Clamp for oil atomizer body end face grinding procedure

A grinding process and face grinding technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of uncontrollable dimensional consistency, small number of injector bodies, and difficulty in ensuring the quality of the process, so as to ensure the quality and size of subsequent processing. Good consistency and the effect of improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

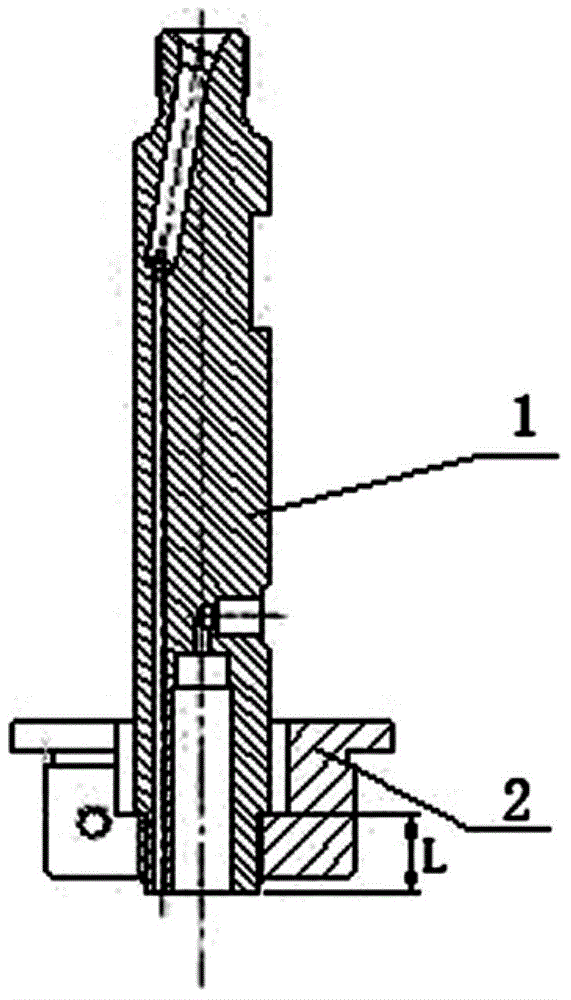

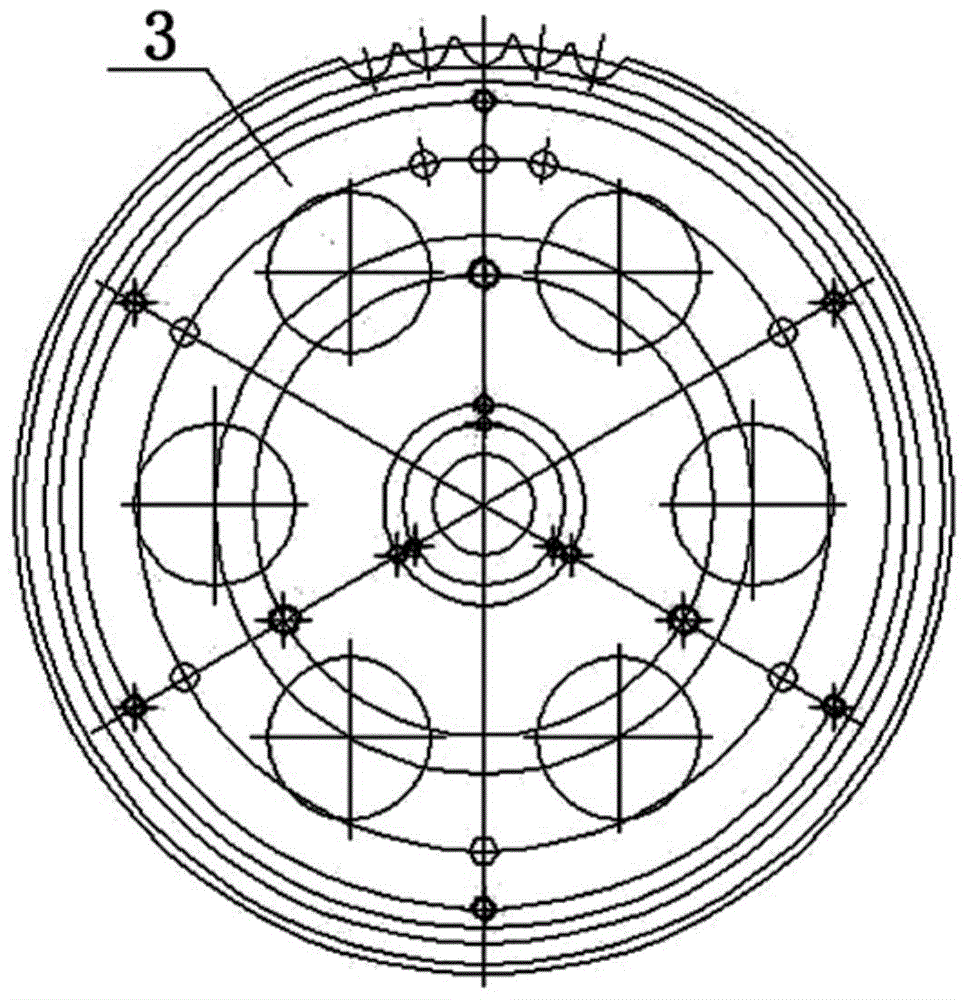

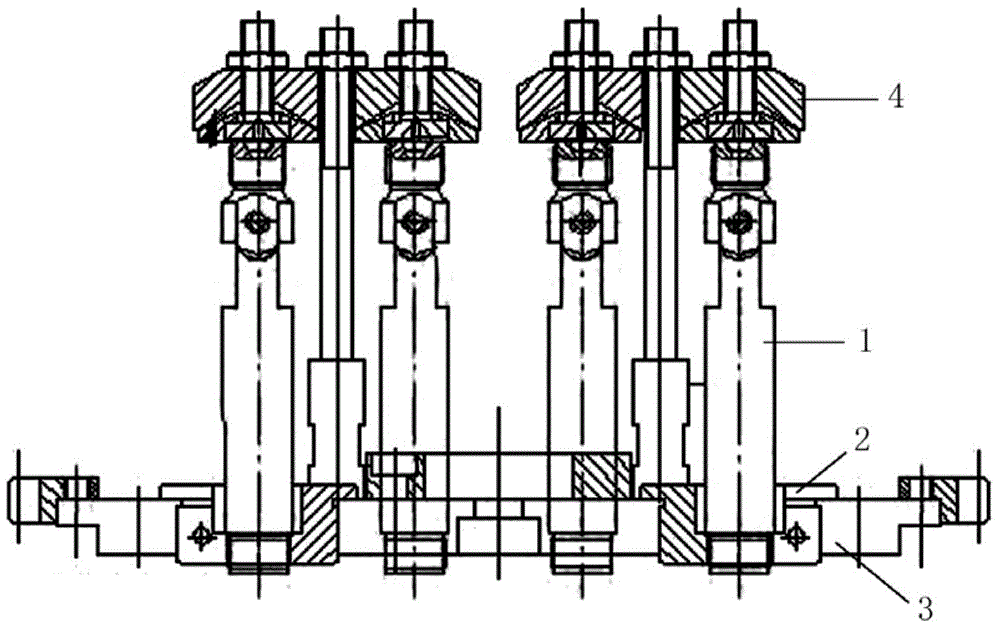

[0018] refer to Figure 4 and Figure 5 , the fixture suitable for the end face grinding and grinding process of the fuel injector body of the present invention includes: a positioning disc assembly, a meteor disc 3 and a clamping assembly, wherein the meteor disc 3 is fixedly installed above the positioning disc assembly, and the disc surface is formed with A through hole for the fuel injector body 1 to pass through; the clamping assembly is fixedly connected to the meteor disk 3 by bolts, and is used for clamping the fuel injector body 1 . The positioning disc assembly and the clamping assembly are described in detail below.

[0019] The positioning disc assembly includes: a positioning disc 5 and a short positioning pin 6 . Short positioning pin 6 is provided with four at least, and it is threadedly connected with positioning disk 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com