Clinker discharging device for cement production and processing

A clinker and cement technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems that affect the processing progress and processing accuracy, it is difficult to control the discharge speed, and the materials affect the discharge effect, so as to ensure the processing progress , Improve the cutting speed and ensure the quality of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

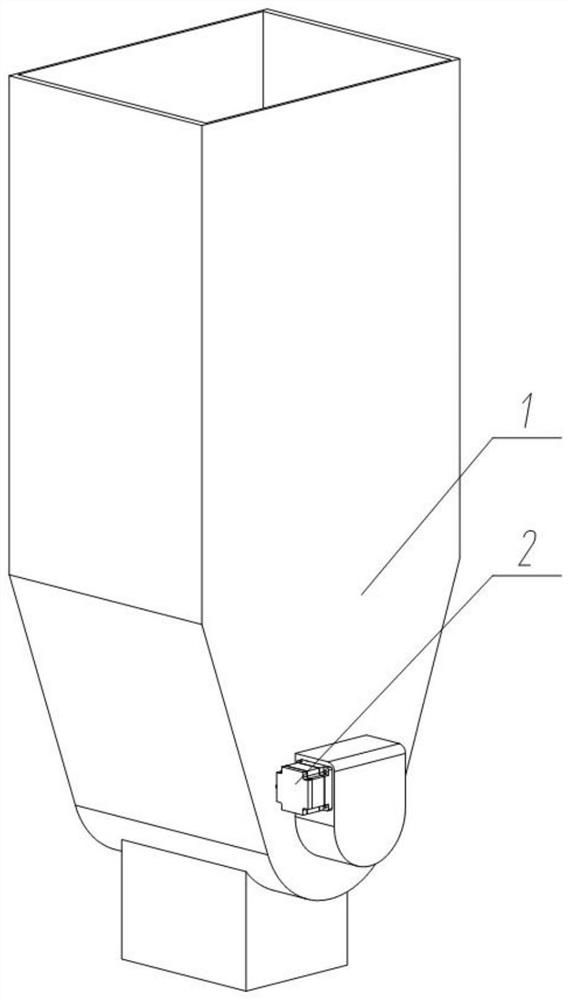

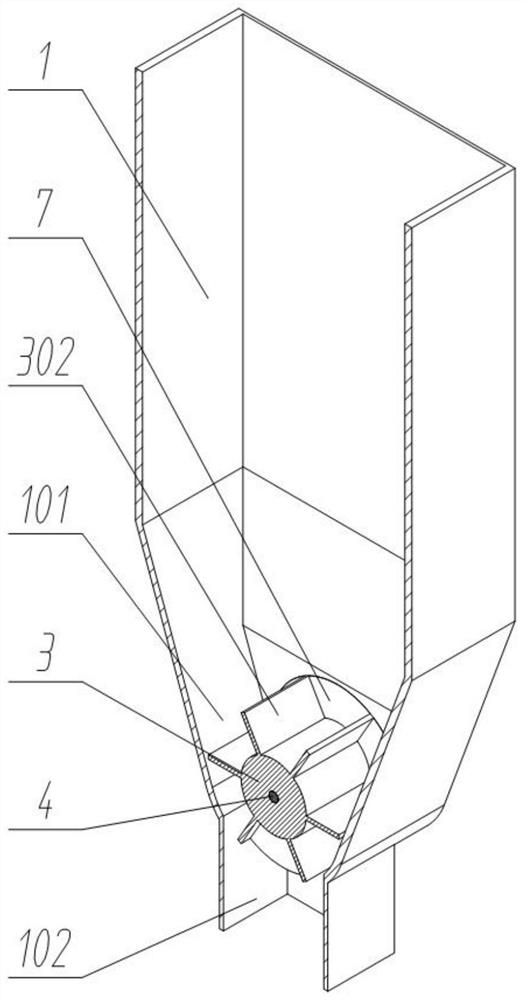

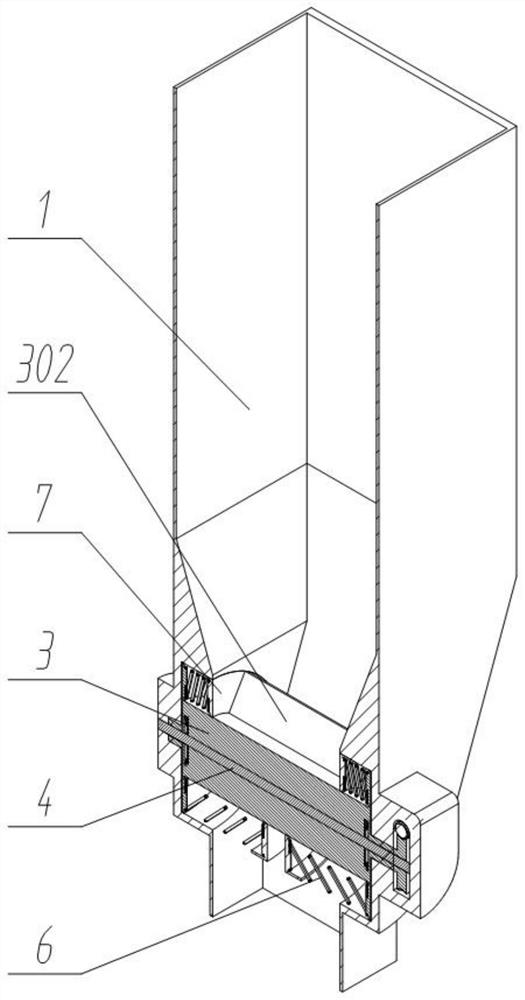

[0052] Example: please refer to Figure 1 to Figure 9 :

[0053] The present invention proposes a clinker unloading device for cement production and processing, comprising: a clinker discharge hopper 1; figure 2 As shown, the clinker discharging hopper 1 also includes: a discharging closing port 101, the discharging closing port 101 is arranged under the interior of the clinker discharging hopper 1, the discharging closing port 101 is an inwardly inclined closing port-like structure, and the discharging closing port 101 The bottom of the clinker is a circumferential surface structure; the discharge port 102, the discharge port 102 is opened at the bottom of the clinker discharge hopper 1, and the discharge port 102 is communicated with the bottom of the discharge closing port 101;

[0054] The discharge drive part 2 is fixedly connected to the right end face of the clinker discharge hopper 1;

[0055]The discharging speed control part 3 is connected to the inner lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com