Macroporous part position accuracy detection positioner

A positioning device and position degree technology, applied in measuring devices, instruments, etc., can solve the problems that affect the detection of hole position degree in large-hole parts, the measurement tool cannot ensure the symmetry of the hole center, and affect the quality of workpiece processing and assembly, etc., to ensure the position. The effect of precision detection, ensuring the quality of subsequent processing, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

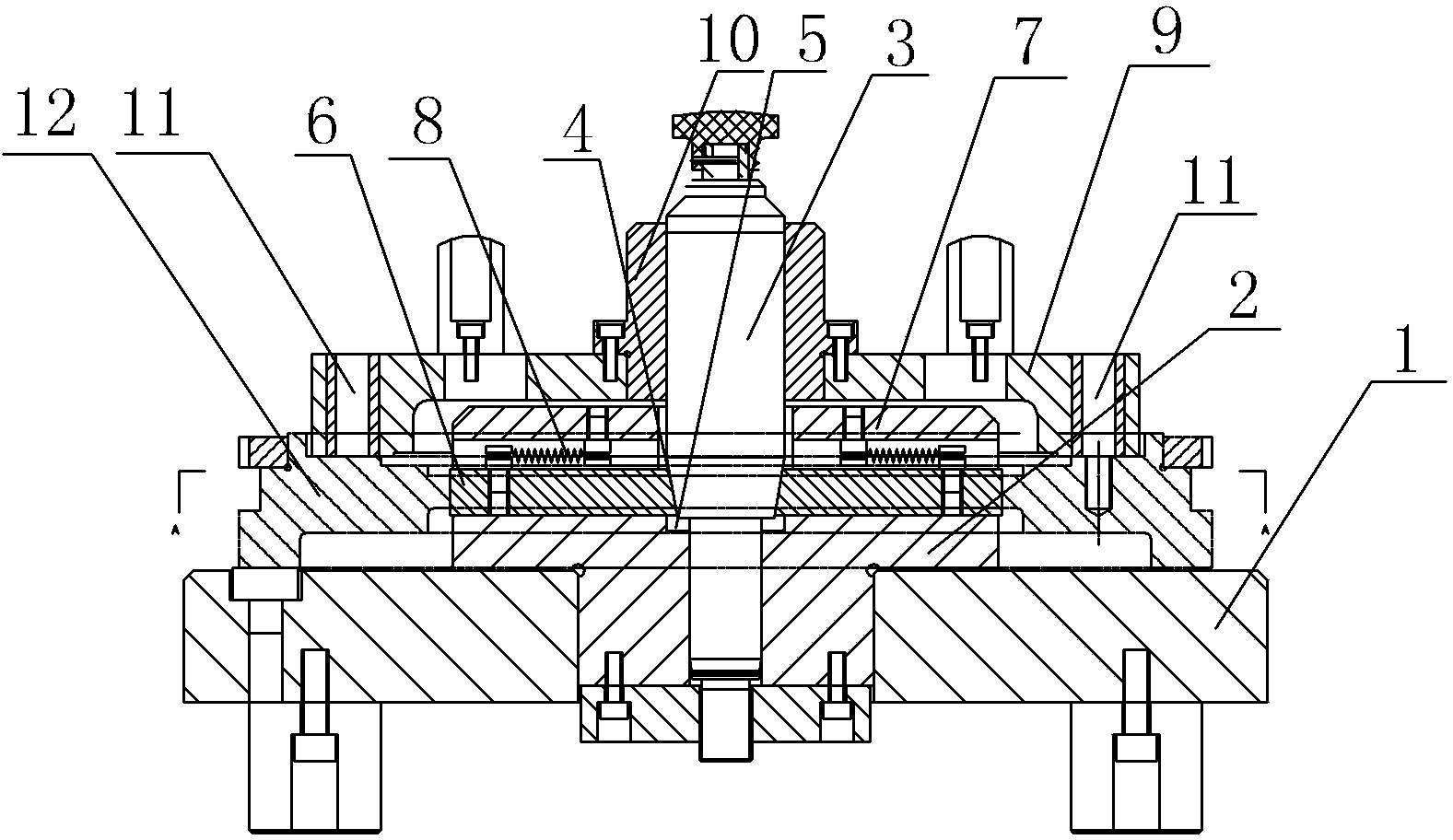

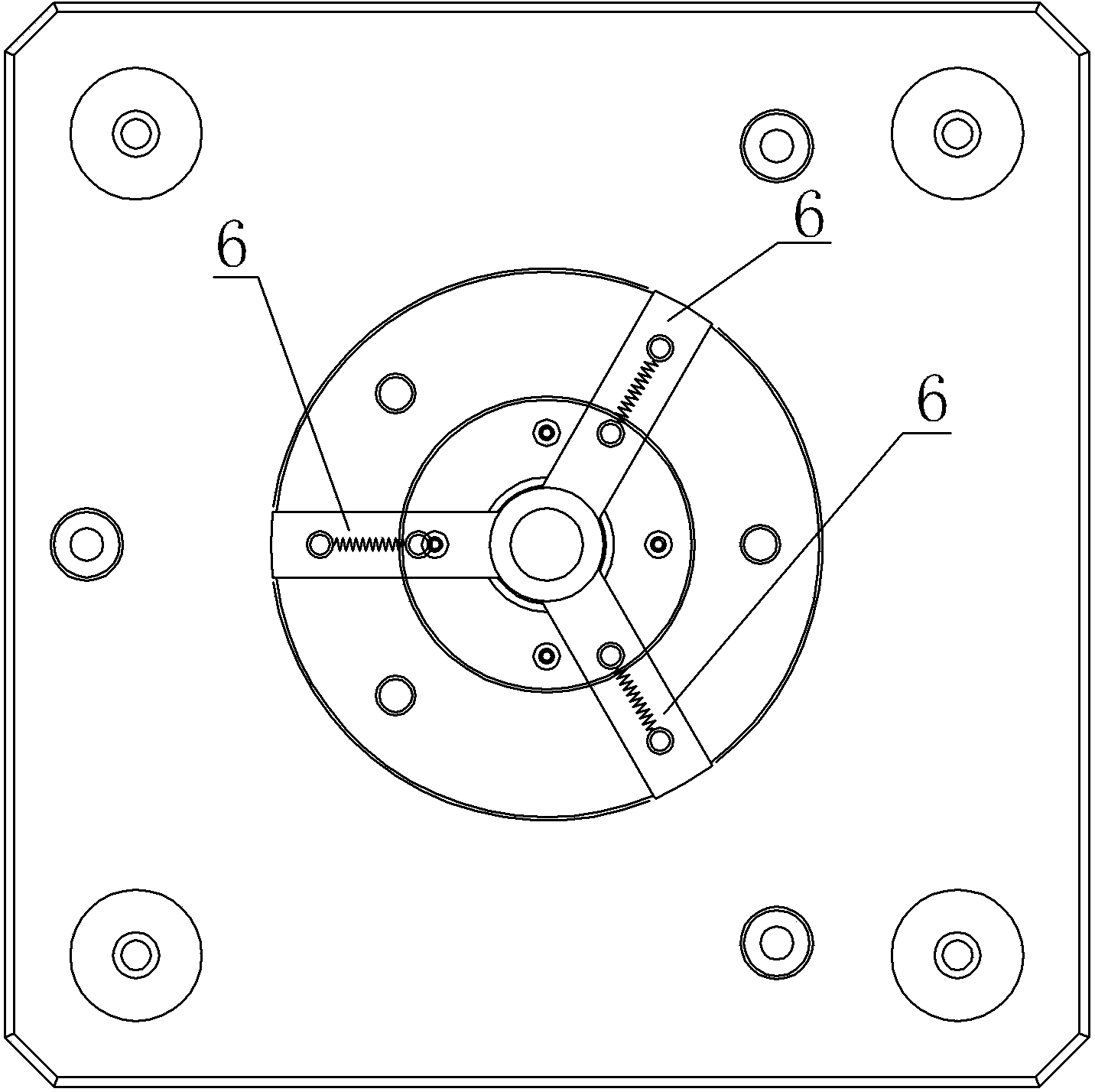

[0009] See figure 1 , figure 2 , a position detection and positioning device for large hole parts, which includes a base plate 1, a flange 2 is set on the base plate 1, and a positioning column 3 for moving up and down is set on the flange 2. The positioning column 3 includes a conical column structure 4, and the flange 2 There is a groove 5 on the top, the conical column structure 4 corresponds to the groove 5, and the upper end of the flange 2 corresponds to the conical column structure 4. Three sliders 6 are evenly arranged on the upper end of the slider 6. The cover plate 7 is set on the positioning On the column 3, the slider 6 is connected to the cover plate 7 through the tension spring 8, the cover plate 7 is provided with a template 9, the positioning column 3 is provided with a guide sleeve 10, the positioning column 3 is connected to the template 9 through the guide sleeve 10, and the template 9 is set on the On the positioning column 3, the template 9 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com