Oil-driven bevel-gear differential-speed-type multi-rotor agricultural spraying aircraft

A bevel gear and multi-rotor technology, which is applied to the transmission device driving multiple propellers, aircraft parts, and power device types, etc., can solve the problems of high spraying cost, short flight time and high cost, and achieve no need for take-off sites. The effect of restraint, smooth flight, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

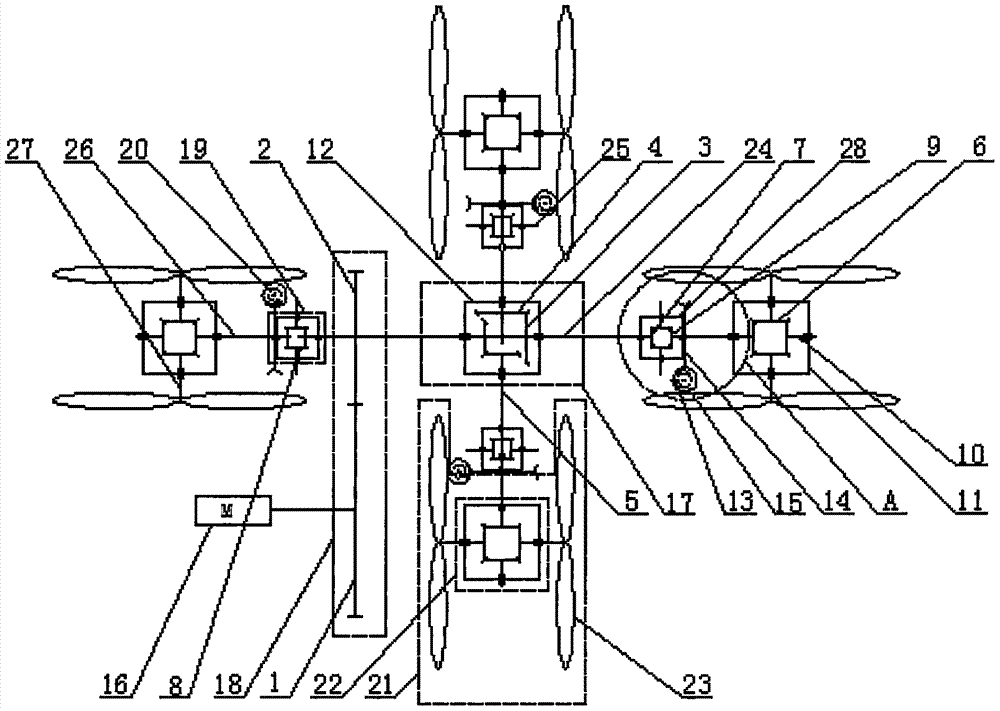

[0016] Specific implementation mode one: as figure 1 and figure 2 As shown, this embodiment discloses an oil-operated bevel gear differential multi-rotor agricultural spraying aircraft, including an engine 16, a central bevel gear transmission box 17, a gear or belt transmission mechanism 18, and four bevel gear differential transmission boxes 19 , four worm and gear transmission mechanisms 20 and four rotor transmission mechanisms 21, each of the rotor transmission mechanisms 21 includes a rotor bevel gear transmission box 22 and two rotor blades 23,

[0017] The output shaft of the engine 16 is fixedly connected with the driving gear 1 in the gear or belt transmission mechanism 18, and the driven gear 2 in the described gear or belt transmission mechanism 18 is fixedly mounted on the horizontal center of the central bevel gear transmission box 17. On the shaft 24, the two ends of the horizontal central axis 24 of the central bevel gear transmission box 17 and the two ends ...

specific Embodiment approach 2

[0020] Specific implementation mode two: as figure 1 and figure 2 As shown, the oil-operated bevel gear differential multi-rotor agricultural spraying aircraft described in Embodiment 1, the central bevel gear transmission box 17 includes a central transmission box body 12, a horizontal central shaft 24, and two central active bevel gears 3. Two central driven bevel gears 4 and two central output shafts 5. Both ends of the horizontal central shaft 24 pass through the central transmission case 12 and are arranged outside the central transmission case 12. The horizontal central shaft 24 and The central transmission box 12 is rotationally connected, the two central driving bevel gears 3 and the two central driven bevel gears 4 are all arranged in the central transmission box 12, and the two central driving bevel gears 3 are fixedly installed in the horizontal center On the shaft 24, each central driving bevel gear 3 meshes with a central driven bevel gear 4, and each said centr...

specific Embodiment approach 3

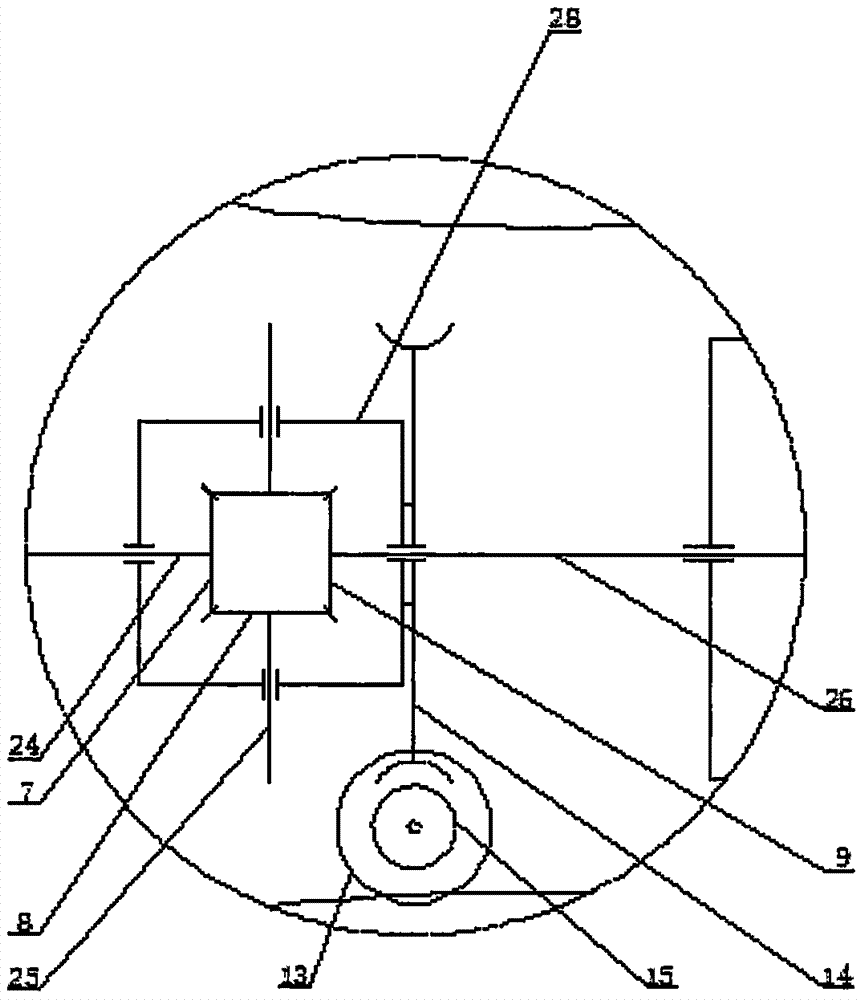

[0021] Specific implementation mode three: as figure 1 and figure 2 As shown, the oil-operated bevel gear differential multi-rotor agricultural spraying aircraft described in Embodiment 1, each of the bevel gear differential transmission boxes 19 includes a bevel gear differential box 28, a bevel gear 7, Bevel gear two 9, two bevel gear three 8 and two bevel gear support shafts 25, the bevel gear one 7, bevel gear two 9 and two bevel gear three 8 are all arranged in the bevel gear differential box 28 , two bevel gear support shafts 25 are respectively rotatably equipped with a bevel gear three 8, and the two bevel gear three 8 are meshed with bevel gear one 7 and bevel gear two 9 at the same time, and the two bevel gear support shafts 25 are all rotatably connected with the side walls of the bevel gear differential case 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com