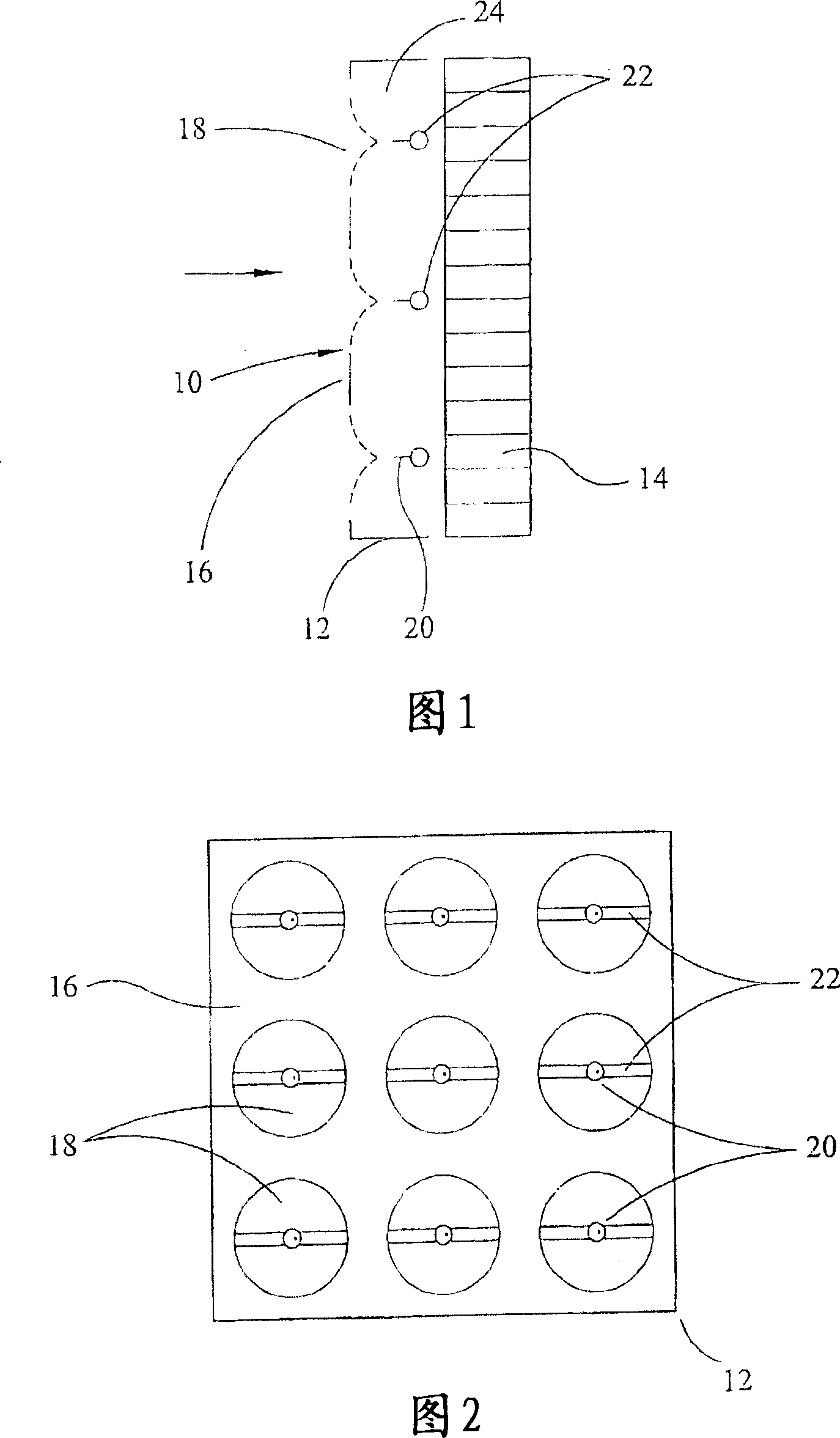

[0025] Referring to Figures 1 and 2 of the drawings, an air cleaning device 10 includes a particle charging zone 12 and a filter 14 . The particle charging area 12 comprises a grounded conductive plate 16 with apertures 18 through which air is drawn or blown in in the direction of the arrow.

[0026] Behind each circular aperture 18 there is located a centrally arranged corona emitter pin 20 , which is supported on a conductive rod 22 and is at high voltage with respect to the conductive plate 16 which is normally at ground potential. A stream of air ions 24 (shown in dashed lines) generated by the emitter pin 20 moves towards the conductive plate 16 under the action of the electric field. The ions 24 spread out in a conical distribution from the ends of the emitter pins 20 and they are substantially all deposited on the conductive plate 16 and more particularly near the circumference around each circular aperture 18 .

[0027] The combination of particle charging region 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com