Electric wire middle conveying device

A technology for conveying devices and electric wires, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as inability to guarantee processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

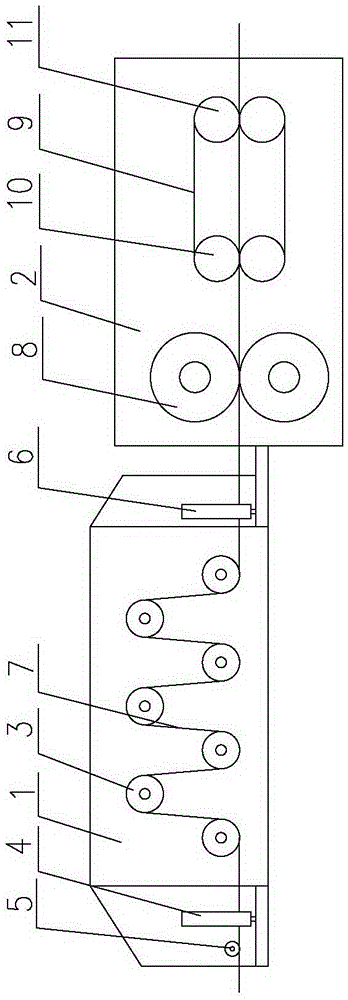

[0007] See figure 1 As shown, a wire intermediate conveying device includes a front frame 1 and a rear frame 2, and two rows of tensioning wheels 3 are installed on the front frame 1, and the two rows of tensioning wheels 3 are staggered up and down. The row of tensioning wheels 3 includes three, and the row of tensioning wheels 3 below includes four. The left and right sides of the two rows of tensioning wheels 3 are respectively provided with guide column mechanisms, and the left guide column mechanism includes two side-by-side left Vertical guide post 4 and horizontal guide post 5, the guide post mechanism on the right side includes two right side vertical guide posts 6 side by side, the gap between the two left side vertical guide posts 4 and the two right side vertical guide posts 6 are equal. Identical to the diameter of the electric wire 7, two guide wheels 8 and two guide conveyor belts 9 are arranged in sequence on the rear frame 2, and the two guide wheels 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com