Solar silicon wafer centring device

A technology of solar silicon wafers and centering devices, which is applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems affecting processing quality, solar silicon wafer offset, etc., and achieve the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

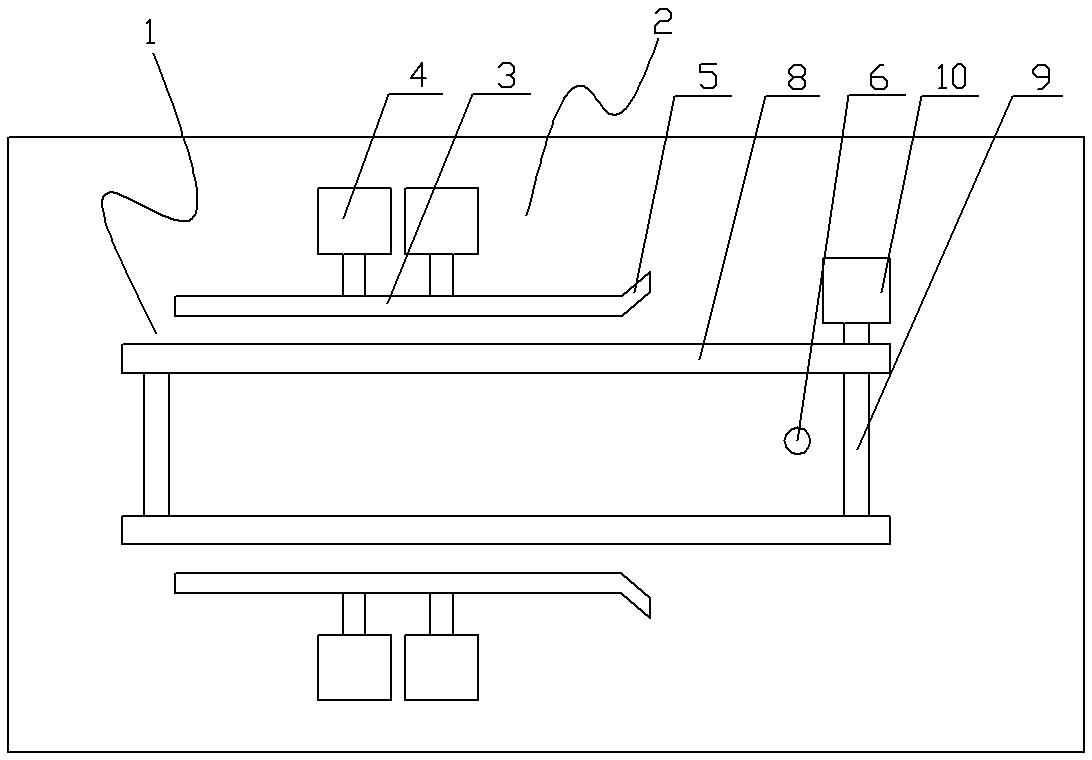

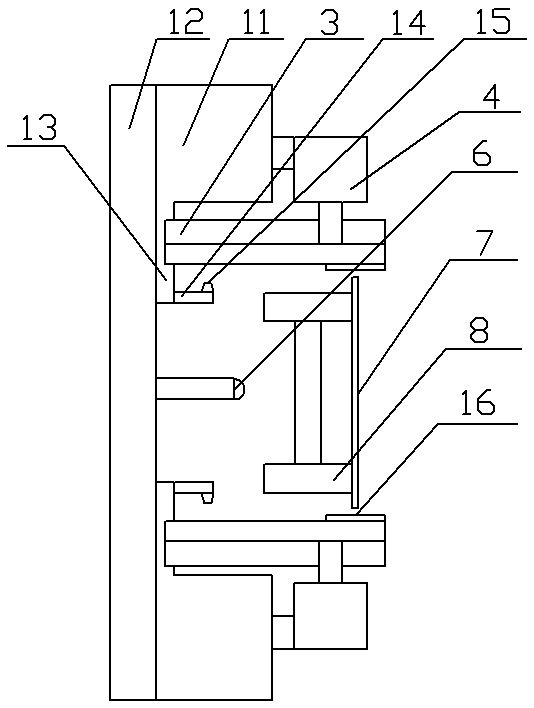

[0013] See figure 1 , figure 2 As shown, a solar silicon wafer centering device includes a conveyor belt mechanism 1, and a pushing device 2 is symmetrically arranged on both sides of the conveyor belt mechanism 1. The pushing device 2 includes a push plate 3, and the outside of the push plate 3 is connected with two Arranged drive cylinder 4, push plate 3 one end is provided with the guide plate 5 that turns outwards, and the guide plate 5 on two push plates 3 forms a trumpet mouth, is convenient to solar silicon wafer 7 to enter, and the guide plate 5 side A photoelectric sensor 6 is arranged in the middle of the conveyor belt mechanism 1, and the photoelectric sensor 6 is electronically connected to the driving cylinder 4. When a solar silicon chip 7 passes by, it sends a signal to the driving cylinder 4 to realize the pushing operation. The inner surface of the push plate 3 is provided with a cushion 16 to protect the solar silicon chip 7 .

[0014] The conveyor belt me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com