Patents

Literature

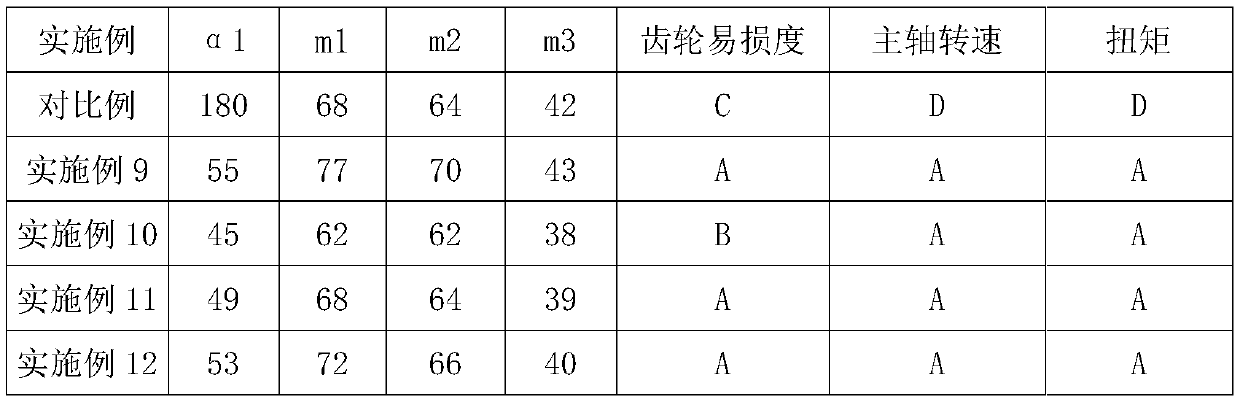

33results about How to "Guaranteed output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

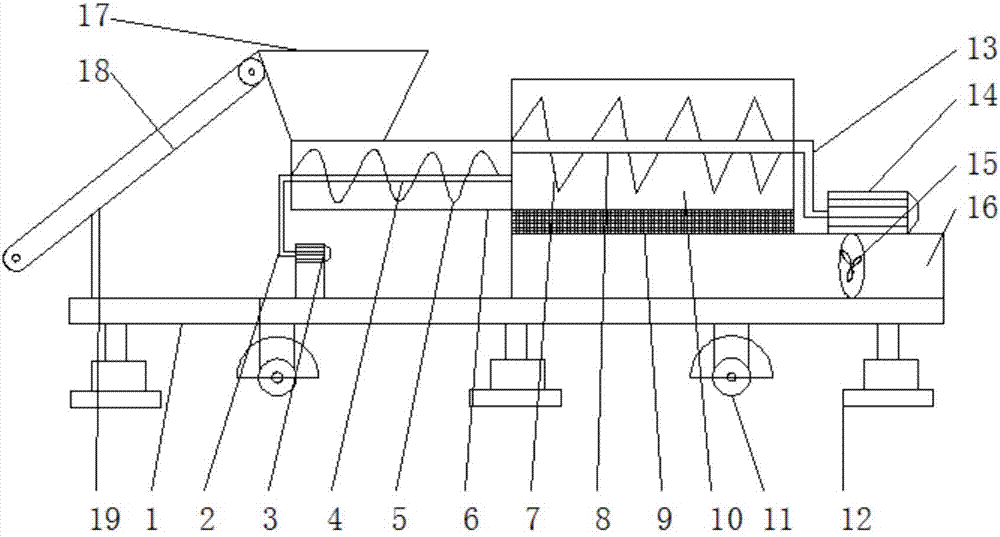

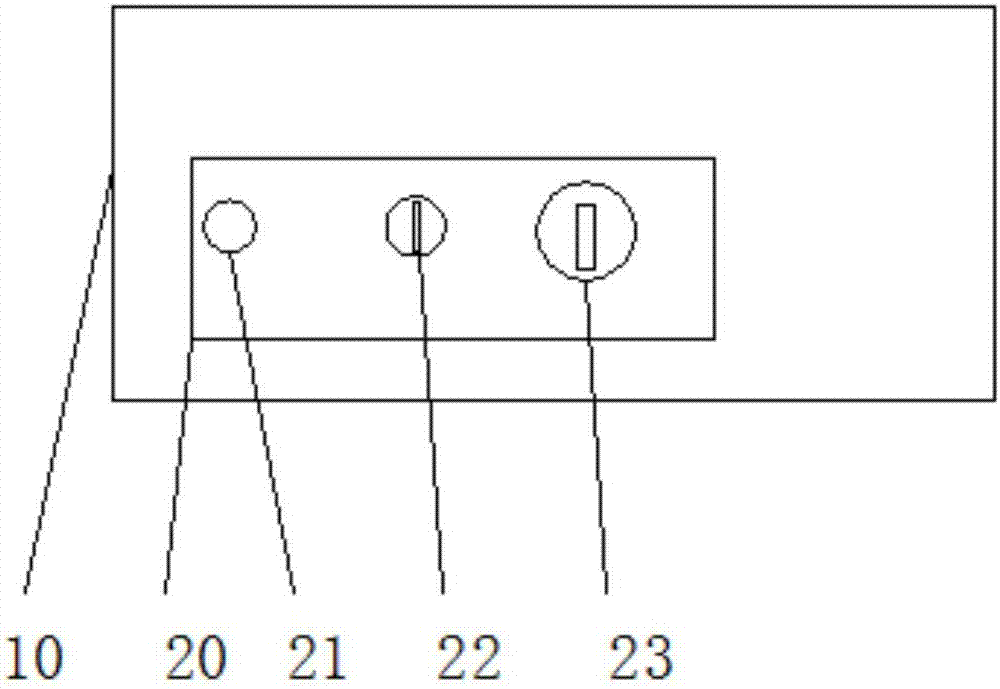

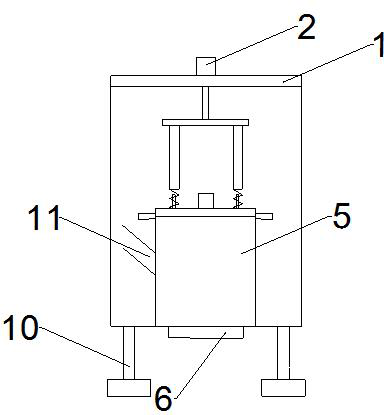

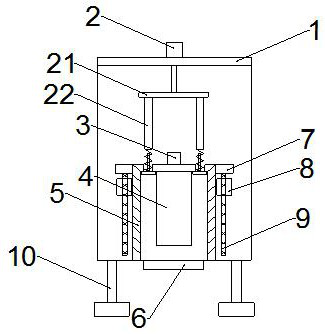

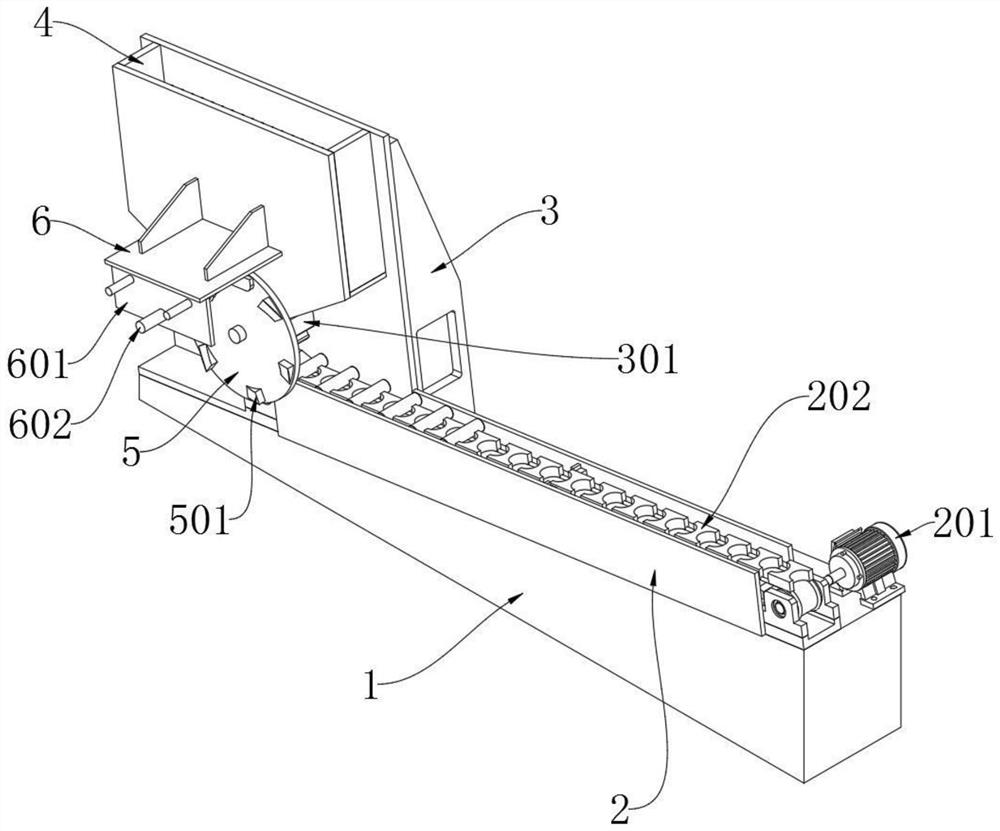

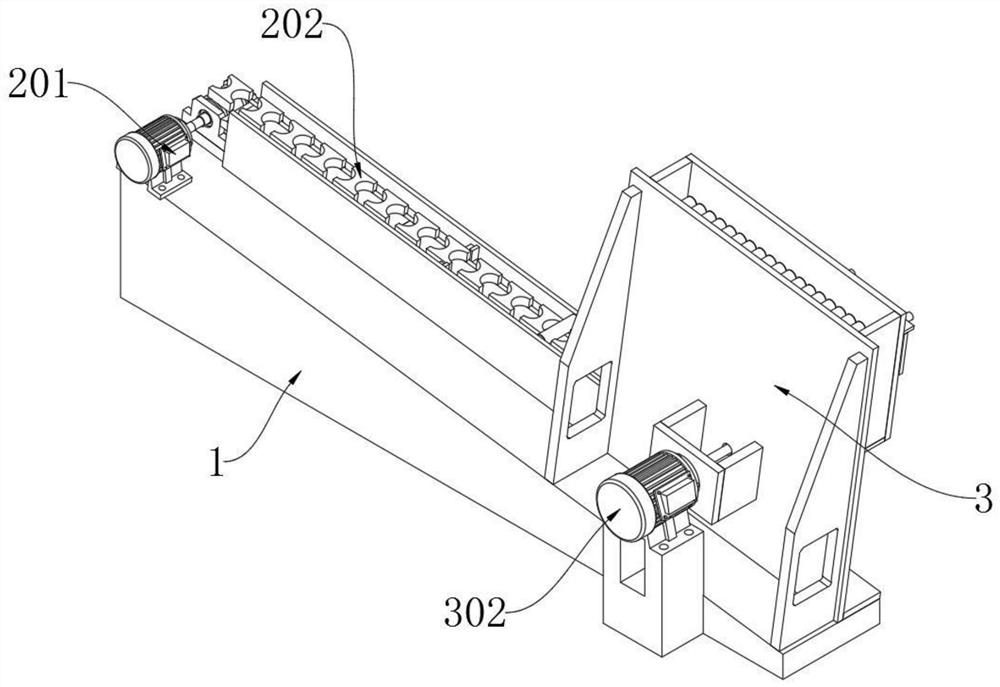

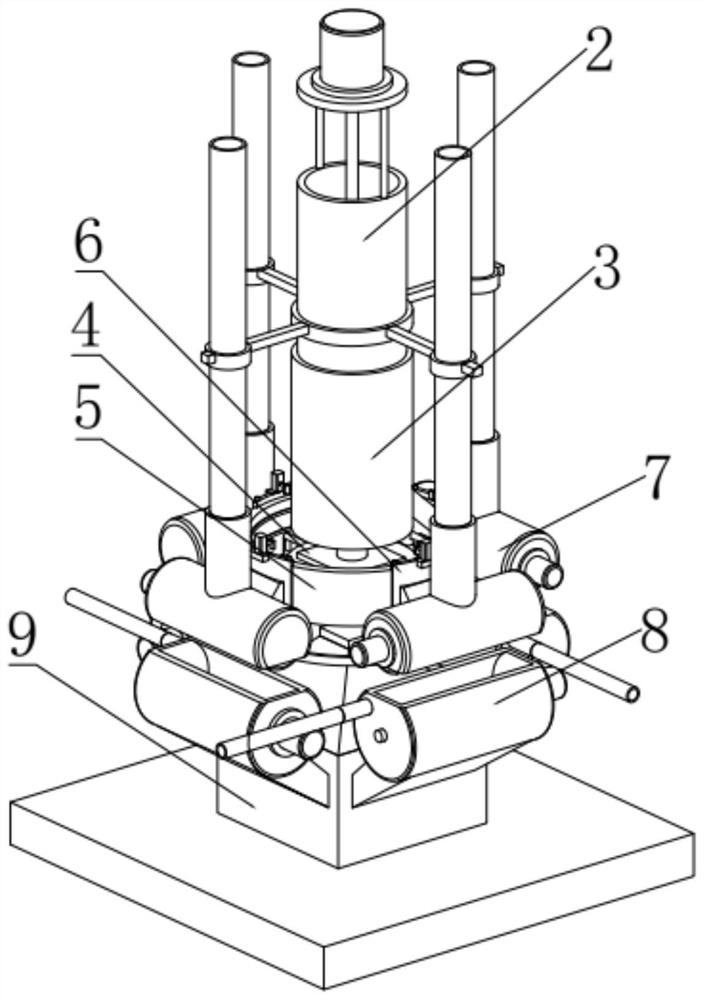

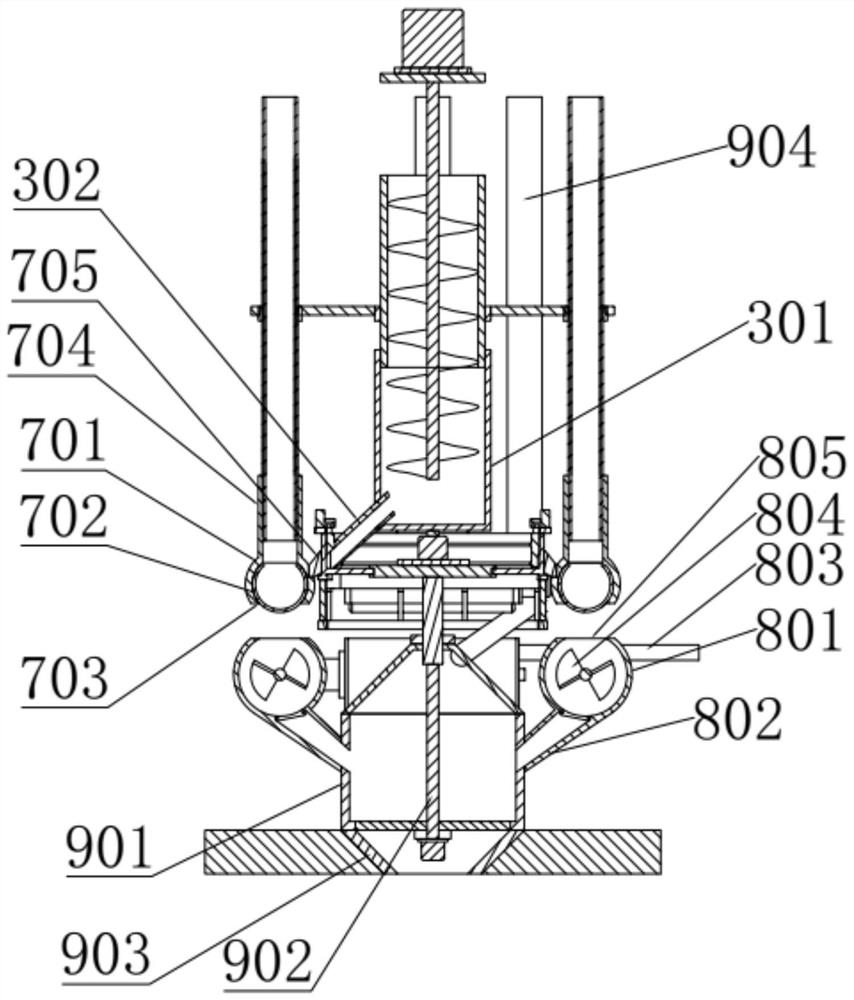

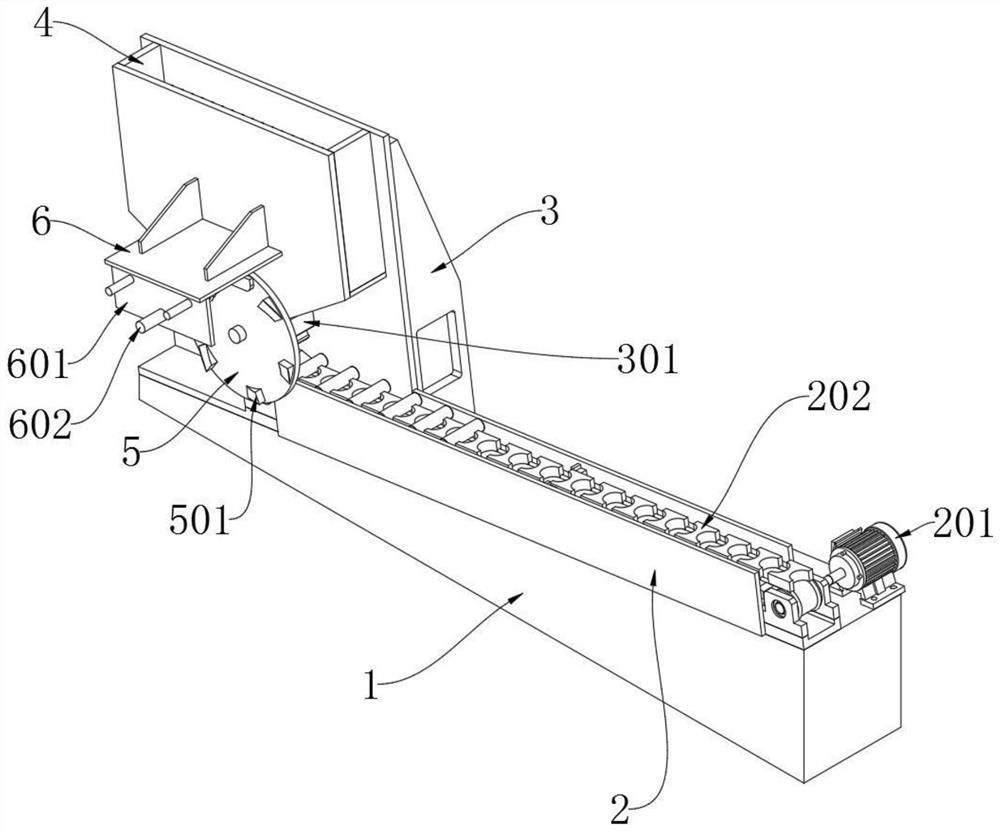

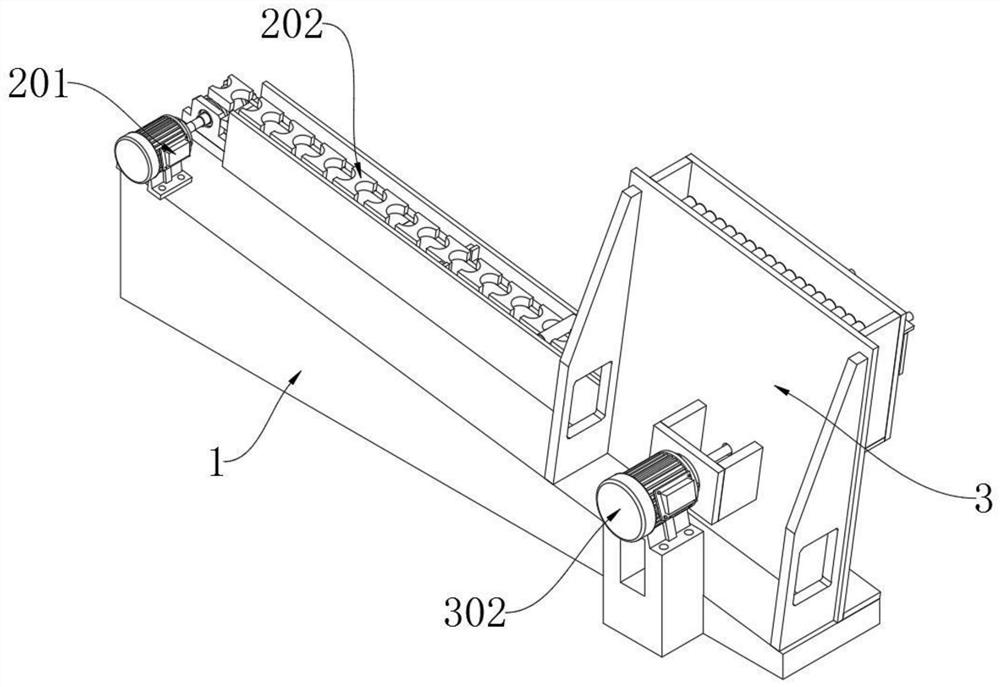

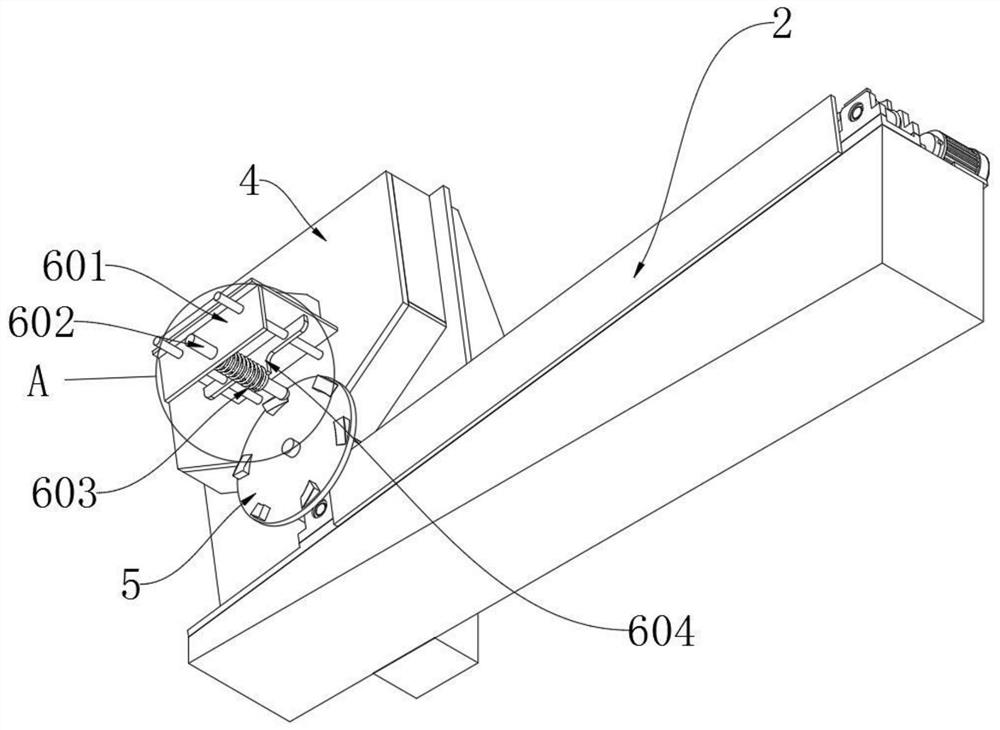

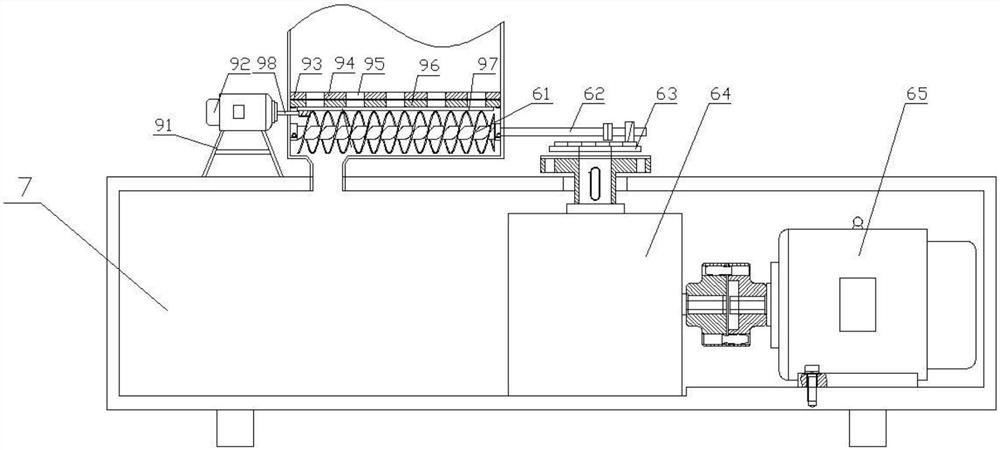

Straw smashing device capable of achieving automatic feeding

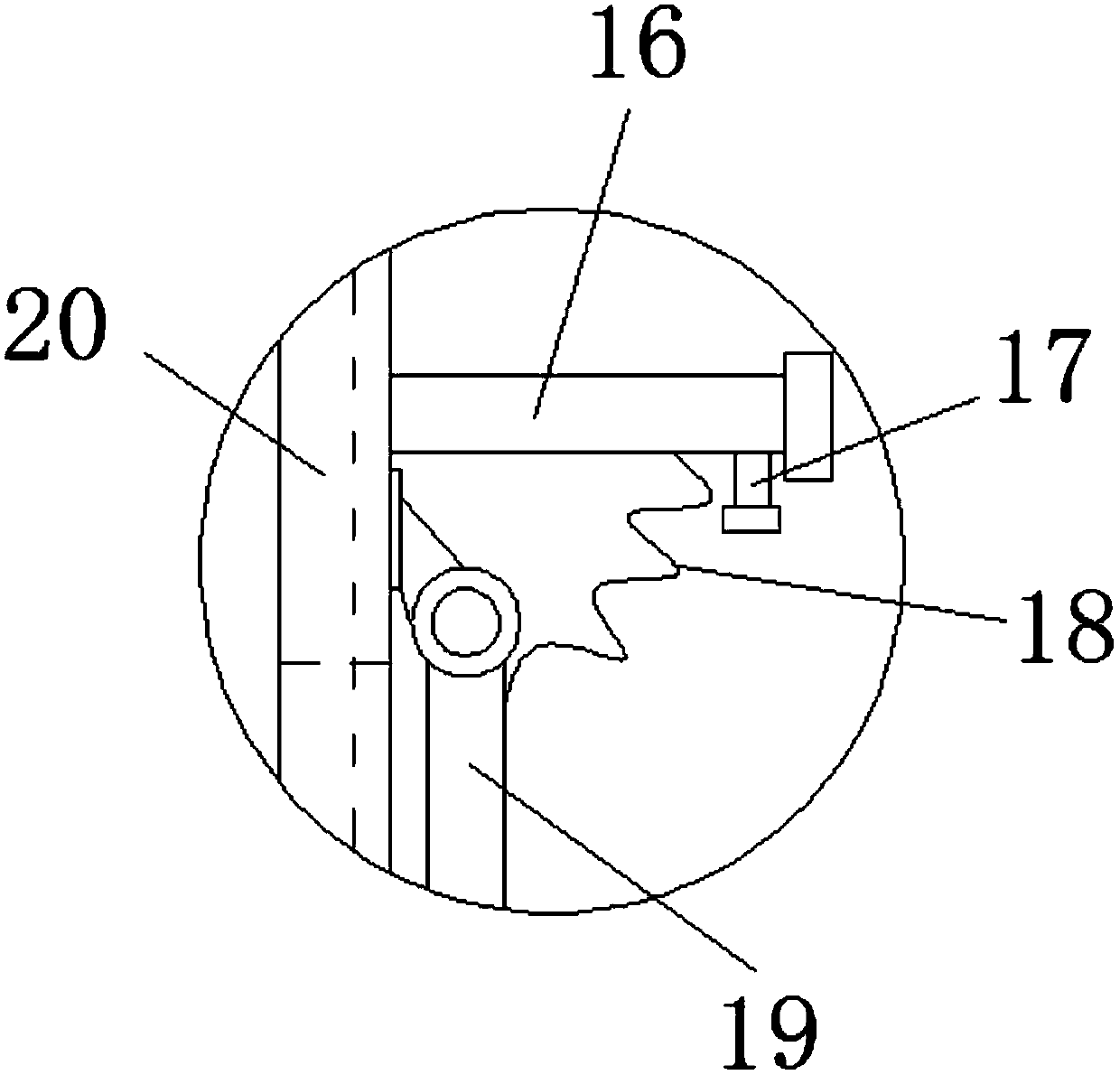

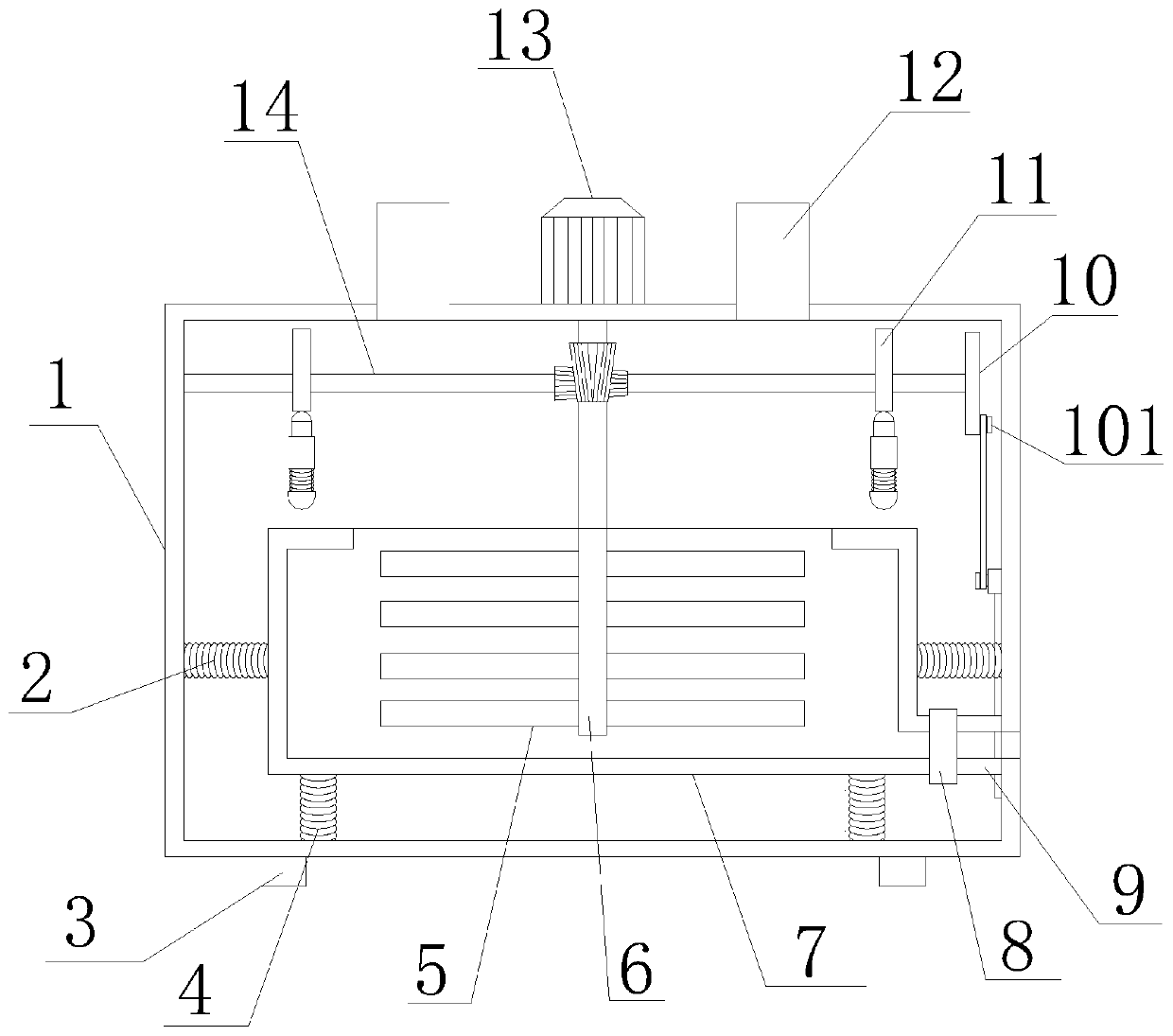

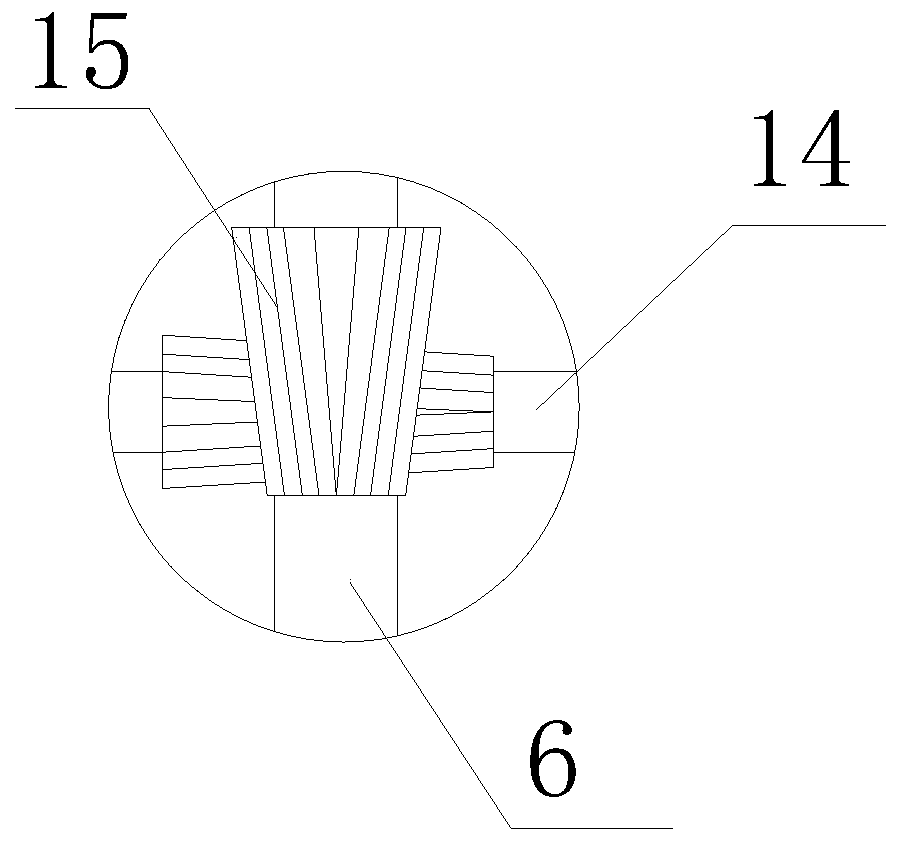

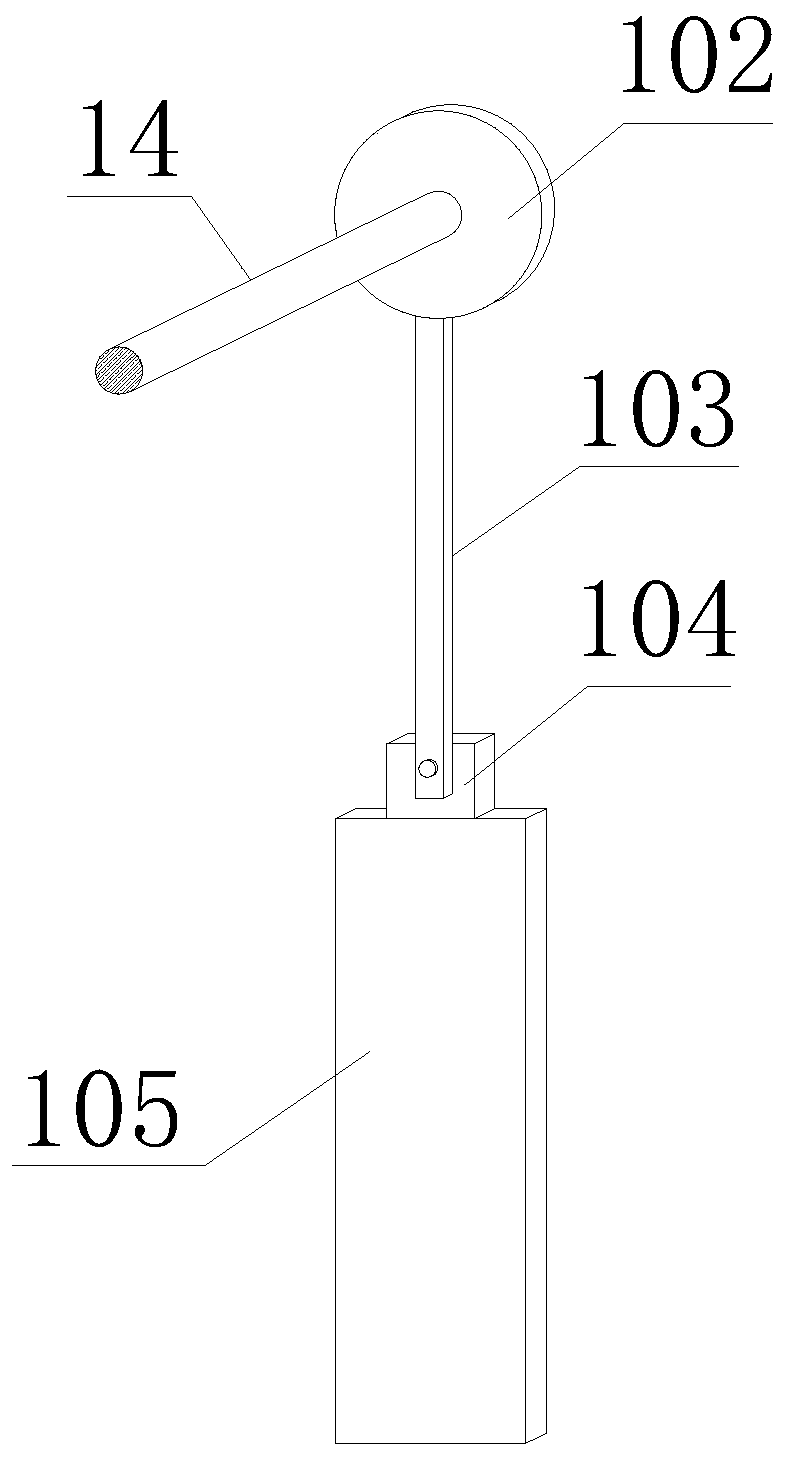

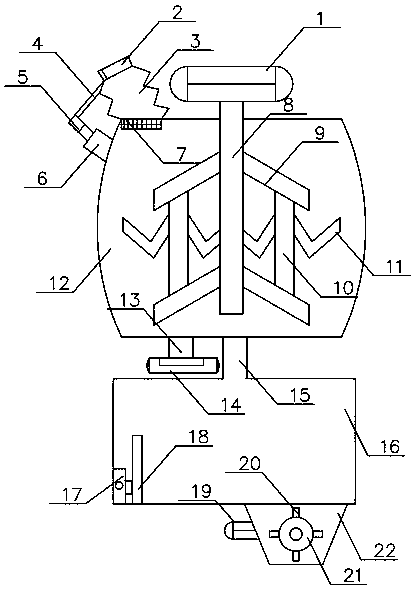

The invention discloses a straw smashing device capable of achieving automatic feeding. The straw smashing device comprises a base, a material smashing device, a discharging channel, a feeding port and a control box; a supporting column and a Y710-14 motor are installed on the upper side of the base, and the Y710-14 motor is connected with a small rolling shaft through a first coupler; a material conveying device is installed on the lower side of the feeding port, and a spiral conveying blade is installed in the material conveying device; a large rolling shaft is installed in the material smashing device, a smashing blade is installed on the surface of the large rolling shaft, and a filter screen is installed on the lower side of the material smashing device; a Y710-16 motor is installed on the upper side of the discharging channel, and a second coupler is installed on the left side of the Y710-16 motor; and a power switch is installed on the surface of the control box. According to the straw smashing device, automatic feeding can be achieved by additionally arranging a conveyer belt, the feeding speed is increased, manpower and time are saved, and the economic benefit is increased.

Owner:天津兴科启智科技发展有限公司

Concrete apparatus with quantitative discharging function

InactiveCN107553738AReduce lossesReduce the burden onDischarging apparatusCement mixing apparatusEngineering

Owner:韩为国

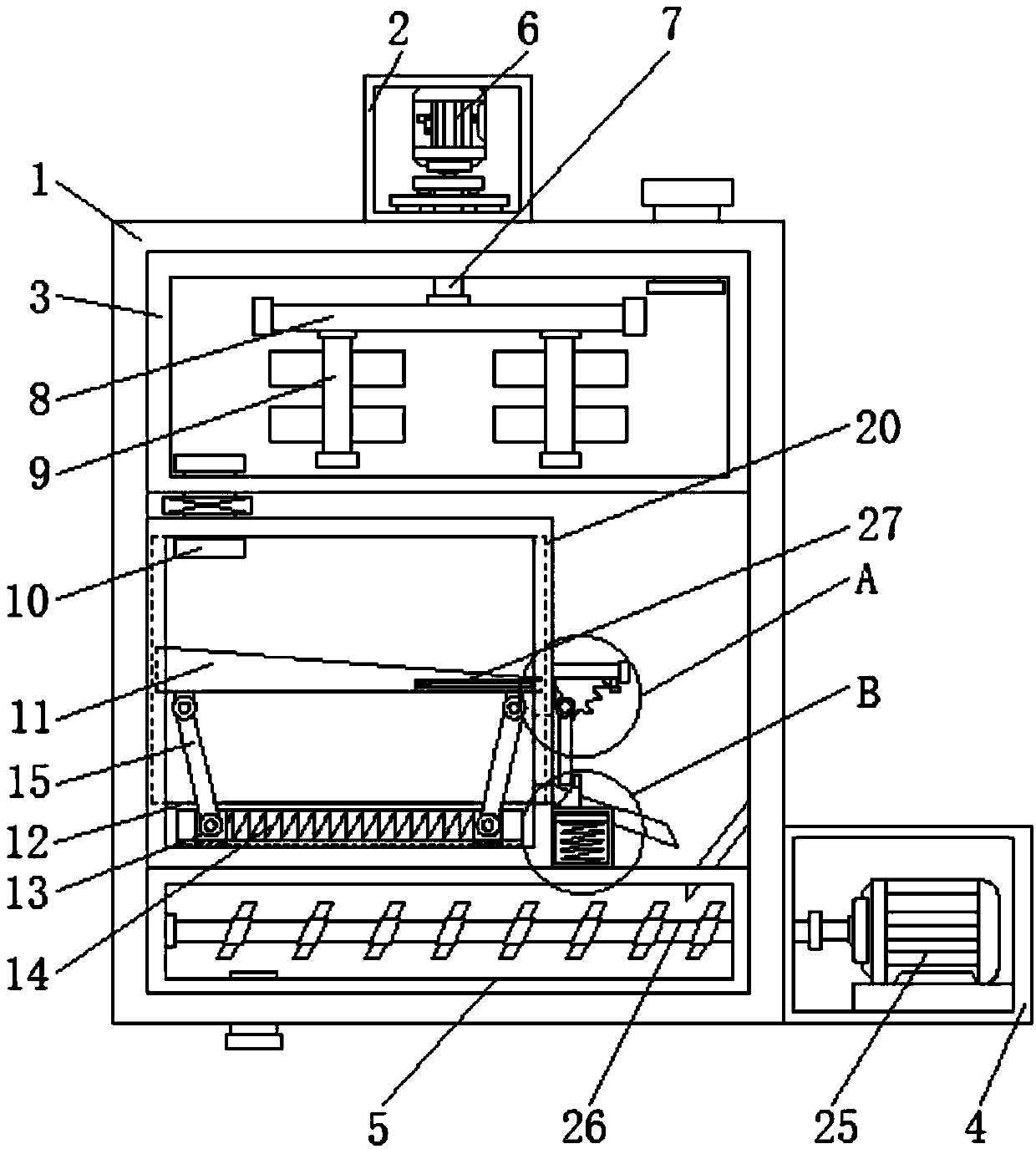

Controller shell production device

InactiveCN109692605AGuaranteed unobstructedSave raw materialsShaking/oscillating/vibrating mixersTransportation and packagingProduction effectDrive shaft

The invention relates to a controller shell production device. The device comprises connecting springs, stirring blades, a stirring shaft, a transmission shaft, cams, transmission rods, vibrating hammers, telescopic springs, guide sleeves, ball bodies, a pin shaft, a rotating disc, a connecting rod, a sliding block and a material blocking plate, the stirring shaft is rotatably connected to the inside of an outer box body, the stirring blades are arranged on the stirring shaft, a discharging valve is arranged at a discharging port, the cam is arranged on the transmission shaft, a section of every transmission rod is located in the corresponding guiding sleeve, the vibration hammers are arranged at the bottom ends of the transmission rods, the ball bodies are arranged at the top ends of thetransmission rods, the vibrating hammers are connected to the bottom ends of the guiding sleeves through the telescopic springs, the rotating disc is arranged on the transmission shaft, the pin shaftis fixed on the right end surface of the rotating disc, the material blocking plate is fixedly connected with the sliding block, and two ends of the connecting rod are respectively connected to the pin shaft and the front end surface of the sliding block. The device has the advantages of good structure, reasonable design, simplicity operation, reduction of the production body, improvement of the product quality, ensuring of the production efficiency, improvement of the production effect, wide application prospect and strong creativity.

Owner:天长市龙亨电子有限公司

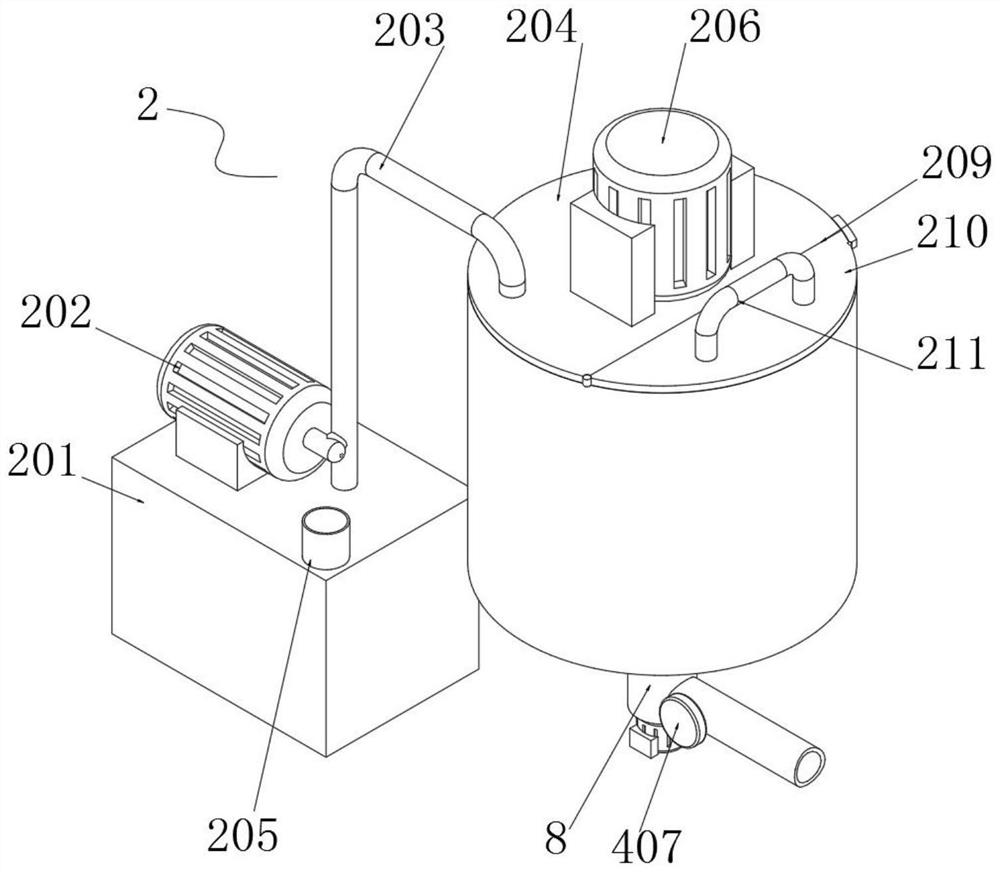

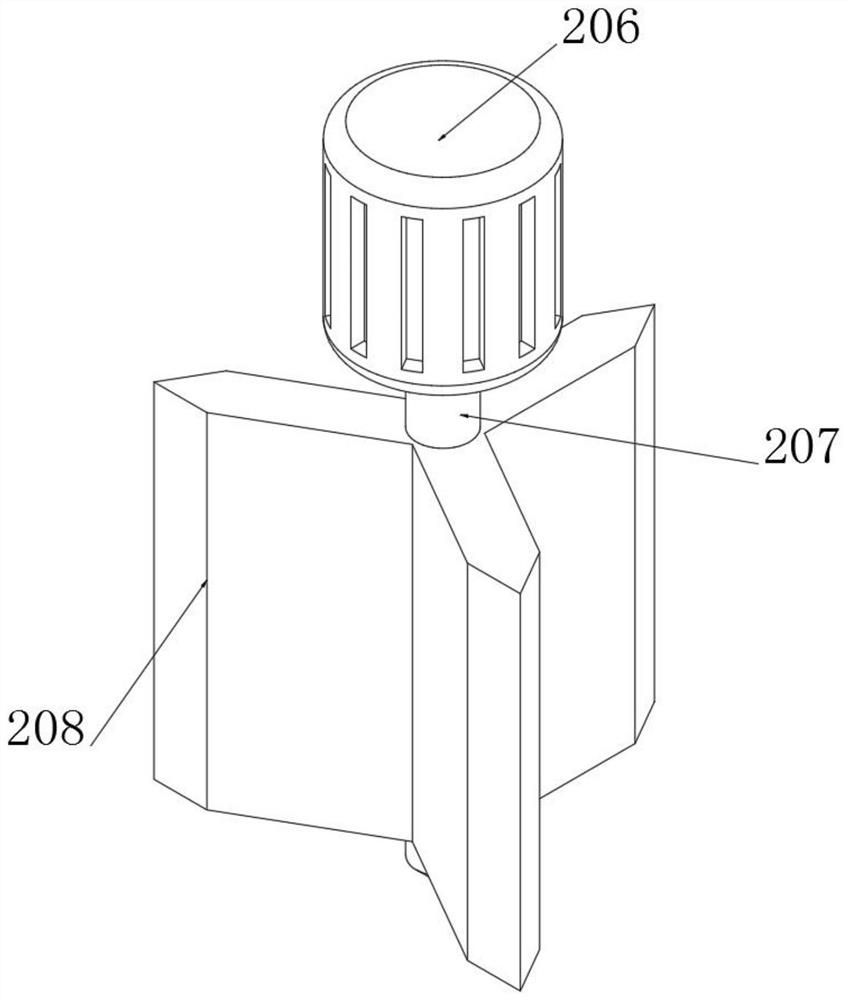

Stirring equipment for precious metal

PendingCN108543466AImprove stirring efficiencyGuaranteed to blockTransportation and packagingRotary stirring mixersPulp and paper industryEngineering

The invention relates to stirring equipment for precious metal and belongs to the technical field of precious metal crushing equipment. A feed port is formed in an upper stirring chamber, a cover is arranged at the upper end of the feed port, a filter screen is arranged at the junction of the feed port and the upper stirring chamber, and a motor is arranged on the upper stirring chamber and connected with main stirring blades through a rotating shaft, reinforcing ribs are arranged between the main stirring blades, each reinforcing rib and the corresponding main stirring blade form an I shape,and V-shaped auxiliary stirring blades are arranged on sides of the reinforcing ribs; a lower stirring chamber is arranged at the lower end of the upper stirring chamber and connected with the upper stirring chamber through a channel, a pusher is arranged at the inner bottom end of the lower stirring chamber and pushes the scraper to run along the bottom end of the lower stirring chamber, and a discharge port is formed in the lower end of the lower stirring chamber. A scraper is pushed by the pusher to drive noble metal to be stirred continuously, and stirring efficiency is improved.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

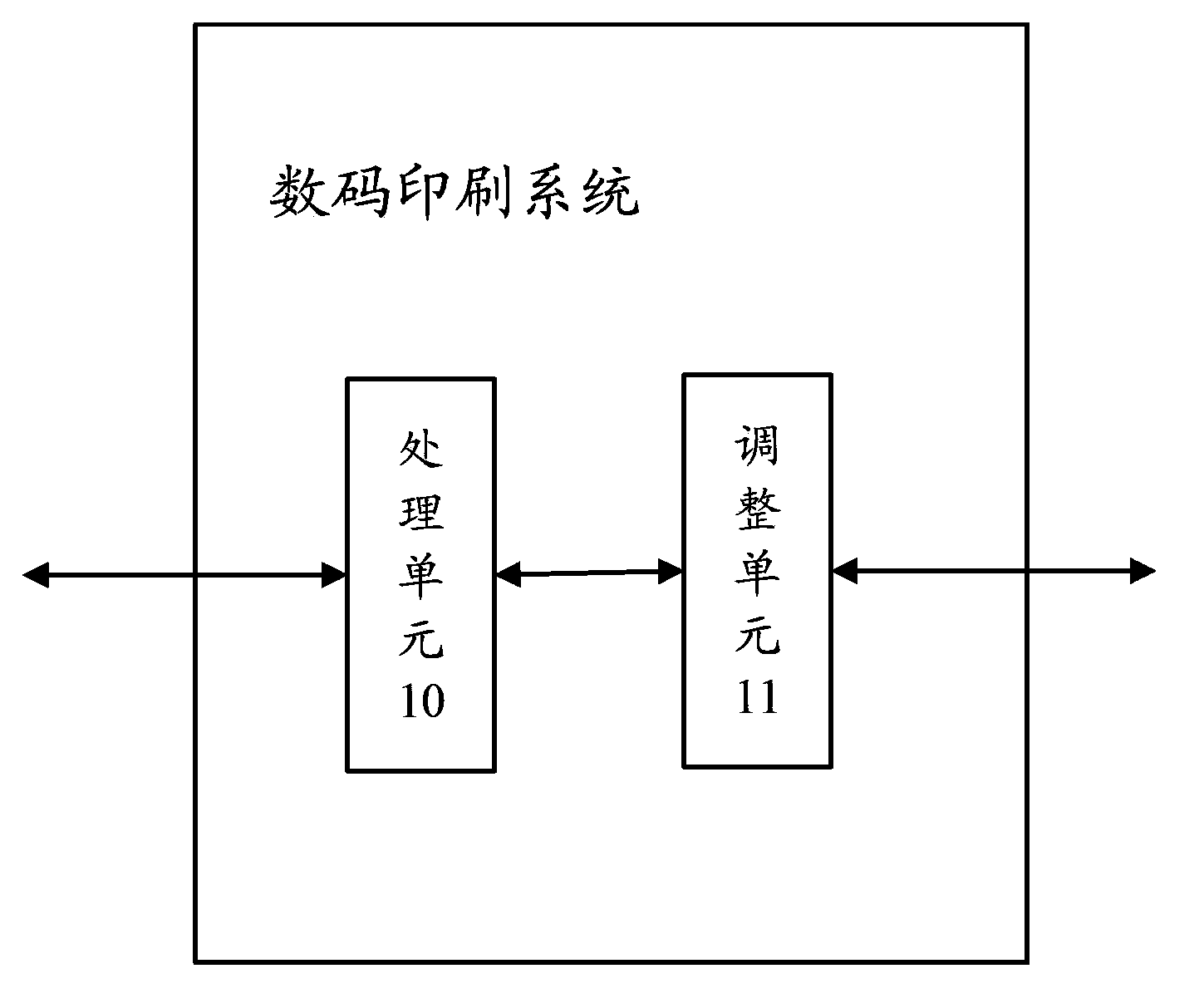

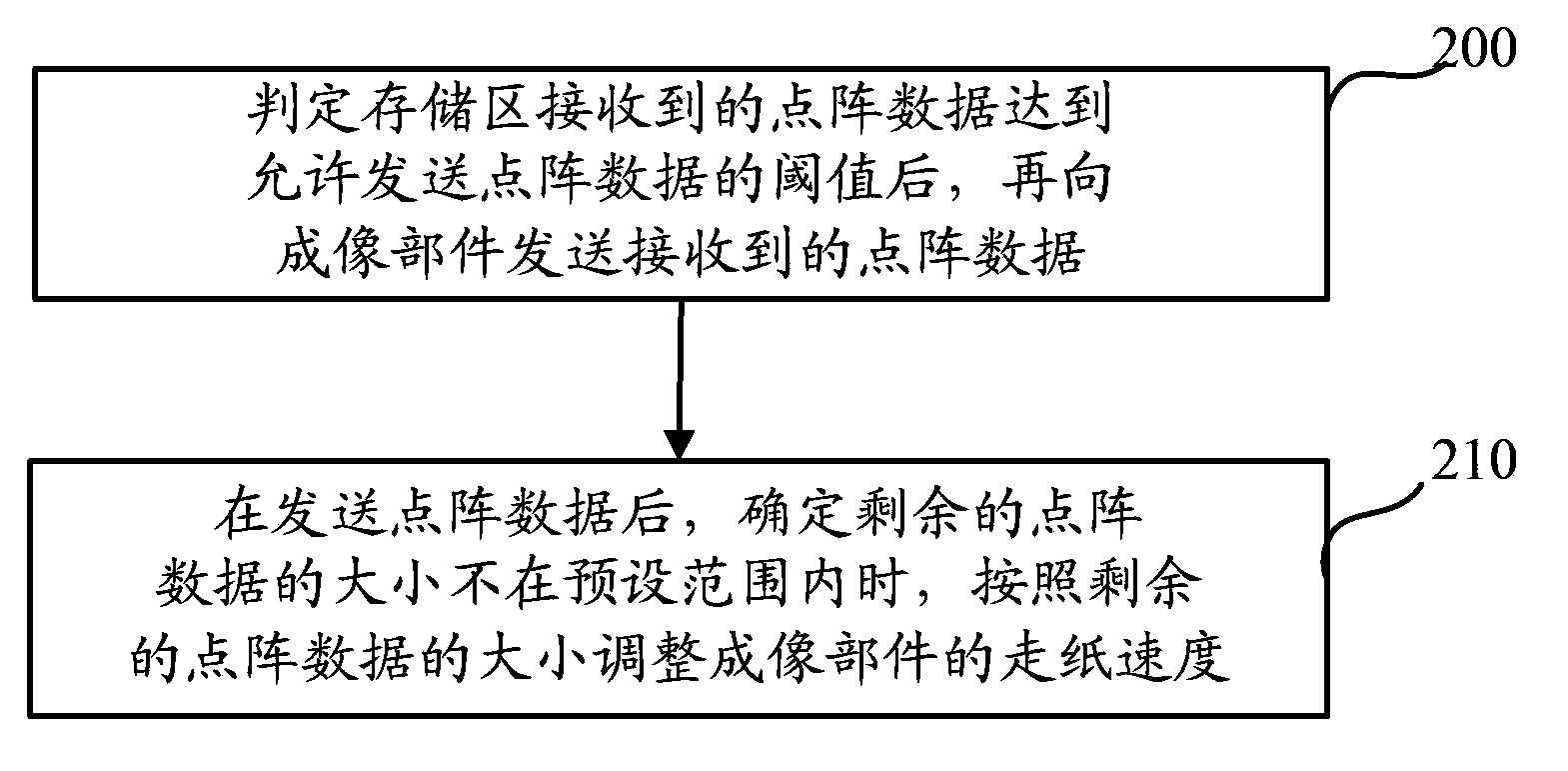

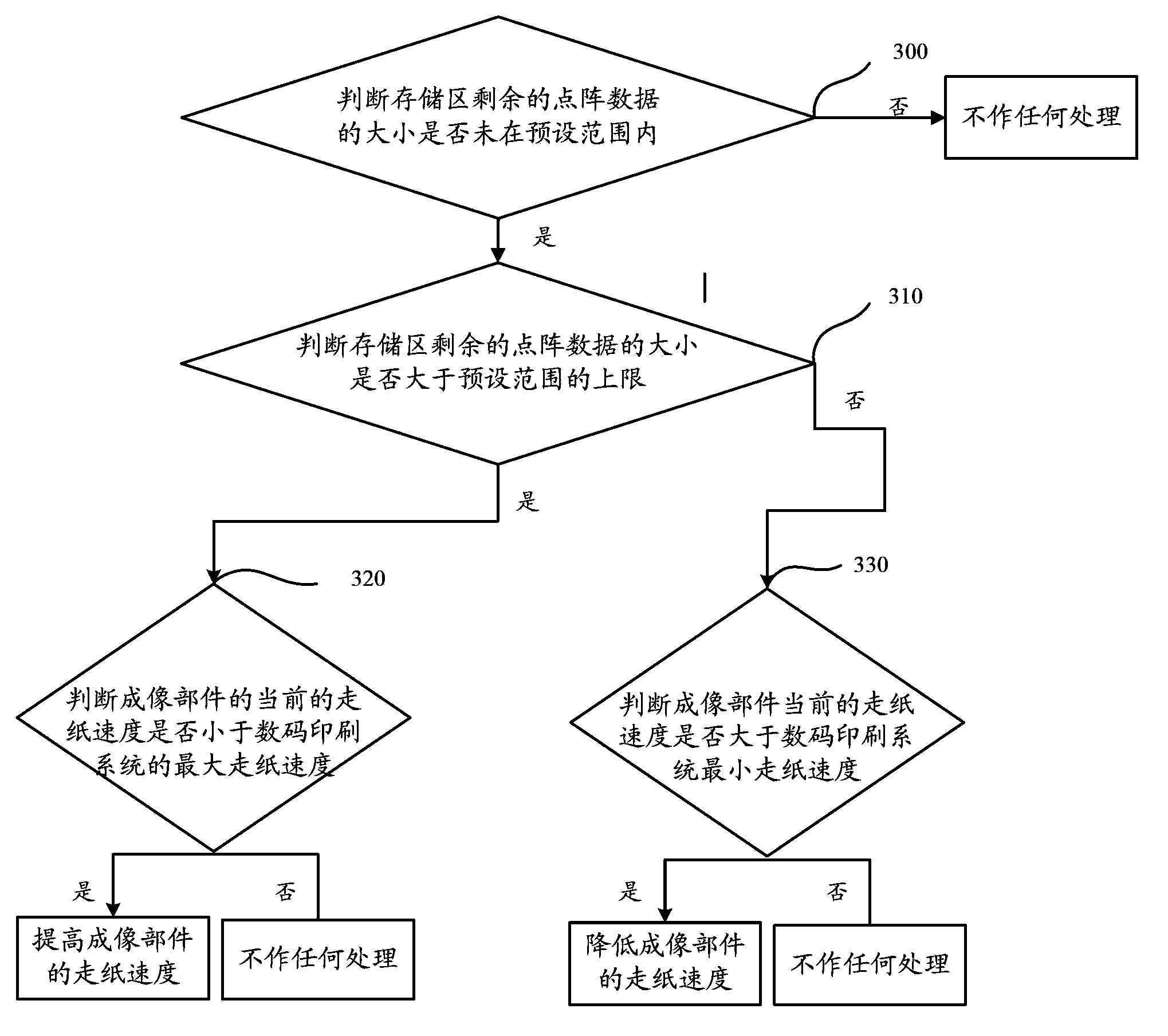

Method and device for adjusting paper speed of digital printing system

InactiveCN103802496AGuaranteed output speedIncrease the output speedVisual presentation using printersOther printing apparatusDigital printingElectrical and Electronics engineering

The invention relates to the technical field of digital printing and discloses a method and a device for adjusting the paper speed of a digital printing system. The method and the device are used for improving the digital printing system printing quality, reducing waste of paper, labor and time and improving the imaging speed and stability of the digital printing system. The method comprises that the digital printing system determines received lattice data reaches thresholds of allowed sending lattice data and then sends the received lattice data to an imaging part; when the remaining lattice data sizes are not in a preset range after the lattice data are sent, the paper speed of the imaging part is adjusted according to the remaining lattice data sizes, and accordingly, that the output speed of the lattice data is far higher than the consumption speed during lattice data printing is prevented from being guaranteed through a server, and effects on the imaging speed and stability during improving of the printing quality through the server are prevented.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

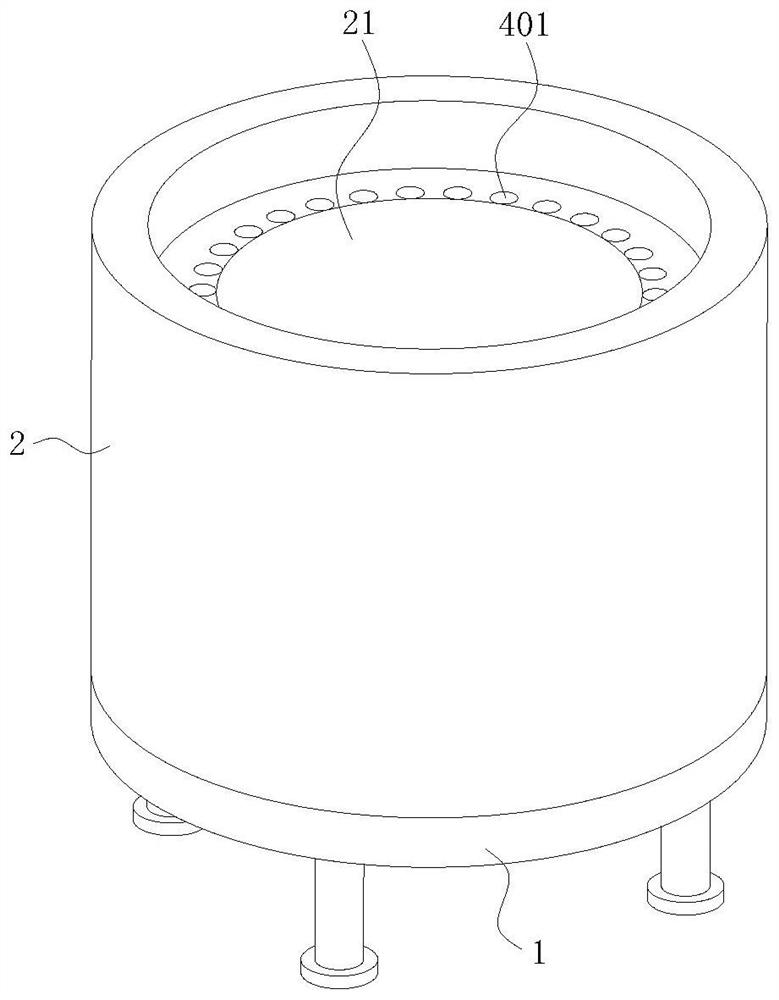

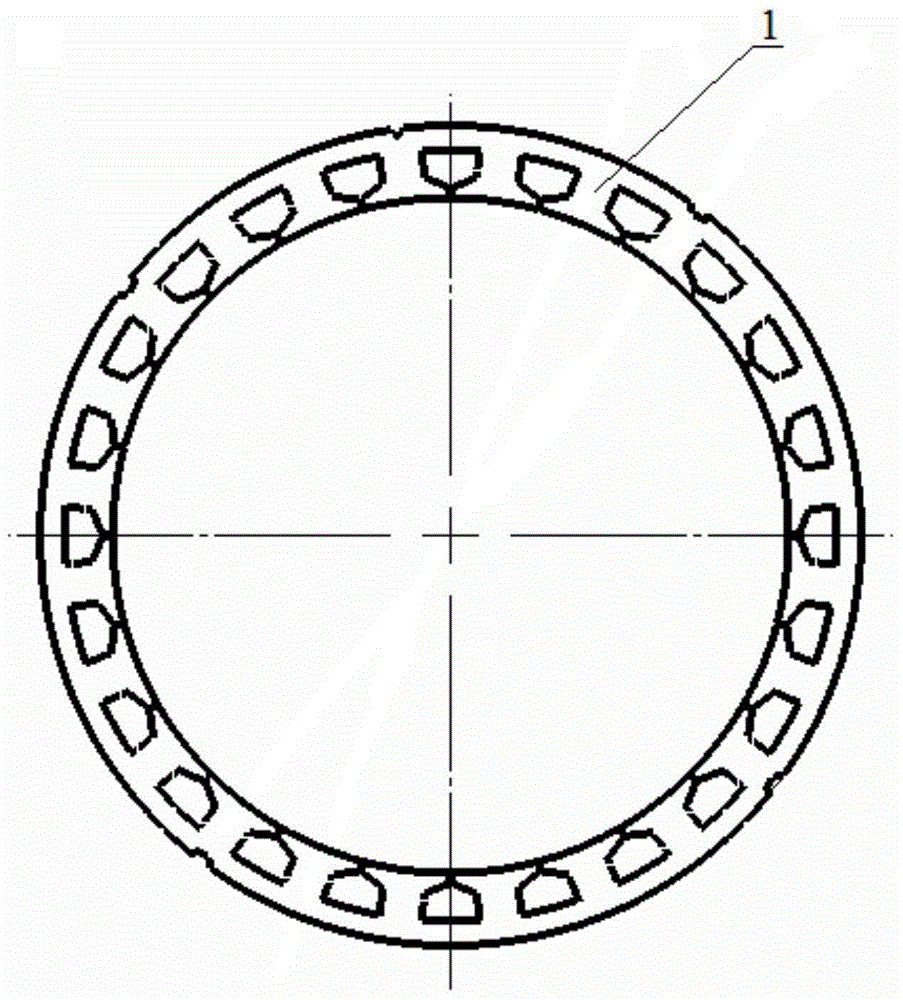

Flour mill for collecting and preparing samples

ActiveCN105833964AReduce wearExtended service lifePreparing sample for investigationGrain treatmentsEngineeringSieve

The invention discloses a flour mill for collecting and preparing samples. The flour mill comprises a flour milling cavity, wherein a feeding opening is formed in the flour milling cavity; a rotary flour-milling rotating blade assembly is arranged inside the flour milling cavity; an annular crushing area used for crushing samples and an annular sieve net area used for filtering samples are formed in the inner annular surface of the rotating circumference of the flour-milling rotating blade assembly in the flour milling cavity; the flour-milling rotating blade assembly rotates at high speed in the flour milling cavity and cooperates with the annular crushing area to collide and crush the samples and then discharge the samples through the annular sieve net. The flour mill has the advantages that the structure is simple and compact, the crushing and sample-preparing accuracy can be further improved, and the service life of the flour mill is prolonged.

Owner:HUNAN SUNDY SCI & TECH DEV

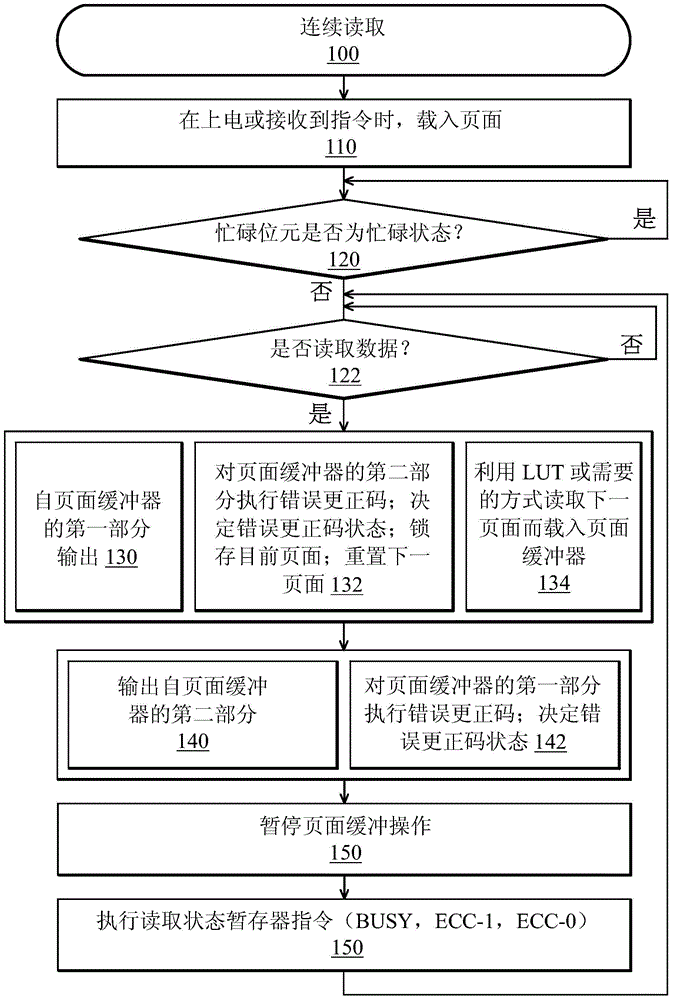

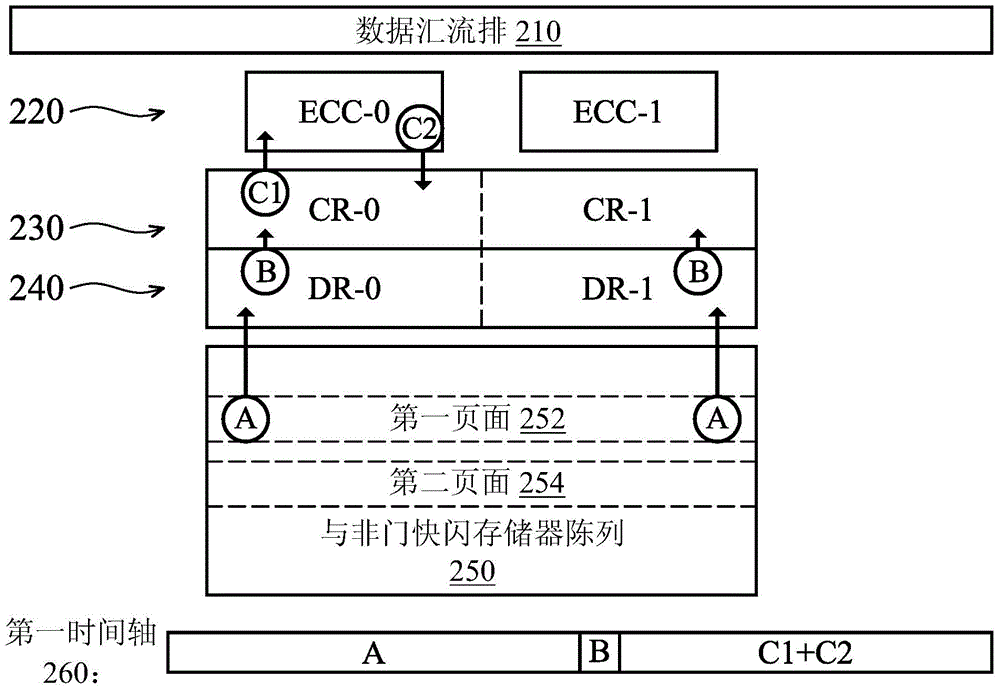

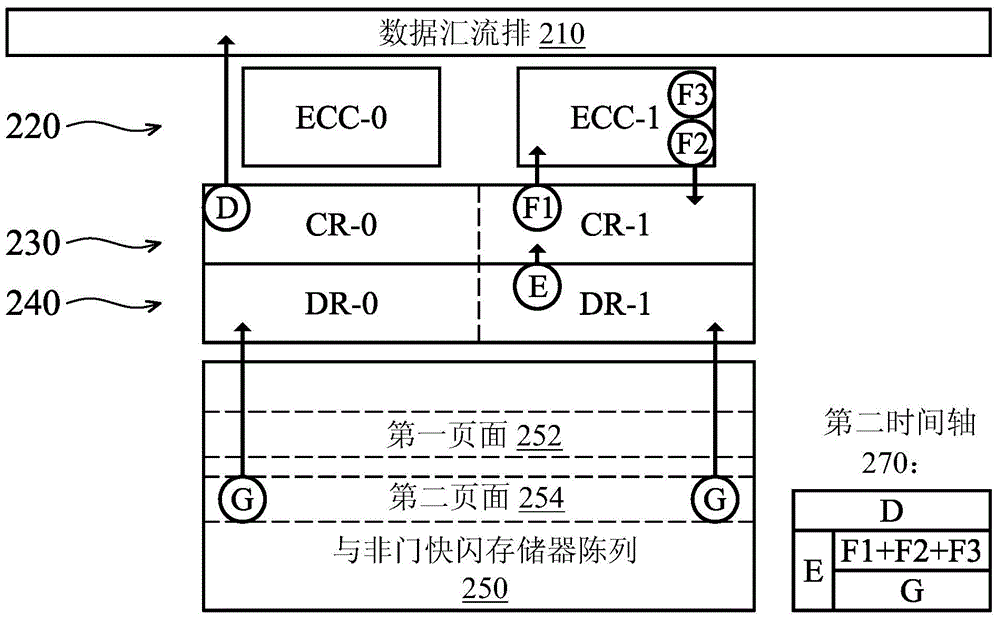

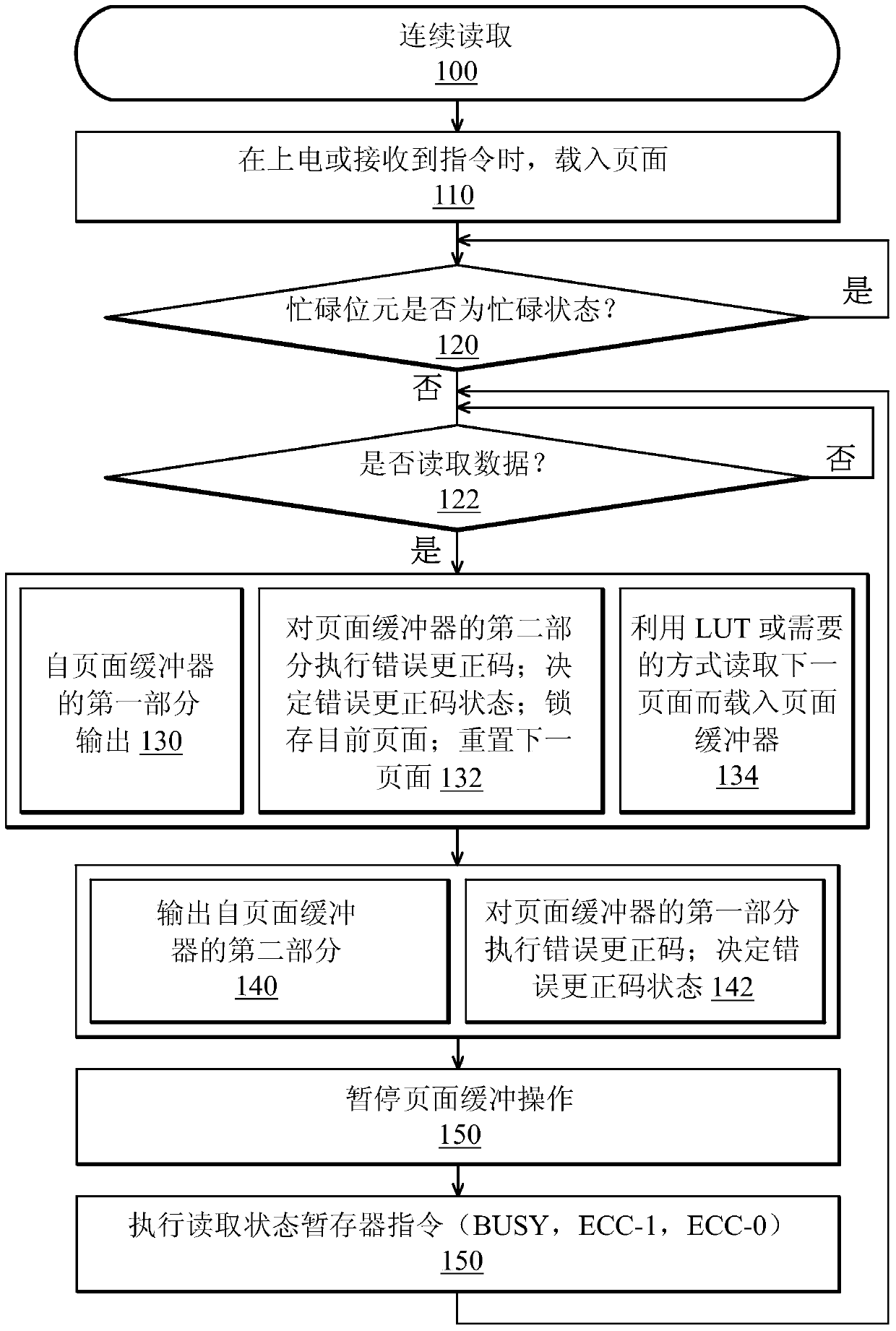

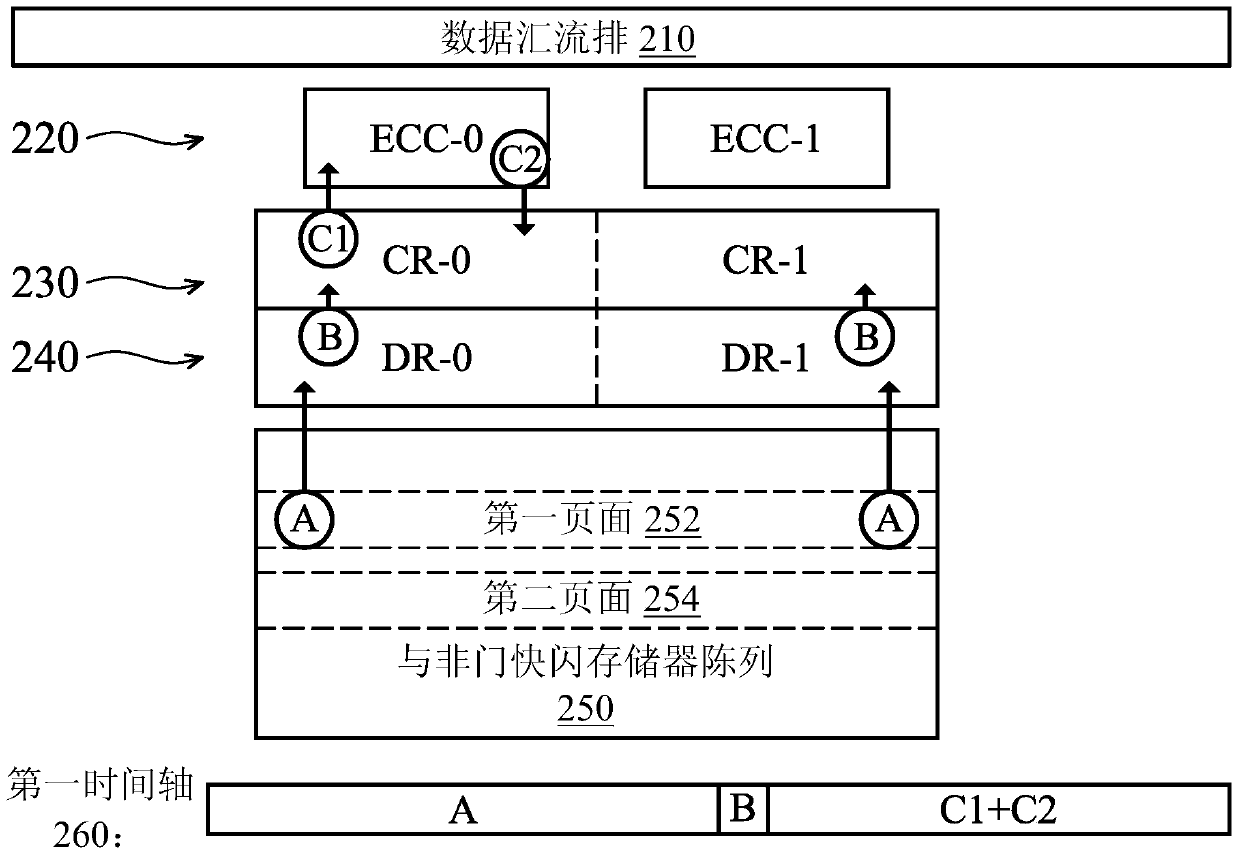

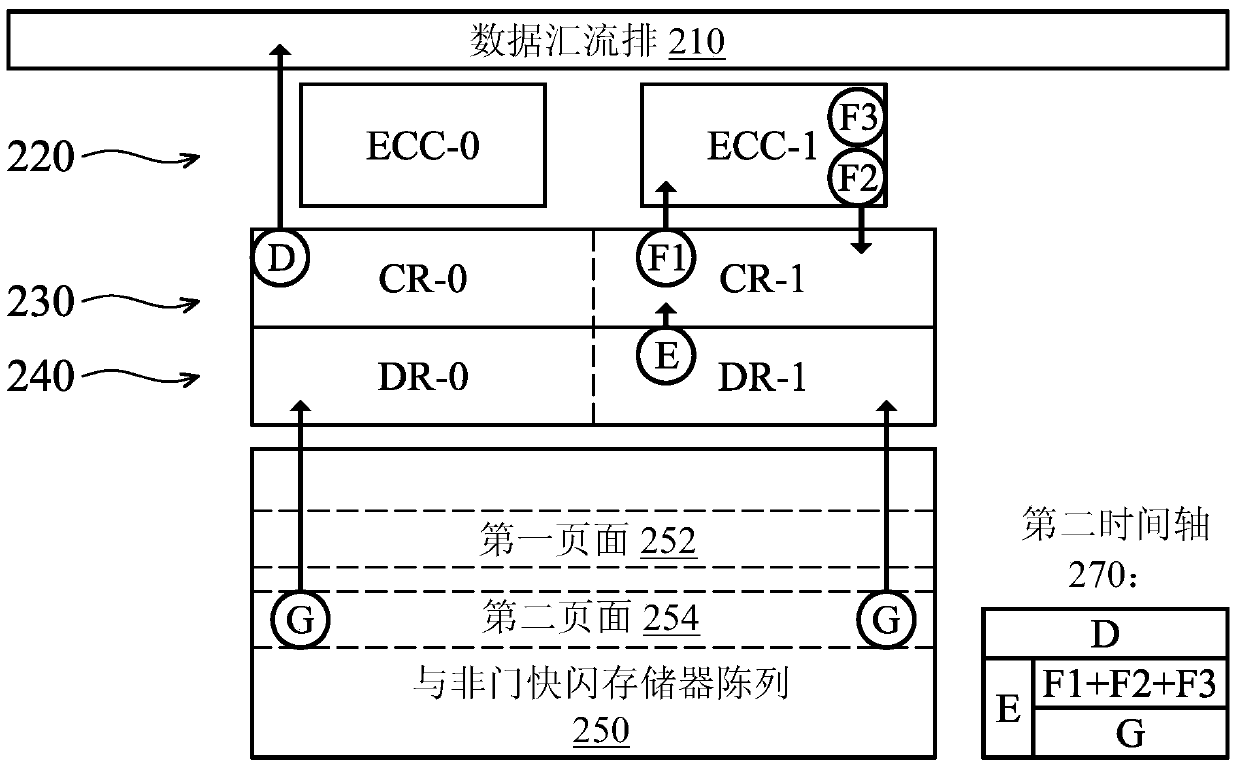

Memory reading method and digital memory device

ActiveCN105825894ALess number of pinsGuaranteed output speedRead-only memoriesScratchpad memoryDigital memory

The invention provides a memory reading method and a digital memory device. The digital memory device is divided into a data temporary memory and a data buffer of a cache register, an internal error correction code relative to the cache register and set by a user, and a rapid bad block management. When data reading is carried out, the internal error correction code is displayed by an error correction code status bit. The status (1:1) can represent that the output data of the whole multi-page includes a continuous read-out mode of more than 4 bit errors on each page, the state of the error correction code of each page or each page partition are required to be known, for the former, when the output page is finished, the state of the error correction code of the whole page is determined, and is stored in a state buffer; for the latter, before the corresponding page partition is output, the state of the error correction code of each page partition is determined and output. The error correction code treatment is integrated, and waiting time is not required.

Owner:WINBOND ELECTRONICS CORP

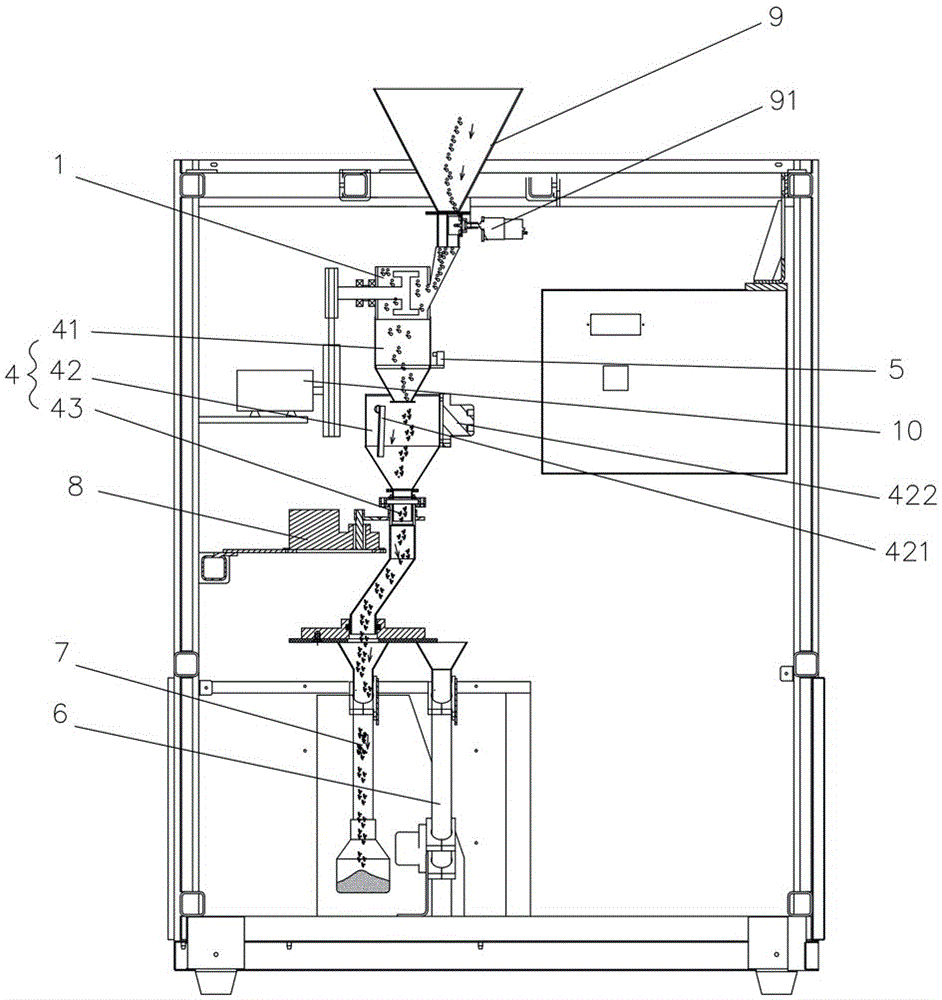

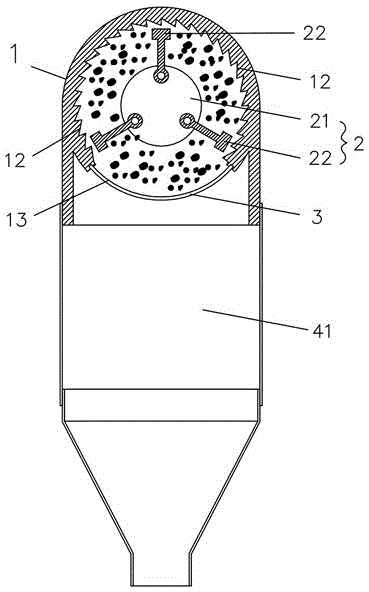

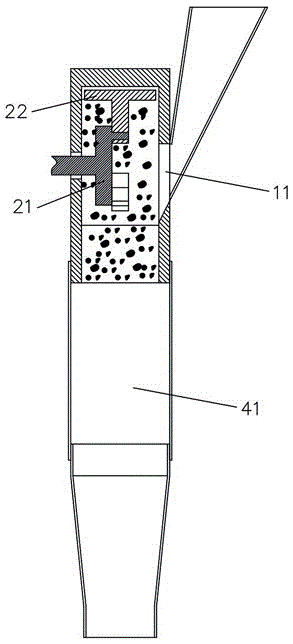

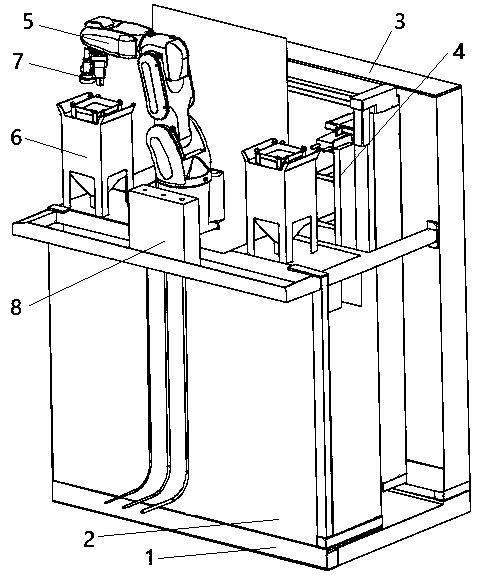

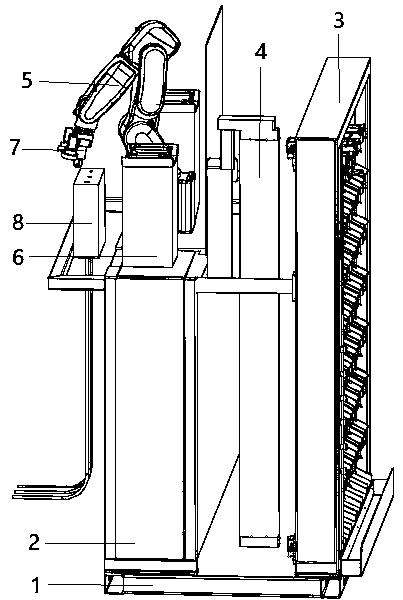

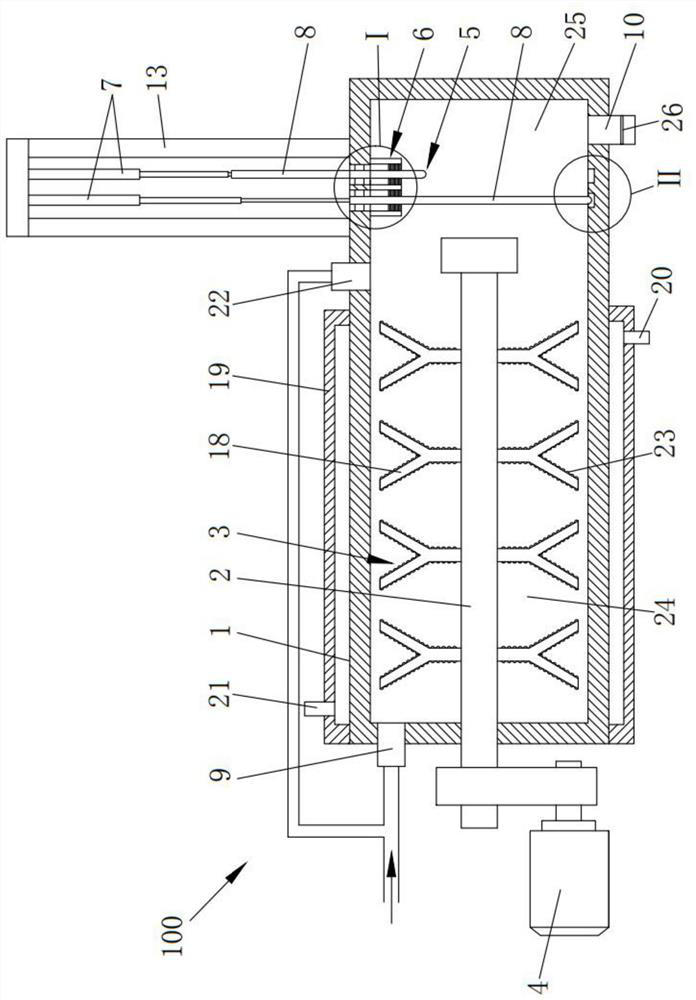

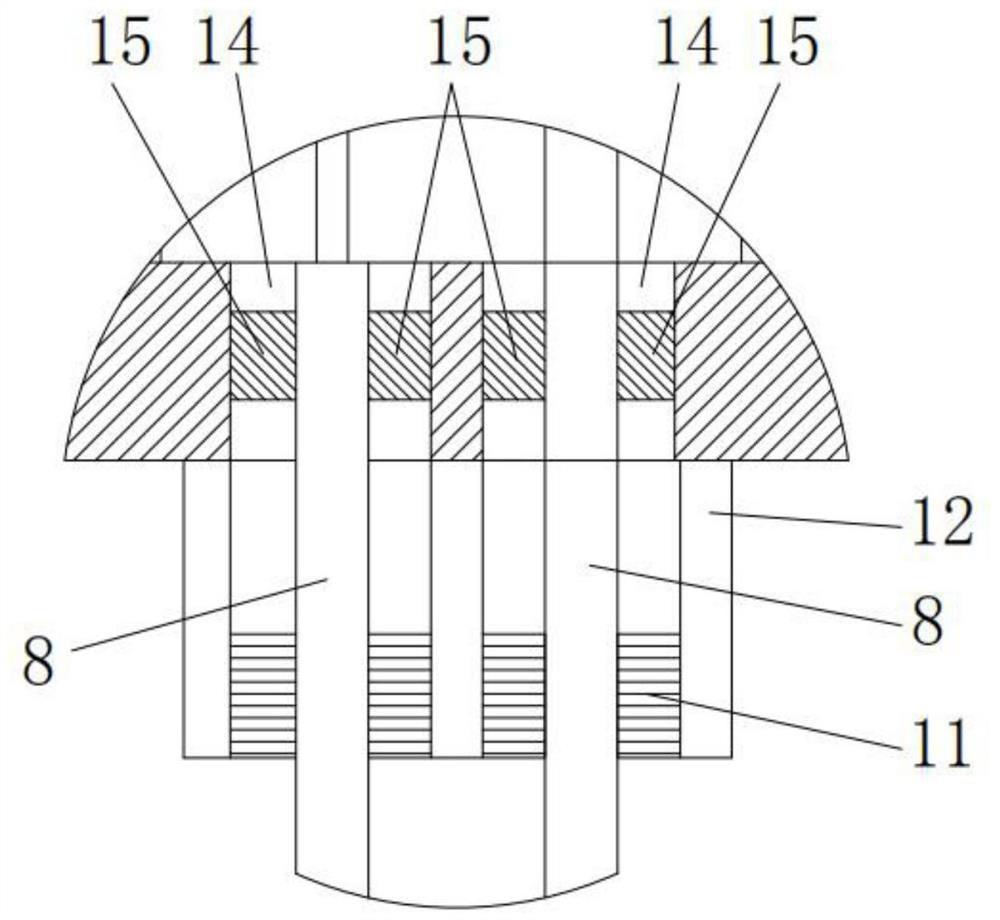

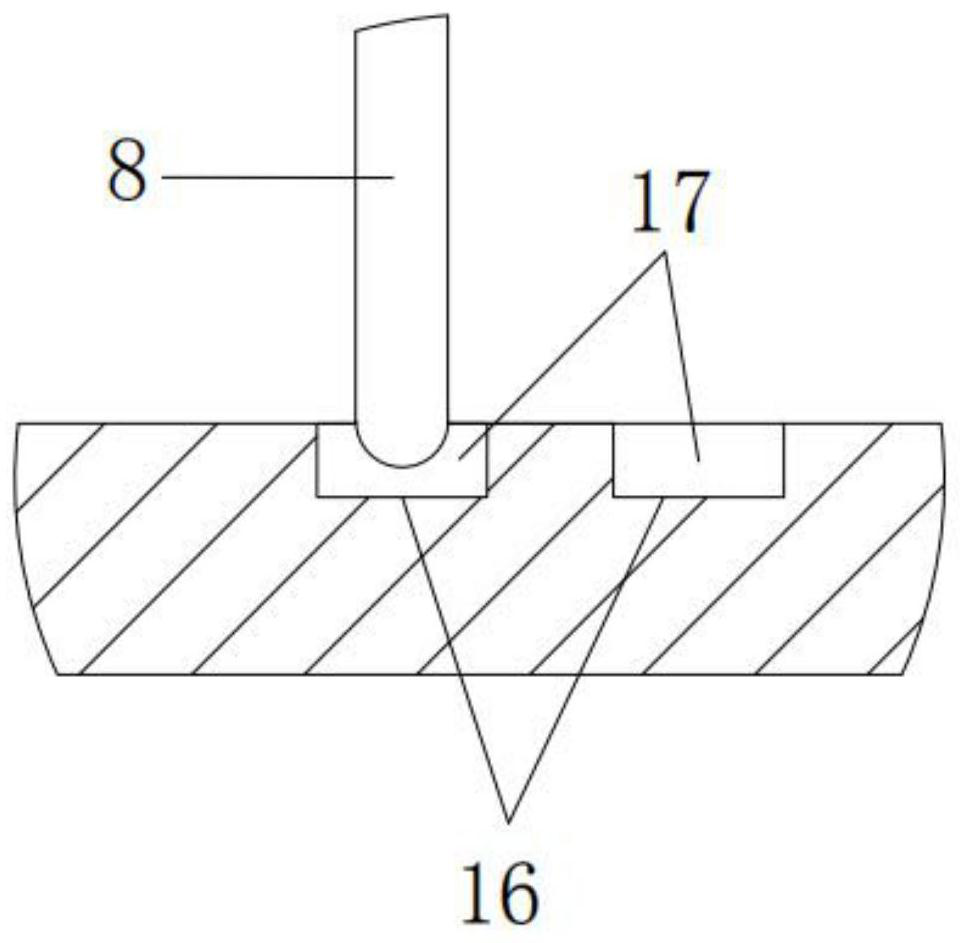

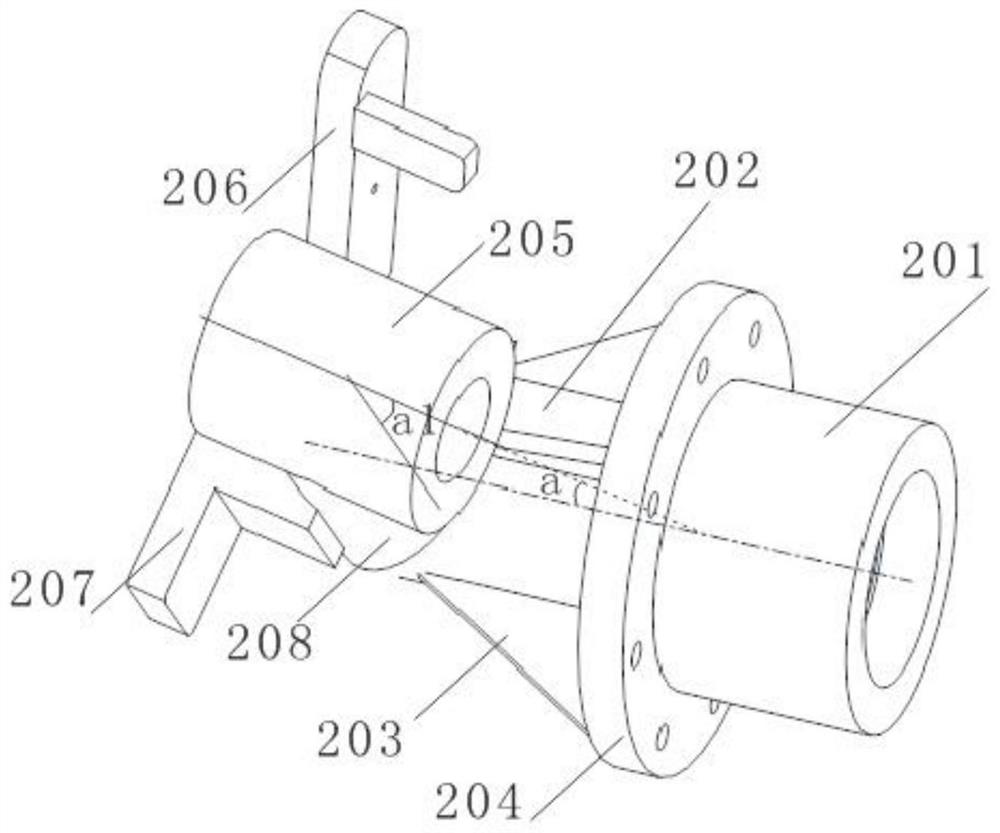

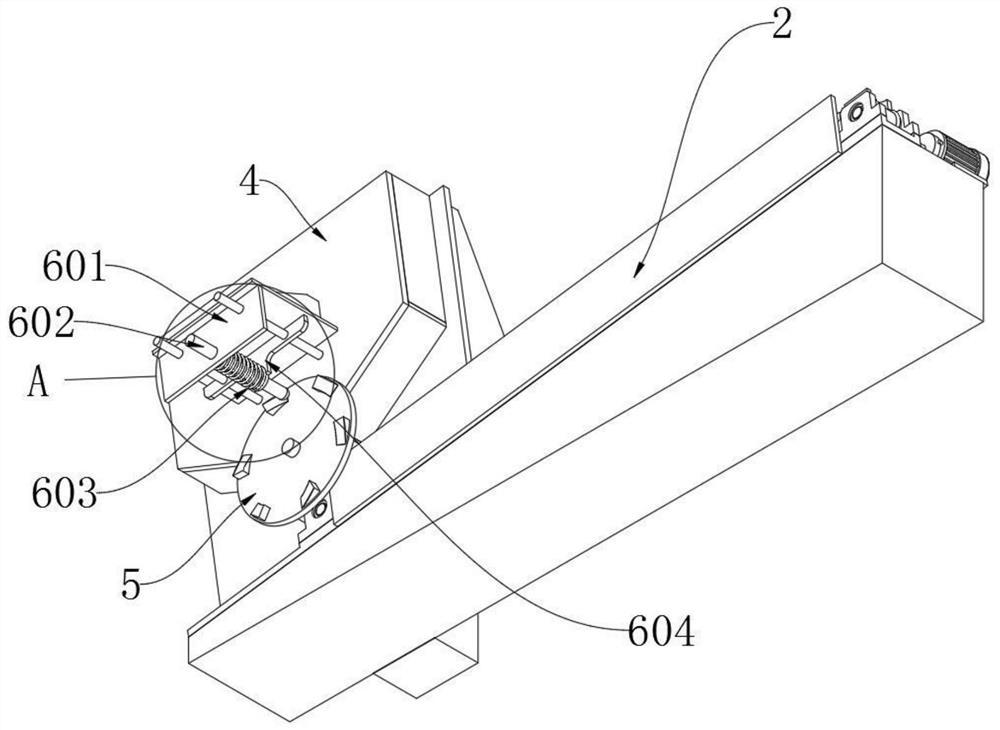

A robot-based automatic nail feeding system and its working method

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

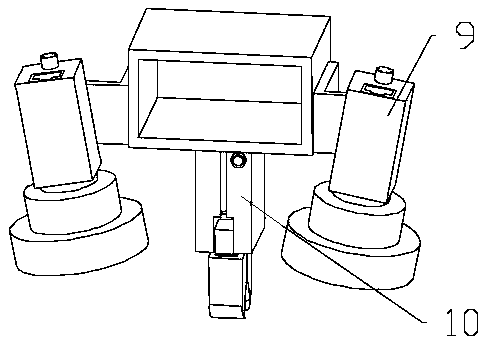

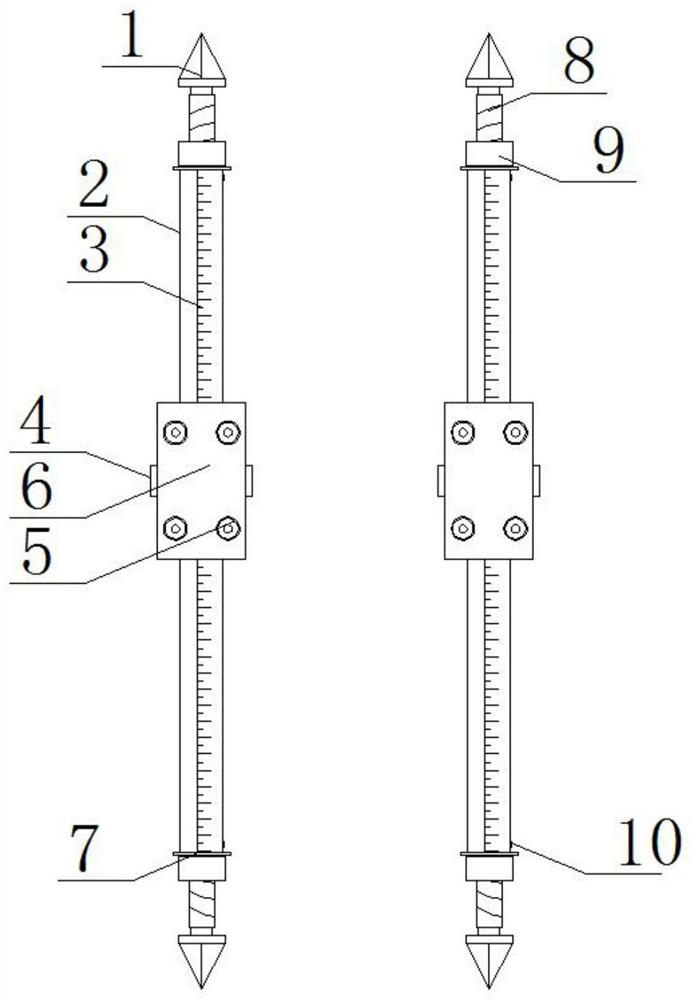

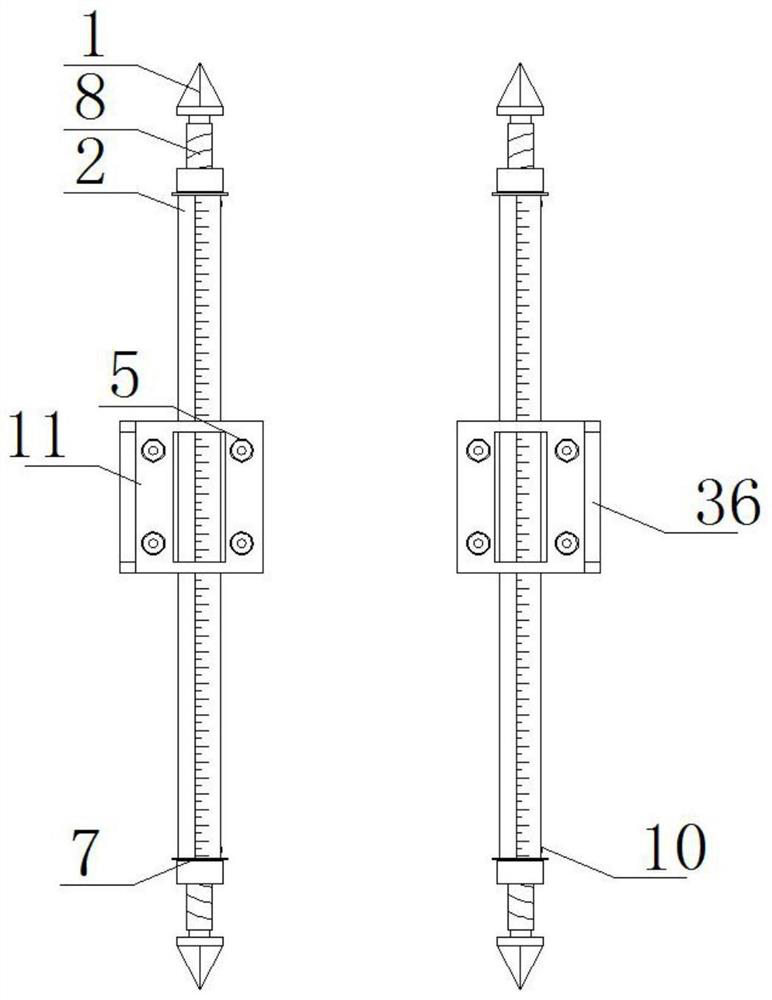

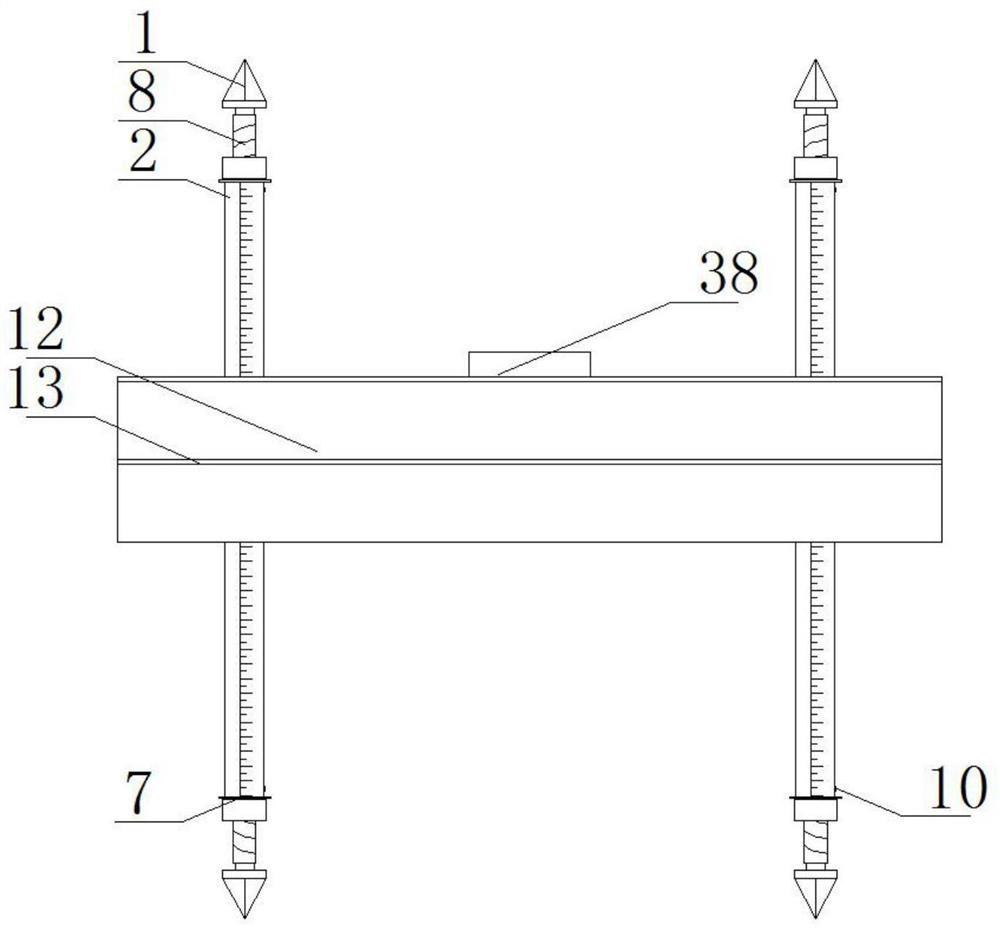

Zero-foundation wall building rapid-forming system

PendingCN112049438AGuaranteed to be verticalEnsure standard specificationsBuilding material handlingArchitectural engineeringPipe

The invention discloses a zero-foundation wall building rapid-forming system. The zero-foundation wall building rapid-forming system comprises a self-plane wall building horizontal ruler and a hand-cranking type self-shaping mortar laying vehicle, wherein the self-plane wall building horizontal ruler comprises two circular steel pipes, scale lines are arranged on the two circular steel pipes, andsliding sleeves are detachably connected to the two circular steel pipes; second fastening bolts are mounted on the sliding sleeves, baffles are detachably connected to one sides of the sliding sleeves, and a transverse horizontal ruler is detachably connected to one sides of the baffles; and an L-shaped plate is fixed to the upper end of the transverse horizontal ruler. The zero-foundation wall building rapid-forming system serves as an auxiliary tool for building wall building and has the characteristics that the efficiency is high, the effect is good, operation is easy, carrying is convenient, material waste caused by slow-down rework is eradicated, and energy is not consumed; and foundation-free personnel can conveniently and rapidly conduct wall building operation, the zero-foundationwall building rapid-forming system can well adapt to various construction environments, the standard degree of wall building operation is increased, meanwhile, the mortar discharging speed can be well guaranteed, mortar laying is conducted according to the needed using amount, and the wall building quality is guaranteed.

Owner:唐传轶

Energy-saving cereal food grinding equipment

The invention relates to the technical field of grinding equipment, and discloses energy-saving whole grain food grinding equipment which comprises a rotating shaft, grinding hammers and a discharging port, reciprocating threads are fixedly arranged on the outer side of the rotating shaft, and a movable plate is movably connected to the outer side of the rotating shaft and located at the reciprocating threads in a sleeving mode. Connecting rods are fixedly connected to the positions, located on the two sides of the rotating shaft, of the top face of the movable plate, through grooves are formed in the upper portions of the interiors of the connecting rods, special-shaped plates are fixedly connected to the top ends of the connecting rods, dredging rods are fixedly connected to the left end and the right end of the bottom face of the movable plate, and air cavities are formed in the upper portions of the interiors of the grinding hammers. An air bag is fixedly connected to the middle of the bottom face of the air cavity. The movable plate is driven to move up and down through rotation of the rotating shaft under the action of reciprocating threads, so that the air bag is extruded through the connecting rod and the special-shaped plate, gas in the air bag blows off coarse cereal powder adhered to the material grinding plate, the contact area between coarse cereals and the material grinding plate is increased, and the working efficiency of the powder grinding equipment is improved.

Owner:DONGTAI XINFUDA MACHINERY

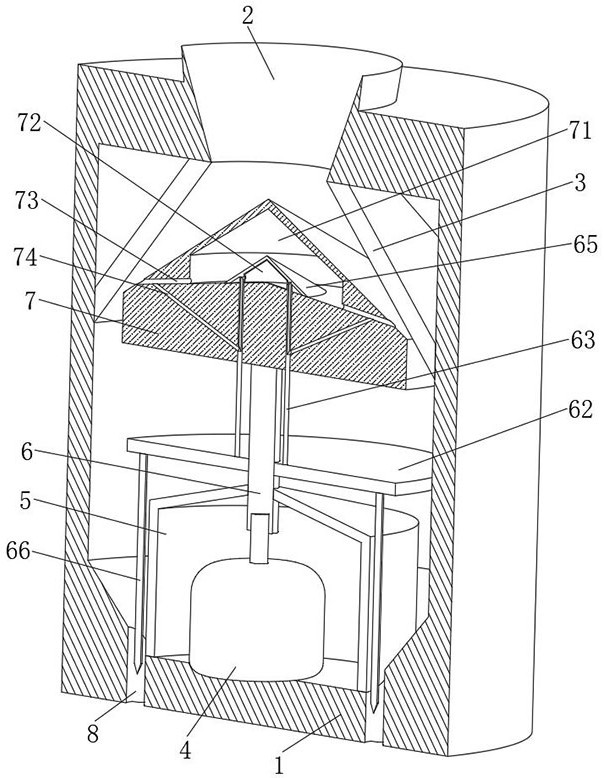

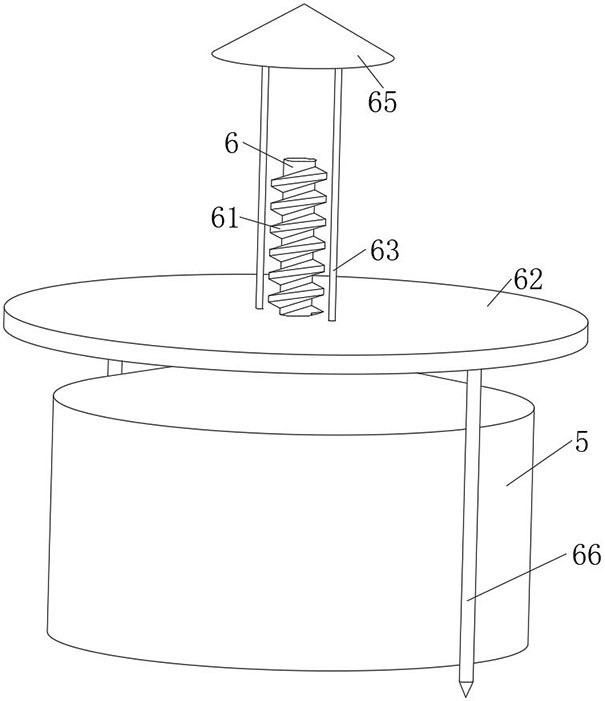

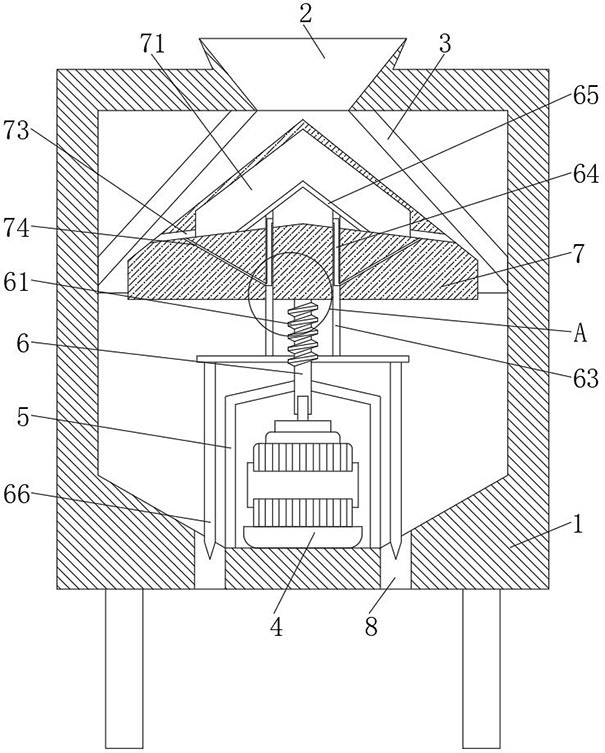

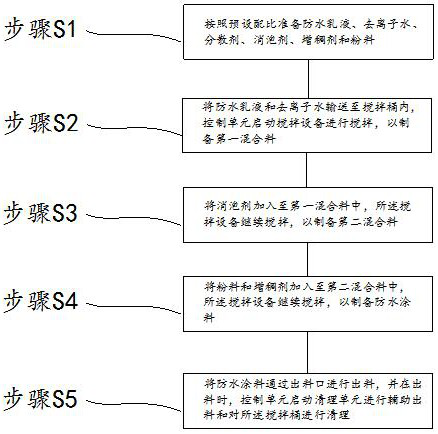

Preparation method of heat-insulating waterproof coating

ActiveCN113828238AReduce adhesionImprove cleaning efficiencyRotary stirring mixersMixer accessoriesEmulsionPhysical chemistry

The invention relates to a preparation method of a heat-insulating waterproof coating, which comprises the following steps: step S1, preparing a waterproof emulsion, deionized water, a dispersing agent, a defoaming agent, a thickening agent and a powder material according to a preset ratio; S2, conveying a waterproof emulsion and the deionized water into a stirring barrel through a feeding port, enabling a control unit to start stirring equipment to stir raw materials in the stirring barrel, and preparing a first mixture; S3, adding a defoaming agent into the first mixture, and continuously stirring by the stirring equipment to prepare a second mixture; S4, adding the powder and the thickening agent into the second mixture, and continuously stirring by the stirring equipment to prepare a waterproof coating; and S5, during discharging, enabling the control unit to start a cleaning unit to assist in discharging and clean the stirring barrel. While the discharging speed is guaranteed, the situation that the waterproof coating is attached to the inner wall of the stirring barrel can be effectively reduced, and then the cleaning efficiency of the inner wall of the stirring barrel is improved.

Owner:潍坊市宇虹防水材料(集团)有限公司

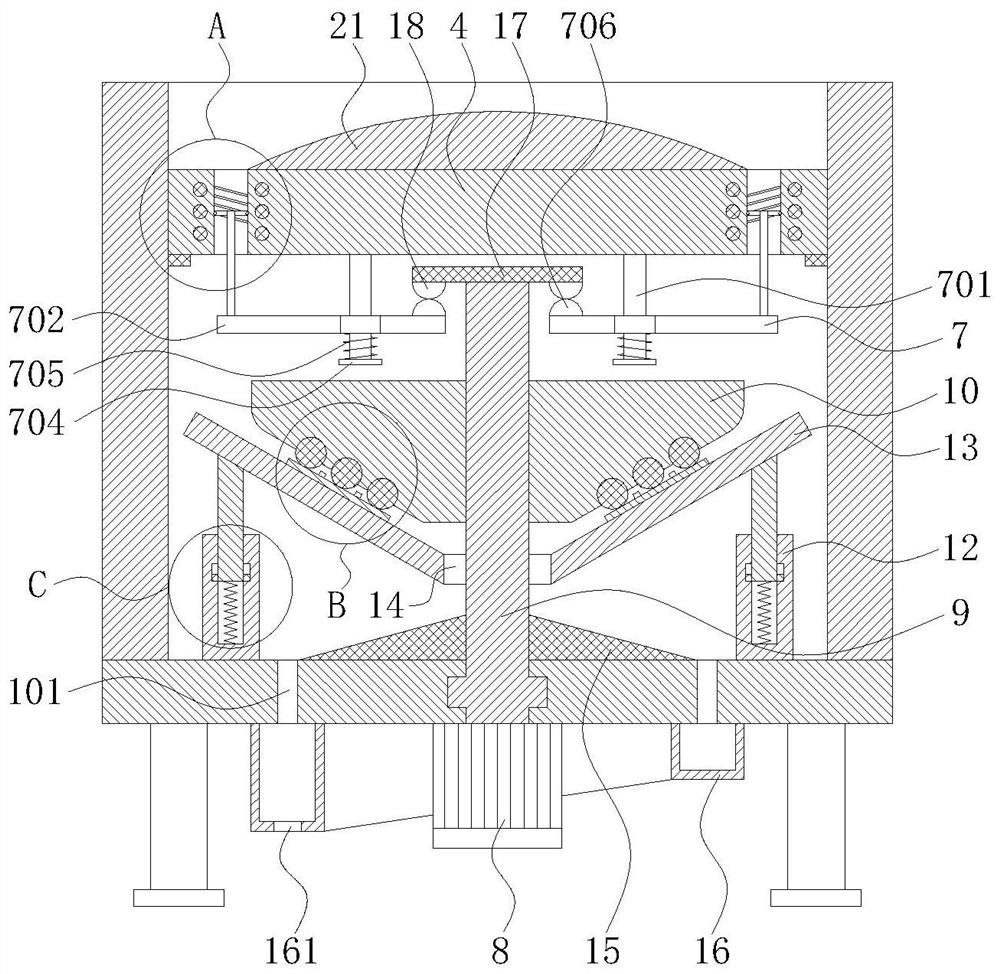

Automatic stone mill flour production unit

The invention belongs to the technical field of flour, and particularly relates to an automatic production unit for stone-milled flour, in the production process of the stone-milled flour, raw materials are heated and dried before being milled, and the raw materials are smashed through a smashing mechanism, so that agglomeration among the raw materials is avoided; therefore, the raw materials can smoothly enter the space between the upper millstone and the lower millstone, and the discharging speed is guaranteed; in the stone mill flour production process, the stone mill balls roll on the lower millstone to mill raw materials, flour attached to the stone mill balls can be scraped off at the edge, making contact with the upper millstone, of the stone mill balls, and therefore the flour is prevented from being attached to the surfaces of the stone mill balls; in the rotating process of the upper millstone and the stone milling balls, the lower millstone vibrates in the vertical direction, so that flour attached to the lower millstone falls off through vibration, the discharging speed is guaranteed, and the milling effect of the stone milling balls is also guaranteed.

Owner:宜川兴华酒业有限责任公司

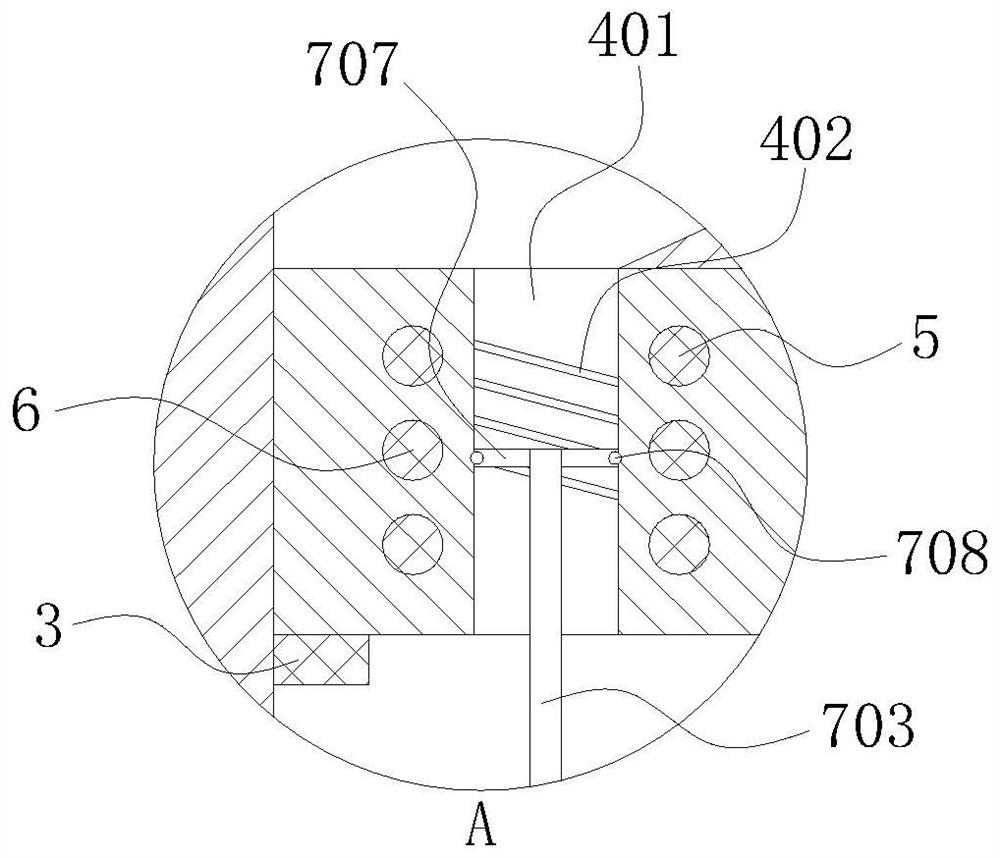

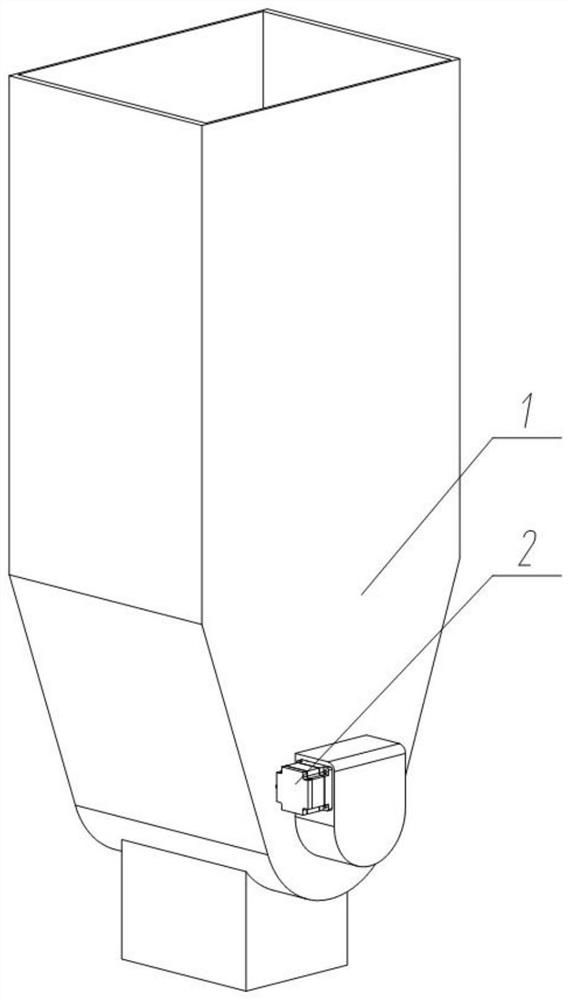

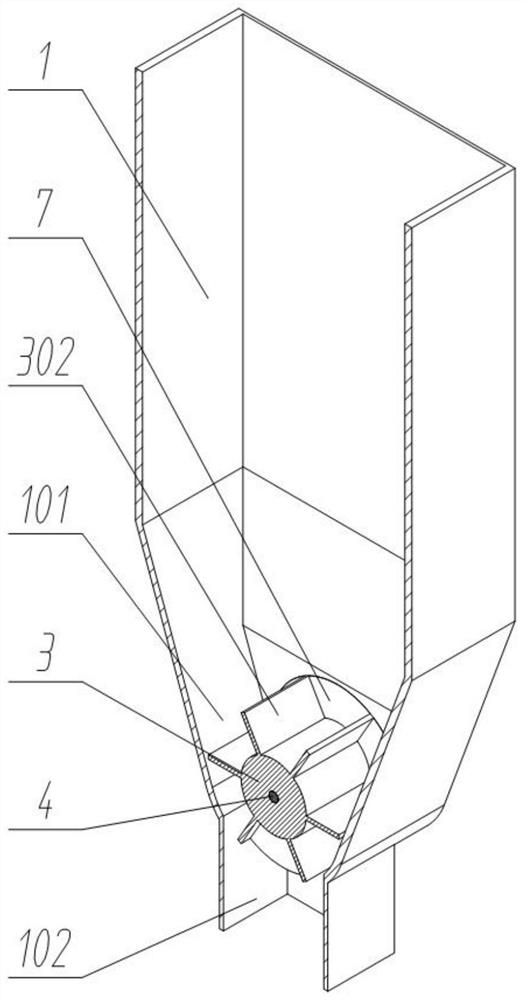

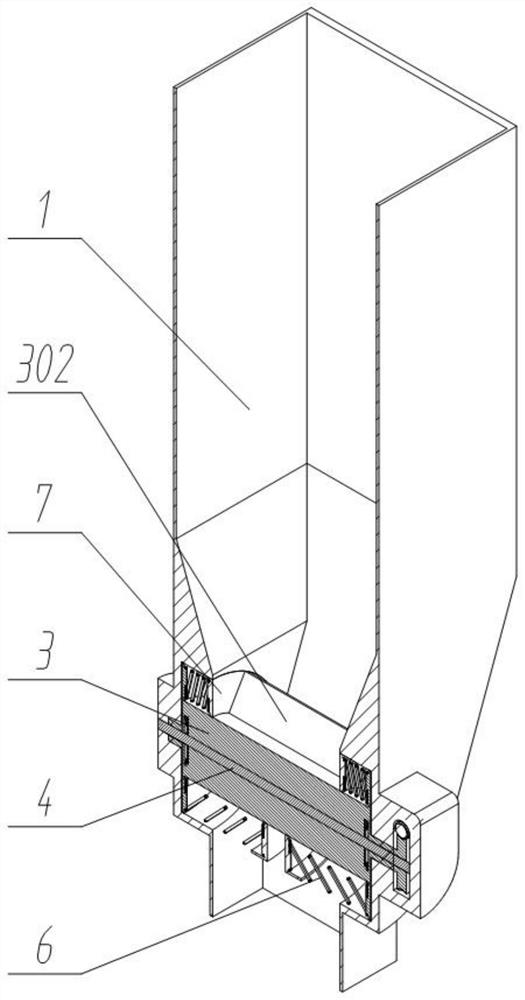

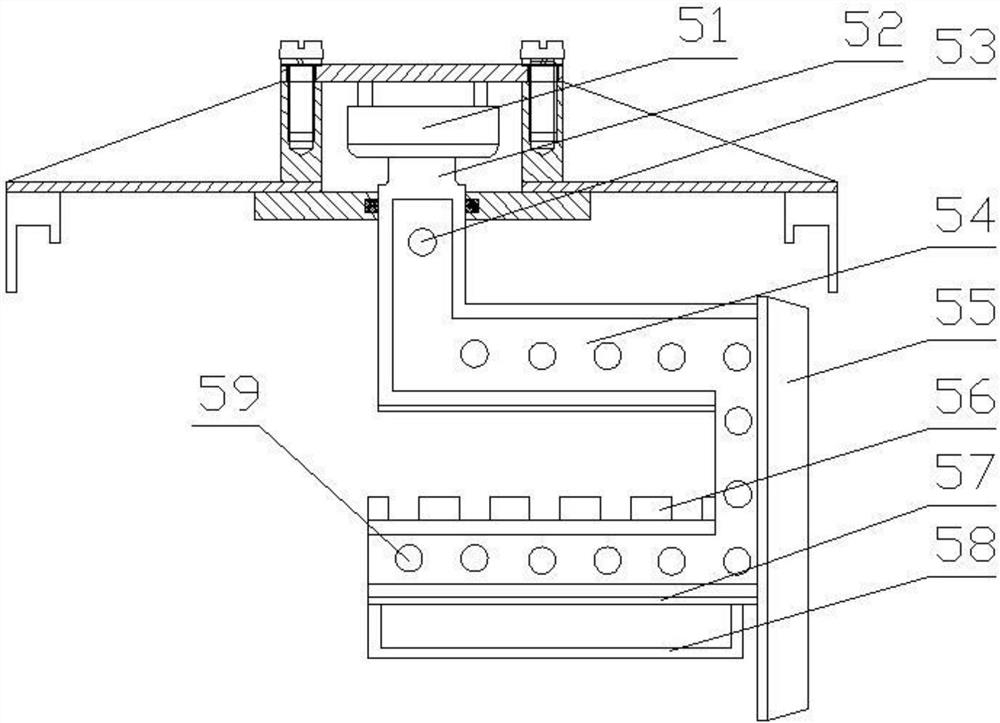

Clinker discharging device for cement production and processing

ActiveCN114684631AAvoid cloggingControl the output speedLarge containersLoading/unloadingProcess engineeringMechanical engineering

The invention provides a clinker discharging device for cement production and processing, and relates to the technical field of cement production. The discharging speed control part is rotationally connected to the lower part of the interior of the clinker discharging hopper; the discharging transmission mechanism is arranged in the right side of the clinker discharging hopper; the cleaning push plates are arranged in pairs, the six pairs of cleaning push plates are arranged, and the six pairs of cleaning push plates are distributed in a circumferential array mode and are slidably connected to the left side and the right side of the clinker discharging hopper; and the cleaning driving mechanism is arranged in the discharging speed control piece, and the discharging speed control piece drives the cleaning push plate to slide left and right through the cleaning driving mechanism. The discharging speed is effectively controlled, materials are effectively prevented from being hardened and blocking the discharging port, smooth discharging is guaranteed, the discharging speed is increased, the follow-up machining quality is guaranteed, and the problems that the discharging speed of an existing clinker bin is difficult to control, and the materials are prone to being hardened and blocking the discharging port to affect the discharging effect are solved.

Owner:GUANGYUAN GUANGWANG LUJIABA CEMENT

Paint sand mill

PendingCN113083448AAvoid lostRealize continuous productionSievingScreeningEngineeringMechanical engineering

The invention discloses a paint sand mill and relates to the technical field of paint coating production equipment. A filter screen set is arranged in a grinding box and divides an inner cavity of the grinding box into a first cavity and a second cavity, a rotating shaft is rotationally connected into the first cavity, and a dispersing device is fixedly connected to the rotating shaft; one end of the rotating shaft penetrates through the side wall of the grinding box and is in transmission connection with a driving device, the filter screen set comprises at least two filter screens, each filter screen is connected with a filter screen driving device, each filter screen driving device can drive the corresponding filter screen to move out of or move into the grinding box, and filter screen cleaning devices corresponding to the filter screens are fixedly arranged on the inner wall of the grinding box; and each filter screen cleaning device can clean the corresponding filter screen in the moving process of the filter screen, a feeding port and a discharging port are formed in the grinding box, the feeding port communicates with the first cavity, and the discharging port communicates with the second cavity. According to the paint sand mill, the filter screens can be cleaned, the discharging speed is guaranteed, in addition, continuous production can be achieved, and the production efficiency is improved.

Owner:开平市优洋化工有限公司

Vehicle tool for complex welding part

PendingCN113752062AImprove processing efficiencyGuaranteed output speedPositioning apparatusMetal-working holdersEngineeringFlange

The invention discloses a vehicle tool for a complex welding part. A supporting assembly used for supporting the complex welding part, pressing assemblies used for pressing the complex welding part and a counterweight assembly are arranged on the front face of a transition disc; the supporting assembly comprises a main supporting part corresponding to the flange plate edge of the complex welding part and an auxiliary movable supporting part corresponding to the thin cylindrical section of the complex welding part, the main supporting part is provided with a large positioning groove matched with the flange plate edge, and the auxiliary movable supporting part is provided with a small positioning groove corresponding to the thin cylindrical section; and the pressing assemblies comprise the first pressing assembly used for pressing a reinforcing rib and the second pressing assembly used for pressing an auxiliary cylindrical section. Through the cooperation of all the components of the vehicle tool, and the complex welding part can be quickly aligned; and after the position of the tool is aligned, follow-up adjustment is not needed, the clamping efficiency is improved, the output speed of workpieces is greatly guaranteed, the production rhythm is guaranteed, and the problem of narrow opening production is solved.

Owner:HUBEI JIANGSHAN HEAVY IND

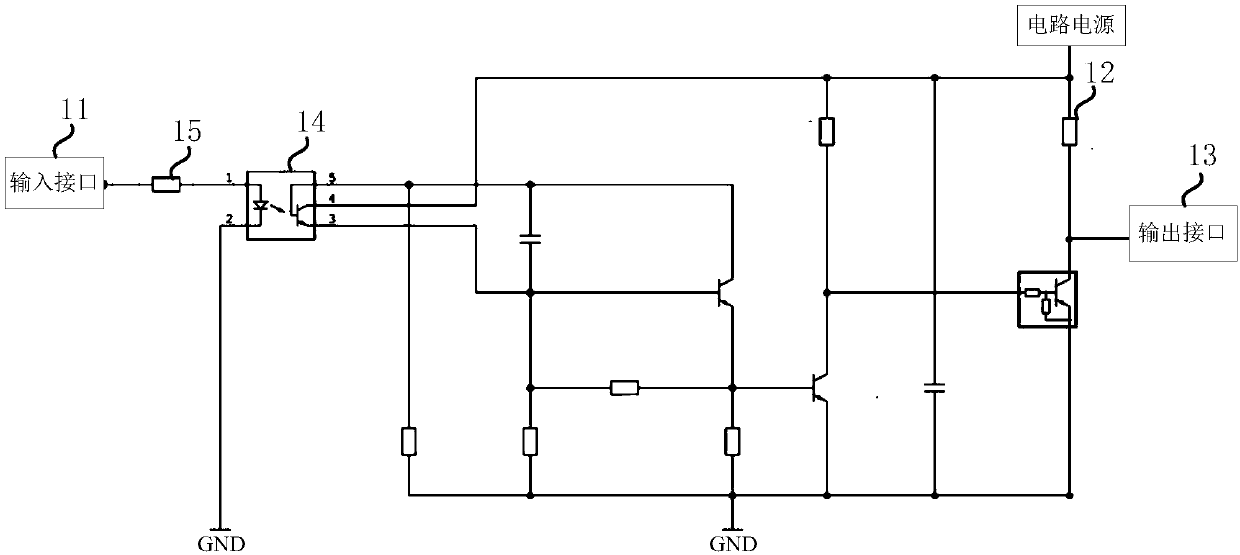

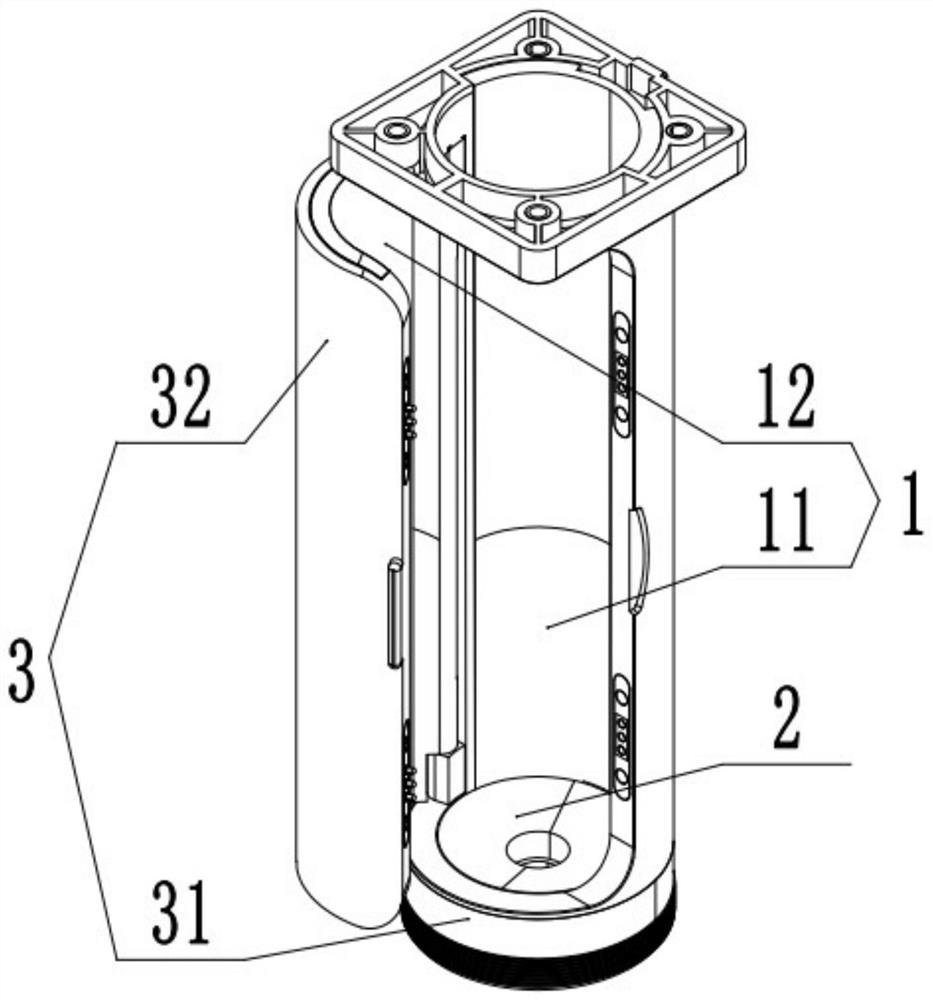

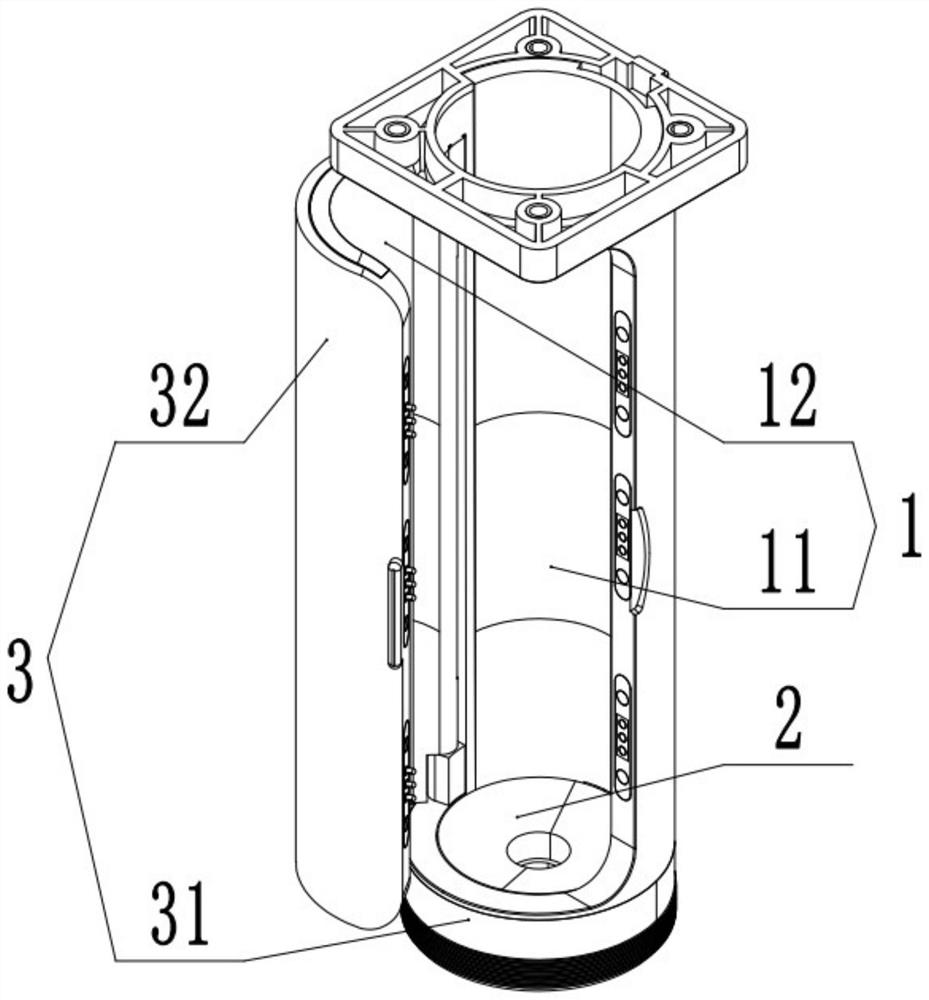

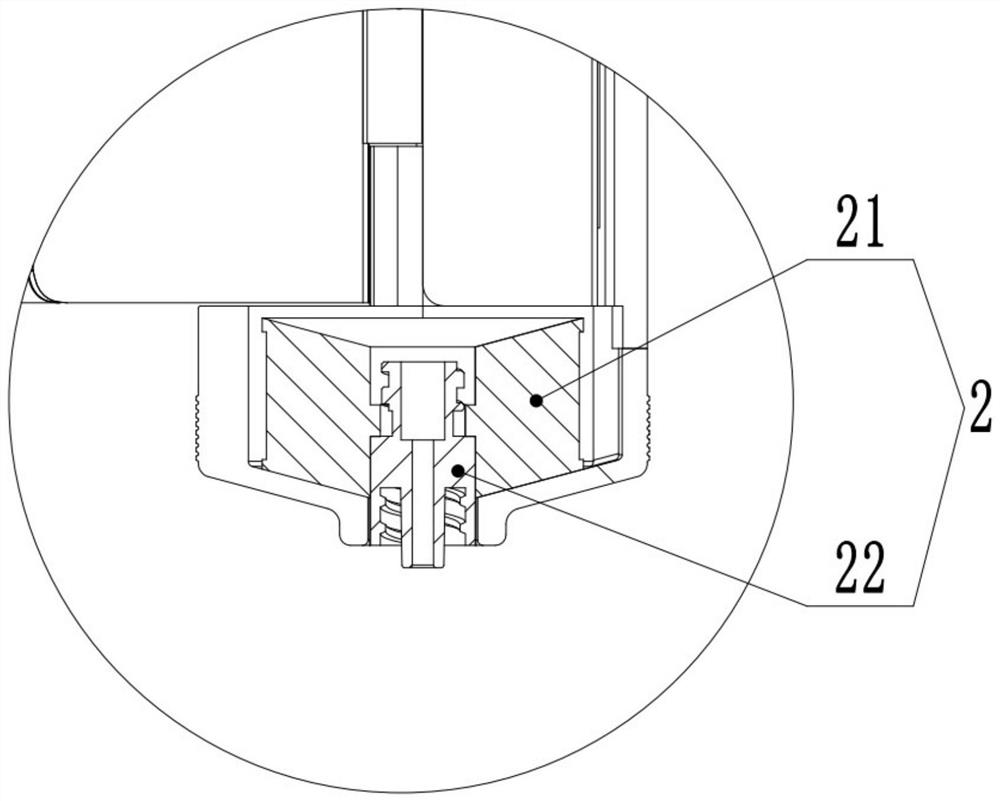

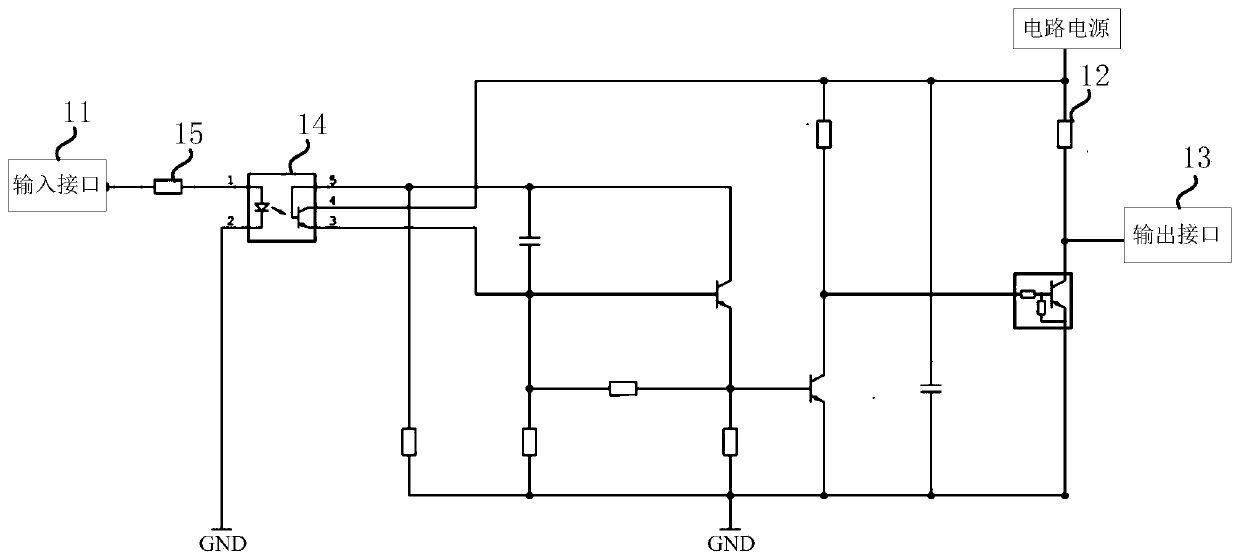

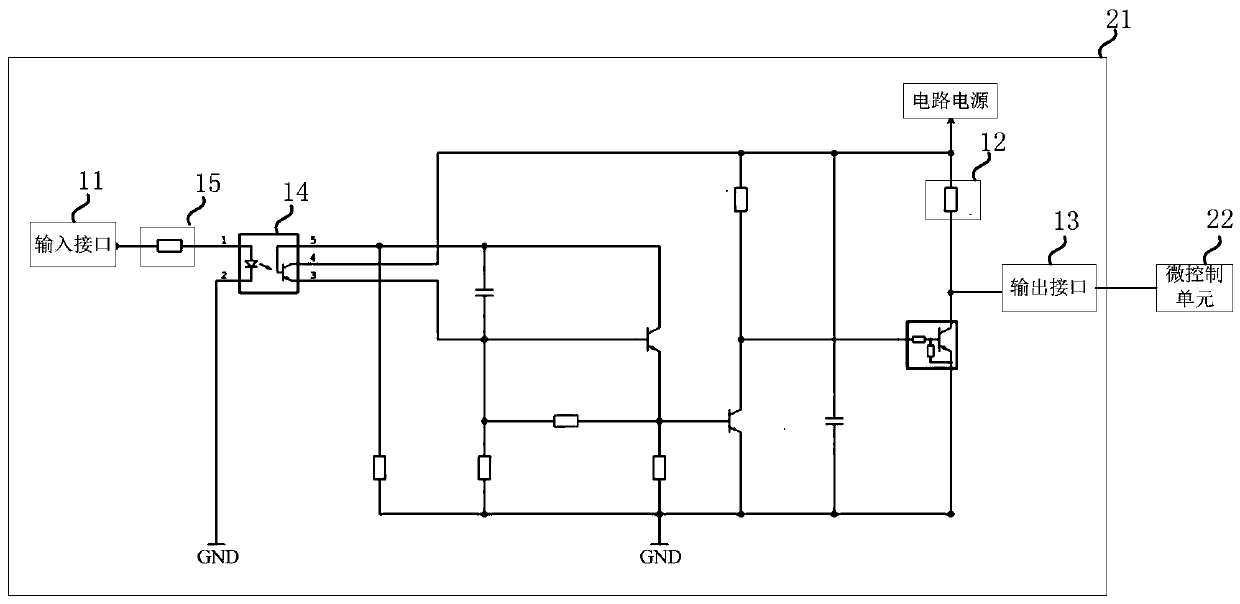

Frequency-adjusting and speed-adjusting interface circuit, fan and fan speed adjusting system and method

ActiveCN107859647ARealize speed regulationGuaranteed output speedPump controlNon-positive displacement fluid enginesUser inputPull-up resistor

The embodiment of the invention discloses a frequency-adjusting and speed-adjusting interface circuit, a fan and a fan speed adjusting system and method. The frequency-adjusting and speed-adjusting interface circuit is connected between a user input device and a micro-control unit. The user input device inputs a speed adjusting numerical value to the micro-control unit through the frequency-adjusting and speed-adjusting interface circuit. The frequency-adjusting and speed-adjusting interface circuit comprises interfaces and a pull-up resistor. The interfaces comprise the input interface connected with the user input device and the output interface connected with the micro-control unit. One end of the pull-up resistor is connected with the input interface and a circuit power source, the other end of the pull-up resistor is connected with the output interface so that a pulse signal from the user input device can be transmitted to the micro-control unit from the output interface, and thusthe micro-control unit performs matching of the corresponding speed adjusting numerical value according to the frequency of the pulse signal to adjust the rotation speed of the fan. By means of the frequency-adjusting and speed-adjusting interface circuit, the influence of temperature can be avoided, high-precision fan speed adjustment is achieved, and the effect that the output speed of the fanmeets the target speed required by users is ensured.

Owner:EMB PAPST VENTILATOR SHANGHAI

Memory reading method and digital memory device

ActiveCN105825894BLess number of pinsGuaranteed output speedRead-only memoriesComputer scienceScratchpad memory

The invention provides a memory reading method and a digital memory device. The digital memory device is divided into a data temporary memory and a data buffer of a cache register, an internal error correction code relative to the cache register and set by a user, and a rapid bad block management. When data reading is carried out, the internal error correction code is displayed by an error correction code status bit. The status (1:1) can represent that the output data of the whole multi-page includes a continuous read-out mode of more than 4 bit errors on each page, the state of the error correction code of each page or each page partition are required to be known, for the former, when the output page is finished, the state of the error correction code of the whole page is determined, and is stored in a state buffer; for the latter, before the corresponding page partition is output, the state of the error correction code of each page partition is determined and output. The error correction code treatment is integrated, and waiting time is not required.

Owner:WINBOND ELECTRONICS CORP

Heating assembly for discharging device

PendingCN113729097ASolve uneven temperatureGuaranteed output speedConfectioneryCocoaControl cellEngineering

The invention discloses a heating assembly for a discharging device, and belongs to the field of 3D printing equipment. The heating assembly comprises a barrel body unit, a base unit and a control unit; the barrel body unit is contained in a shell assembly of the discharging device, connected with the inner wall of the shell assembly and used for heating a containing space of the shell assembly; the base unit is contained in the shell assembly of the discharging device and connected with the bottom wall, provided with a discharging hole, of the shell assembly, and is used for heating the containing space of the shell assembly; and the control unit is electrically connected with the barrel body unit and the base unit and used for adjusting the heating temperature of the barrel body unit and the base unit, so that a temperature difference exists between the heating temperature of the barrel body unit and the heating temperature of the base unit. The barrel body unit and the base unit are arranged in the shell assembly, the temperature difference exists between the heating temperature of the barrel body unit and the heating temperature of the base unit through the control unit, the barrel body unit and the base unit can output different heating temperatures at different positions of the shell assembly, and then the discharging speed is guaranteed.

Owner:NANJING WIIBOOX 3D TECH CO LTD

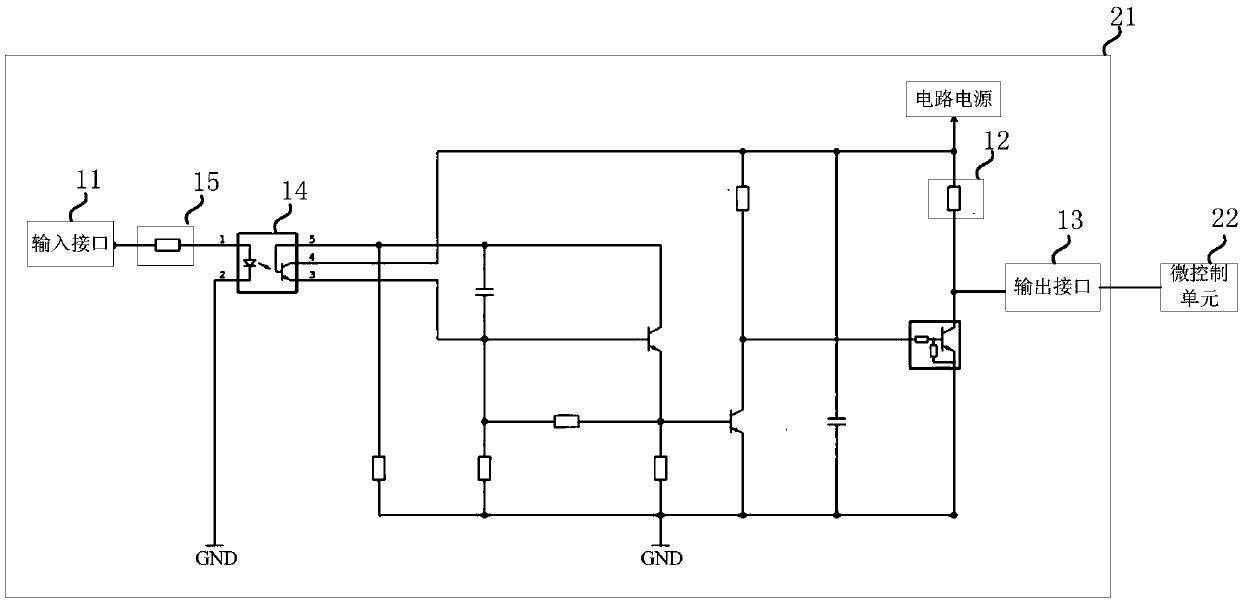

A frequency modulation speed regulation interface circuit, fan, fan speed regulation system and speed regulation method

ActiveCN107859647BRealize speed regulationGuaranteed output speedPump controlNon-positive displacement fluid enginesControl cellPull-up resistor

The embodiment of the invention discloses a frequency-adjusting and speed-adjusting interface circuit, a fan and a fan speed adjusting system and method. The frequency-adjusting and speed-adjusting interface circuit is connected between a user input device and a micro-control unit. The user input device inputs a speed adjusting numerical value to the micro-control unit through the frequency-adjusting and speed-adjusting interface circuit. The frequency-adjusting and speed-adjusting interface circuit comprises interfaces and a pull-up resistor. The interfaces comprise the input interface connected with the user input device and the output interface connected with the micro-control unit. One end of the pull-up resistor is connected with the input interface and a circuit power source, the other end of the pull-up resistor is connected with the output interface so that a pulse signal from the user input device can be transmitted to the micro-control unit from the output interface, and thusthe micro-control unit performs matching of the corresponding speed adjusting numerical value according to the frequency of the pulse signal to adjust the rotation speed of the fan. By means of the frequency-adjusting and speed-adjusting interface circuit, the influence of temperature can be avoided, high-precision fan speed adjustment is achieved, and the effect that the output speed of the fanmeets the target speed required by users is ensured.

Owner:EMB PAPST VENTILATOR SHANGHAI

Rubber band double-cam feeding control method

InactiveCN110683425AGuaranteed output speedReduce load inertiaFilament handlingKinematic controllerEngineering

The invention relates to the field of sanitary article manufacturing, and provides a rubber band double-cam feeding control method. The method comprises the following steps that (1) a rubber band curve feeding device controlled by a PLC is arranged to adjust the changing height of rubber band curve feeding, so that the stretching degree of a rubber band adapts to the stretching degree required byrubber bands corresponding to different products respectively; and (2) the PLC controls a first motion controller, then the first motion controller controls and adjusts the forward and reverse rotation angle of a first servo motor to adjust and control the swing angle of a swing rod, meanwhile, the PLC controls a second motion controller according to a rubber band curve feeding graph, the swing speed of the swing rod and the rubber band conveying rate, and the second motion controller controls the operation speed of a second servo motor to guarantee the rubber band output speed. The method solves the problems that the rubber band rate of existing rubber band curve feeding cannot be effectively controlled and the changing rate of the rubber bands cannot be changed in real time to adapt to production switching of various products.

Owner:QUANZHOU HANWEI MACHINERY MFG

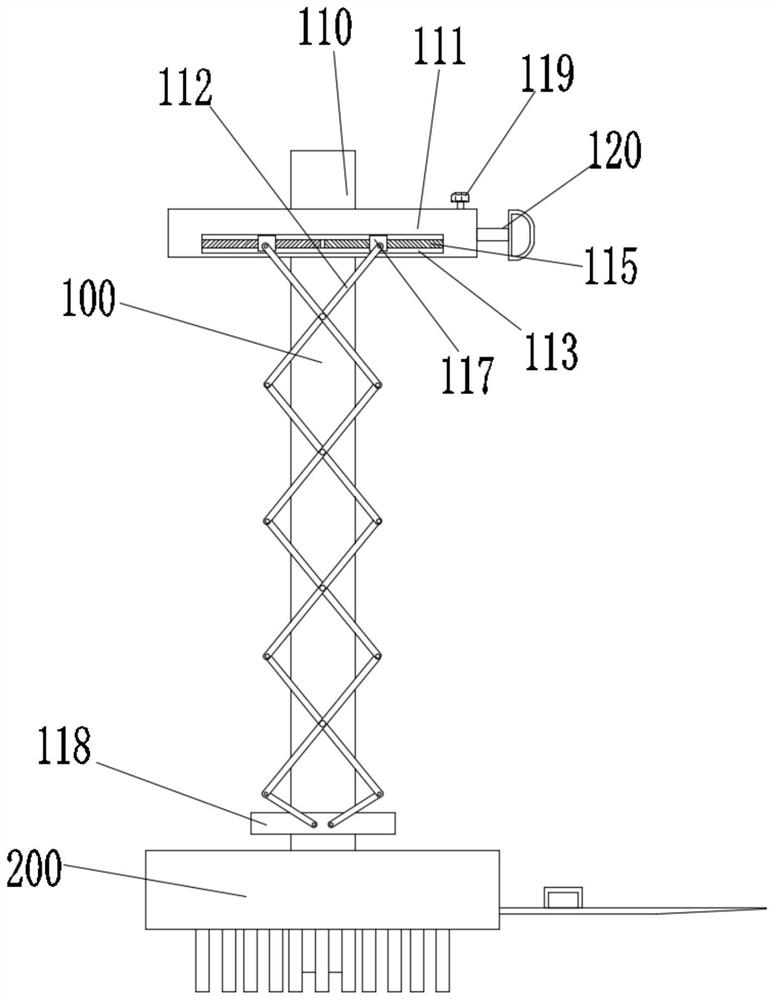

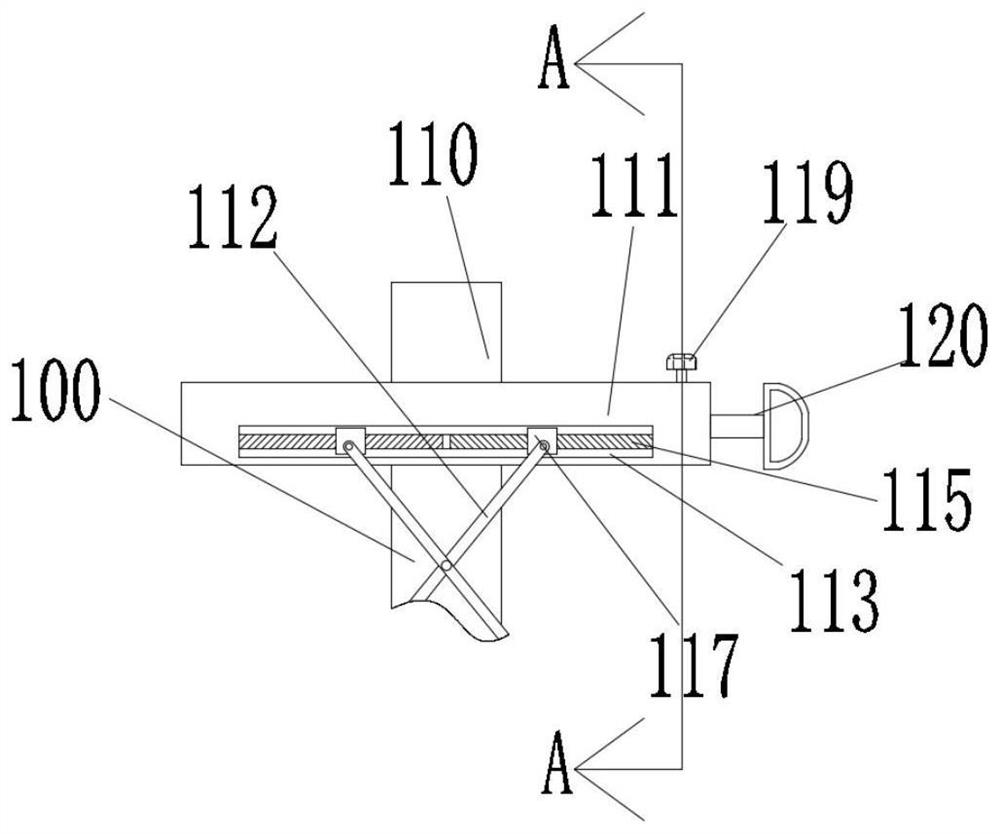

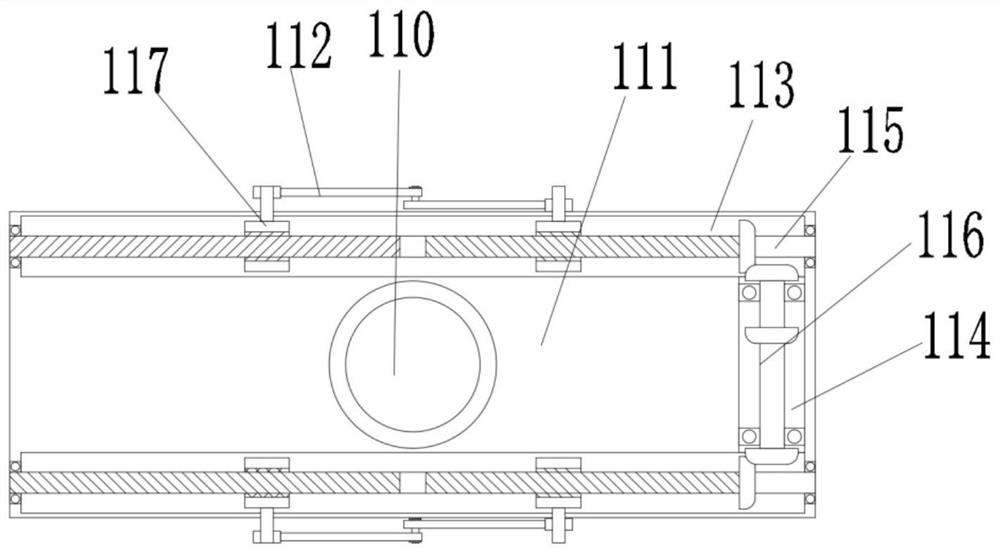

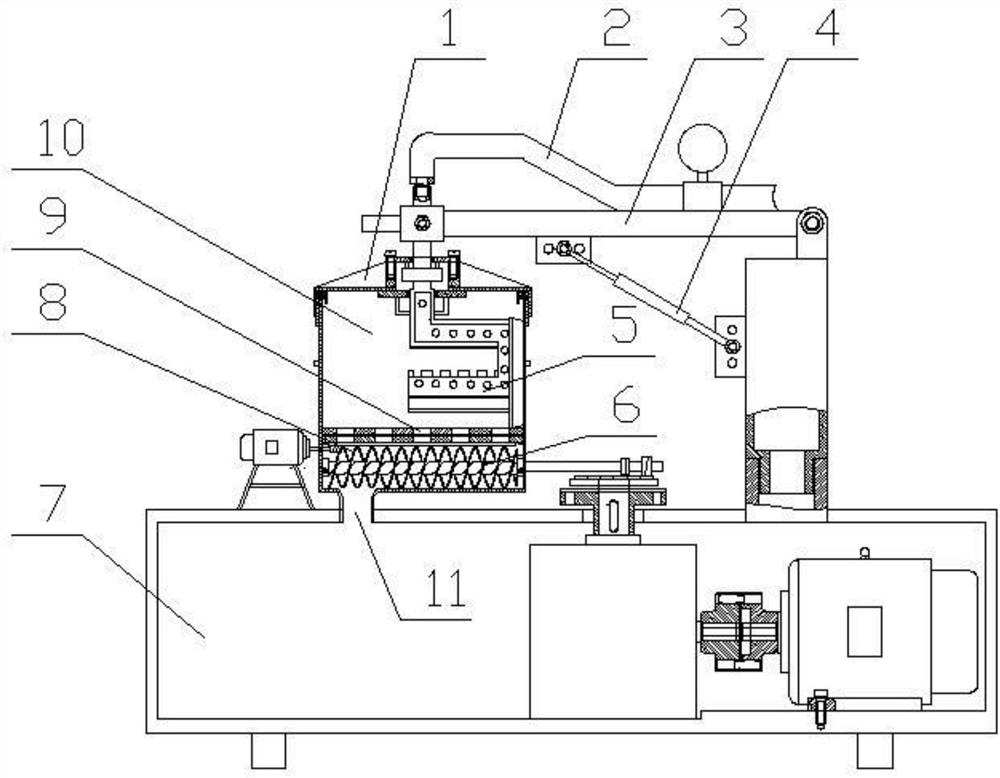

Feeding bin device of electronic index plate

The invention provides a feeding bin device of an electronic index plate, relates to the technical field of feeding bins, and aims to solve the problems that an existing index plate is uneven in feeding and feeding speed and prone to blockage and vacancy on the index plate, a machining production line is vacant, and production efficiency is reduced. The feeding bin device comprises a base table, wherein a feeding mechanism is fixedly installed at the right end of the top plane of the base table, and a driving mechanism is fixedly installed at the rear end of the left end of the top plane of the base table vertically and upwards. According to the feeding bin, the lower end of the feeding bin is of a three-box structure with the middle protruding downwards, a rectangular discharging openingis formed in the middle of the lower end of the feeding bin, a cambered-surface-shaped guide plate is fixedly installed on the edge of the left end of the discharging opening, and the guide plate is arranged along the outer wall of the index plate and is in butt joint with a conveyor in the feeding mechanism, when a workpiece is placed in a clamping groove of the index plate, the outer wall of theworkpiece is further tangent to the inner wall of the guide plate, uniform transmission of the workpiece can be guaranteed, and clamping is avoided.

Owner:周建新

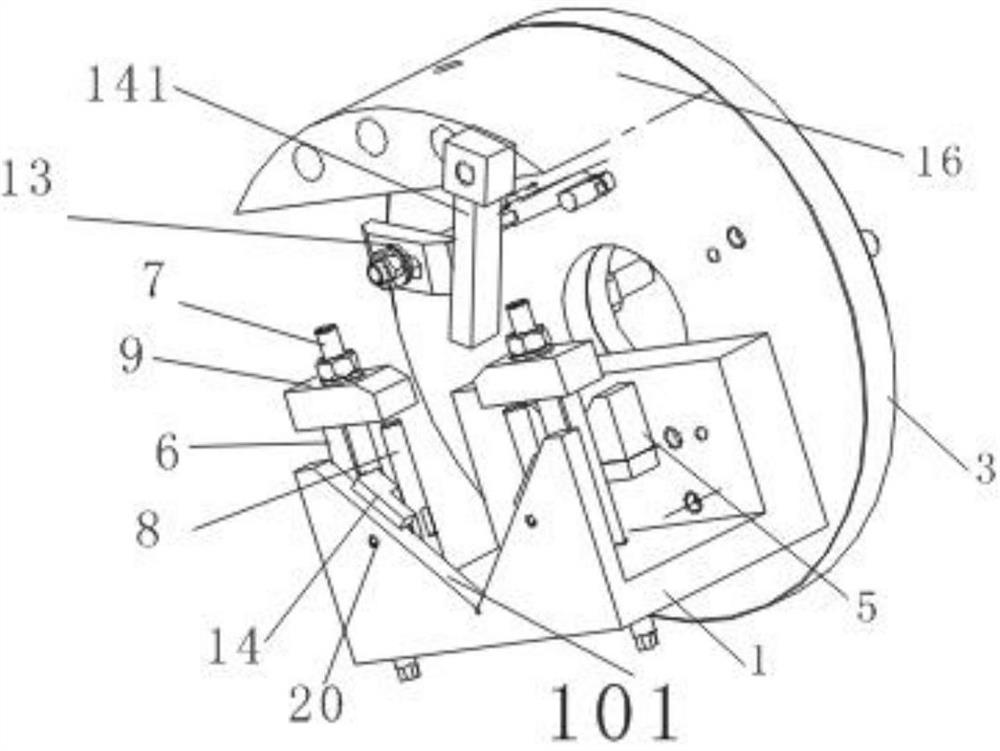

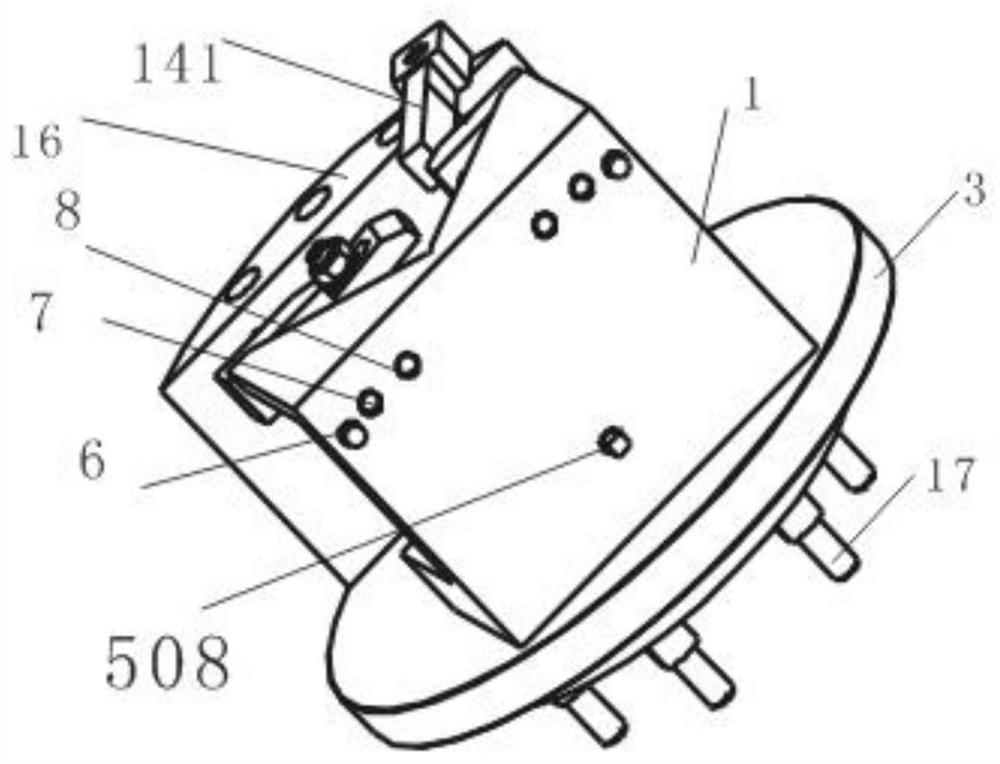

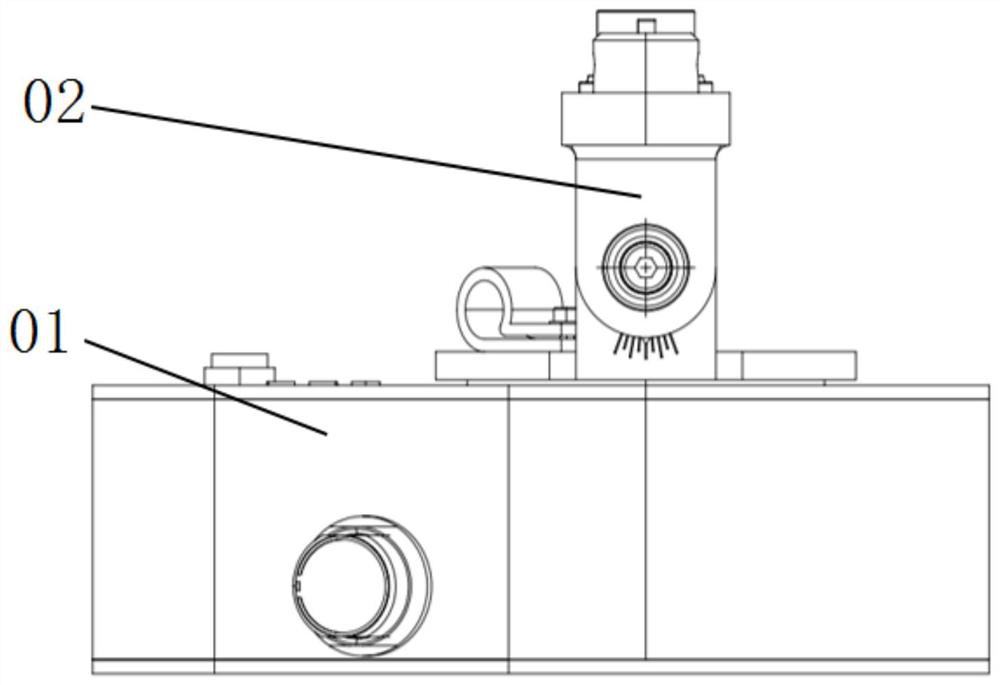

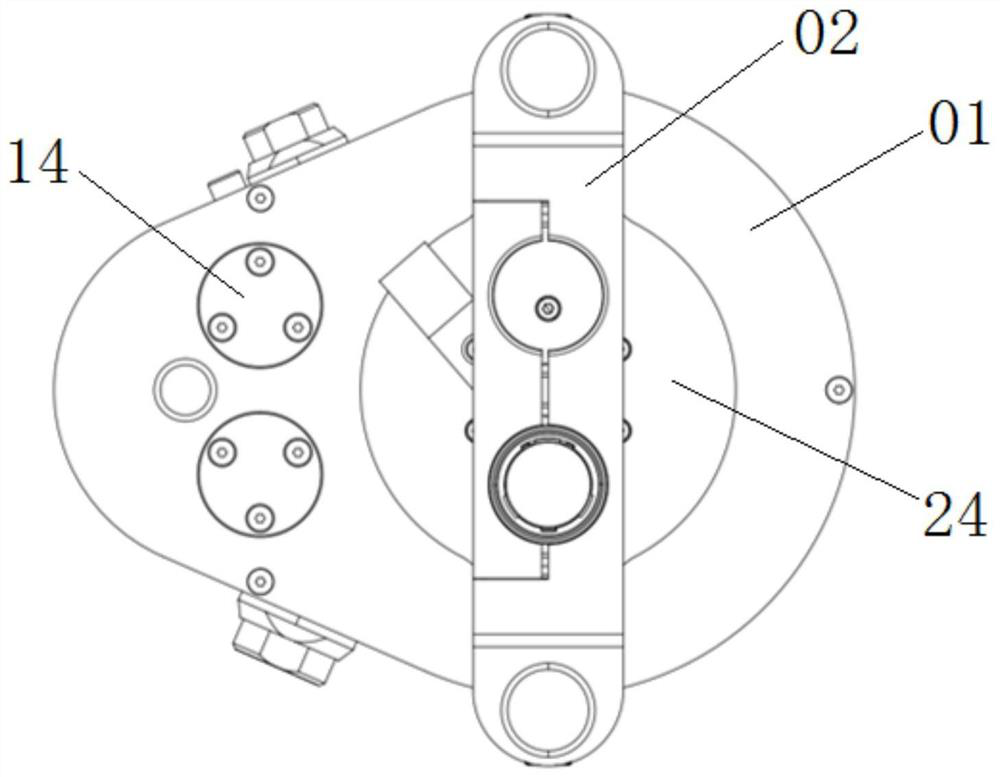

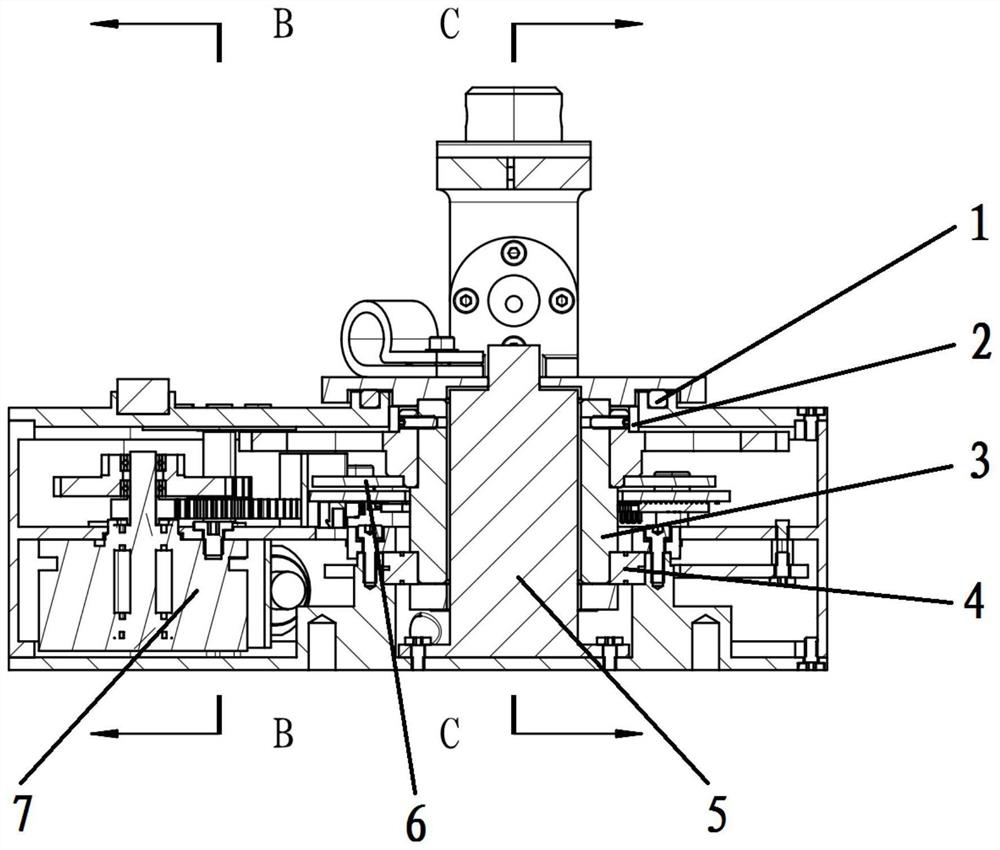

A compact radar antenna turntable

ActiveCN111969292BCompact structureReduce unbalanced momentAntenna supports/mountingsRadar antennasGear drive

The invention relates to a compact radar antenna turntable, comprising an azimuth adjustment unit and a pitch adjustment unit. The azimuth adjustment unit includes a casing, a disc motor, a gear transmission mechanism, an output flange, a manifold ring, and an encoder; the gear transmission mechanism includes a driving gear, a variable speed gear assembly, and a driven gear, and the driving gear is fixedly installed on the output shaft of the disc motor. It is connected with the driven gear through the speed change gear assembly. The driven gear is fixedly sleeved on the outside of the output flange, the lower end of the output flange is rotatably connected with the outer casing, the upper end extends out of the outer casing, and the confluence ring is arranged in the hollow of the output flange. In the cavity, the encoder moving plate is fixedly connected with the lower surface of the driven gear. The pitch adjustment unit includes a support base, a pitch axis, a clamp for installing the radar antenna, and a locking mechanism; the support base is fixedly installed on the upper end of the output flange, and both ends of the clamp are hinged to the support base through the pitch axis, and the locking mechanism is used for In the pitch attitude of the fixed hoop.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

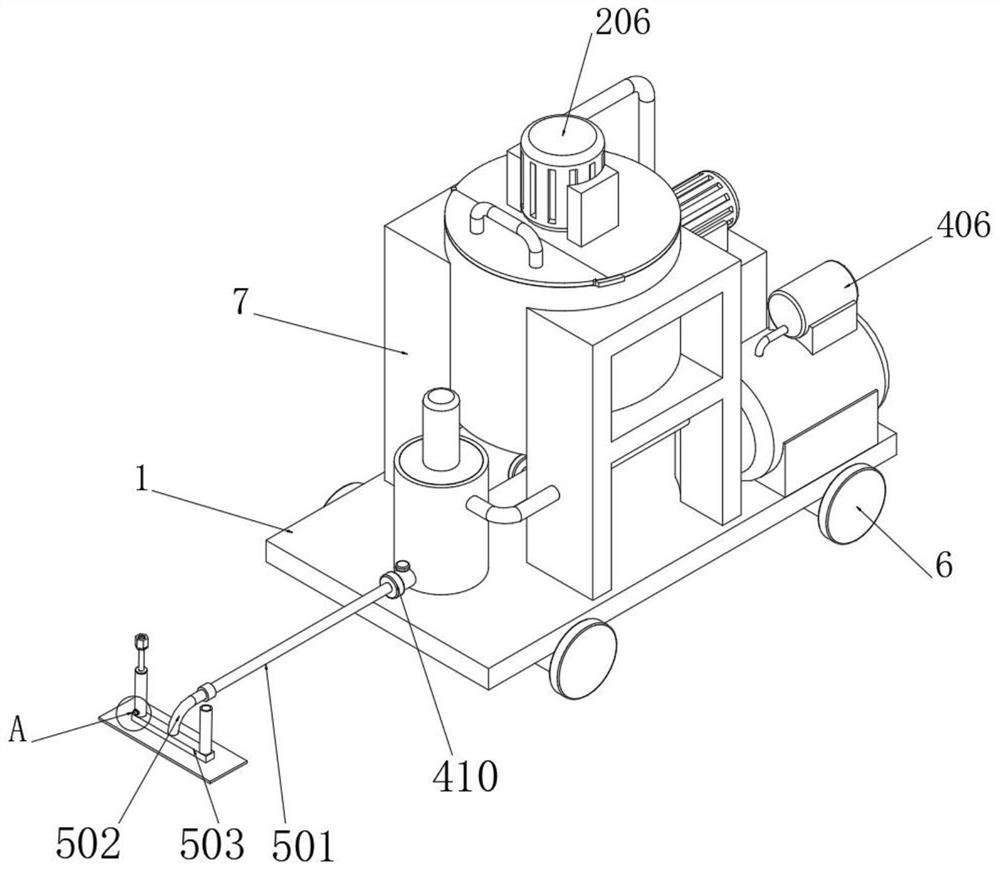

Full-automatic multifunctional puttying machine

PendingCN111636655AScientific and reasonable structureEasy to useTransportation and packagingMixersPlate pressureControl engineering

The invention discloses a full-automatic multifunctional puttying machine. A feeding pipe is mounted on one side of a discharging pipe, one end of the feeding pipe is mounted on one side of a pressurebarrel, an air cylinder is mounted on the inner side of the pressure barrel in an embedded mode, the input end of the air cylinder is connected with a gas transmission pipe, one end of the gas transmission pipe is connected with the output end of a gas storage tank, a high-pressure gas pump is mounted at the top end of the gas storage tank, the output end of the high-pressure gas pump is connected with the input end of the gas storage tank, a first limiting valve is mounted on one side of the feeding pipe, a push plate is welded to the bottom end of the air cylinder, a blowdown pipe is mounted on one side of the pressure barrel, and a second limiting valve is mounted on one side of the blowdown pipe. A feeding assembly is arranged, gas is supplied to the air cylinder through the gas storage tank, thus the air cylinder pushes the push plate conveniently, putty delivered into the pressure barrel is pressurized, the putty is delivered to the required position height conveniently, a worker does not need to take a putty barrel, thus using by the worker is facilitated, and meanwhile, the labor intensity of the worker is reduced.

Owner:保定程飞智能科技有限公司

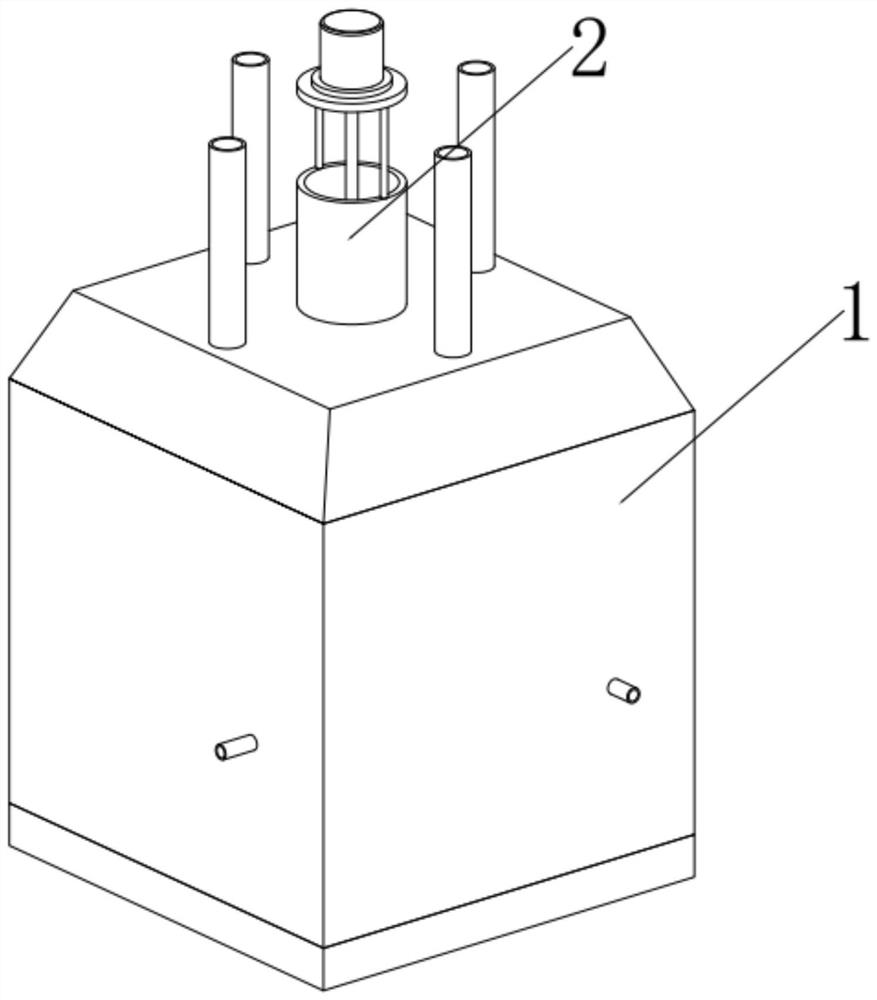

Resource utilization device for arsenic-containing waste

The arsenic-containing waste resource utilization device comprises an outer shell, a mounting frame and an arsenic removal treatment device are fixedly mounted in the outer shell, a quantitative feeding mechanism is arranged at the top of the outer shell, a discharging opening in the lower end of the quantitative feeding mechanism is rotationally connected to a selective feeding structure, and the mounting frame comprises an annular frame; a plurality of hot phase separation devices are evenly arranged on the outer side of the annular frame in the circumferential direction, each hot phase separation device is provided with a feeding port, the feeding ports are in separable butt joint with a feeding port of the selective feeding structure, and a plurality of mixing and stirring devices in one-to-one correspondence with the hot phase separation devices are arranged on the outer side of the arsenic removal treatment device; and the bottom of the mixing and stirring device is communicated with the inner cavity of the arsenic removal treatment device through a channel provided with an electric control valve. According to the invention, the cured material can be continuously supplied and subjected to a series of process steps of thermal phase separation, additive mixing and arsenic removal treatment, and a fault device can be skipped for continuous treatment, so that the influence of faults on the treatment efficiency is reduced.

Owner:内蒙古新创环境科技有限公司

Concrete filling device with anti-blocking structure

PendingCN113530248AGuaranteed output speedEasy to operateBuilding material handlingEngineeringAir bubble

Owner:宋俊轻

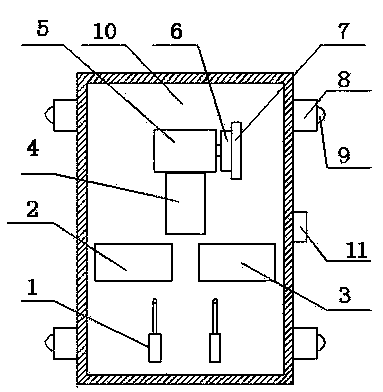

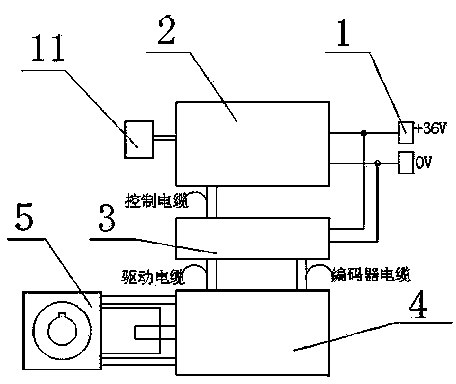

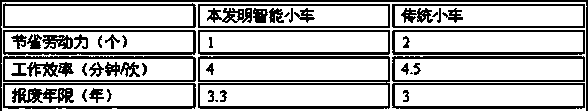

Intelligent physical distribution trolley driven by constant torque low-voltage direct current

InactiveCN103420107ASolve the problem of small loadNo pollutionMechanical conveyorsDrive shaftLow voltage

The invention relates to an intelligent physical distribution trolley driven by a constant torque low-voltage direct current. The intelligent physical distribution trolley comprises a support, a copper brush, a control board, a driver, an electromotor, a reduction box and a gear, wherein a power rubber wheel is installed on a driven shaft of the reduction box, four bearing wheels are installed below the four corners of the support, guide wheels are fixed to the axes of the bearing wheels, the guide wheels make contact with the side walls of tracks on the two sides, a fixed electronic tag recognizer is installed in the middle of the right side of the support, the driver is a low-voltage direct current servo driver, and the low-voltage direct current servo motor is of a non-carbon-brush structure. The intelligent physical distribution trolley effectively solves the problem that a traditional physical distribution trolley is small in load capacity, the low-voltage direct current servo motor can provide more constant torque than a low-voltage brushed direct current motor when the trolley climbs uphill, the output power and speed are ensured, the transmission efficiency is improved, dust pollution does not exist, and the intelligent physical distribution trolley has the advantages of being easy to maintain, low in noise and large in torque.

Owner:GUANGXI MANCHEBISI AUTOMATION EQUIP

An electronic indexing plate loading bin equipment

ActiveCN112079082BUniform deliveryAvoid getting stuckConveyor partsProduction lineStructural engineering

The invention provides an electronic indexing plate loading bin equipment, which relates to the technical field of loading bins, to solve the problem of the existing indexing plate loading, the speed of feeding is uneven, and the indexing plate is prone to jamming and empty materials. In some cases, there is a vacancy in the processing production line, which leads to the problem of a decrease in production efficiency, including the abutment; the right end of the top plane of the abutment is fixedly installed with a feeding mechanism, and the rear end of the left end of the top plane of the abutment is fixedly installed with a driving mechanism vertically upward. mechanism. In the present invention, since the lower end of the upper material bin is a three-piece box structure with a downward convex middle part, and the middle part of the lower end of the upper material bin is provided with a rectangular-shaped discharge port, the left edge of the discharge port is fixedly equipped with an arc-shaped The guide plate is arranged along the outer wall of the indexing plate and connected to the conveyor in the feeding mechanism. When the workpiece is placed in the slot of the indexing plate, the outer wall of the workpiece is also tangent to the inner wall of the guiding plate. It can ensure the uniform transfer of workpieces and avoid jamming.

Owner:周建新

A stirring device for coloring acrylic raw materials

A mixing device used for coloring acrylic raw materials. The frame is equipped with a lifting mechanism, which is connected to the bucket cover through a support arm. The support arm is equipped with a feeding mechanism. There is a stirring mechanism in the bucket, and the stirring mechanism includes a primary stirring mechanism and a secondary stirring mechanism. The coloring agent can be put in according to the demand through the feeding mechanism, and the coloring agent can be added in stages, and the multi-point output can be realized through the liquid outlet on the stirring paddle, so that the coloring effect is more ideal. The separation structure makes the mixing tank divided into multi-stage independent stirring. The first-stage stirring is to uniformly mix the raw materials and colorants, and the second-stage stirring is to compact and stir the colored raw materials after stirring and discharge air bubbles. The color is more uniform and the effect is more ideal. Through the scraper in the primary mixing chamber and the auger in the secondary mixing chamber, the remaining residue on the inner wall of the mixing tank can be cleaned, so that the inner wall of the mixing tank can be kept clean, and the waste of remaining residual material can also be reduced.

Owner:泰州市永宁亚克力制品有限公司

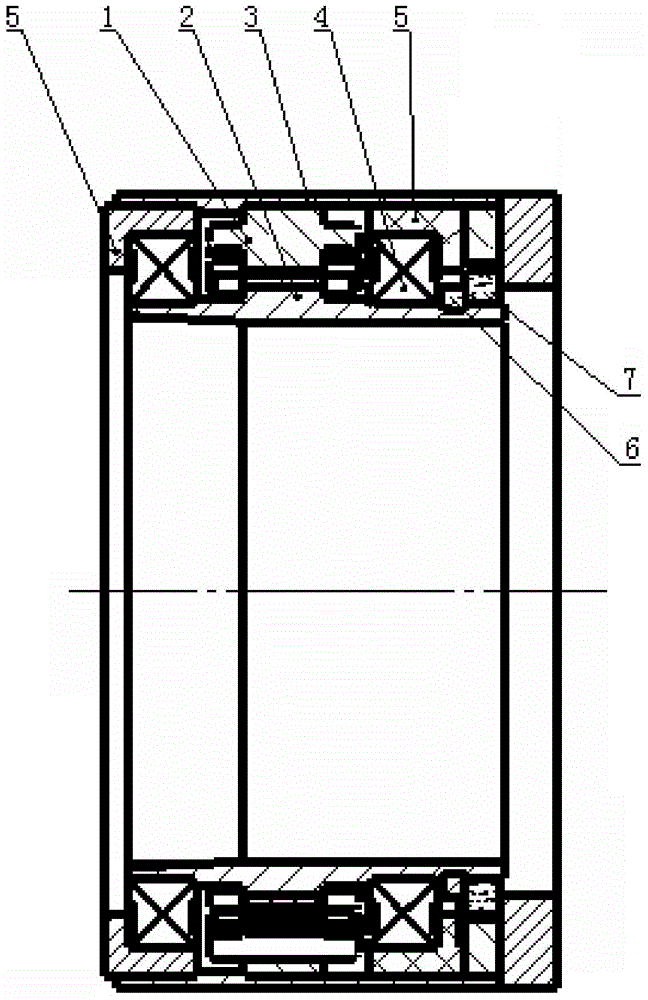

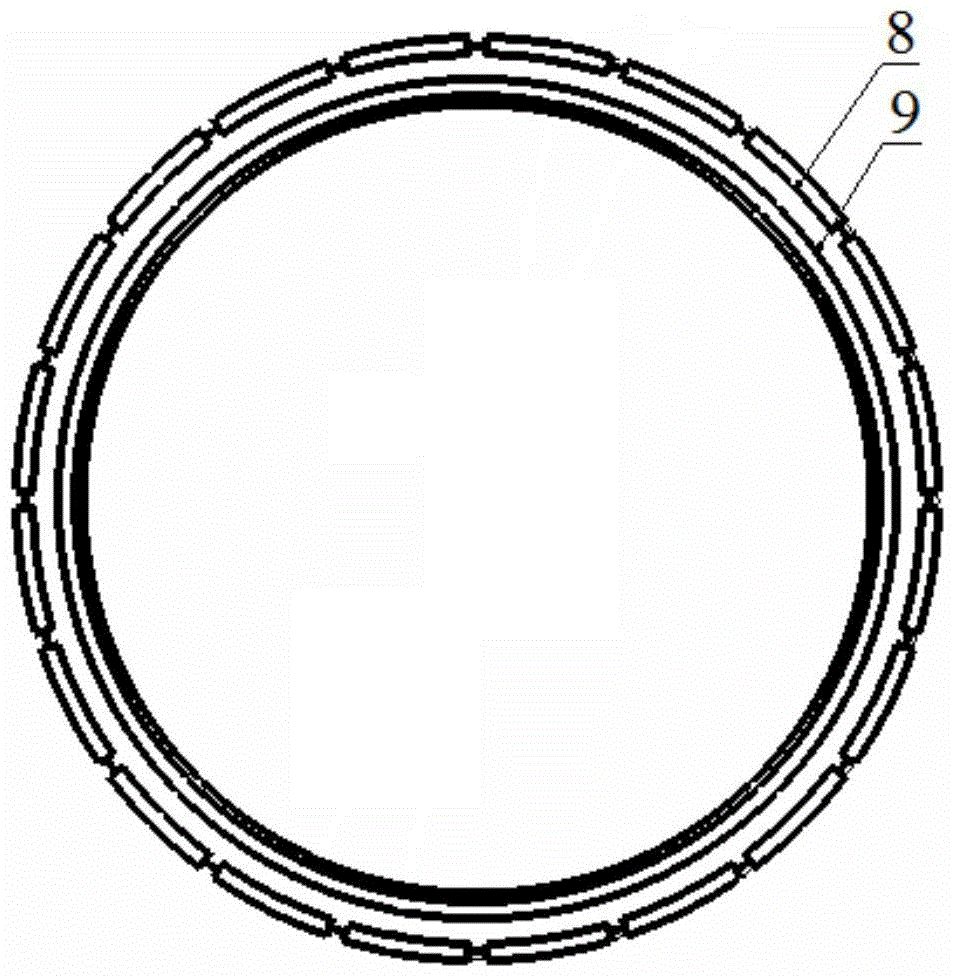

Permanent magnet synchronous rotation elimination motor of rotation elimination platform

InactiveCN106329864AReduce weightSimple structureSynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsHigh fluxSurface mounting

The invention relates to a permanent magnet synchronous rotation elimination motor of a rotation elimination platform. The permanent magnet synchronous rotation elimination motor comprises a machine shell, a stator and a rotor which are arranged from outside to inside in sequence, wherein the rotor is connected with the machine shell through a bearing; the stator is connected with a servo motor driver; the inner circumference of the stator adopts a regularly-round multi-groove structure; the rotor adopts a near-polar-slot surface-mounted type structure; the rotor comprises a rotor iron core and permanent magnets; the rotor iron core adopts an annular structure; multiple convex rotor teeth are uniformly distributed on the outer surface of the rotor iron core; the permanent magnets are fixed between adjacent rotor teeth; and the permanent magnets are cuboid-shaped magnetic steel or arc-shaped magnetic steel with equal thickness in each place. Compared with the prior art, the permanent magnet synchronous rotation elimination motor has the advantages of simple structure, light weight, low rotational inertia, high efficiency, high power density, short end part winding, relatively high flux-weakening capability and the like, and is applicable to motor structure design of specific dimensions in the rotation elimination platform; and meanwhile, the speed of the permanent magnet synchronous rotation elimination motor can reach 780r / min within 0.06s.

Owner:上海航天智能装备有限公司

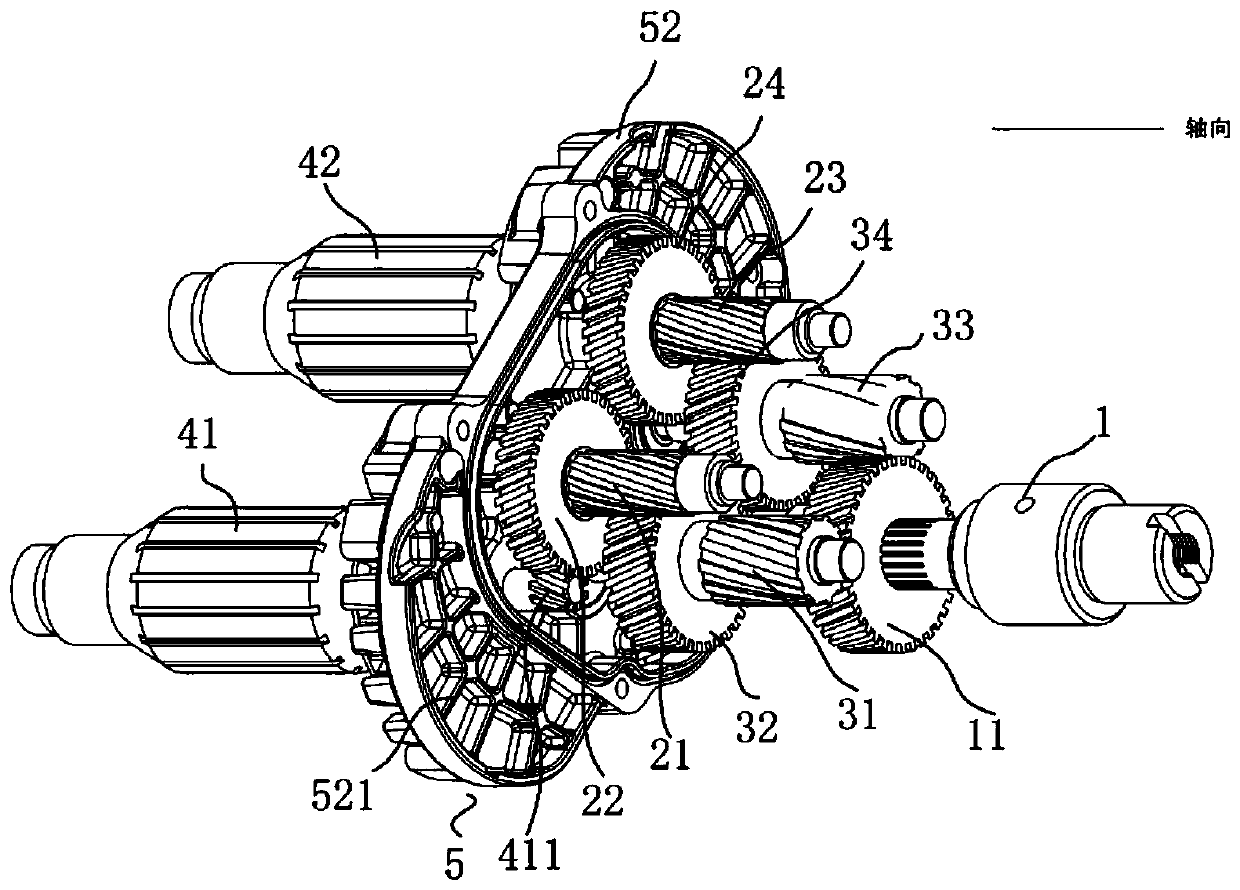

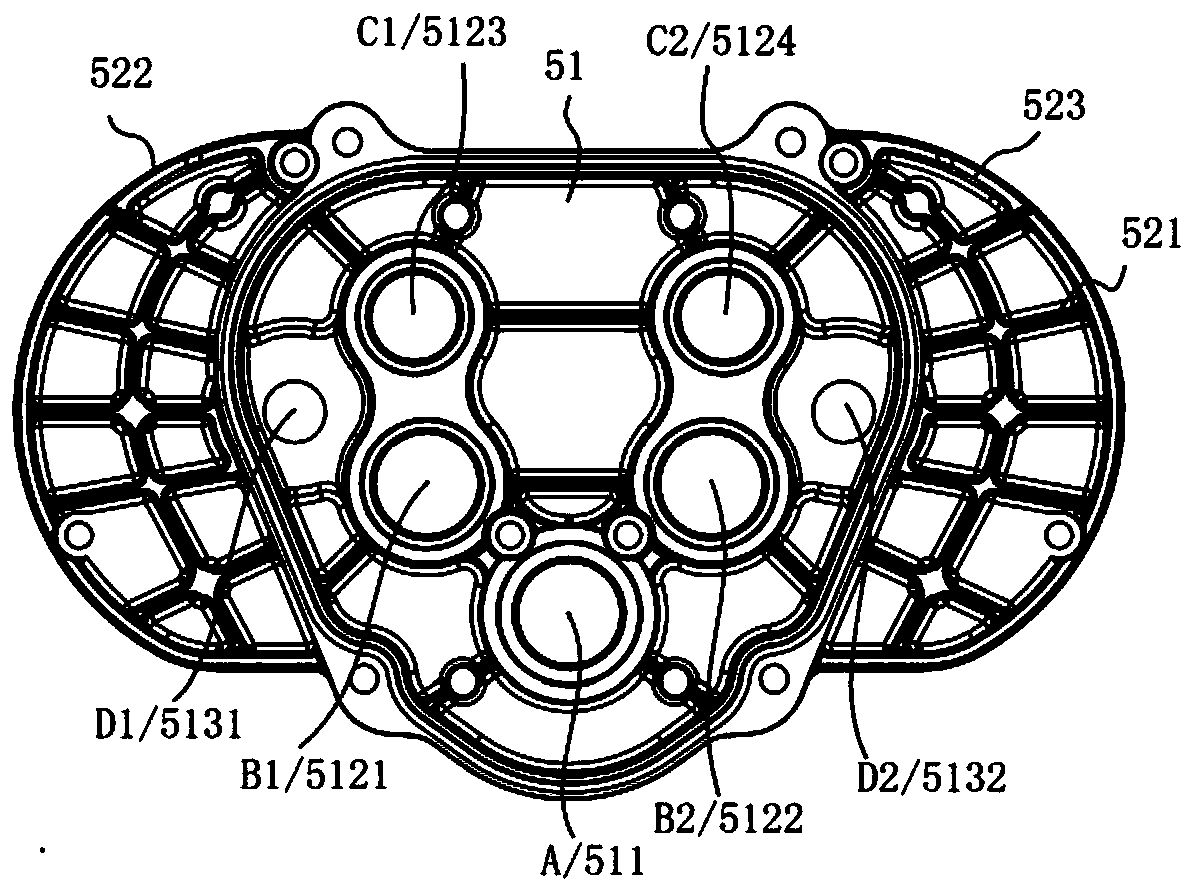

Dual-motor transmission structure and wall cutting machine provided with the same

PendingCN111251478AImprove cooling effectCompact layoutWorking accessoriesMechanical energy handlingDrive wheelGear wheel

The invention relates to a dual-motor transmission structure which comprises a spindle, a spindle gear and a driving wheel set sequentially connected, wherein the driving wheel set comprises at leasttwo conveying wheel sets; every two adjacent conveying wheel sets are in drive joint; each of the conveying wheel sets comprises a first gear shaft, a second gear shaft, a first plate gear connected with the first gear shaft, and a second plate gear connected with the second gear shaft; the first gear shaft and the second gear shaft are symmetrically arranged on the two sides of the spindle; and afirst secondary gear shaft and a second secondary gear shaft are arranged between the spindle and the plane of a first primary gear shaft and a second primary gear shaft. The invention further relates to a wall cutting machine provided with the dual-motor transmission structure. The dual-motor transmission structure can increase the torque and the output speed, reduces the size and prolongs the service life.

Owner:上海得宴电动工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com