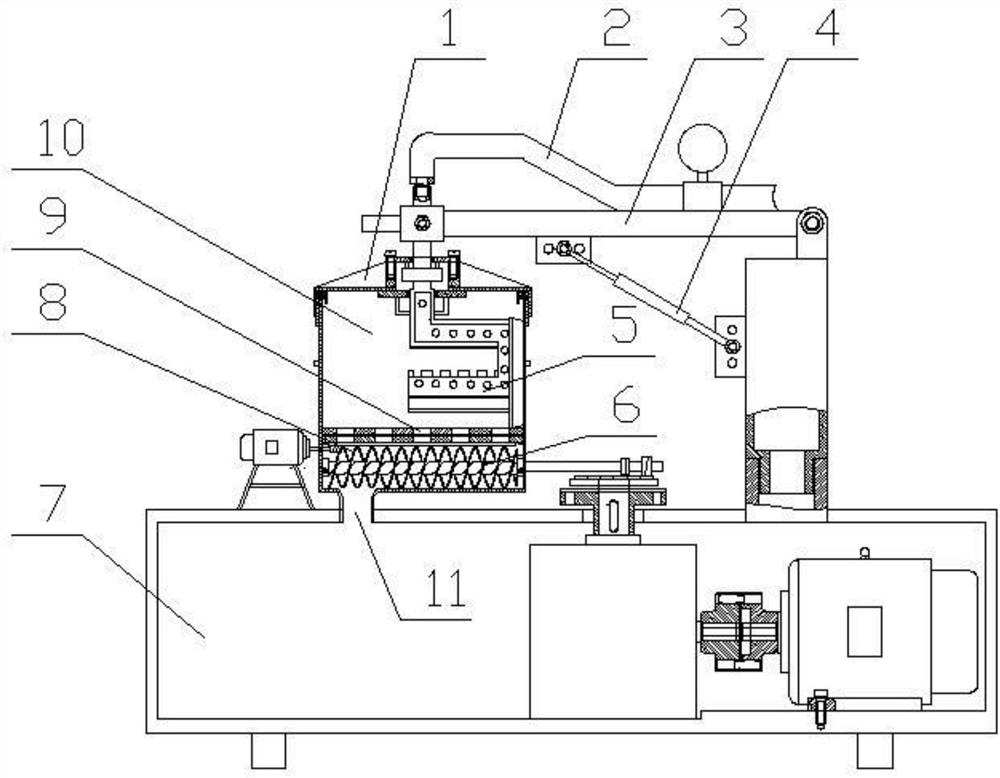

A stirring device for coloring acrylic raw materials

A mixing equipment and acrylic technology, which is applied in the field of mechanical equipment, can solve the problems of uneven coloring of acrylic raw materials, and achieve ideal effects, convenient blanking, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

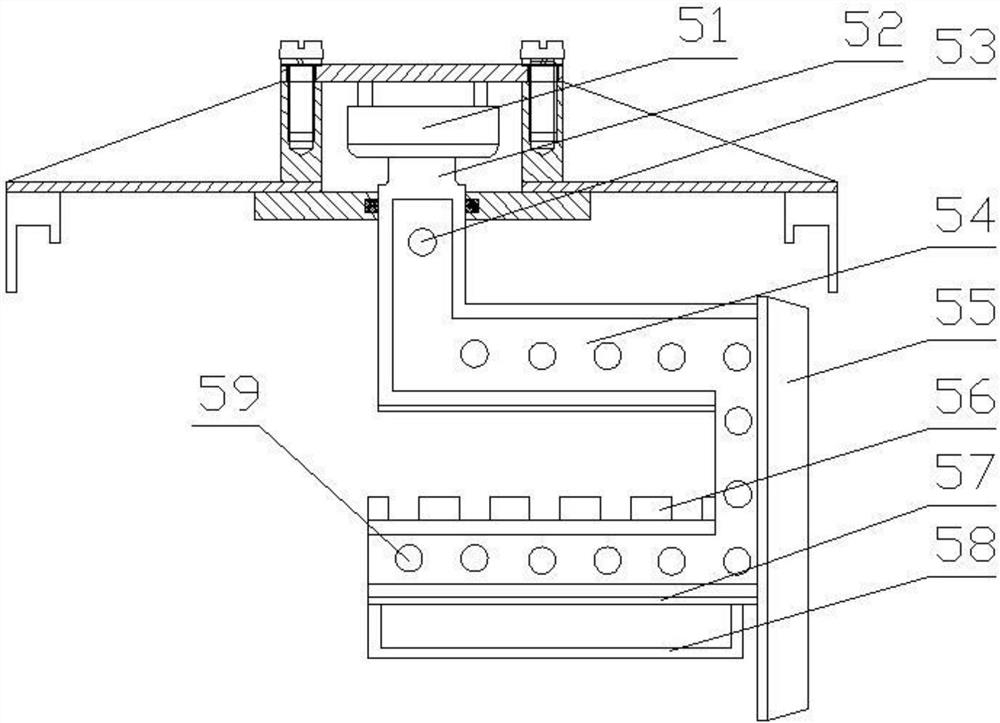

Method used

Image

Examples

Embodiment 2

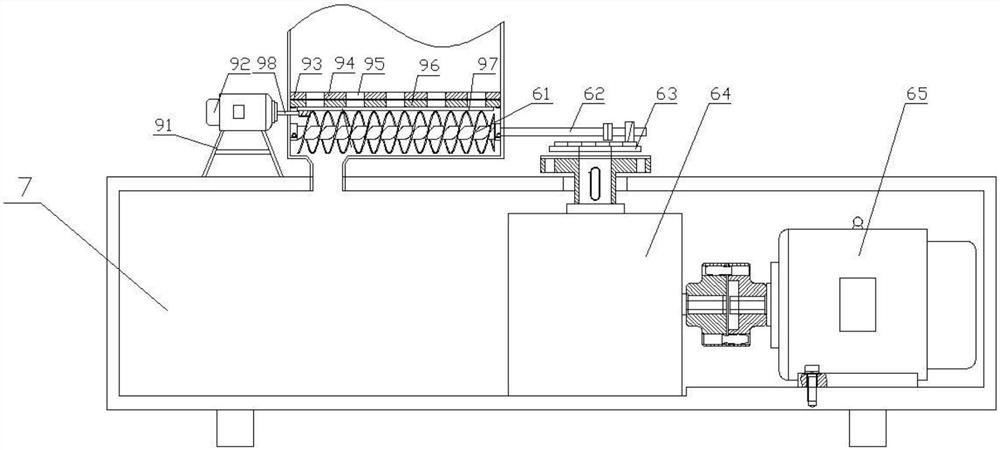

[0043] Embodiment 2, refer to Figure 1-7 , a stirring device for coloring acrylic raw materials, the secondary stirring chamber 8 is a receiving cavity with an inclined inner wall and an arc-shaped bottom, and the arc-shaped bottom is in contact with the auger 61 .

[0044] Working principle: Compared with Example 1, the bottom of the second stirring chamber whose inner wall is inclined and has an arc-shaped bottom receiving cavity is in contact with the auger 61 to achieve a pushing and scraping state, so that the inner wall of the second stirring chamber is kept clean, and at the same time, the Waste of residual material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com