Intelligent physical distribution trolley driven by constant torque low-voltage direct current

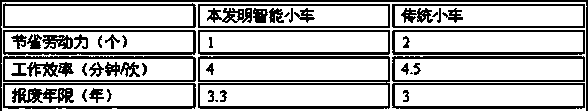

A low-voltage direct current, smart car technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem of small load, to achieve the effect of ensuring output power and speed, improving transmission efficiency, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

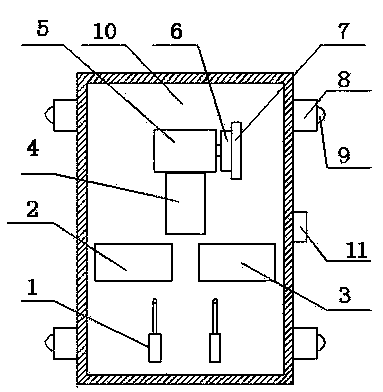

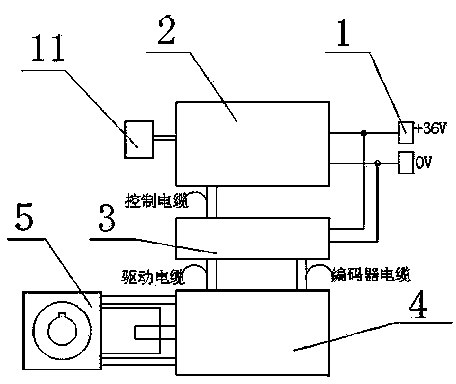

[0013] Such as figure 1 , 2 As shown, when the present invention does not work, the two copper brushes 1 are in contact with the conductive copper rails in the track and wait for the current input, and the control board 2 is fixed on the bracket 10. When there is no voltage, the control board does not work, and the low-voltage DC servo driver 3 and the control board 2 are fixed side by side on the bracket, and the two are connected by a control cable. The low-voltage DC servo motor 4 is connected behind the low-voltage DC servo driver 3, and the reducer 5 is connected to the output end of the low-voltage DC servo motor 4. 6 and the power rubber wheel 7 are respectively installed on the main shaft and the slave shaft of the 5th axis of the reducer. There are four load-bearing wheels 8 under the support, wherein the guide wheel 9 is fixedly installed on the bearing wheel axis, and the control panel 2 is also installed with When the electronic identifier 11 is not powered on, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com