Vehicle tool for complex welding part

A kind of welded parts and complex technology, which is applied in the field of vehicle tooling and outer circle turning of welded parts, can solve the problems of low machining efficiency and unqualified roughness of welded workpieces, so as to ensure production rhythm and good roughness of forming surface , Improve the effect of clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

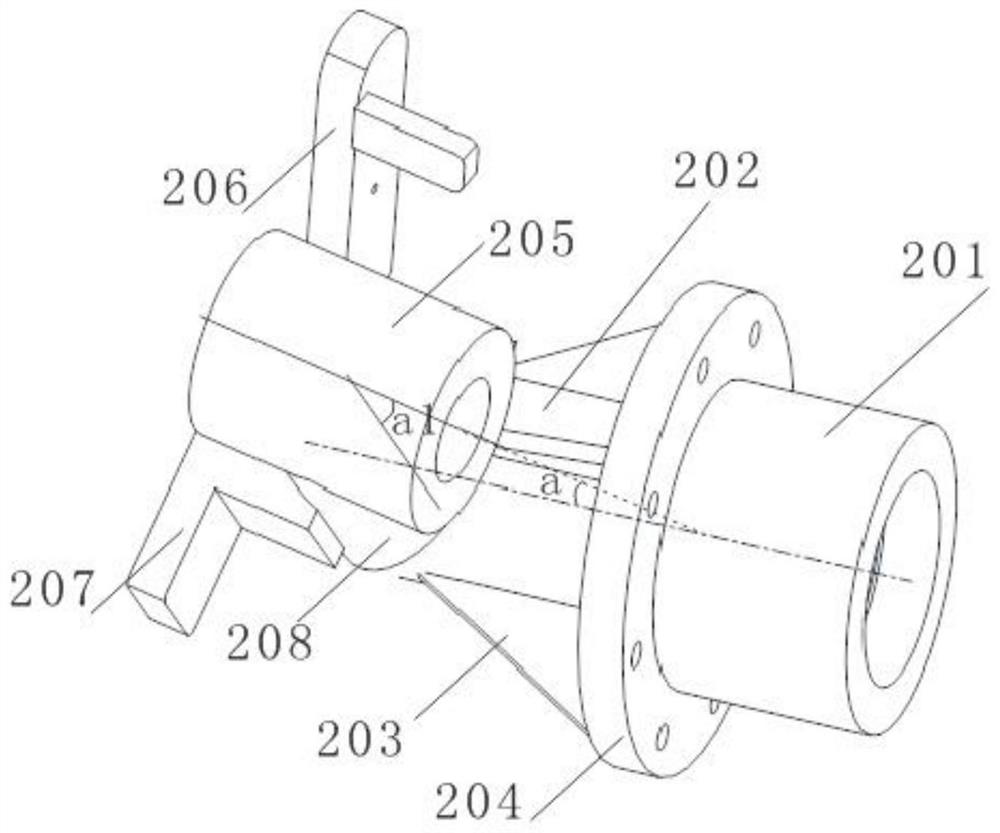

[0033] figure 1 In the complex welded (referred to as workpiece) 2 includes a main circular section, a transition cylindrical section 208, auxiliary circular section 205; the main cylindrical section is a stepped structure, including a crude cylindrical section 201 located at the front end, a fine cylindrical section located behind the rear end 202. The outer circle of the roller section 201 rear end has a circle of flange 204, and there is a circle of reinforcing thus 203 between the flange 204 and the fine circumn section 202, and the lower end of the main circle section is connected to the secondary circumn section 205, the main circular section The axis of the axis is coincident with the axis of the transition disk 3, and the axis of the main circular section and the axis of the secondary circle section 205 is a, the axis of the transition cylindrical section 208 and the axis of the auxiliary circle section is A1, complex welding 2 There is also a fastening block 206, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com