Feeding bin device of electronic index plate

An electronic indexing and indexing plate technology, which is applied in the field of feeding bins, can solve the problems of empty material jamming on the indexing plate, uneven feeding speed, and decreased production efficiency, so as to avoid jamming and ensure material discharge. The effect of speed and uniform delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

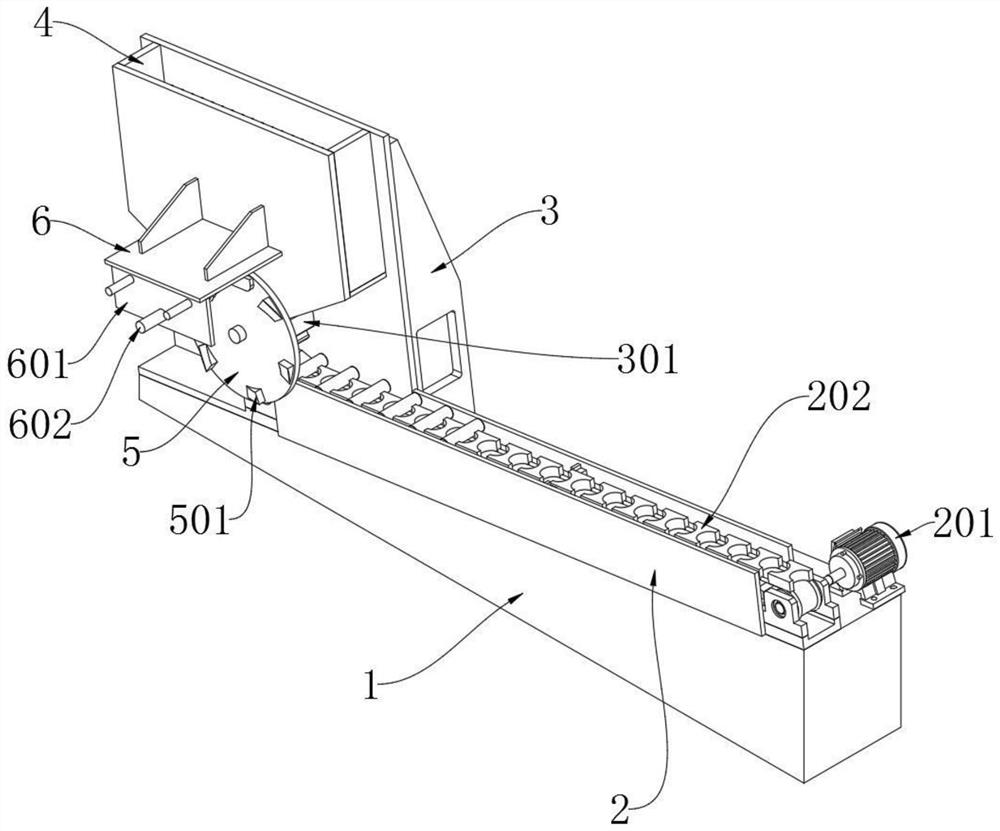

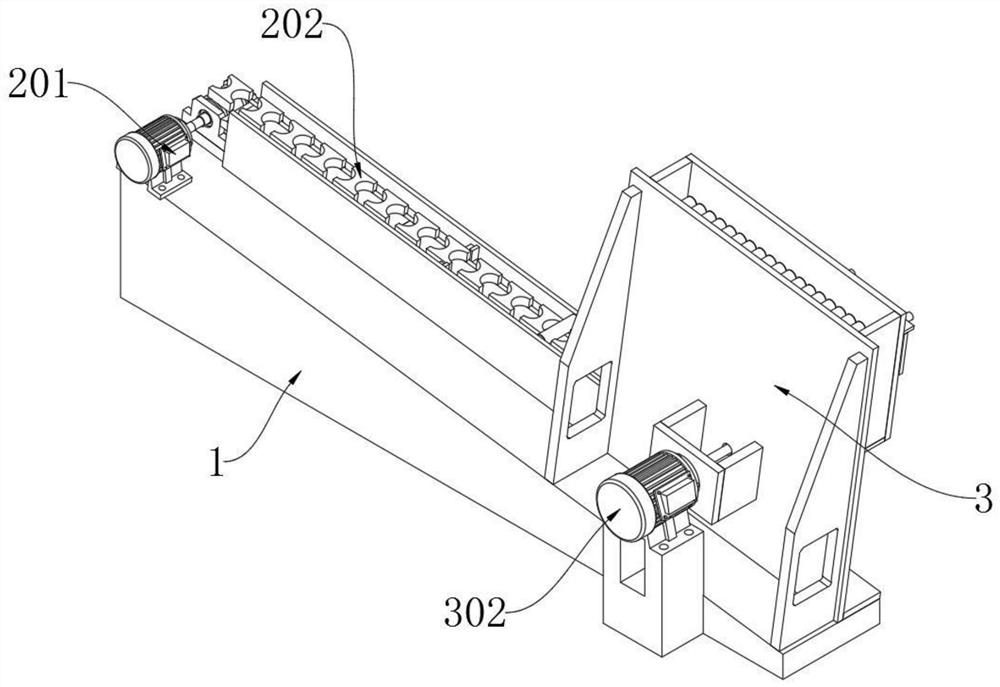

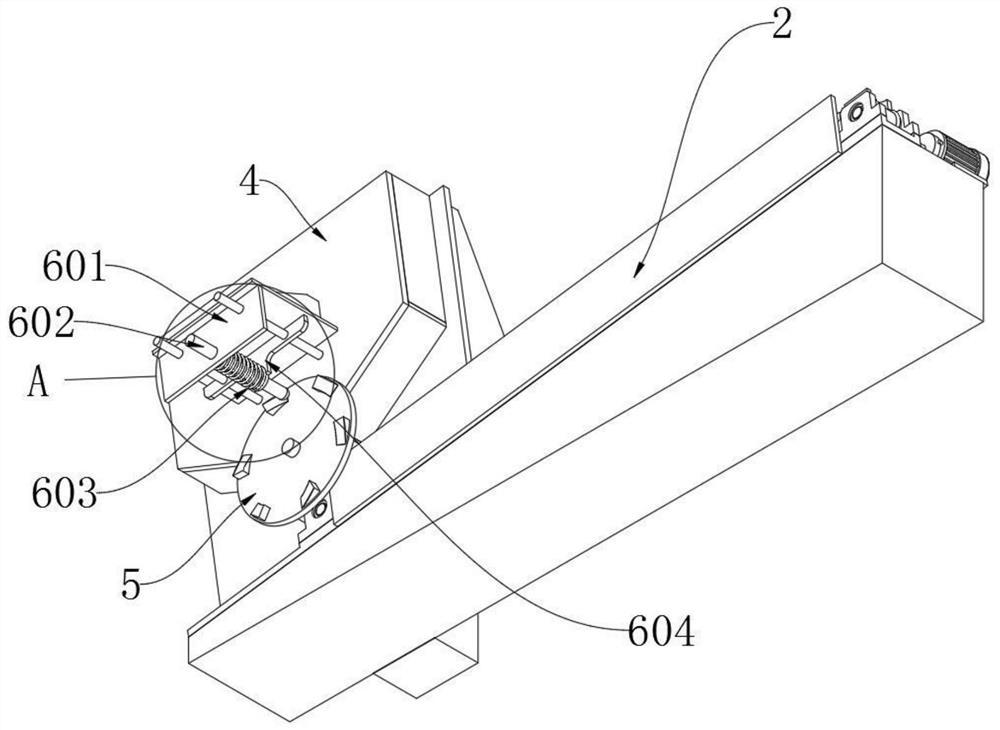

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034] The invention provides an electronic indexing plate loading bin equipment, which includes a base 1; a feeding mechanism 2 is fixedly installed on the right end of the top plane of the base 1, and a driving mechanism 2 is fixedly installed on the rear end of the left end of the top plane of the base 1 vertically upward. Mechanism 3; driving mechanism 3 comprises index plate 301, driving motor 302 and draw-in groove 303, and the middle part of the lower end of driving mechanism 3 back plane is fixedly installed with driving motor 302, and on the front end rotating shaft of driving motor 302, indexing plate 301 is fixedly installed, The indexing plate 301 is placed directly below the upper material bin 4, and the outer wall of the indexing plate 301 is evenly provided with slots 303 suitable for the cylindrical workpiece. When the driving motor 302 rotates, the indexing plate 301 can be rotated. , and then make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com