Patents

Literature

47results about How to "Guaranteed production rhythm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

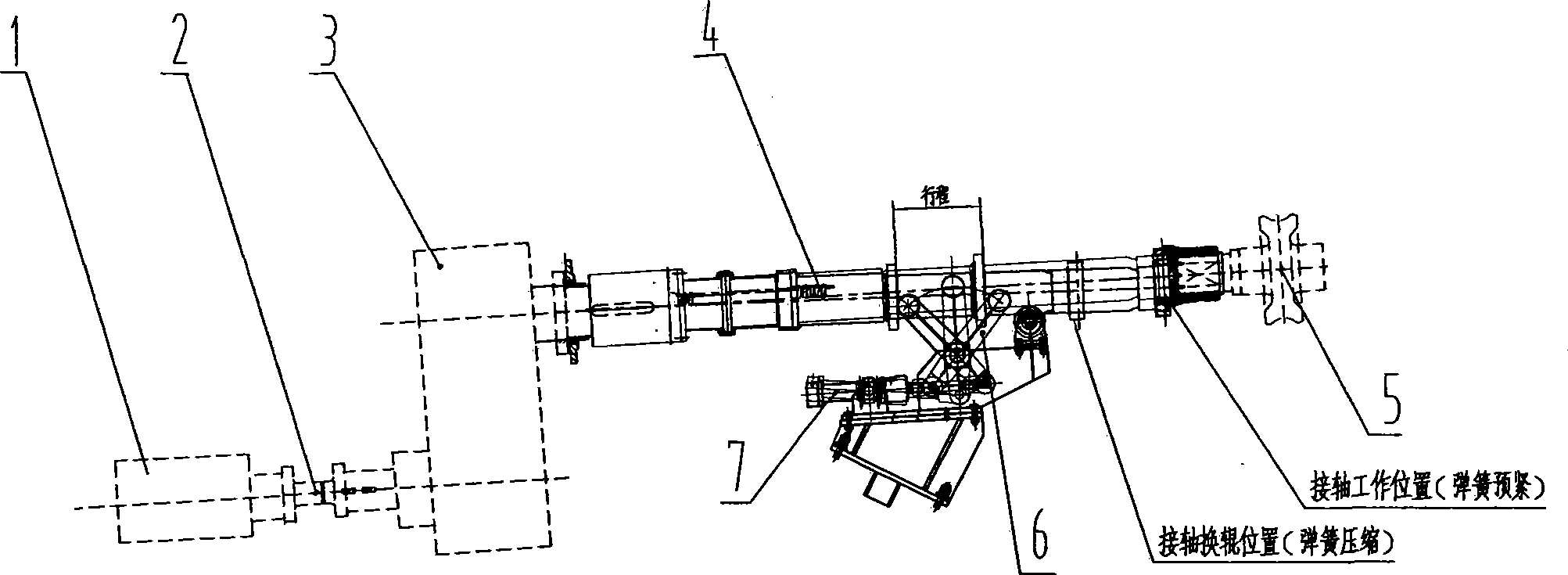

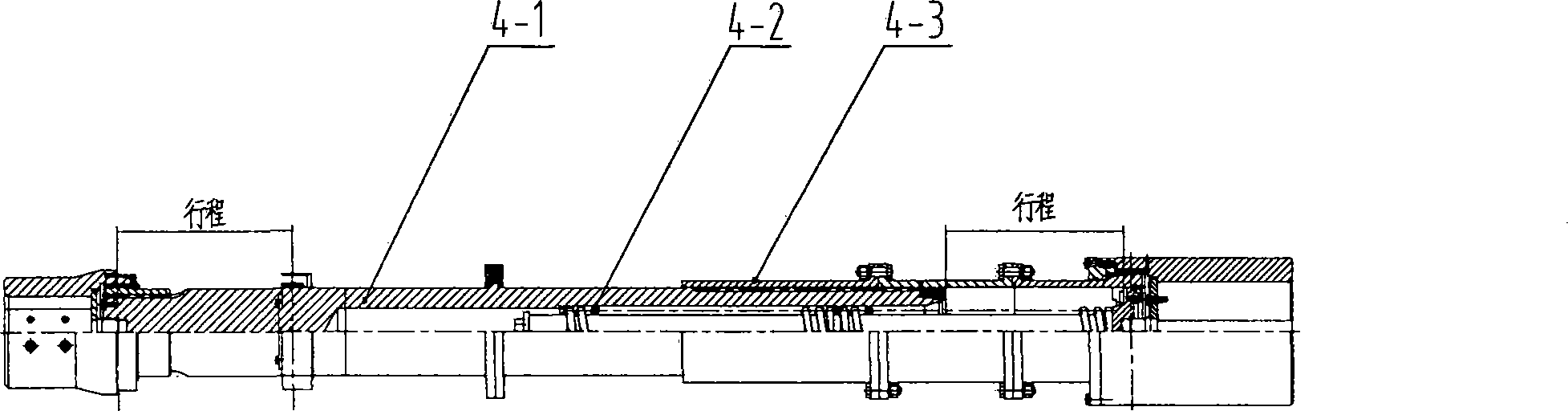

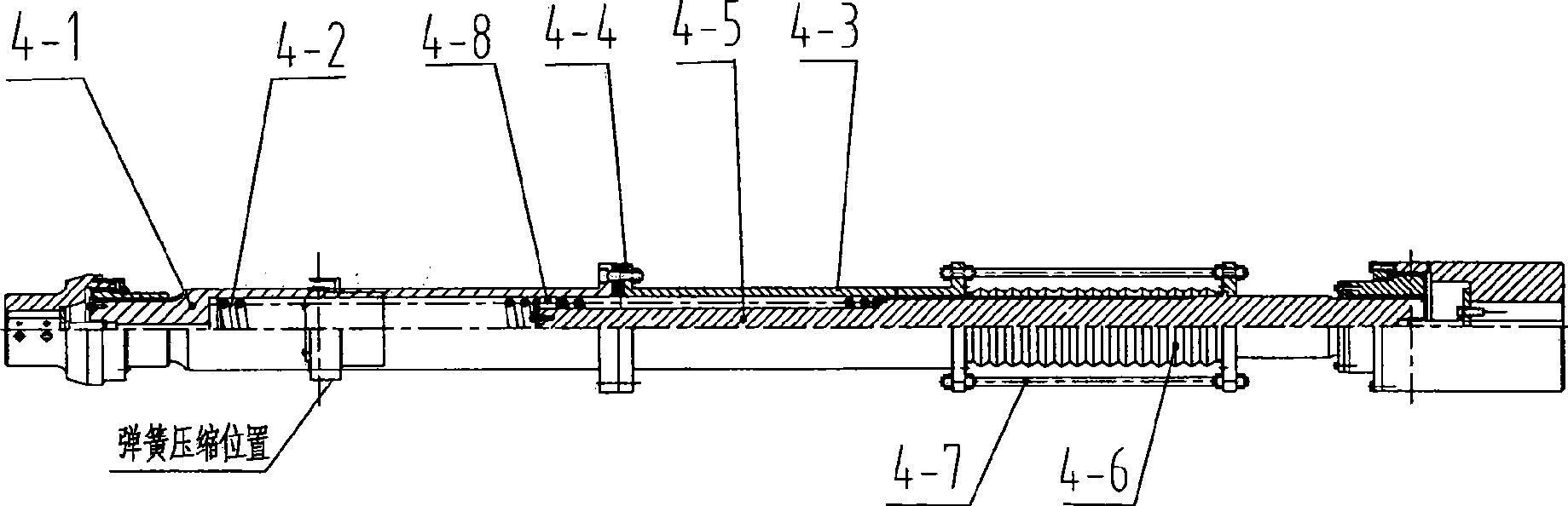

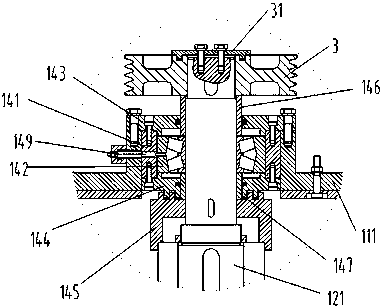

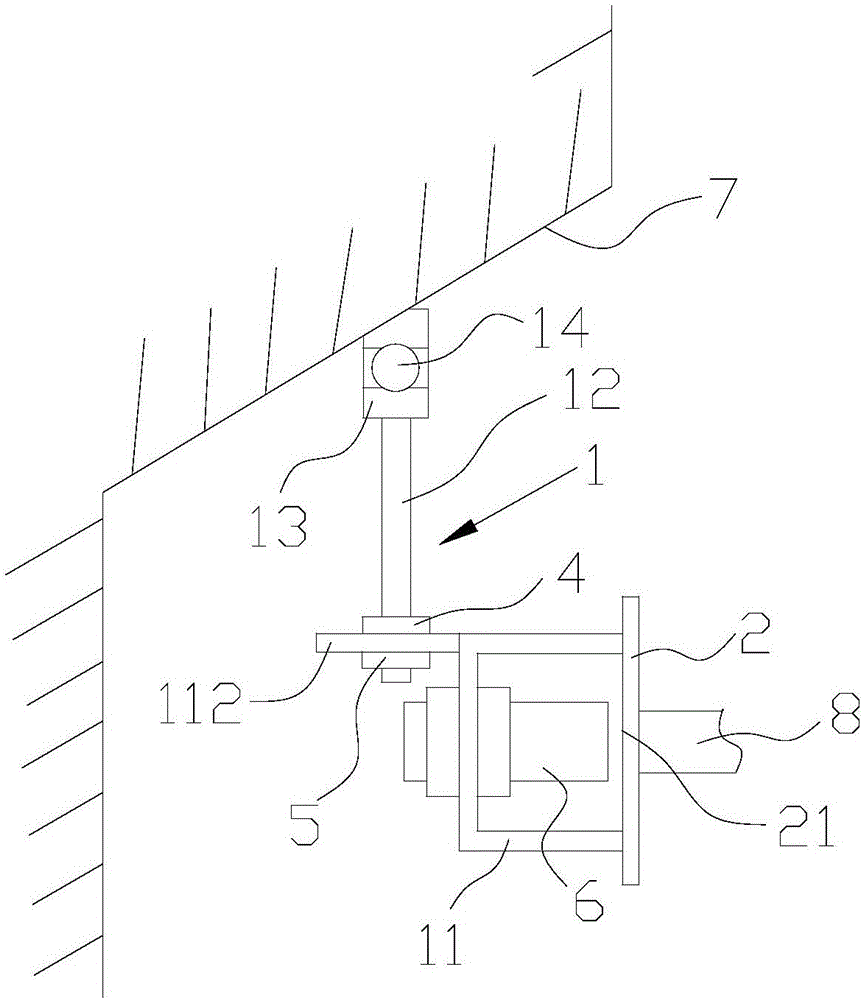

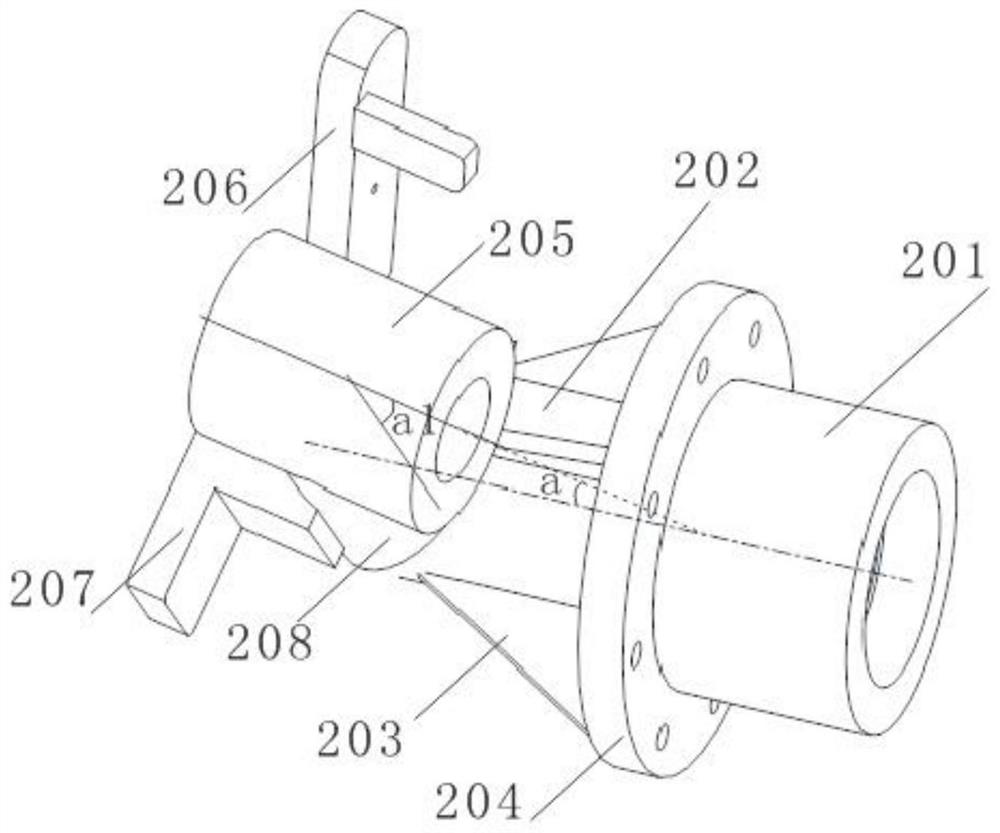

Main transmission spindle for three-roller tandem rolling tube machine

ActiveCN101439355AReduce wall thicknessIncrease stiffnessRolling mill drivesMetal rolling arrangementsEngineeringRolling mill

A main transmission connecting shaft for a three-roller continuous tube rolling mill relates to a production device of a seamless steel pipe. The invention mainly solves the problem in the prior art that roll change time of the connecting shaft is longer and unstable production factors exist so that the production rhythm of the device is affected. A movable spline shaft and an internal spline housing are connected into a sliding component by a flange; a fixed spline shaft is arranged in the sliding component; a spring is mounted between the fixed spline shaft and the sliding component; and a supporting stud is additionally arranged in the working position of the connecting shaft. The main transmission connecting shaft improves the work stability of the connecting shaft in the high-speed state, shortens the roll change time of the continuous tube rolling mill, ensures the production rhythm of the device and improves the output.

Owner:TAIYUAN HEAVY IND

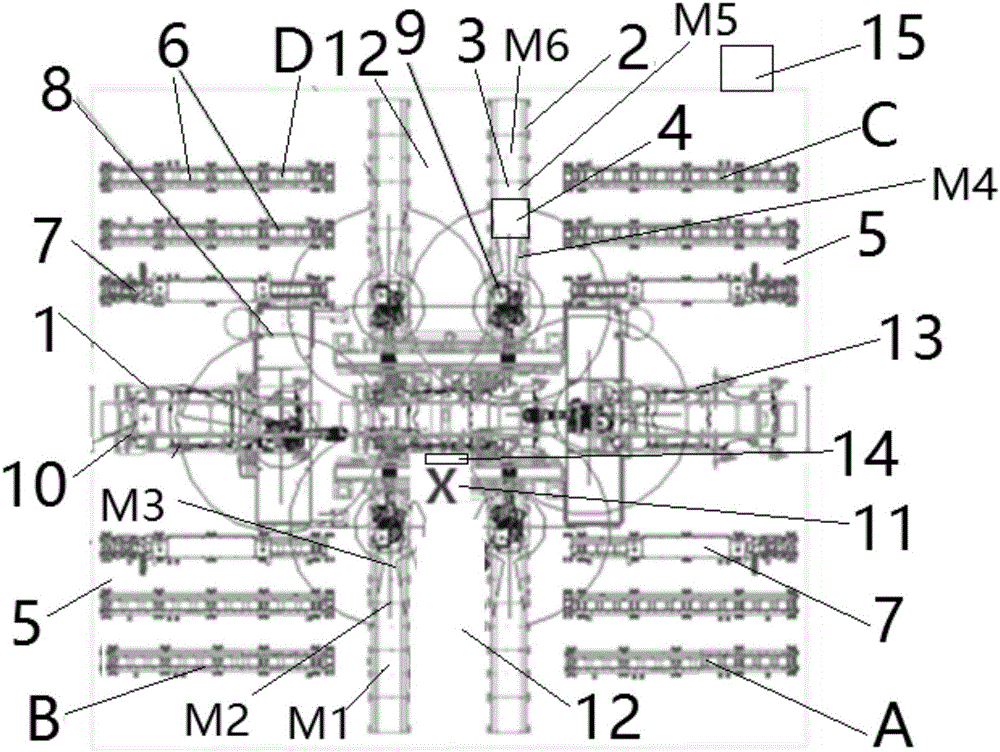

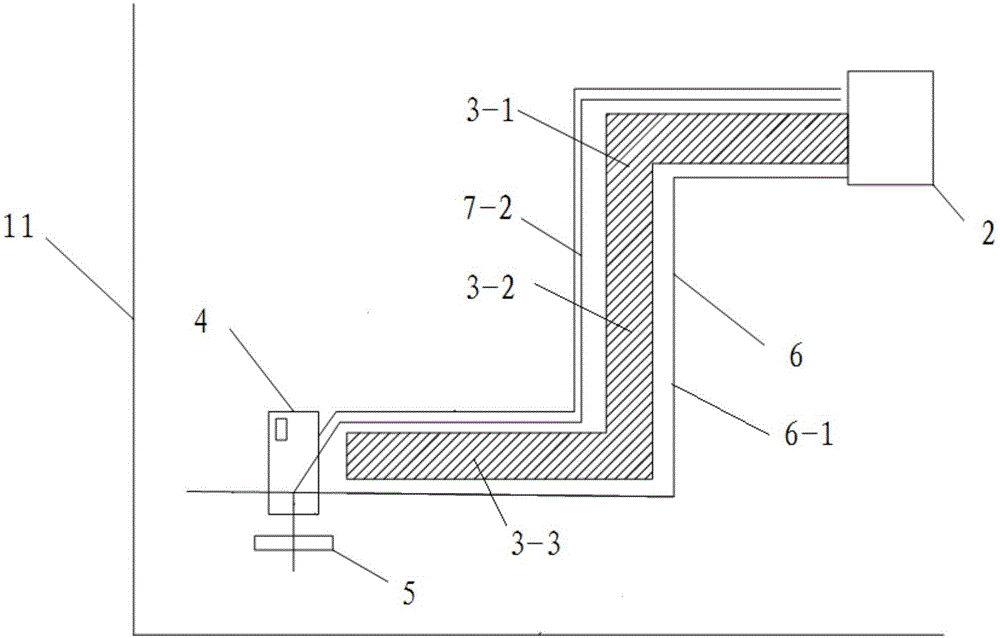

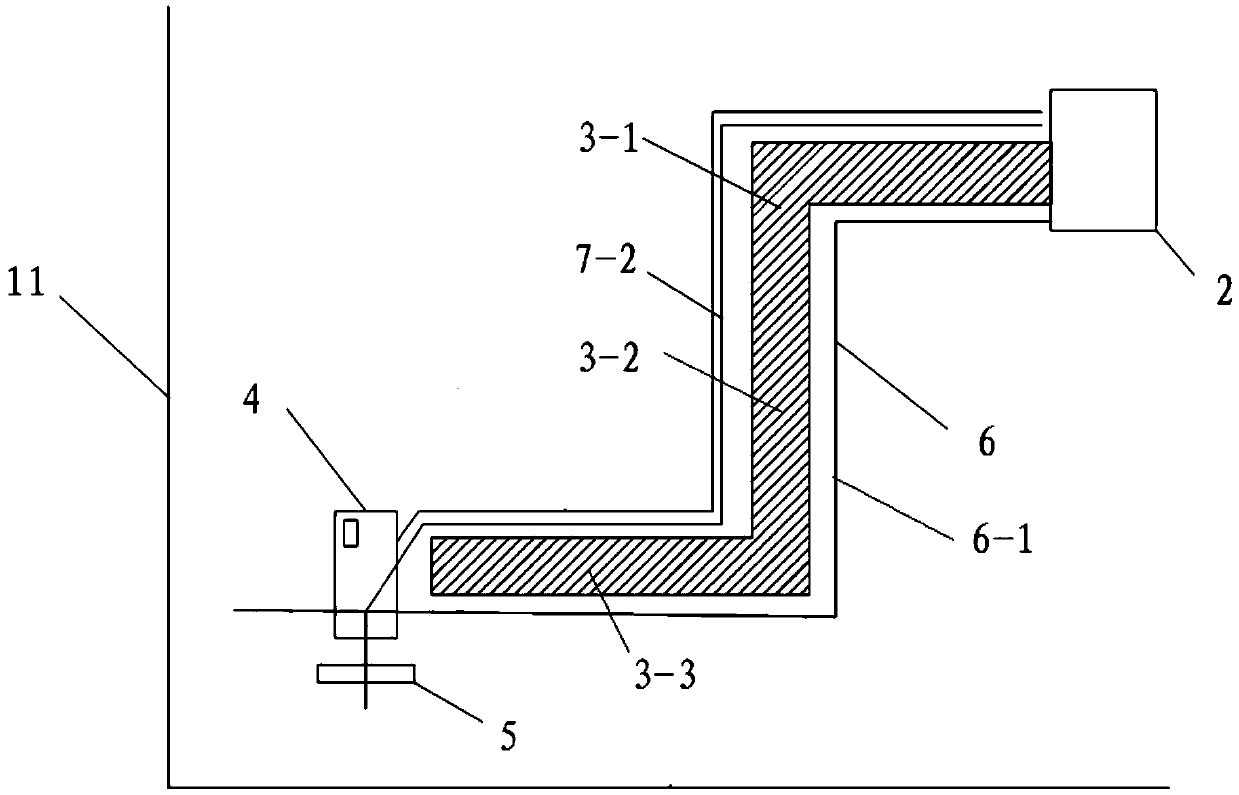

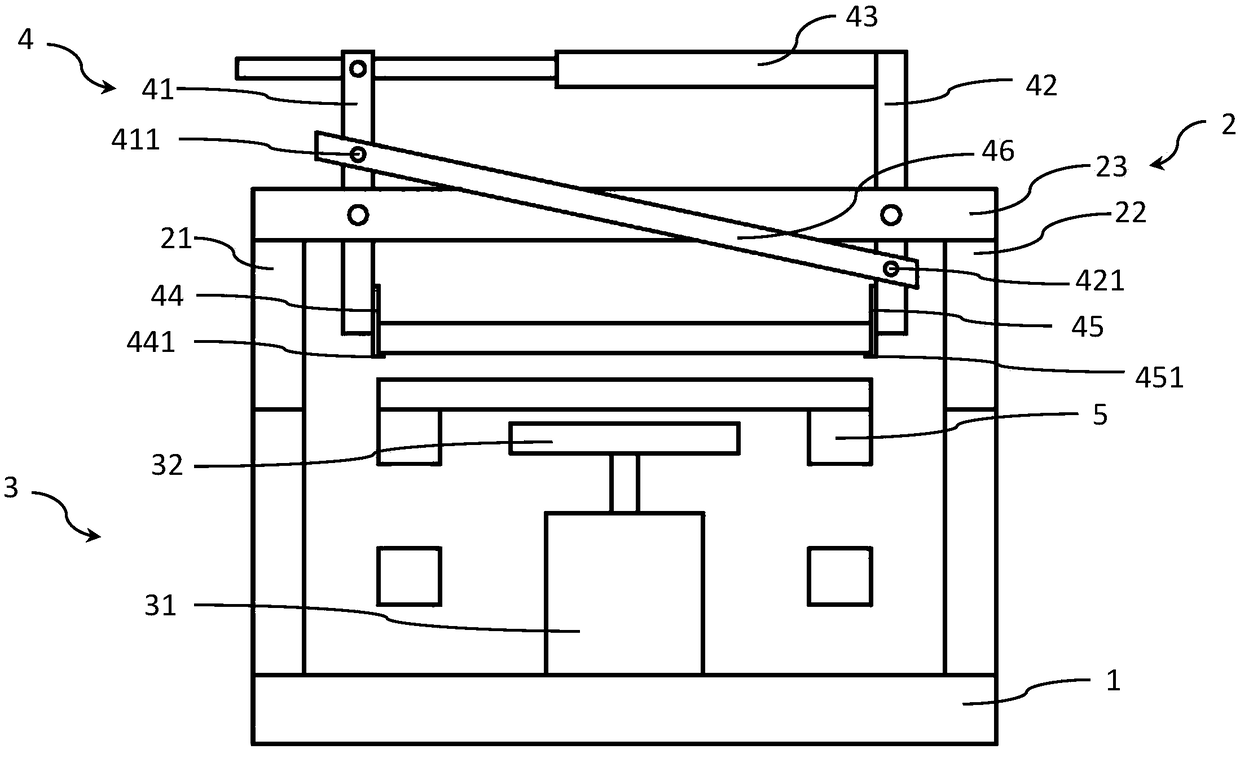

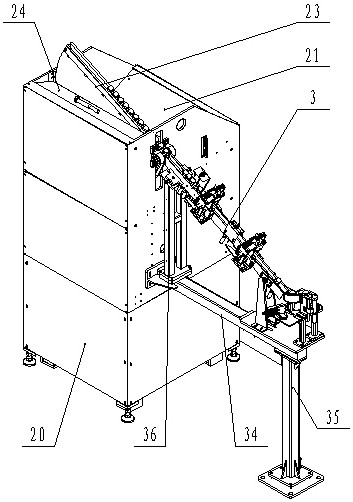

Welding production line suitable for switching of various vehicles

InactiveCN106583970AQuick switchEasy to storeWelding/cutting auxillary devicesAuxillary welding devicesProduction lineControl theory

The invention provides a welding production line suitable for switching of various vehicles and belongs to the technical field of automotive part welding and machining equipment. A servo translating track (3) of a servo translating component (2) of the welding production line suitable for switching of various vehicles is perpendicular to a vehicle body conveying track (1), a servo trailer wagon (4) is arranged on the servo translating track (3), a plurality of storage regions (5) are arranged on two sides of the servo translating track (3), and each storage region (5) is a structure in which a machining clamp (6) can be stored. The welding production line suitable for switching of various vehicles is simple in structure and low in cost; production clamps are stored conveniently; the production clamps suitable for different vehicles are arranged simultaneously, switching of the different production clamps can be realized conveniently and rapidly when parts of the different vehicles are welded, therefore, the welding and machining efficiency of the parts of the different vehicles is improved effectively, the investment of equipment of the production line is reduced, and the occupied area of the production line is also reduced.

Owner:ANHUI RUIXIANG IND

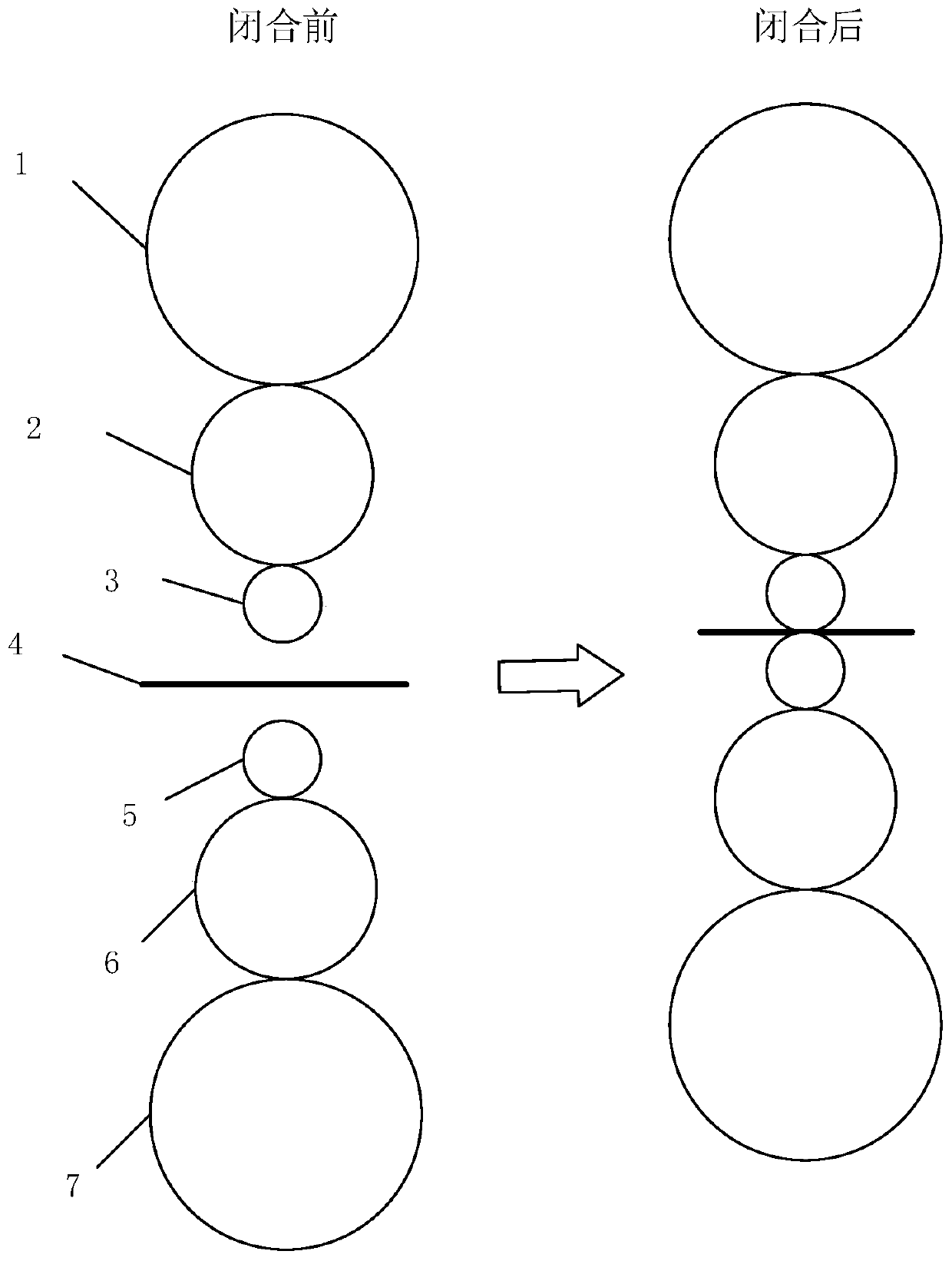

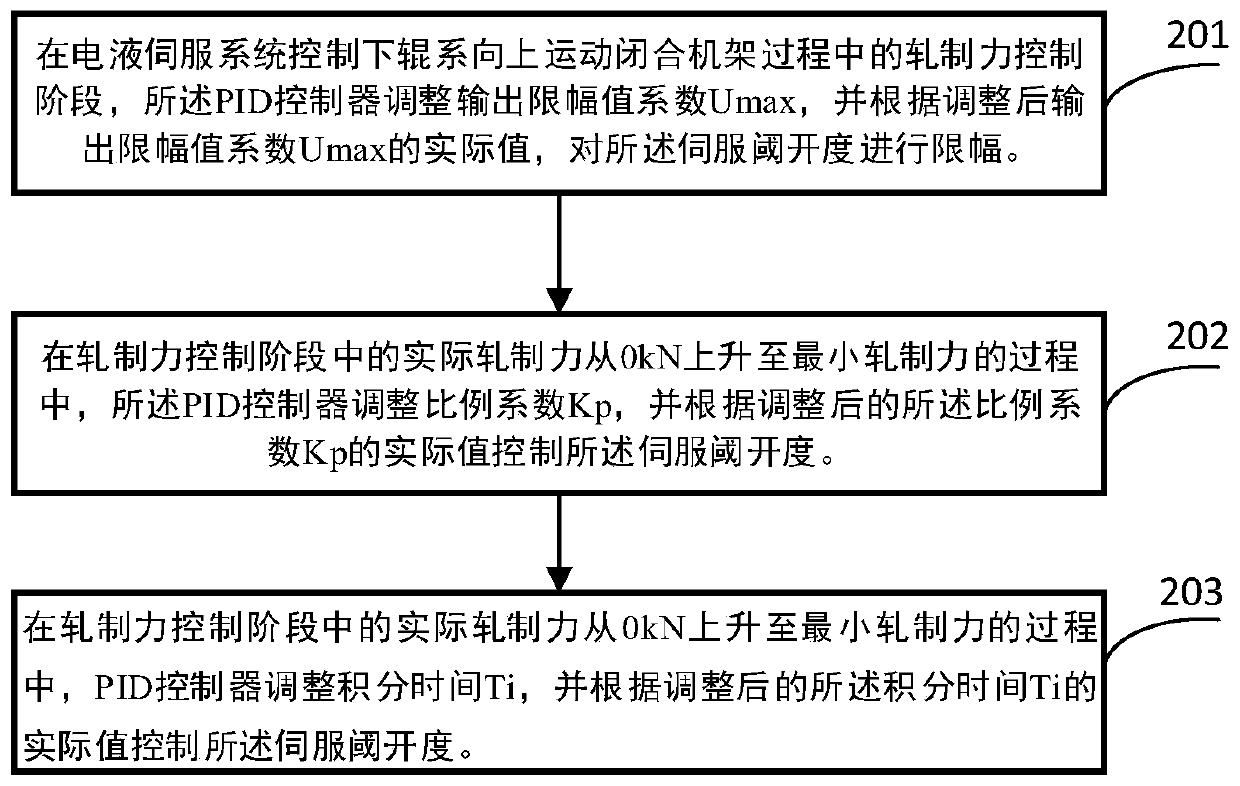

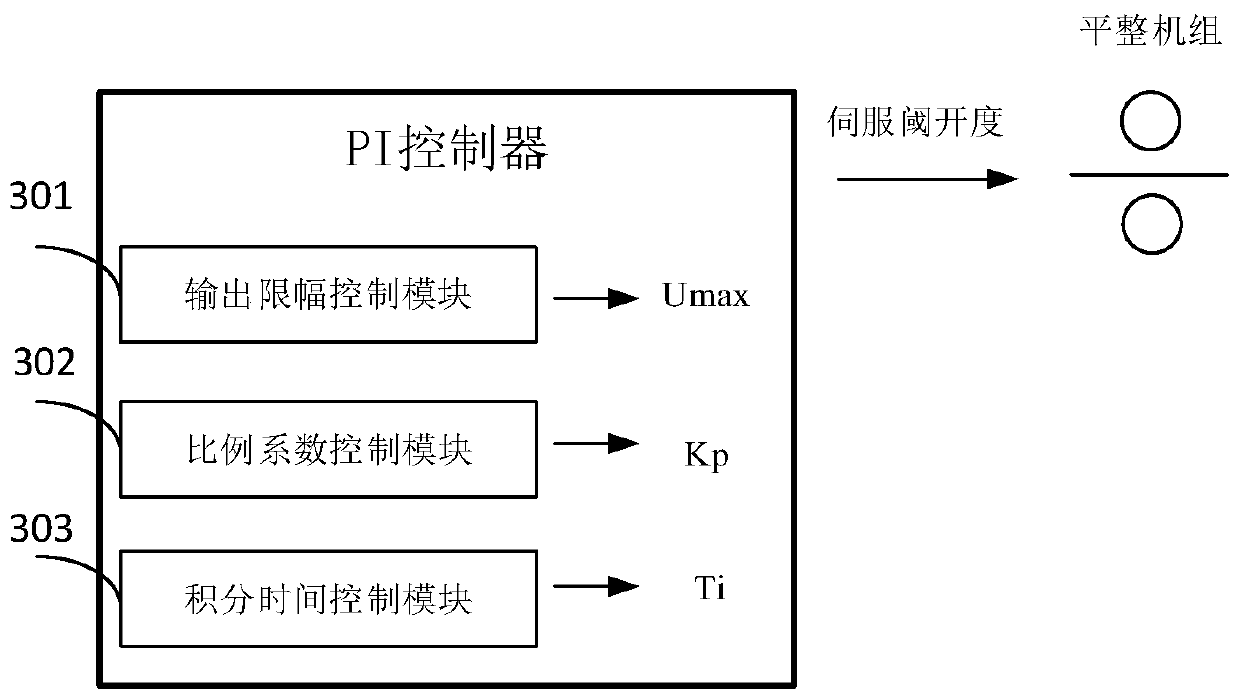

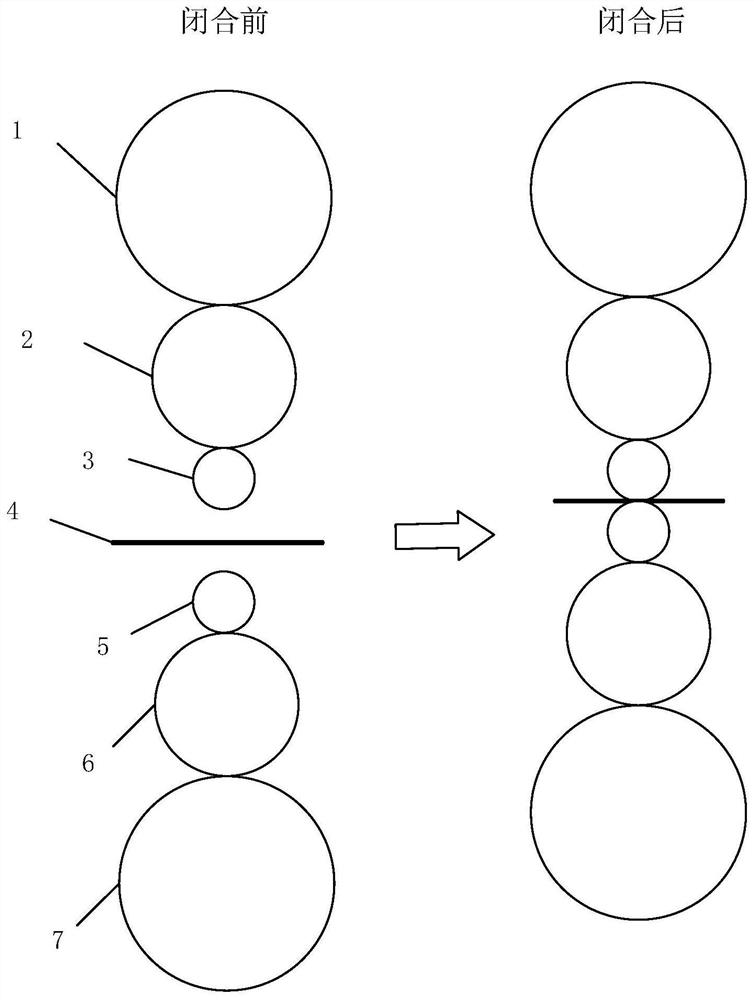

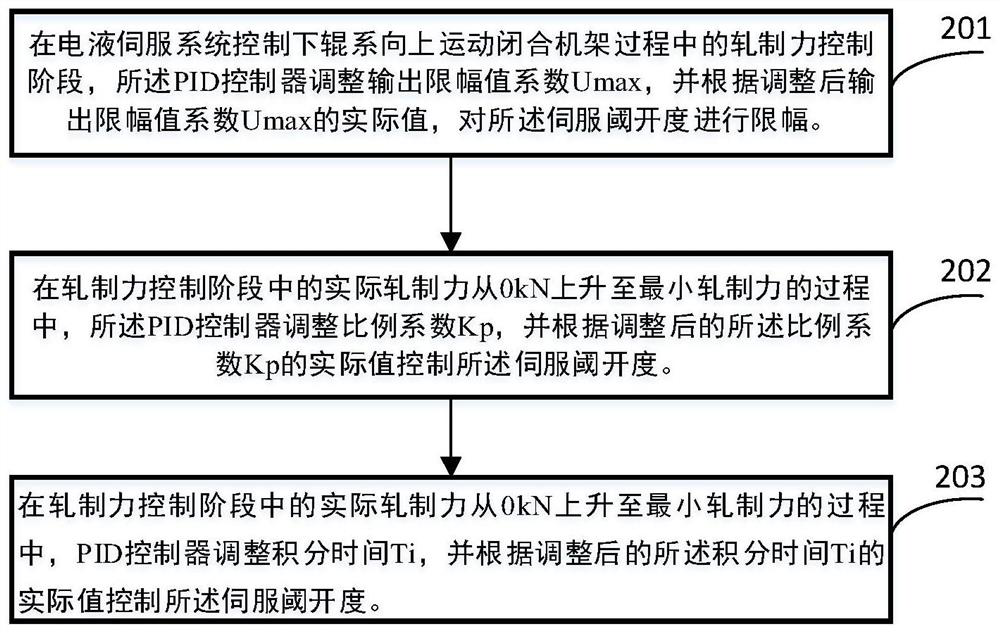

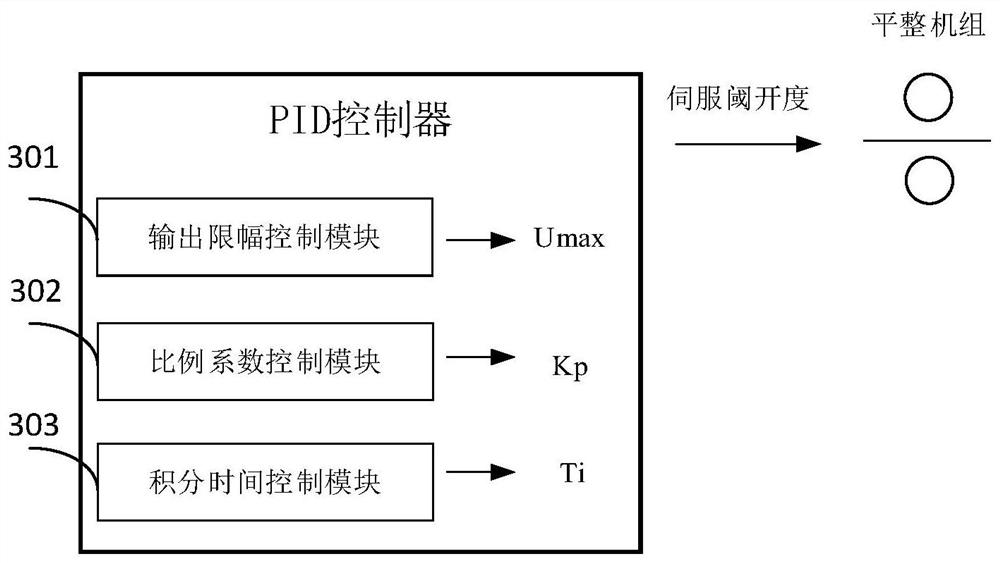

Method of controlling temper mill and electro-hydraulic servo system for controlling temper mill

ActiveCN110038907AAvoid damageElimination of "transverse roll printing" defectsRoll force/gap control deviceElectro hydraulicStrip steel

In order to solve the technical problem that after a working roller of a temper mill is replaced, the roller surface of the working roller is damaged in the machine frame closing process, the invention provides a method of controlling the temper mill. The temper mill comprises a machine frame and an electro-hydraulic servo system. The machine frame comprises an upper roller system and a lower roller system, and the electro-hydraulic servo system controls the machine frame to be opened and closed. The electro-hydraulic servo system comprises a PID controller which adjusts the servo threshold opening degree of the electro-hydraulic servo system. In the rolling force control stage of the process that the electro-hydraulic servo system controls the lower roller system to upwards move to closethe machine frame, the PID controller adjusts the output amplitude limiting value coefficient Umax, the amplitude limiting is conducted on the servo threshold opening degree, the inertia impact forcewhich is generated when rollers make contact with strip steel in the closing process of the temper mill is reduced, the phenomenon that the damage to the roller surface of the new working roller exists in the closing process is avoided, and therefore the defect of transverse roller marks which appear on the surface of the strip steel in the vehicle starting production process is overcome, and thesurface quality of the strip steel is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Smelting method of high-nitrogen sulfur-containing free-cutting steel

InactiveCN111876688AImprove purityQuality improvementManufacturing convertersProcess efficiency improvementSlagIngot

The invention discloses a smelting method of high-nitrogen sulfur-containing free-cutting steel. The smelting method mainly comprises the following steps of converter smelting tapping, LF refining furnace treatment, RH vacuum furnace treatment and continuous casting; an aluminum ingot is added in the tapping process for pre-deoxidation, low-alkalinity slag is made by an LF refining furnace, a small amount of aluminum particles are added in the slag surface, the diffusion deoxidation efficiency is improved, and molten steel is greatly purified; and an RH vacuum furnace adopts nitrogen drive, limit vacuum is kept for a certain time, a first-stage pump is retreated to a fourth-stage pump after vacuum breaking, a nitrogen-containing alloy is added, and circulation is conducted for 5 min, so that the S content and the N content in the steel can be accurately controlled, narrow-range accurate control over molten steel components is guaranteed, meanwhile, the refining period is stabilized, operation is easy, and the method is suitable for mass production. The method is simple, effective, easy to operate, capable of accurately controlling refining time and refining components, improving molten steel quality and guaranteeing the production rhythm and suitable for wide popularization.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

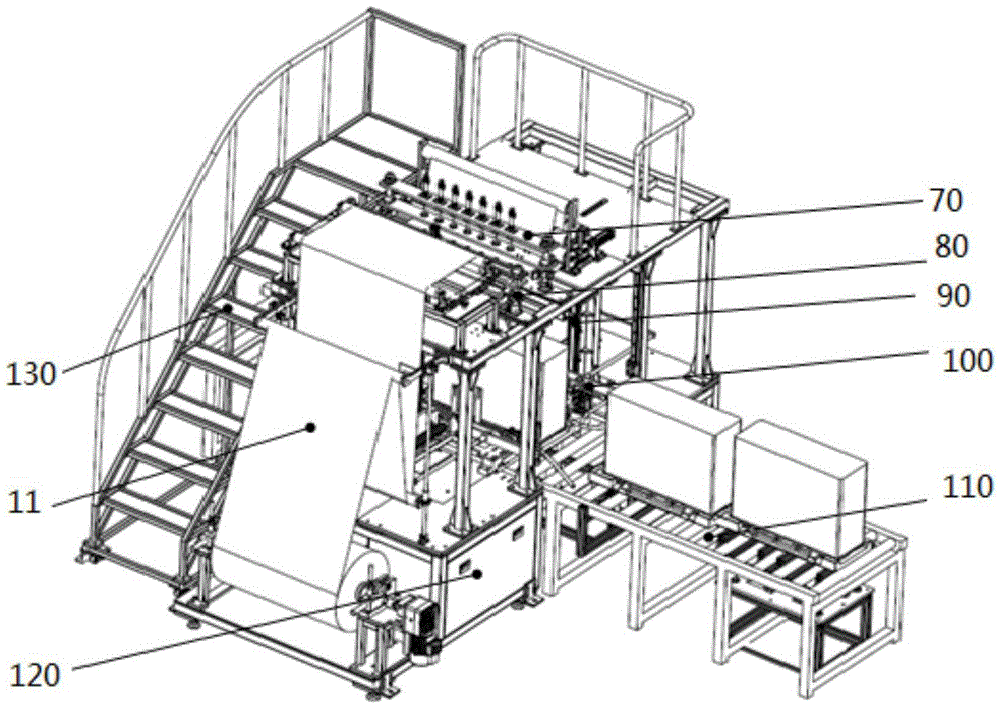

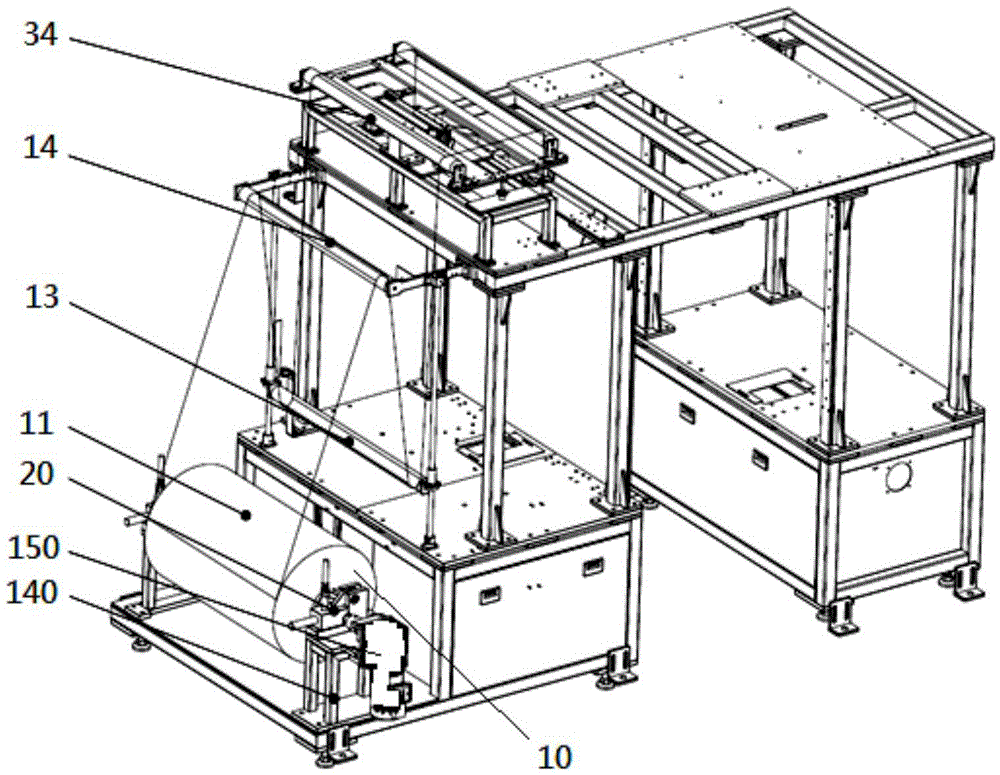

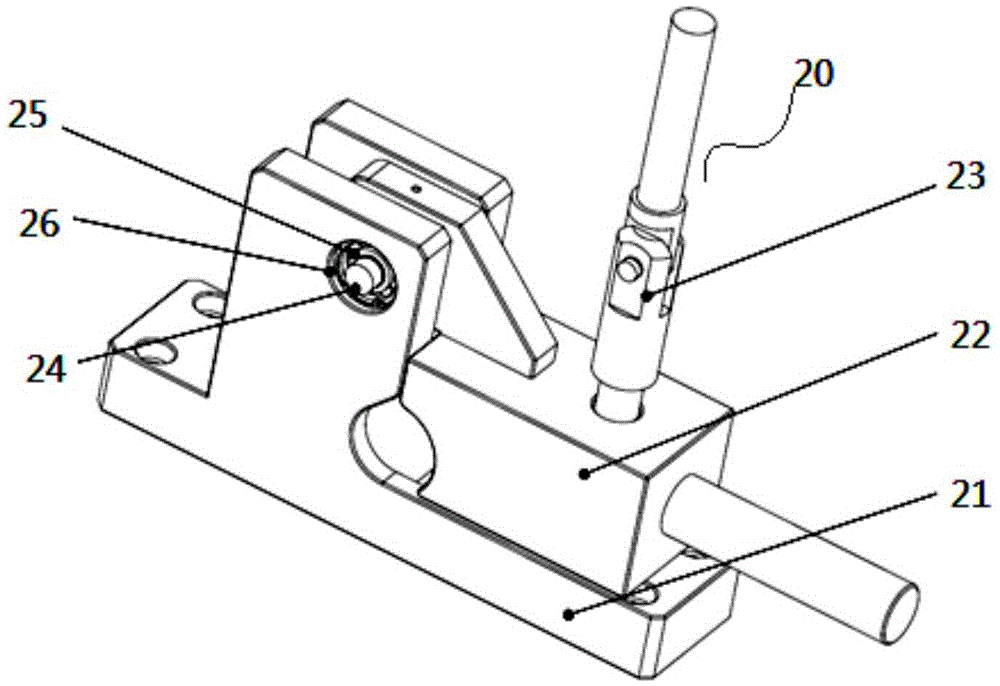

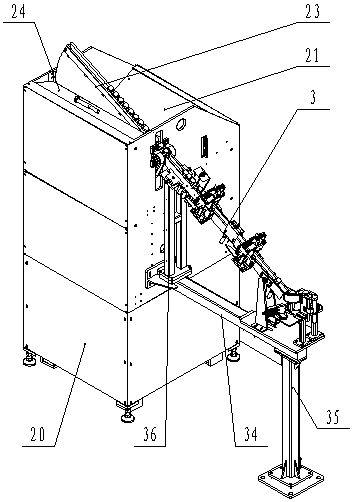

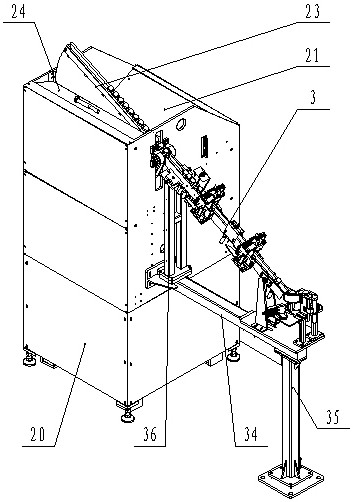

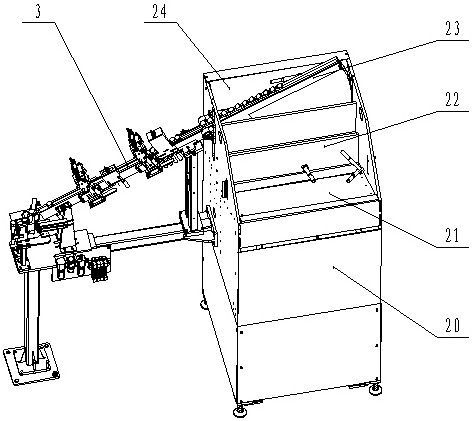

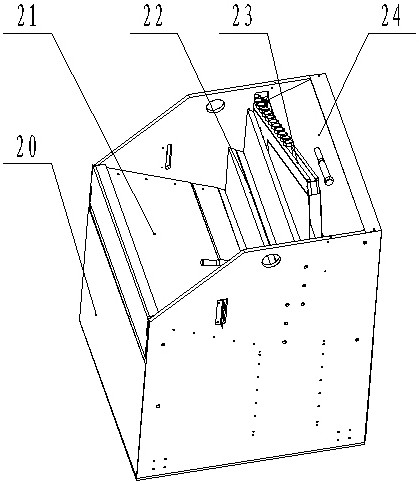

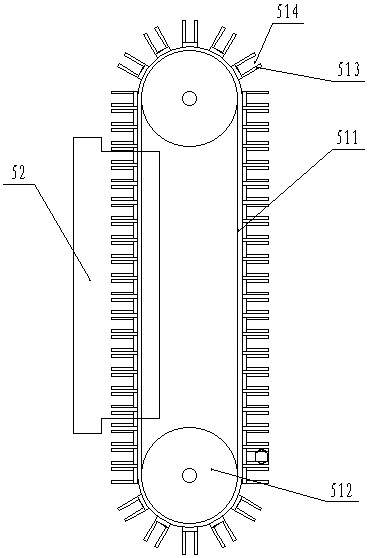

Feeding system and packaging bagger

InactiveCN105417226ASpeed up the flowGuaranteed production rhythmWebs handlingMechanical engineeringMotion direction

The invention provides a feeding system and a packaging bagger. The feeding system comprises coiling blocks, two clamping mechanisms, a deviation correcting mechanism and a conveying roller assembly, wherein each coiling block is formed by coiling a material or the material is coiled on each coiling block; the two clamping mechanisms are positioned at the two sides of the coiling blocks; the coiling blocks are arranged on the clamping mechanisms; a deviation correcting part of the deviation correcting mechanism swings to correct deviation of the conveying position of the material; the deviation correcting mechanism is positioned in the downstream position of the coiling blocks; the conveying roller assembly is positioned between the coiling blocks and the deviation correcting mechanism in the motion direction of the material. The feeding system disclosed by the invention solves the problem that in the prior art, material deviation happens of a feeding system and accordingly normal production is affected .

Owner:GREE ELECTRIC APPLIANCES INC

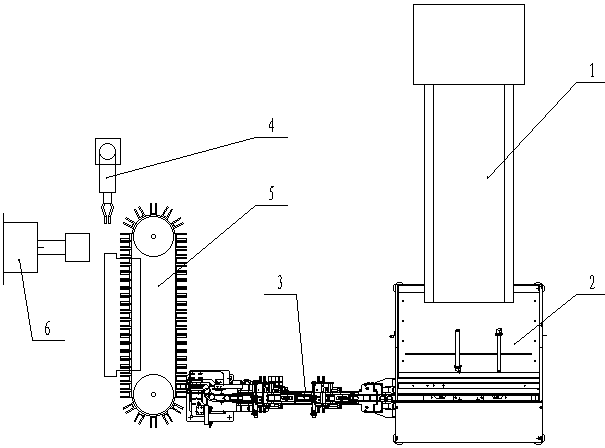

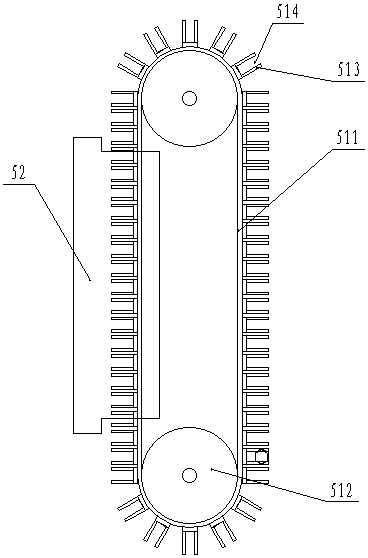

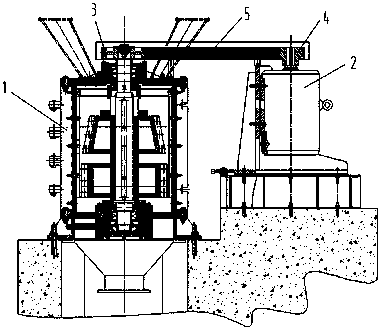

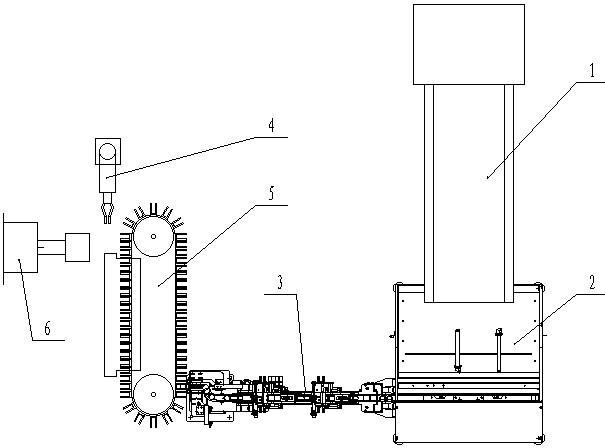

Automatic production system of spike

ActiveCN110340263AIncrease productivityGuaranteed production rhythmMetal-working feeding devicesScrew-threads articlesEngineeringFeeding mode

The invention discloses an automatic production system of a spike. The automatic production system comprises an automatic spike feeding machine, a spike heating machine and a spike thread rolling machine, wherein the automatic spike feeding machine comprises a spike feeding line, a stepped feeding machine and a discharging mechanism, the spike feeding line is used for conveying the spike to the stepped feeding machine, and the stepped feeding machine conveys the spike to the discharging mechanism in a stepped feeding mode; the spike heating machine is arranged at the tail end of the discharging mechanism of the automatic spike feeding machine, the spike heating machine comprises a rotary disc type feeding mechanism and a heating mechanism, the heating mechanism is arranged on a conveying route of the rotary disc type feeding mechanism, and the spike on the rotary disc type feeding mechanism is heated; a robot gripper is arranged between the spike thread rolling machine and the rotary disc type feeding mechanism, and the robot gripper grabs the spike which passes through the heating mechanism and moves the spike to the spike thread rolling machine to carry out thread rolling operation. According to the automatic production system of the spike, the automatic and systematized production of the spike is realized, and the production efficiency is improved.

Owner:中原利达铁路轨道技术发展有限公司

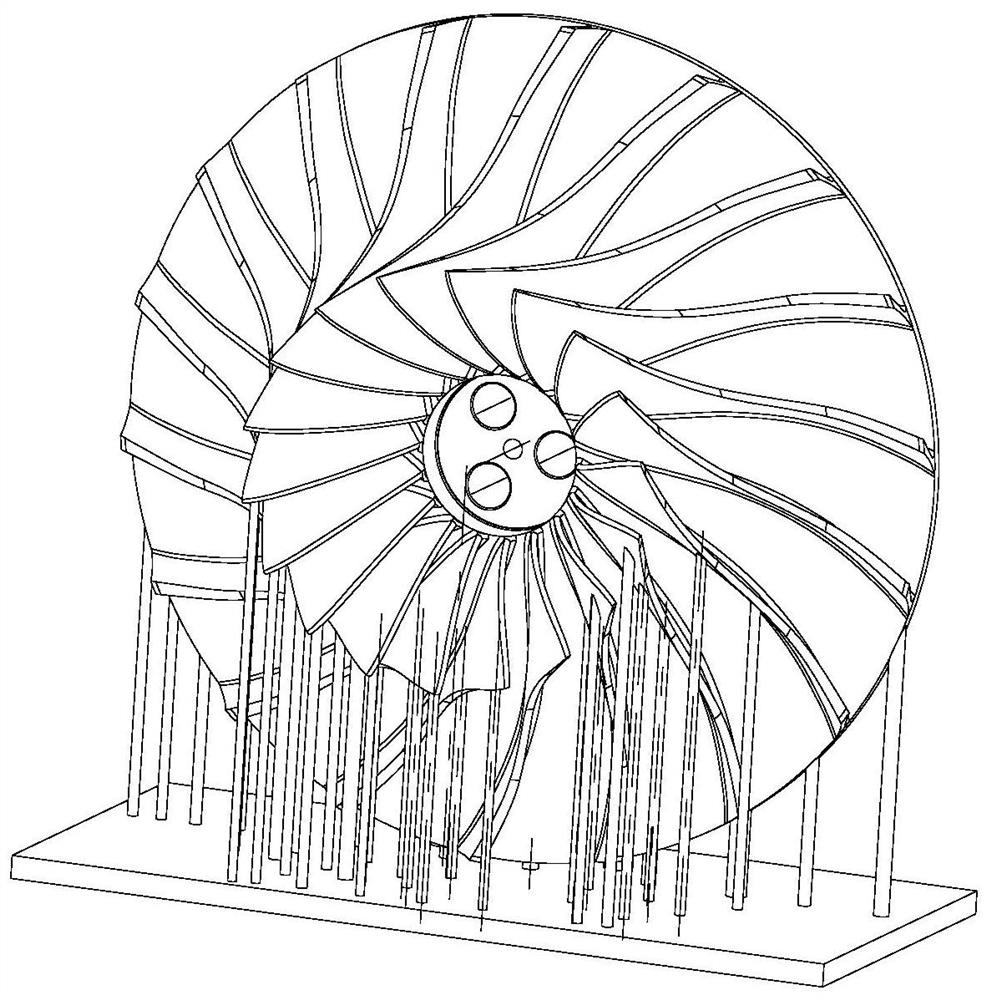

M-cavity sand making machine

InactiveCN109046601AIncrease productivityAvoid unsmooth feedingGrain treatmentsWear resistantElectric machinery

The invention discloses an M-cavity sand making machine, and relates to the field of sand making machines. The M-cavity sand making machine comprises a machine body and a motor, the machine body comprises a shell body and a rotating device, the shell body comprises a feeding port, a top plate, a cylinder body, a base and a discharging port which are sequentially arranged from top to bottom, and awear-resistant lining plate is arranged in the cylinder body; the rotating device comprises a rotating shaft, a conical boss type upper rotating frame, a connecting spacer bush and a cylindrical lowerrotating frame are sequentially and fixedly arranged on the rotating shaft, a wear-resistant plate hammer a is arranged on the upper rotating frame, and a wear-resistant plate hammer b is arranged onthe lower rotating frame; one end of the rotating shaft is inserted into the center of the base and is movably connected with the base, the lower rotating frame is arranged close to the base, the other end of the rotating shaft penetrates through the center of the top plate and is movably connected with the top plate, a belt wheel a is fixedly arranged at the end of the rotating shaft, and a beltwheel b is fixedly arranged at the end of an output shaft of the motor; and the M-cavity sand making machine further comprises a belt, and the belt wheel a and the belt wheel b are in transmission connection through the belt. According to the M-cavity sand making machine, materials can be fully crushed in the machine, the sand making efficiency is high, moreover, discharging is smooth, manual operation and screening are not needed, and the labor intensity is reduced.

Owner:SICHUAN JIANGYOU XINCHUAN MINE MACHINERY

Carbonization furnace wall spray repair device and method

ActiveCN106244174AGood for longevityReduce labor intensityCoke oven safety devicesBrickwork leakage repair/preventionRepair timeProgrammable logic controller

The invention discloses a carbonization furnace wall spray repair device and method belonging to the technical field of coke making. In the carbonization furnace wall spray repair device, one end of a positioning mechanism is movably arranged in a sliding chute; a high-temperature imaging instrument is arranged at the other end of the positioning mechanism; a closing plate is arranged at the other end of the positioning mechanism; one end of a purging mechanism is arranged on a coke leveling vehicle, and the other end is arranged on one side of the closing plate; one end of a refractory mortar conveying mechanism is arranged on the coke leveling vehicle, the other end is communicated with the closing plate, and the refractory mortar conveying mechanism is communicated with one end of the purging mechanism; and a programmable logic controller is connected with the positioning mechanism, the high-temperature imaging instrument, the purging mechanism, the refractory mortar conveying mechanism and the coke leveling vehicle. According to the carbonization furnace wall spray repair device and method, artificial high-temperature repair work in a carbonization chamber can be replaced, thus effectively relieving the labor intensity and ensuring the production safety; and no cooling treatment is needed, thus shortening the repair time, ensuring the production rhythm and being beneficial to the long service life of a carbonization chamber walling.

Owner:武汉钢铁有限公司

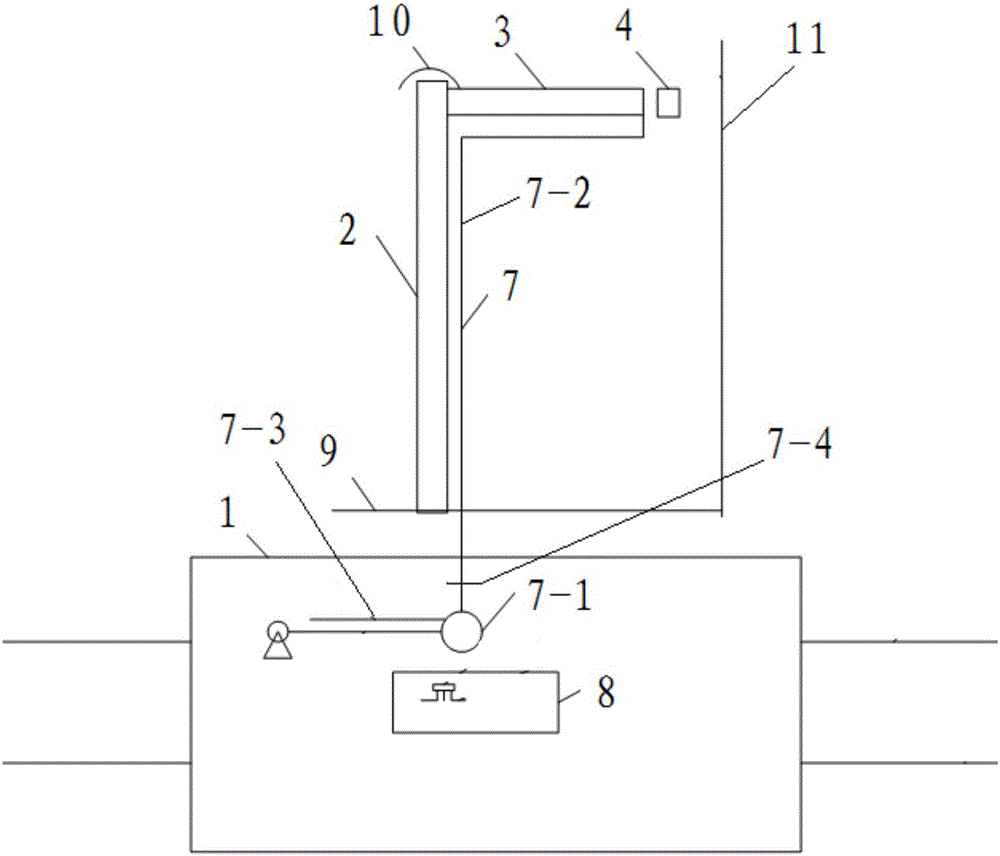

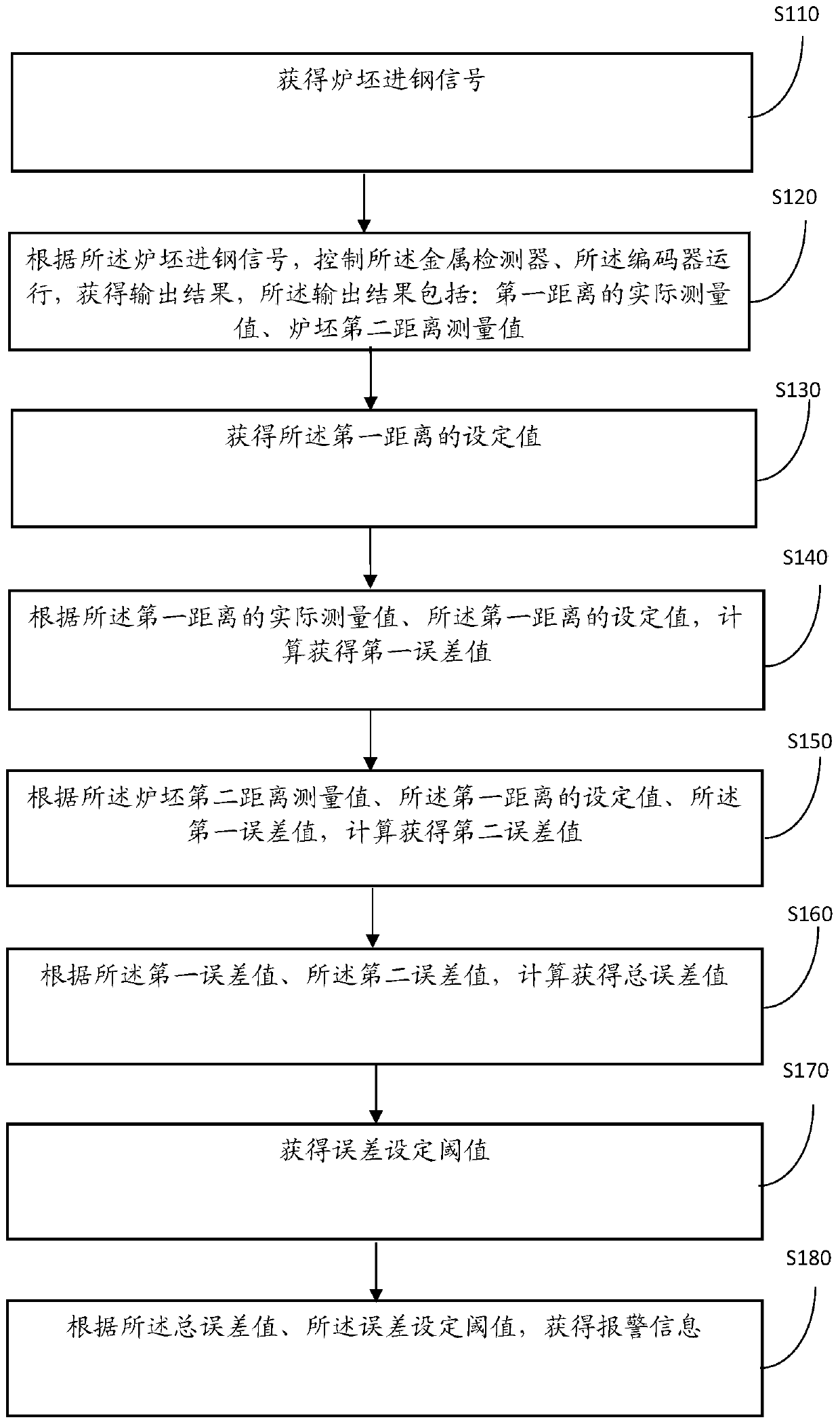

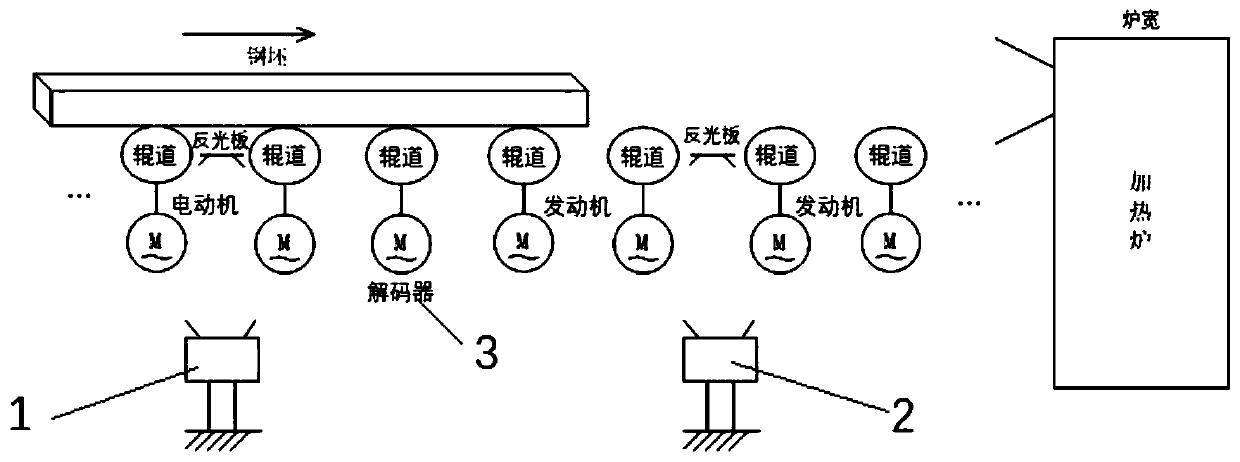

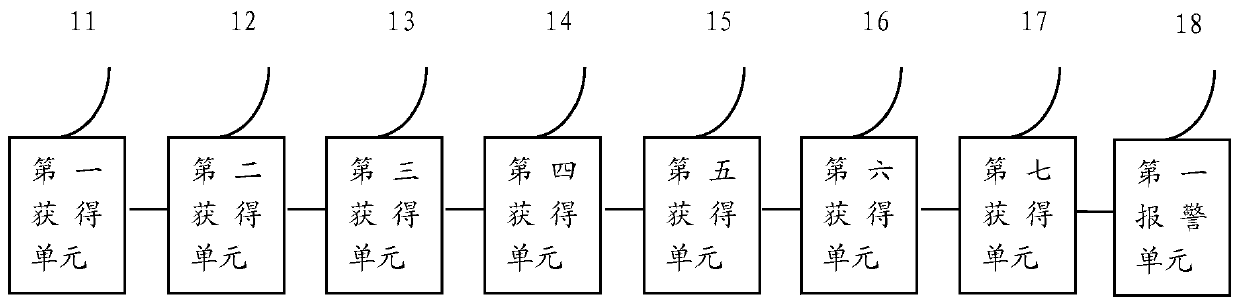

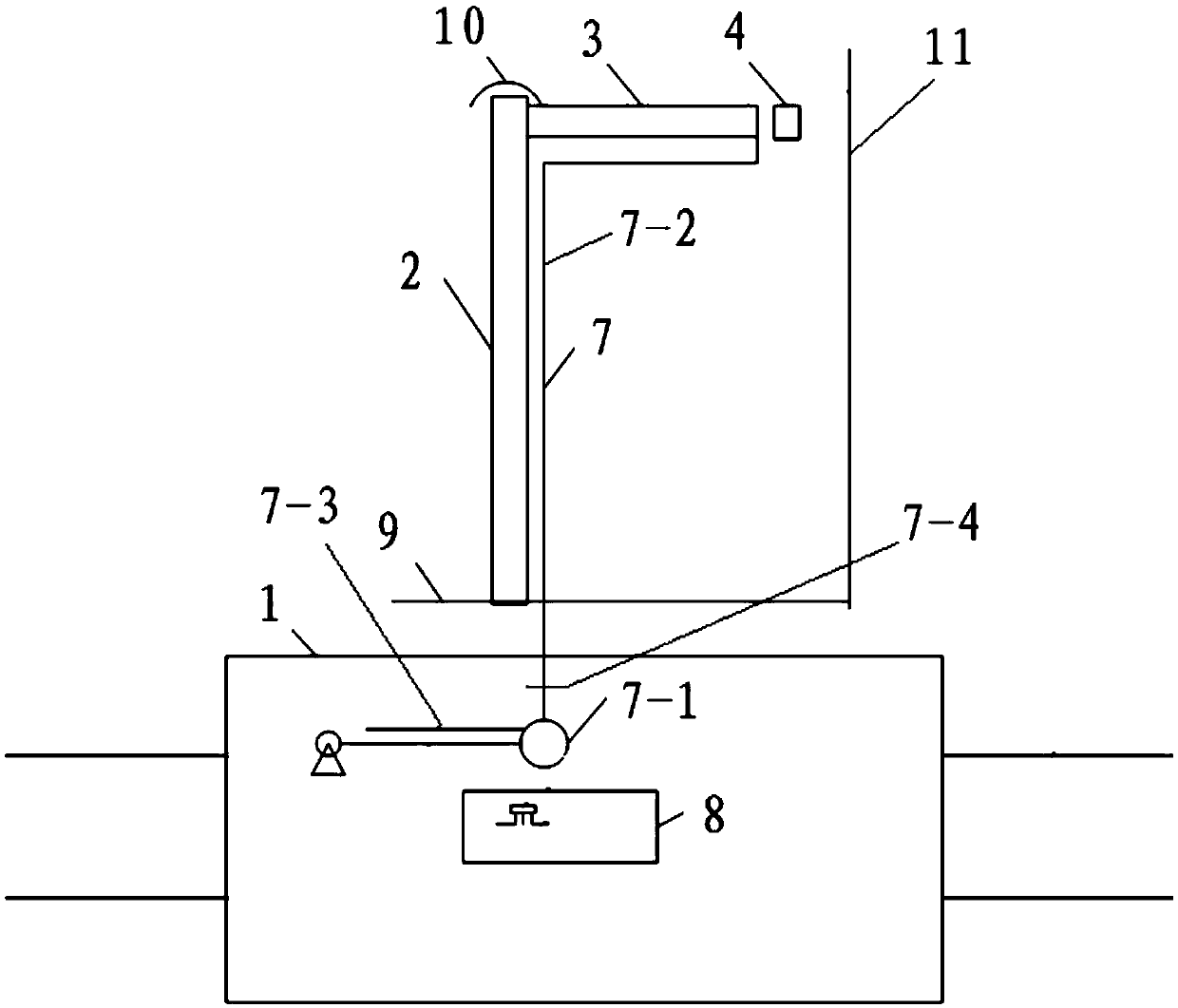

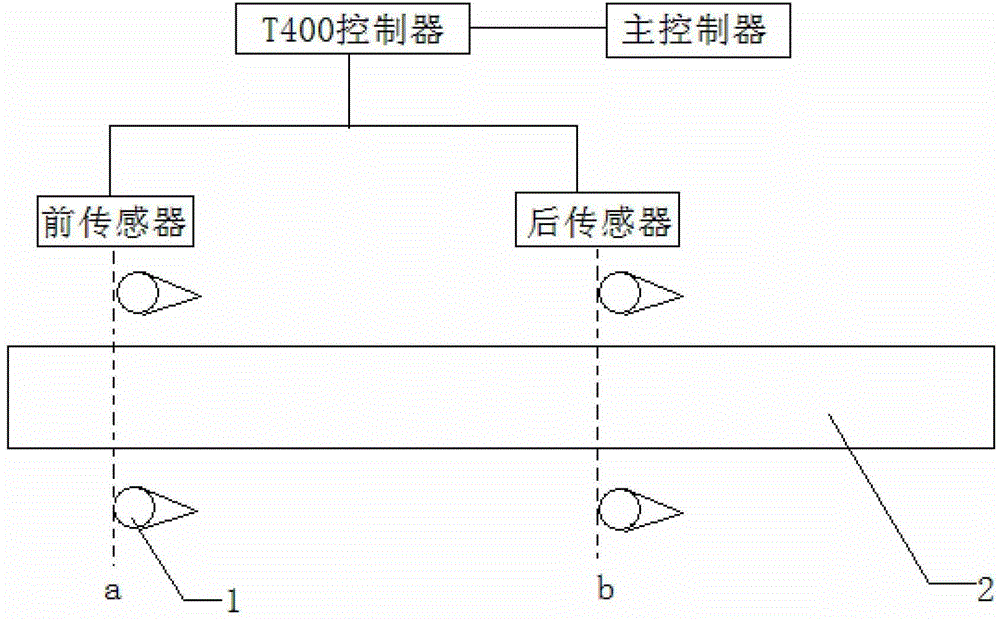

Steel rolling heating furnace charging blank length measurement alarm method and device

ActiveCN110986611AGuaranteed uptimeGuaranteed accuracyControl devices for furnacesHeating furnaceAlarm message

The invention provides a steel rolling heating furnace charging blank length measurement alarm method and device. The method comprises the steps that a furnace blank steel feeding signal is obtained;according to the furnace blank steel feeding signal, a metal detector and an encoder are controlled to operate, and output results including a first distance actual measurement value and a second distance measurement value of a furnace blank are obtained; a first distance set value is obtained; a first error value is calculated according to the first distance actual measurement value and the firstdistance set value; a second error value is calculated according to the second distance measurement value of the furnace blank, the first distance set value and the first error value; a total error value is obtained according to the first error value and the second error value; an error setting threshold is obtained; and the alarm information is obtained according to the total error value and theerror setting threshold. The technical problems that a method used in the prior art is large in measurement value error, false alarm is likely to be generated, and the production rhythm is influencedare solved. The technical effects that the length detection result is more accurate, the accuracy of alarm information is ensured, and the false alarm rate is effectively reduced are achieved.

Owner:JIANGSU YONGGANG GROUP CO LTD

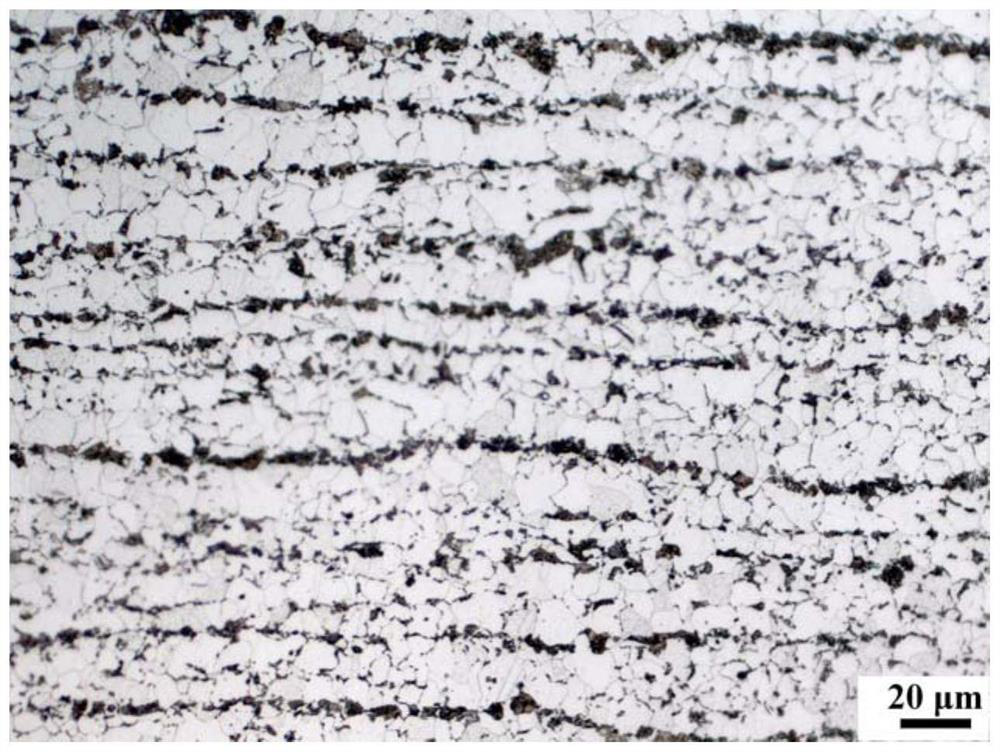

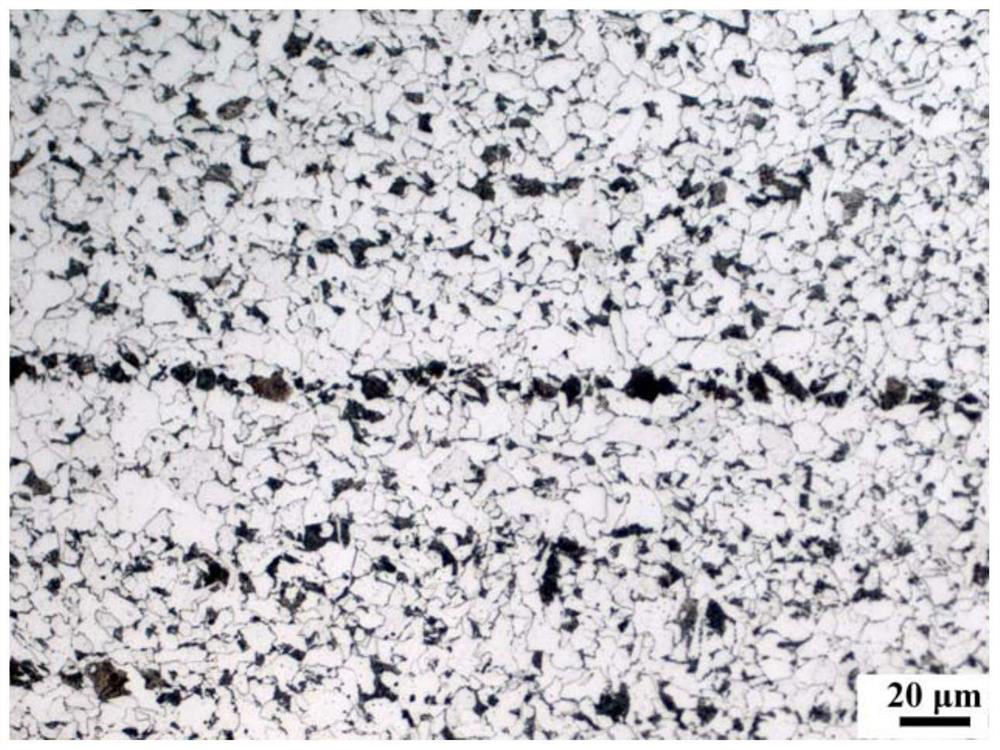

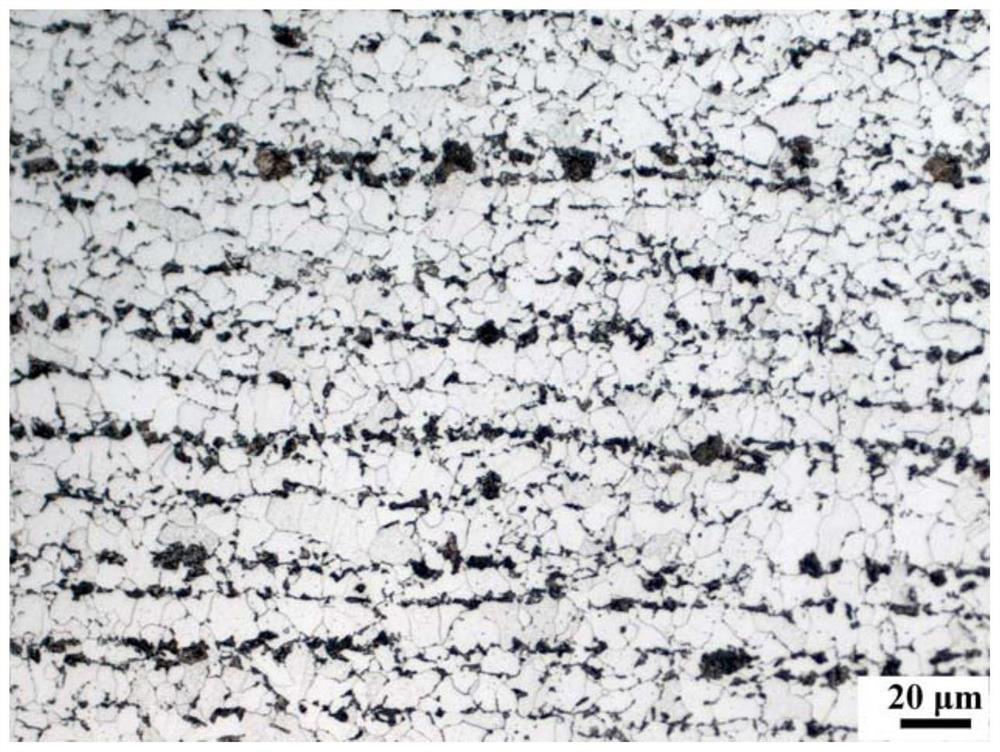

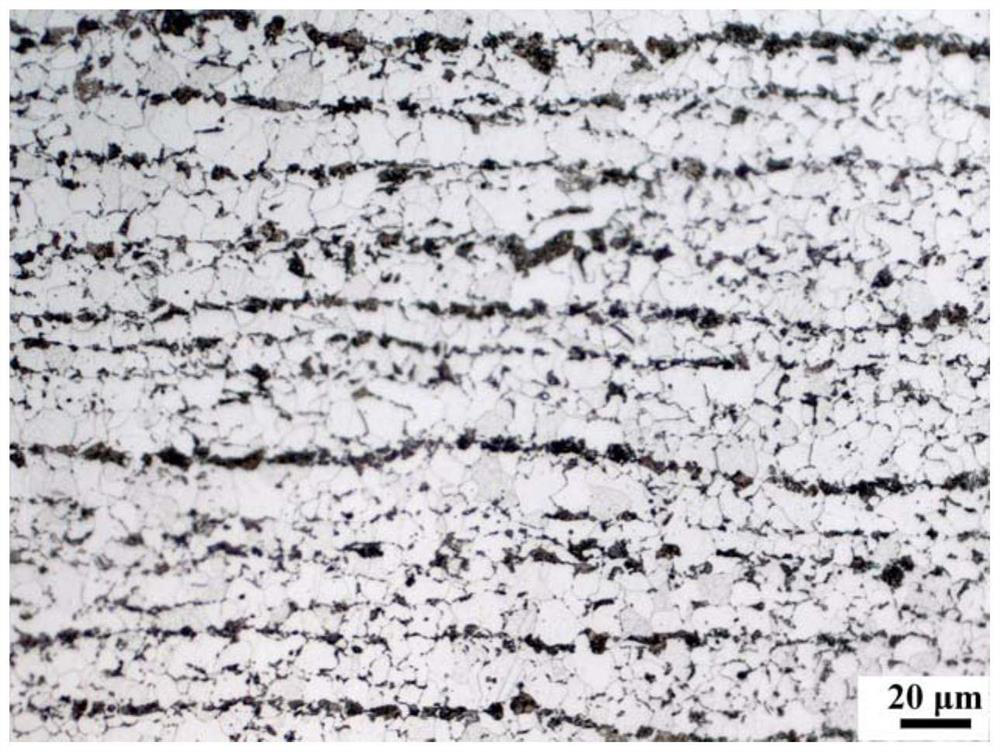

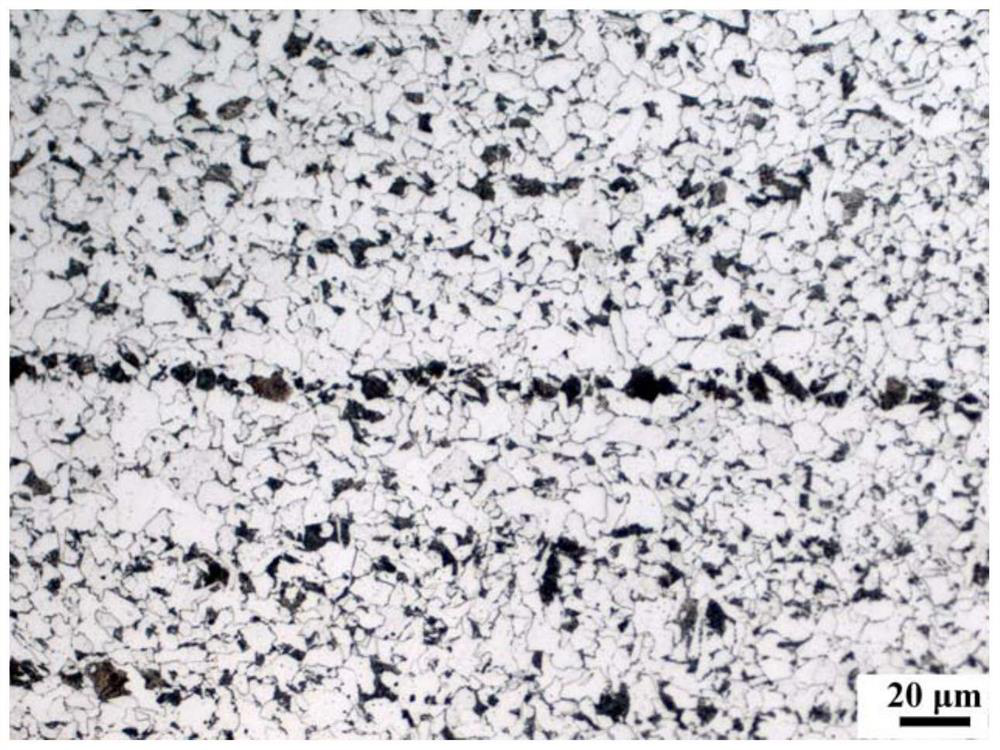

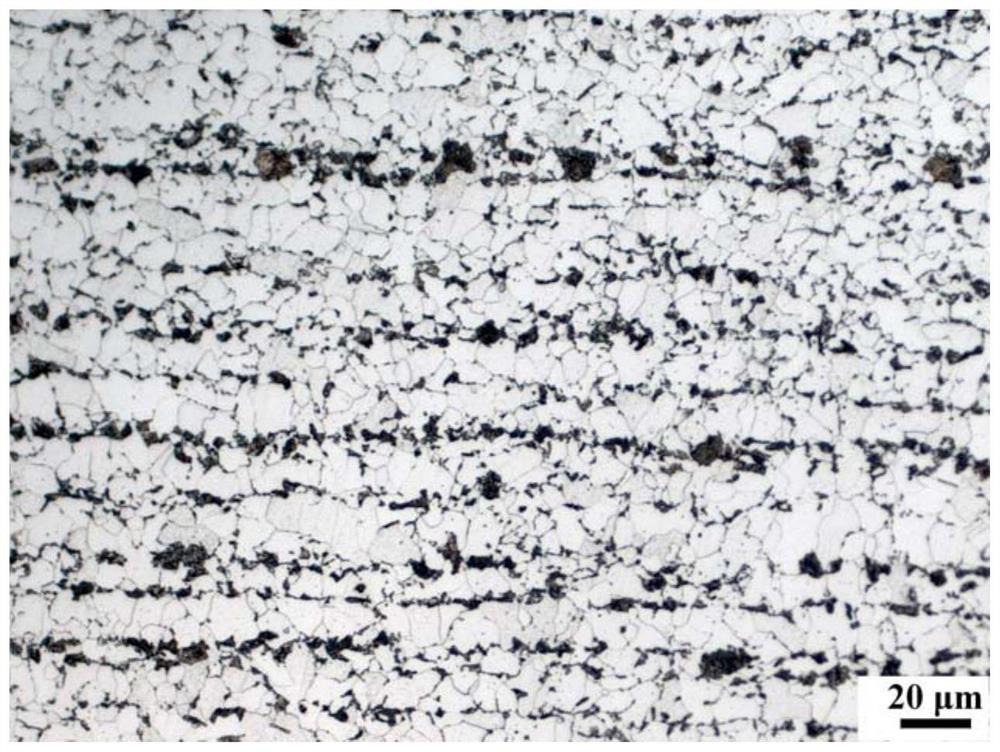

TMCP type bridge steel plate with small same-plate strength difference and production method thereof

ActiveCN112359191AHigh strengthImprove toughnessHeat treatment process controlUltimate tensile strengthMechanical engineering

The invention discloses a TMCP type bridge steel plate with small same-plate strength difference and a production method thereof. According to the production method, a continuous casting billet is sequentially and continuously subjected to a heating procedure, a recrystallization zone rolling procedure, an intermediate billet head and tail shielding and cooling procedure, a non-recrystallization zone rolling procedure and a cooling procedure to be manufactured into the bridge steel plate, in the intermediate billet head and tail shielding and cooling procedure, multi-stage cooling is carried out on a intermediate billet until the intermediate billet is cooled to the final cooling temperature of 860 DEG C + / -15 DEG C and the temperature difference between the head, the middle and the tail of intermediate billet is smaller than or equal to 30 DEG C; and the cooling process of each stage comprises the following steps of determining head and tail low-temperature parts and shielding percentage of the intermediate billet according to a temperature detection result of a whole plate; carrying out non-shielding water cooling on the middle main body of the intermediate billet; and meanwhile,carrying out shielding cooling on the head and tail low-temperature parts according to the determined shielding percentage. The same-plate strength difference of the obtained bridge steel plate is smaller than or equal to 30 MPa, the structure is uniform, the plate shape is good, the head and tail excision amount is reduced, the yield and percent of pass are improved, and the short-length rate ofthe steel plate is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

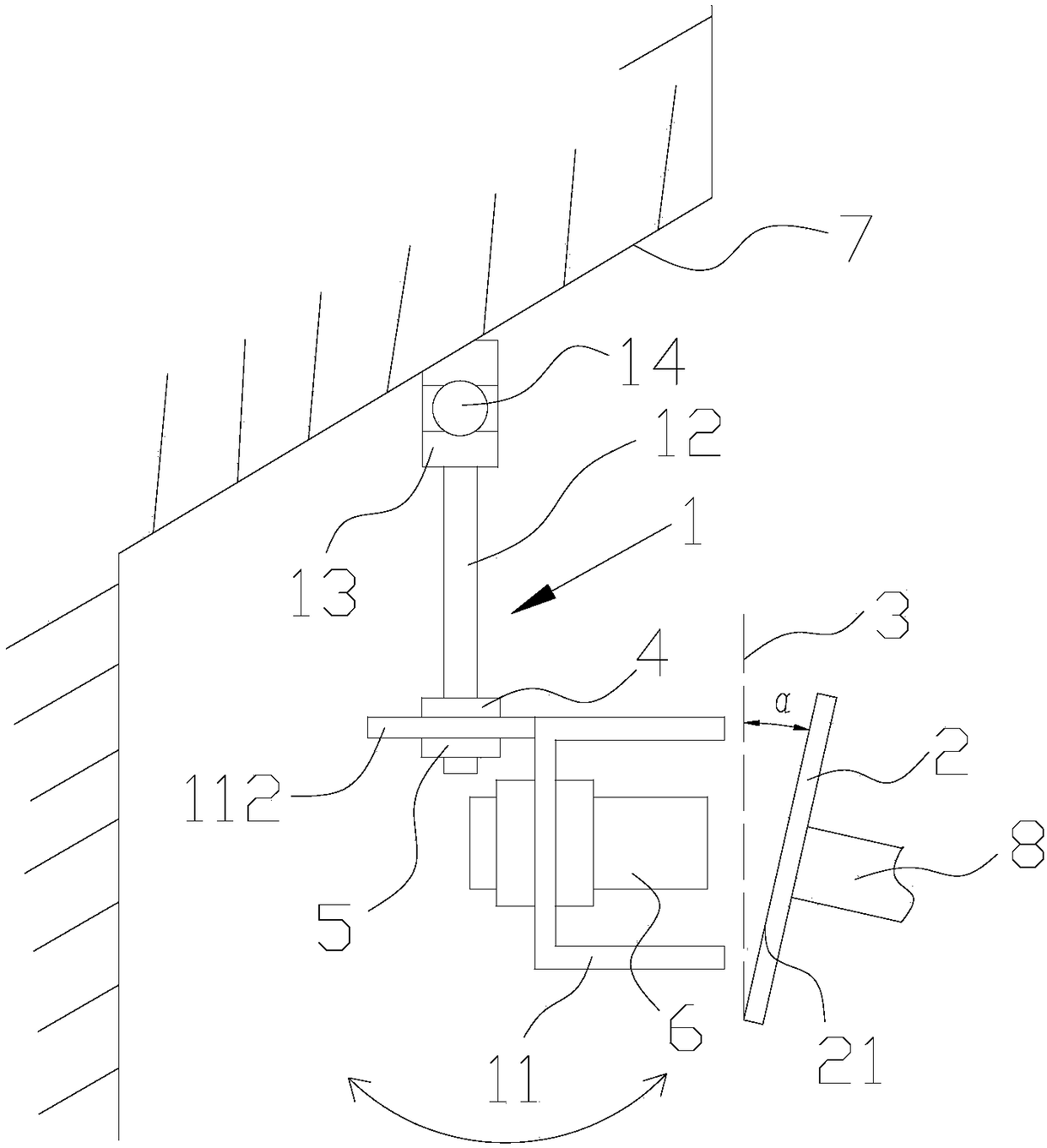

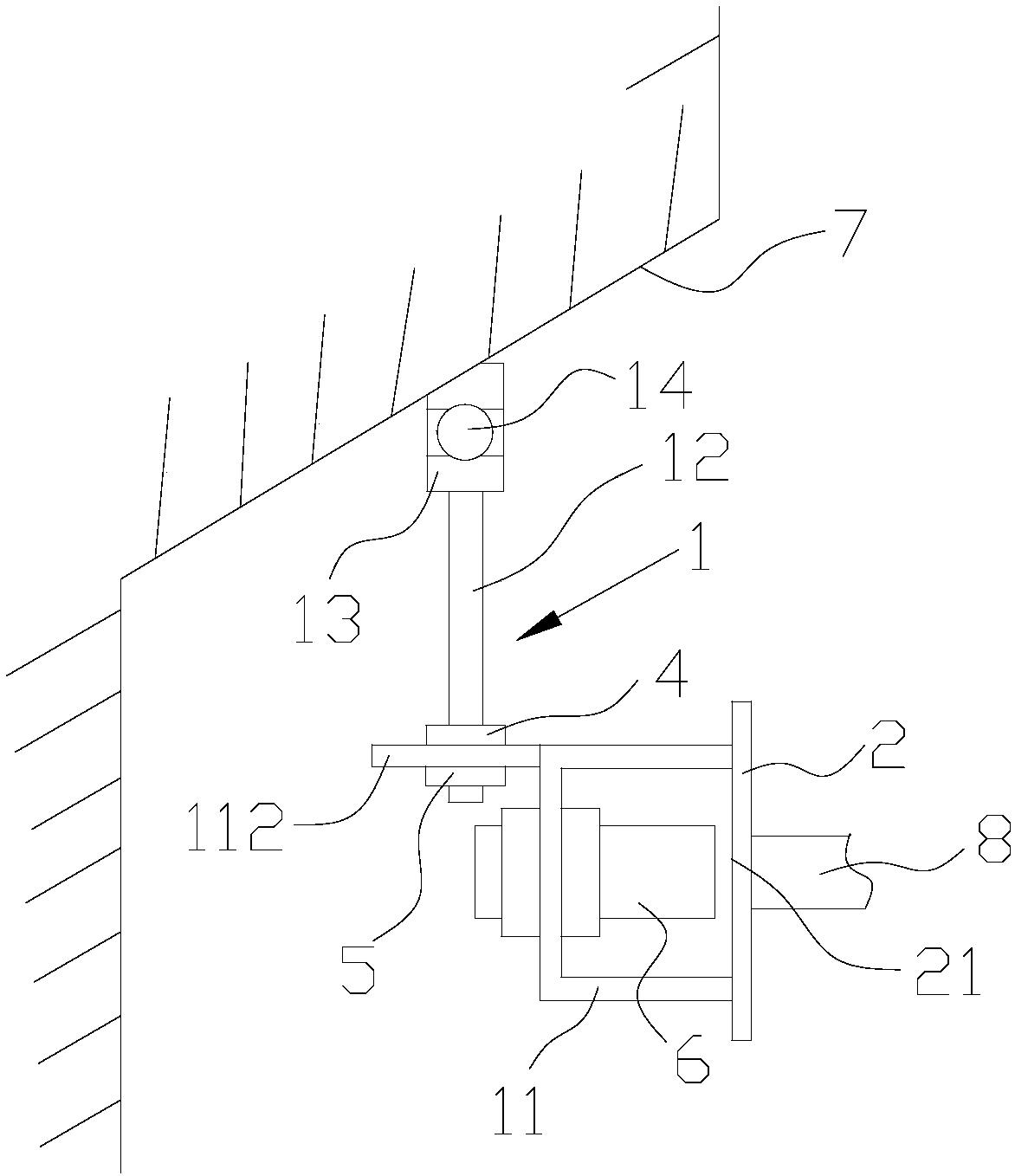

Proximity switch installation device

The invention discloses a mounting apparatus of a proximity switch, comprising a mounting bracket and a baffle. The mounting bracket includes a proximity switch mounting groove, a connecting rod and a mounting seat. The proximity switch mounting groove is a U-shaped groove. A first connecting end of the connecting rod is connected with the proximity switch mounting groove. A second connecting end of the connecting rod is hinged with the mounting seat through an articulated shaft. The articulated shaft is in parallel to a length direction of the proximity switch mounting groove. The baffle is mounted on a device to be detected, and an included angle alpha of an induction surface and a vertical surface of the baffle is 5-15 degrees. An opening of the proximity switch mounting groove faces the induction surface of the baffle. The mounting apparatus of the proximity switch can prevent the proximity switch from being damaged, and can prolong the service life of the proximity switch. Meanwhile the device can swing in a large range and won't cause adverse detection of the proximity switch, and affects the detection stability and the device safety. The device fault hidden trouble caused by false detection is eliminated. It is convenient to adjust the mounting position and the mounting height of the proximity switch.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

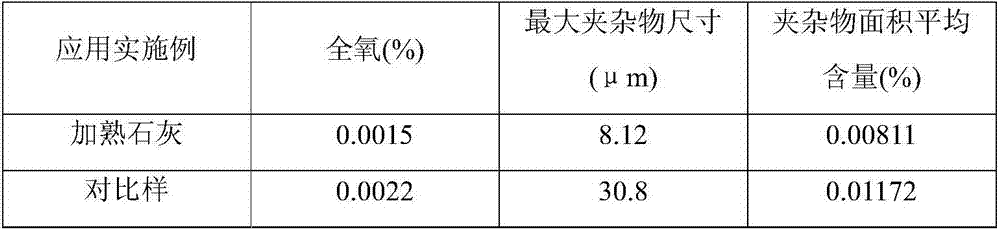

Method for producing clean steel through RH

The invention discloses a method for producing clean steel through RH. The method for producing clean steel through RH comprises the following steps that (1) tapping from a converter in a boiling or semi-boiling mode is conducted, and then steel enters an RH station; decarburization is conducted after temperature measurement and oxygen determination are conducted, after carbon is decarburized to a target value, the temperature measurement and oxygen determination are conducted; (2) aluminum is one-time added according to oxygen activity, the objective adding amount is 0.003%-0.007% more than the upper limit of the weight percentage of the aluminum; while adding the aluminum, slaked lime is added to a vacuum chamber through an overhead bunk, wherein the adding amount of the slaked lime is 0.4-0.6 kg per ton of steel, circulation is conducted for 3-5 min, and the temperature measurement and oxygen determination are conducted; and (3) when the oxygen activity is less than 0.0010%, the aluminum is not added any more, or the aluminum is replenished; the rest alloy materials are added and circulated for 3-5 min; then the temperature measurement and oxygen determination are conducted for ensuring that hydrogen content is less than 0.00015%, vacuum is eliminated, and then steel is moved out; still standing for 15-30 min and pouring on a machine are conducted. Total oxygen of the IF steel billet treated in this way decreases averagely 0.0005%-0.0008%, the size of the maximum inclusion is significantly reduced, and cleanliness is improved obviously.

Owner:ANGANG STEEL CO LTD

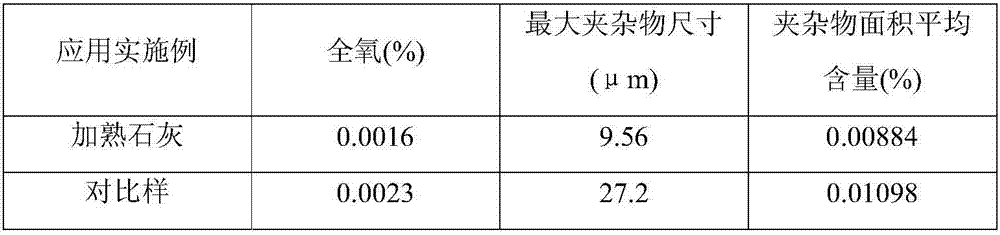

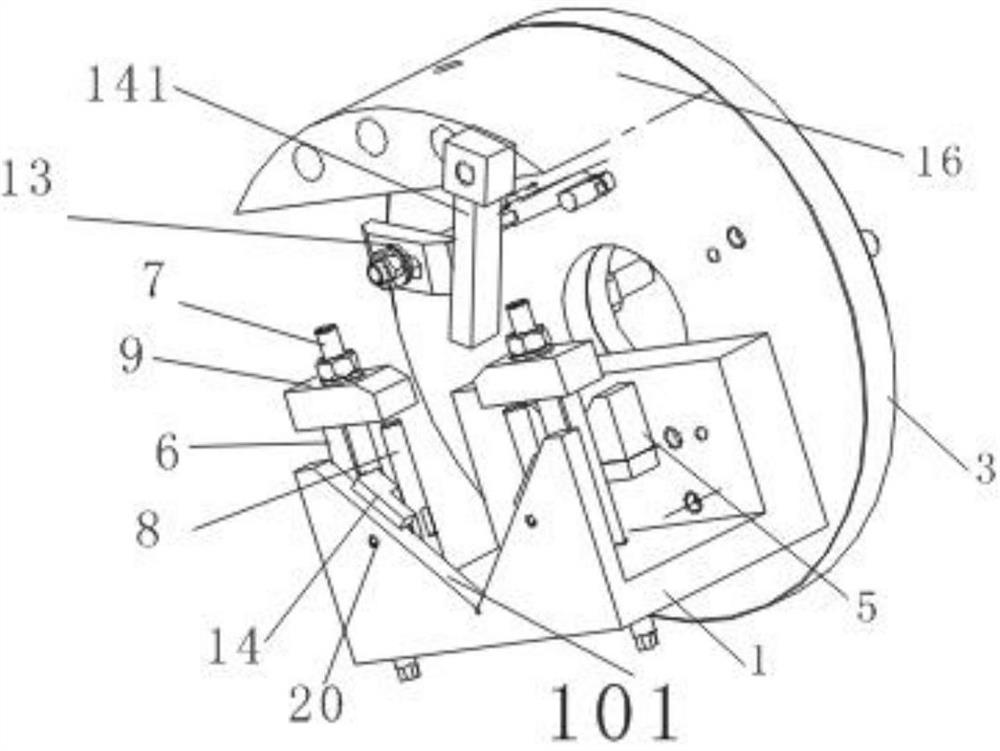

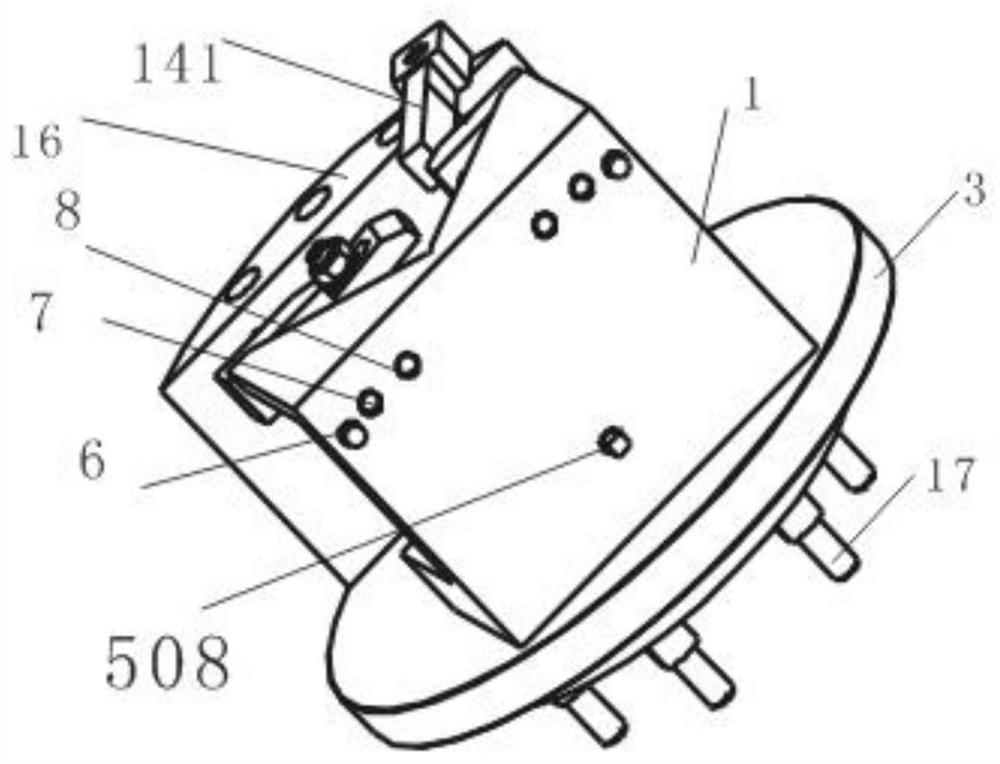

Mounting apparatus of proximity switch

ActiveCN106098426APrevent crashExtended service lifeContact operating partsEngineeringDevice failure

The invention discloses a mounting apparatus of a proximity switch, comprising a mounting bracket and a baffle. The mounting bracket includes a proximity switch mounting groove, a connecting rod and a mounting seat. The proximity switch mounting groove is a U-shaped groove. A first connecting end of the connecting rod is connected with the proximity switch mounting groove. A second connecting end of the connecting rod is hinged with the mounting seat through an articulated shaft. The articulated shaft is in parallel to a length direction of the proximity switch mounting groove. The baffle is mounted on a device to be detected, and an included angle alpha of an induction surface and a vertical surface of the baffle is 5-15 degrees. An opening of the proximity switch mounting groove faces the induction surface of the baffle. The mounting apparatus of the proximity switch can prevent the proximity switch from being damaged, and can prolong the service life of the proximity switch. Meanwhile the device can swing in a large range and won't cause adverse detection of the proximity switch, and affects the detection stability and the device safety. The device fault hidden trouble caused by false detection is eliminated. It is convenient to adjust the mounting position and the mounting height of the proximity switch.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Production method of high-strength alloy r320cr rail

ActiveCN105063267BShorten heating timeReduce burning lossManufacturing convertersProcess efficiency improvementHeating timeWater flow

The invention adopts the technical scheme that a production method for high-strength alloy R320Cr steel rails comprises the steps of molten iron desulphurization, converter smelting, LF refining, RH refining, continuous casting and rolling. The production method is characterized in that in the converter smelting step, the content of C in tapped steel is controlled to be 0.01-0.02%, and the tapping temperature is controlled to be 1640-1670 DEG C; in the continuous casting step, constant pulling rate operation is adopted, and the pulling rate is controlled to be 0.6-0.7 m / s; meanwhile, super-weak cooling preparation water is adopted in a secondary cooling section, and the specific water flow is controlled to be 0.15-0.25 L / kg. By adopting the production method disclosed by the invention, the holo-aluminium content in R320cr steel is controlled to be 0.0025%-0.0035%, so that the anti-fatigue ability of the steel rails is improved; the yield of Cr alloy is more than 90%, so that cost is reduced; the heating time of LF refining is 40-50 minutes, and the LF refining can be matched with the continuous casting, so that the production tempo is totally met, and the qualification rate of occluded foreign substance reaches 100%. The extension strength Rm of the obtained R320Cr steel is 1130-1190 MPa; the percentage elongation A after fracture is 9%-12%; and the surface hardness is 325-355 HB, so that a high-quality high-strength alloy R320Cr steel casting blank which can meet product requirements is obtained with low cost.

Owner:武汉钢铁有限公司

A carbonization furnace wall gunning device and method

ActiveCN106244174BGood for longevityReduce labor intensityCoke oven safety devicesBrickwork leakage repair/preventionRepair timeProgrammable logic controller

The invention discloses a carbonization furnace wall spray repair device and method belonging to the technical field of coke making. In the carbonization furnace wall spray repair device, one end of a positioning mechanism is movably arranged in a sliding chute; a high-temperature imaging instrument is arranged at the other end of the positioning mechanism; a closing plate is arranged at the other end of the positioning mechanism; one end of a purging mechanism is arranged on a coke leveling vehicle, and the other end is arranged on one side of the closing plate; one end of a refractory mortar conveying mechanism is arranged on the coke leveling vehicle, the other end is communicated with the closing plate, and the refractory mortar conveying mechanism is communicated with one end of the purging mechanism; and a programmable logic controller is connected with the positioning mechanism, the high-temperature imaging instrument, the purging mechanism, the refractory mortar conveying mechanism and the coke leveling vehicle. According to the carbonization furnace wall spray repair device and method, artificial high-temperature repair work in a carbonization chamber can be replaced, thus effectively relieving the labor intensity and ensuring the production safety; and no cooling treatment is needed, thus shortening the repair time, ensuring the production rhythm and being beneficial to the long service life of a carbonization chamber walling.

Owner:武汉钢铁有限公司

Vehicle tool for complex welding part

PendingCN113752062AImprove processing efficiencyGuaranteed output speedPositioning apparatusMetal-working holdersEngineeringFlange

The invention discloses a vehicle tool for a complex welding part. A supporting assembly used for supporting the complex welding part, pressing assemblies used for pressing the complex welding part and a counterweight assembly are arranged on the front face of a transition disc; the supporting assembly comprises a main supporting part corresponding to the flange plate edge of the complex welding part and an auxiliary movable supporting part corresponding to the thin cylindrical section of the complex welding part, the main supporting part is provided with a large positioning groove matched with the flange plate edge, and the auxiliary movable supporting part is provided with a small positioning groove corresponding to the thin cylindrical section; and the pressing assemblies comprise the first pressing assembly used for pressing a reinforcing rib and the second pressing assembly used for pressing an auxiliary cylindrical section. Through the cooperation of all the components of the vehicle tool, and the complex welding part can be quickly aligned; and after the position of the tool is aligned, follow-up adjustment is not needed, the clamping efficiency is improved, the output speed of workpieces is greatly guaranteed, the production rhythm is guaranteed, and the problem of narrow opening production is solved.

Owner:HUBEI JIANGSHAN HEAVY IND

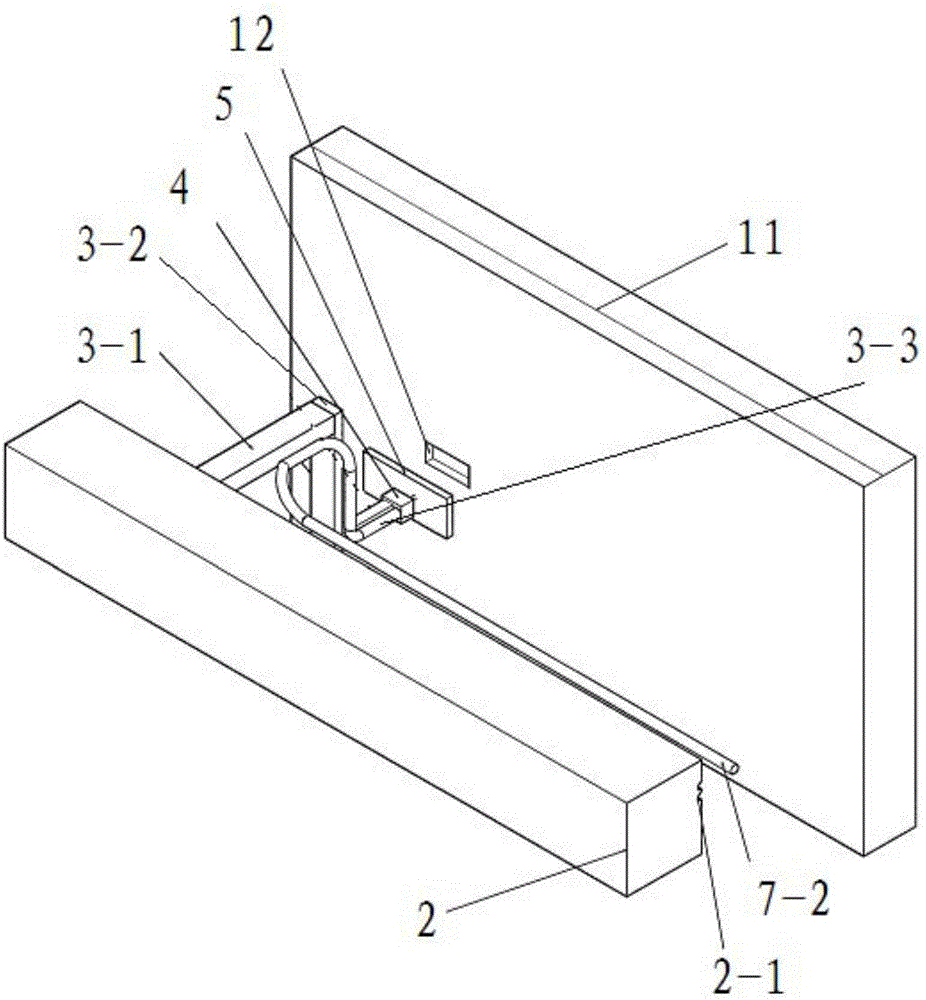

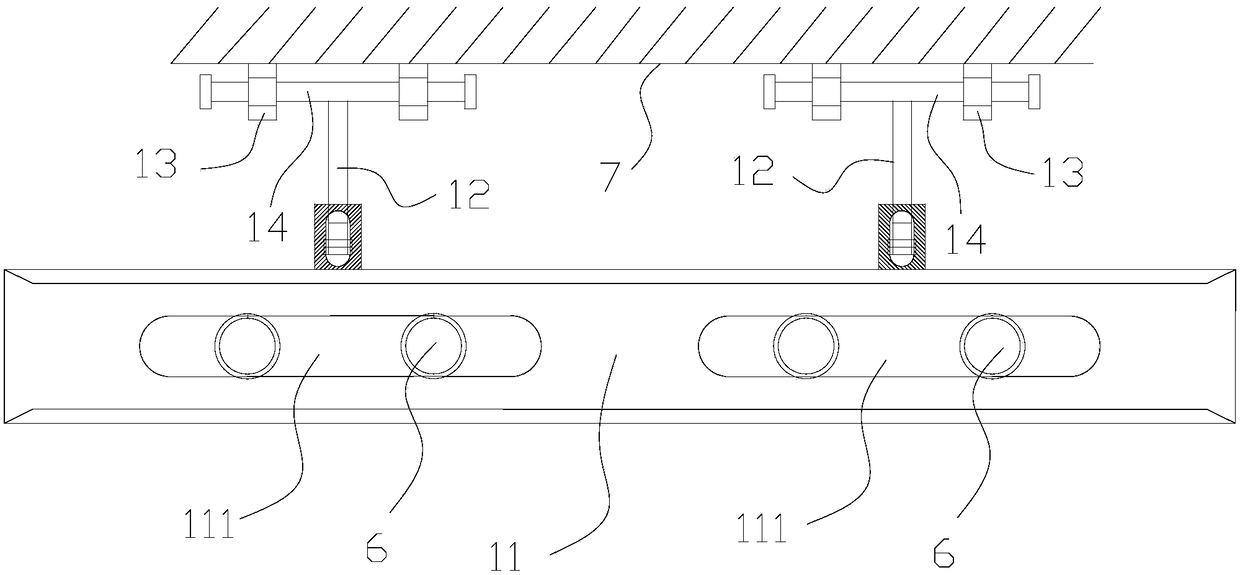

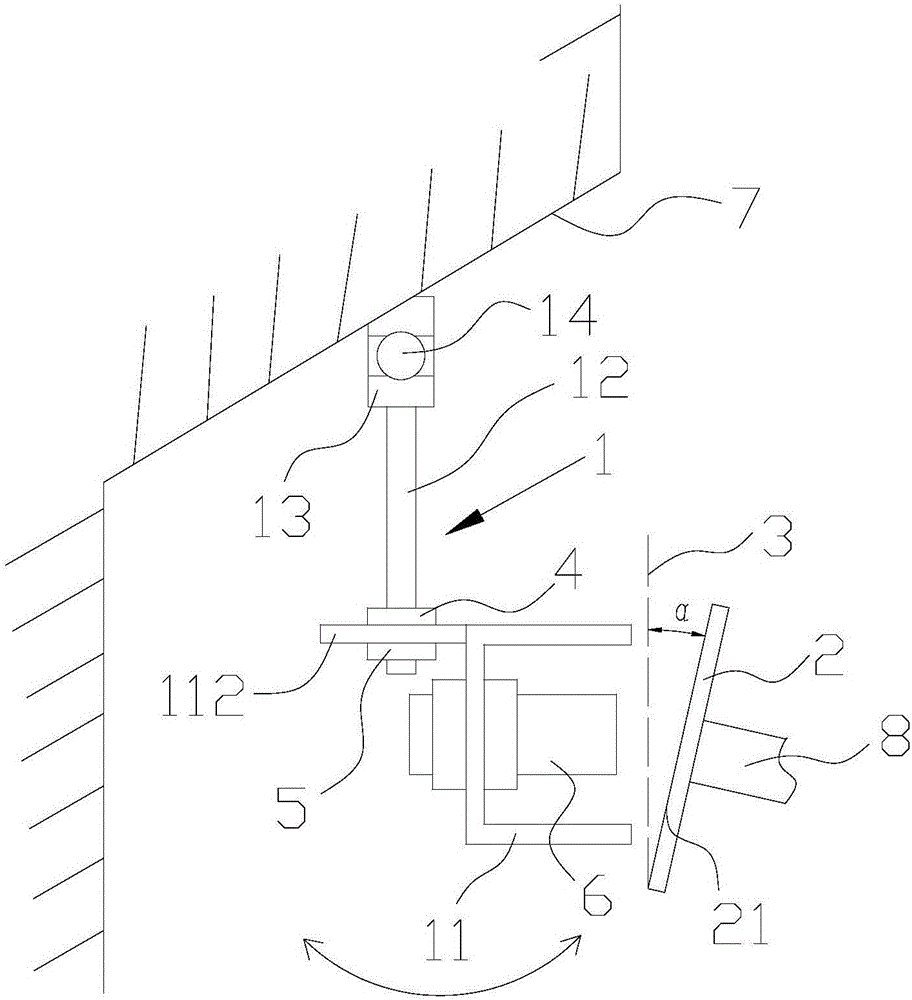

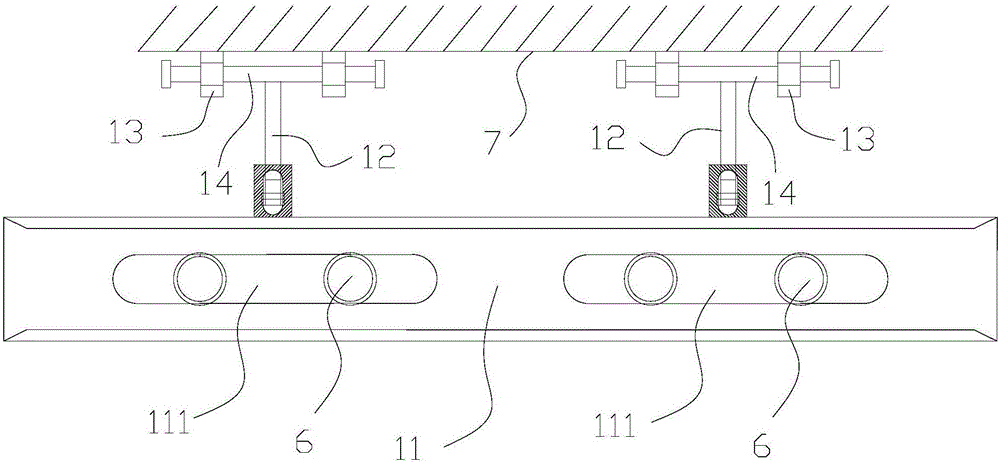

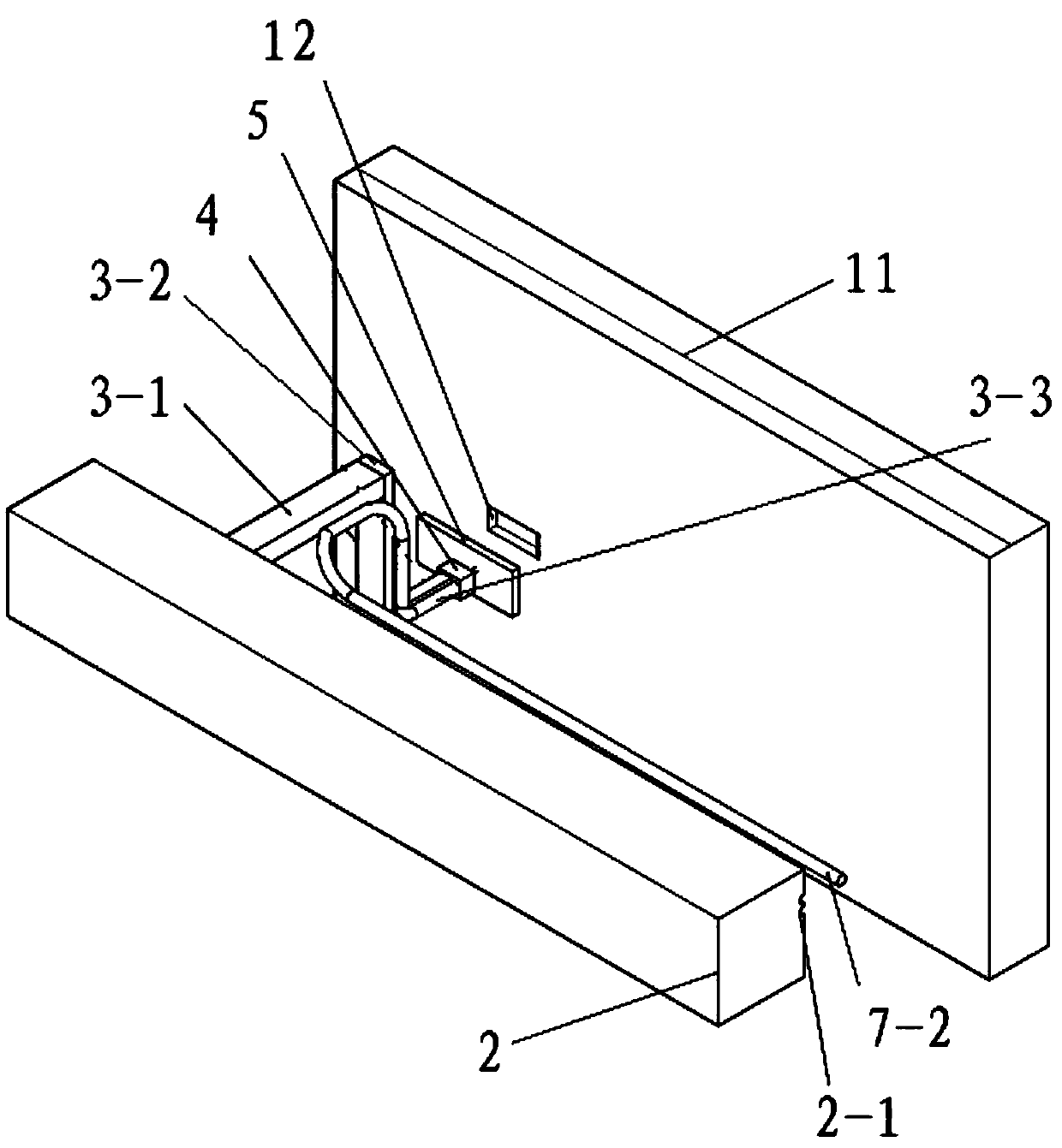

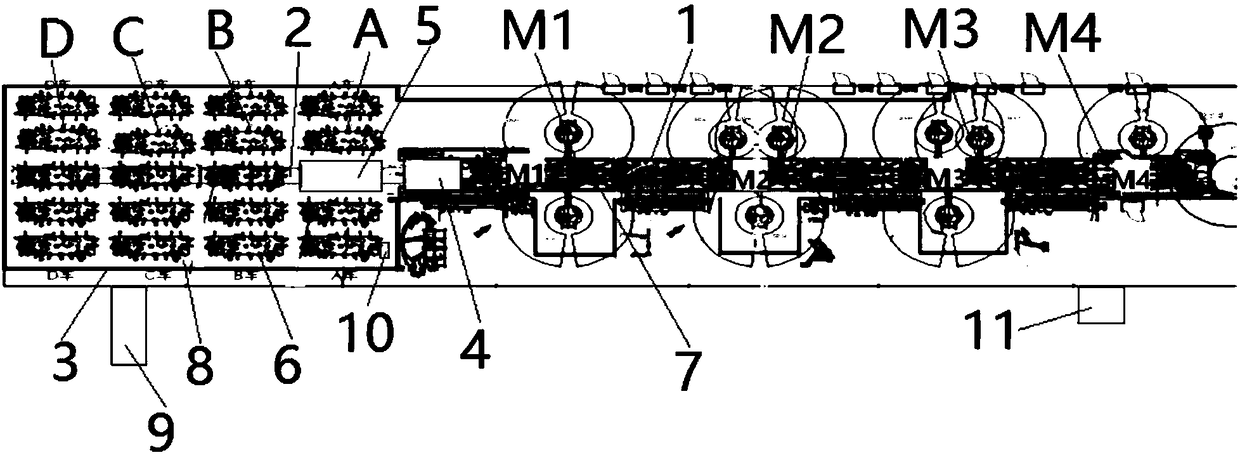

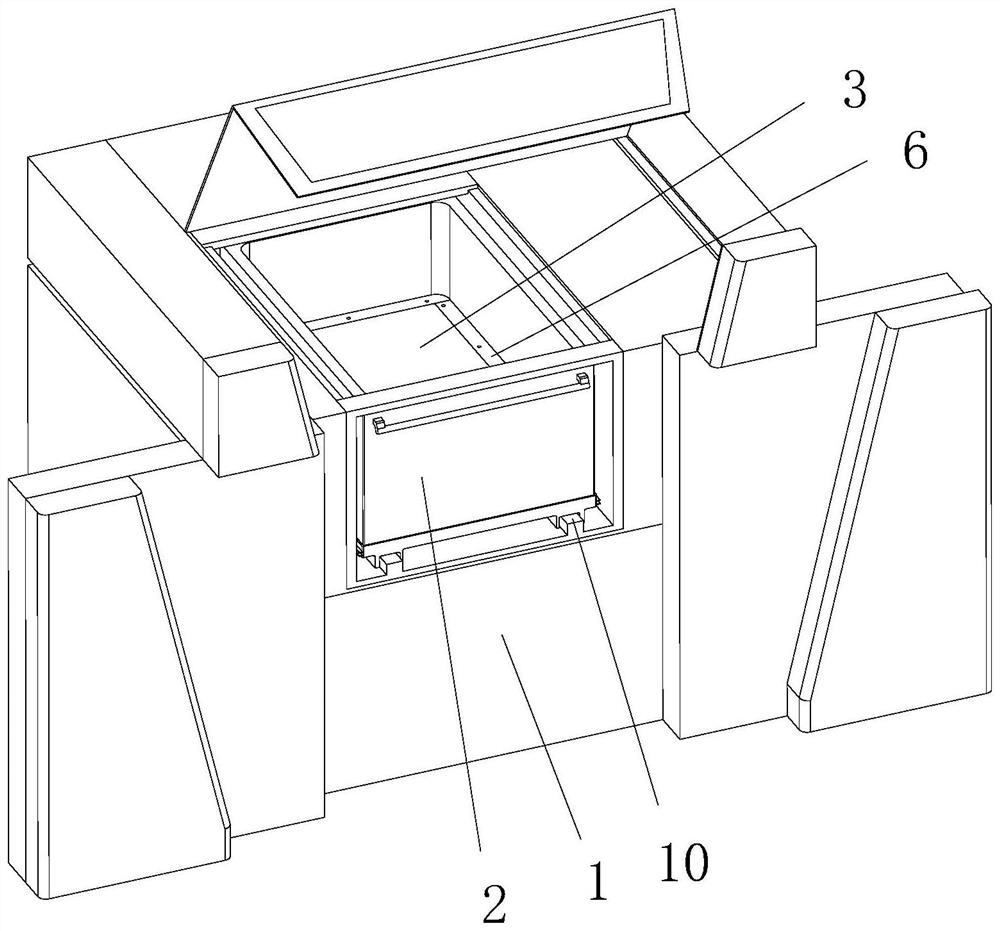

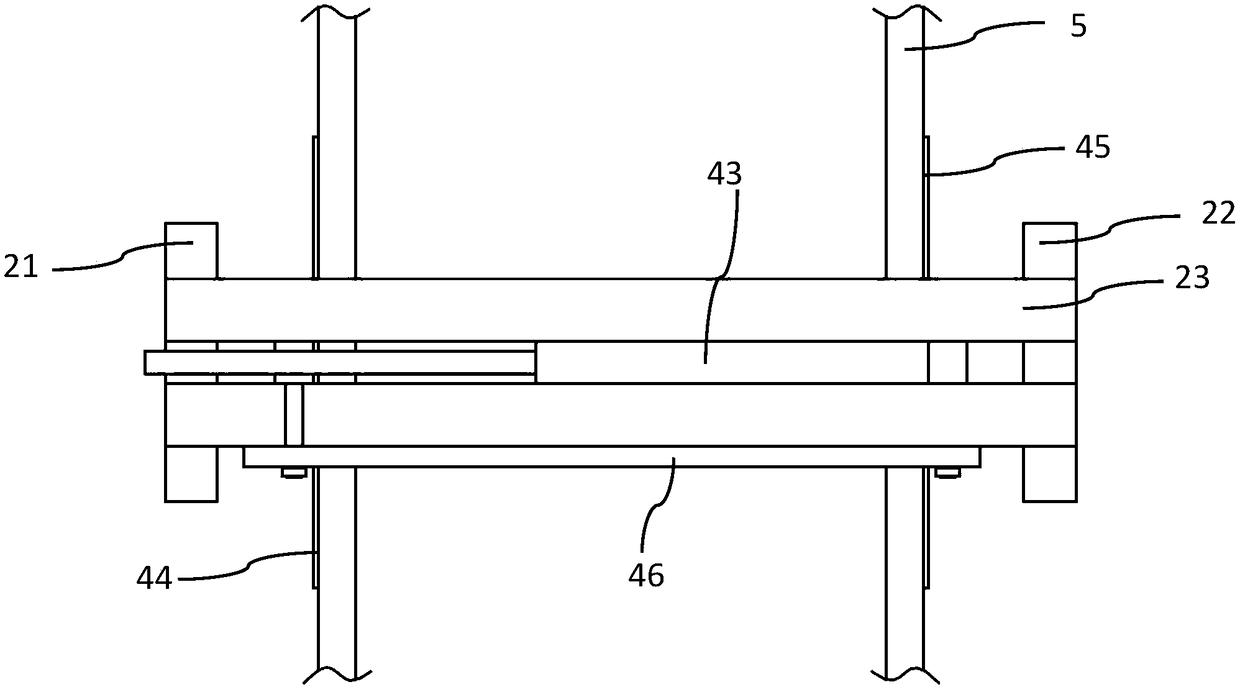

A multi-vehicle shared welding production line structure

ActiveCN106670684BGuaranteed production rhythmImprove welding process efficiencyWelding/cutting auxillary devicesAuxillary welding devicesProduction lineMachining

The invention provides a welding production line structure shared by multiple vehicles, and the welding production line structure is applied to the technical field of automobile part welding machining equipment. One end of a traction rail (2) of the welding production line structure shared by the multiple vehicles is connected with a production rail (1), and the other end of the traction rail (2) extends into a fixture storage warehouse (3). A servo tractor (4) is installed on the production rail (1). A storage tractor (5) is installed on the traction rail (2). The fixture storage warehouse (3) is internally provided with a plurality of sets of process fixtures (6). Each set of process fixture (6) is arranged to be the structure which can be suitable for the different vehicles. According to the welding production line structure shared by the multiple vehicles, the structure is simple; the cost is low; the process fixtures suitable for the different vehicles are integrated; and when parts of the different vehicles are welded, the different process fixtures can be conveniently and rapidly switched, thus, the welding machining efficiency of the parts of the different vehicles is effectively improved, and the equipment input and the occupied area of a production line are reduced.

Owner:ANHUI RUIXIANG IND

A linkage supply type spike conveying equipment

ActiveCN110436173BGuaranteed production rhythmReduce the phenomenon of material jamConveyorsControl devices for conveyorsSensory controlControl theory

The invention discloses linkage supply-type rail spike conveying equipment. The linkage supply-type rail spike conveying equipment comprises a rail spike feeding line, a stepped feeding machine, a discharging mechanism and an orderly feeding control detection system. The rail spike feeding line is used for conveying rail spikes onto the stepped feeding machine, and the stepped feeding machine feeds the rail spikes onto the discharging mechanism in a stepped feeding mode. The discharging mechanism comprises a discharging channel communicating with a tilted channel upper discharging opening. A material control device is arranged on the discharging channel and further comprises two material control units which are arranged on the discharging channel in a spaced mode in the conveying directionof the discharging channel. The orderly feeding control detection system comprises a center control processor and a sensory control mechanism arranged at the position of the discharging channel. By adoption of the linkage supply-type rail spike conveying equipment, automated linkage supply is realized, the rail spikes can be discharged in an orderly mode, and the material jamming phenomenon is reduced.

Owner:中原利达铁路轨道技术发展有限公司

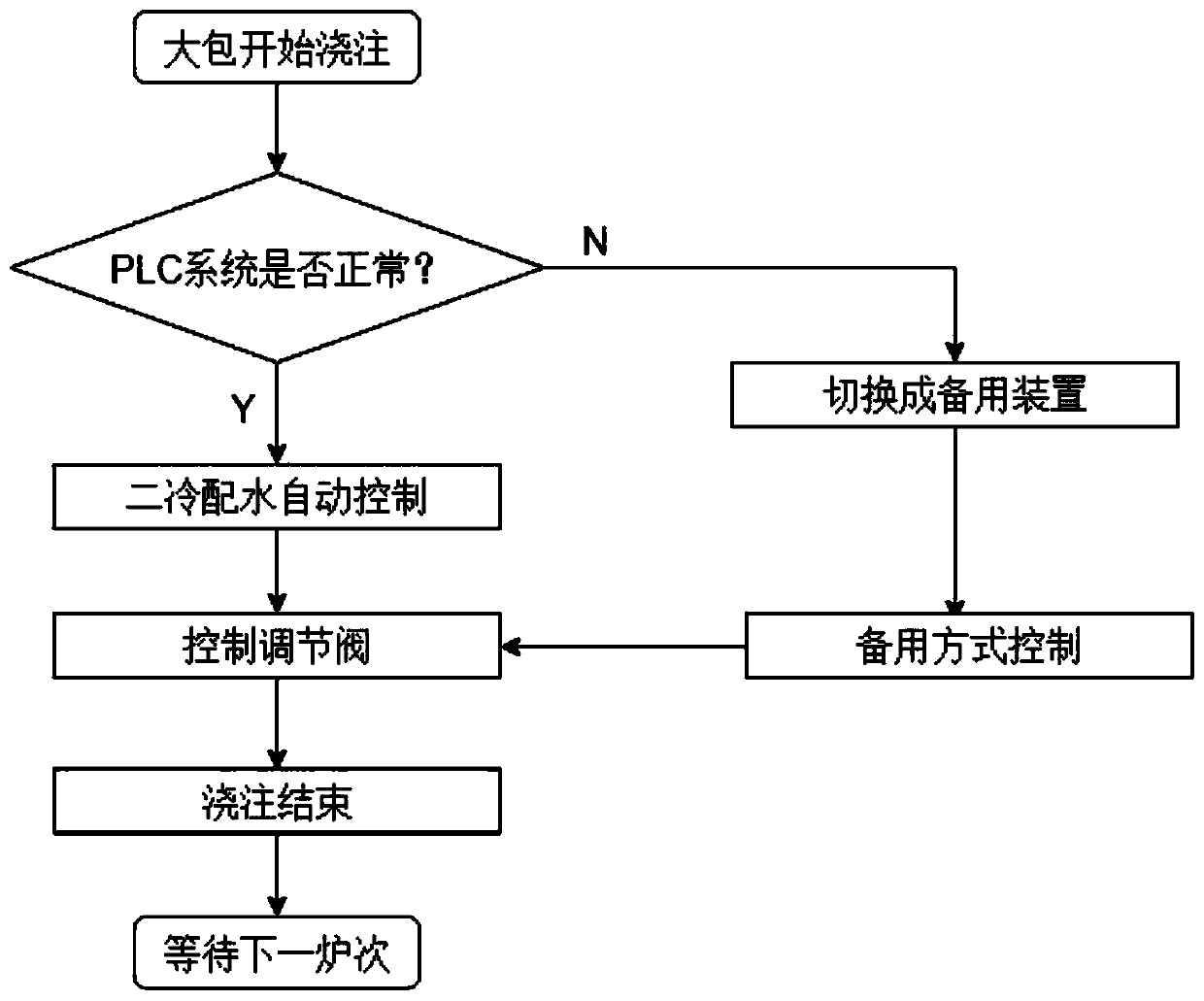

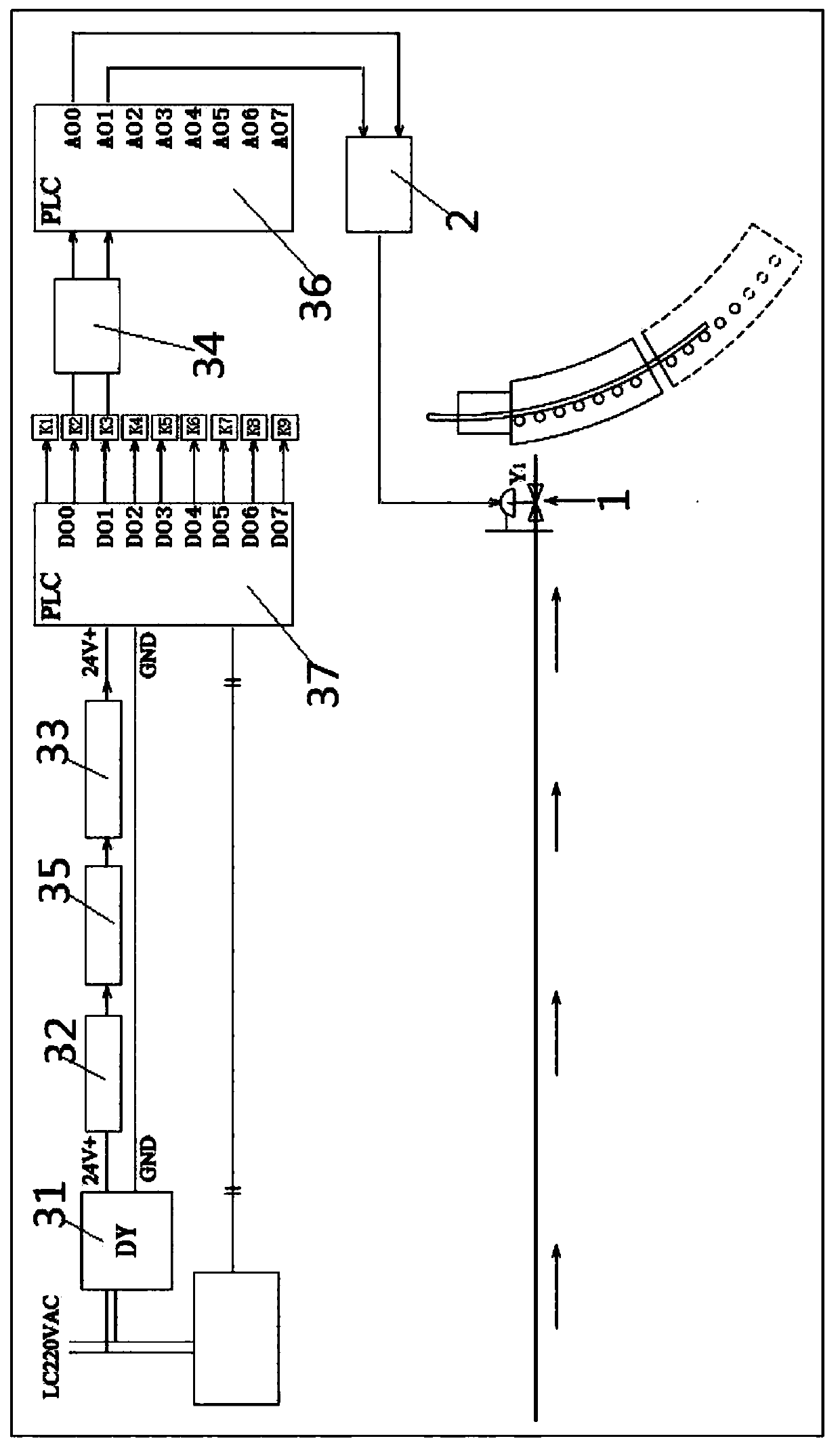

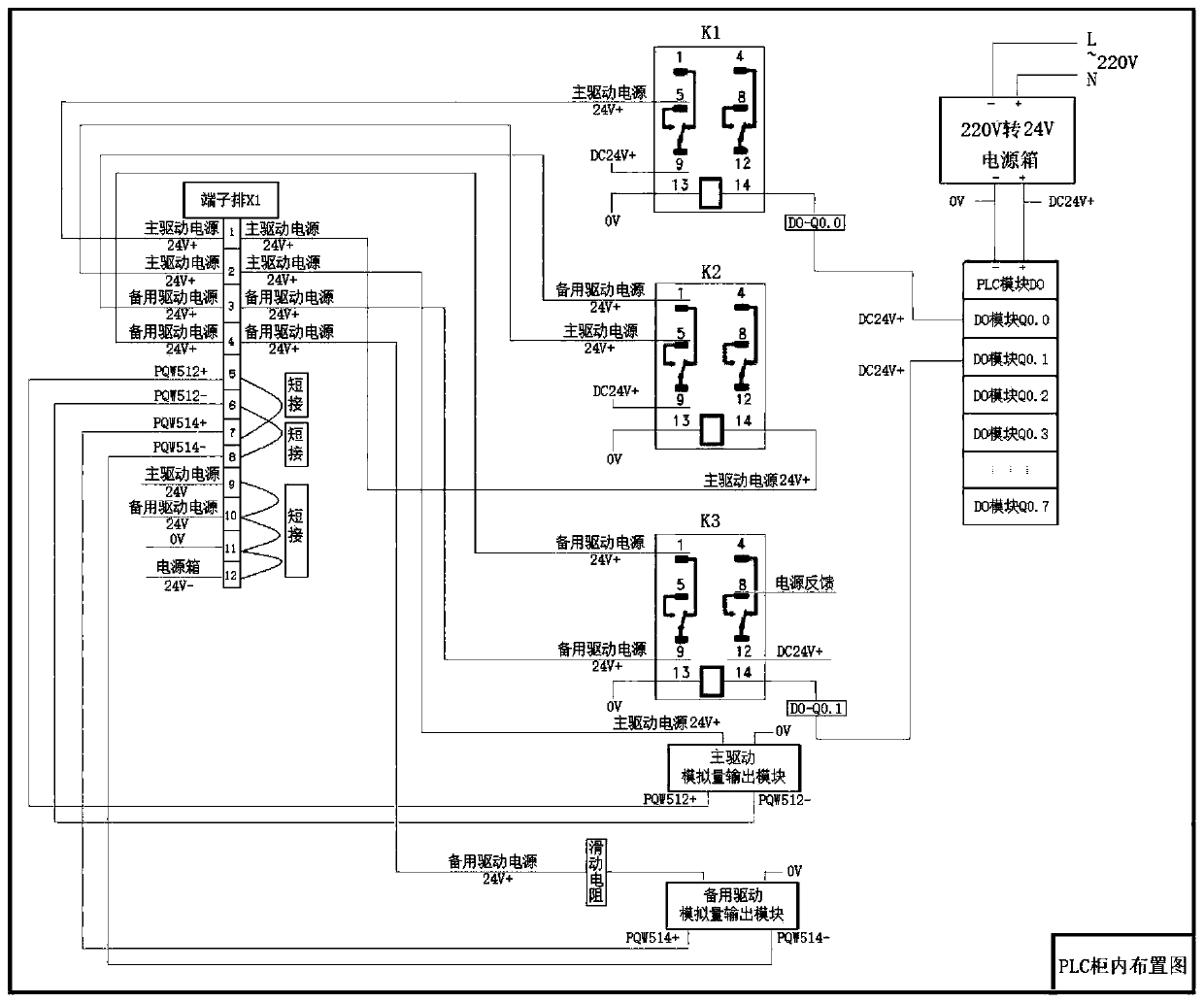

Standby switching system for pneumatic regulating valves of continuous casting machine and control method of standby switching system

The invention discloses a standby switching system for pneumatic regulating valves of a continuous casting machine, and further provides a control method applied to the standby switching system. The standby switching system comprises pneumatic valves and a PLC. The PLC includes a power box, a main drive module, a valve control module, a standby drive module and a fault judgment module, wherein themain drive module, the valve control module and the standby drive module are electrically connected in sequence. The main drive module and the standby drive module are both electrically connected with a digital output module, so that the main drive module or the standby drive module is energized. The valve control module and the pneumatic valves are all electrically connected with an analog output module. The fault judgment module is used for detecting the running state and the network communication state of the PLC in real time, and controlling the main drive module to be energized when no fault occurs and controlling the standby drive module to be energized when a fault occurs. The standby switching system can enable the cooling mode of a casting blank to be stable and reliable, can guarantee the surface quality of the casting blank, and increases the yield of molten steel and economic benefits. The cooling mode of the casting blank can be stable and reliable.

Owner:SHANDONG IRON & STEEL CO LTD

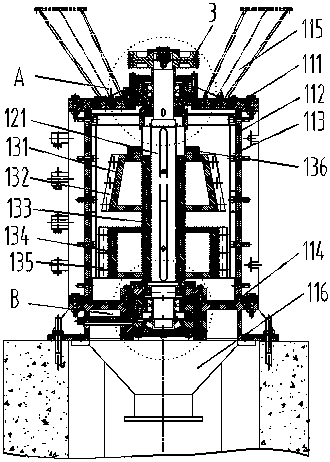

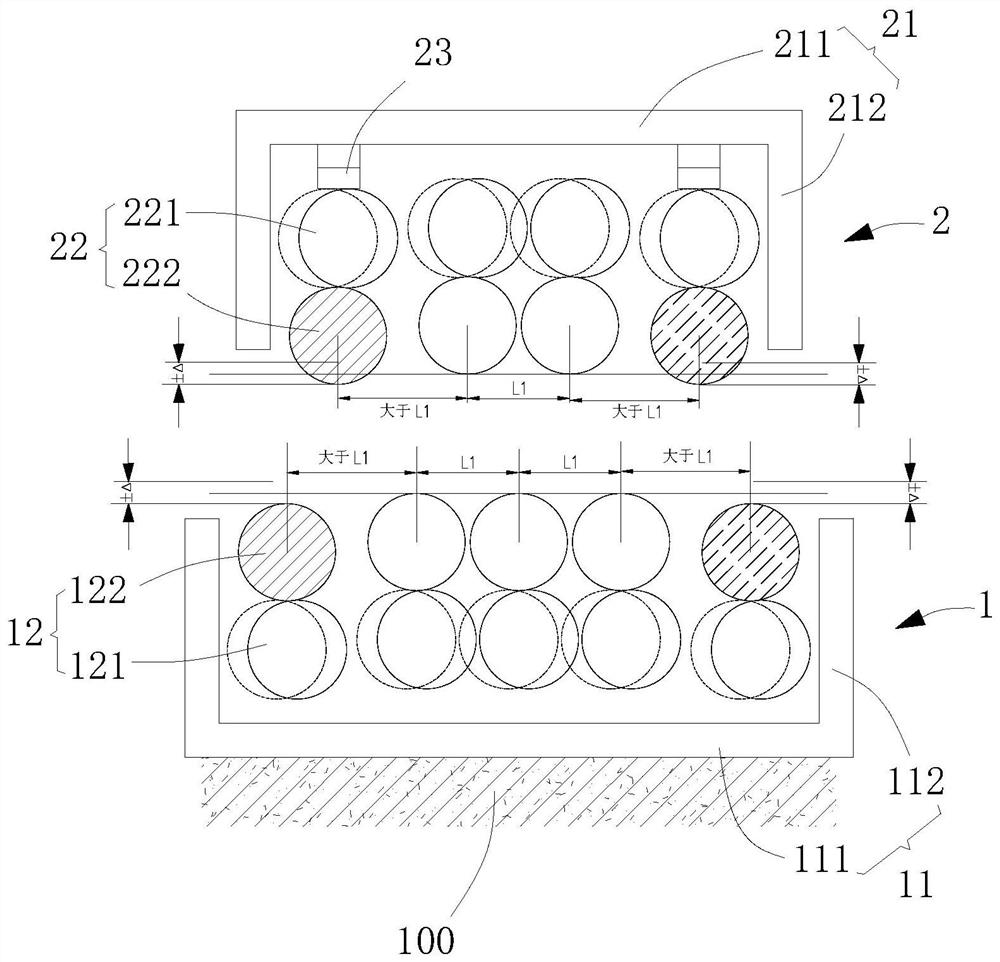

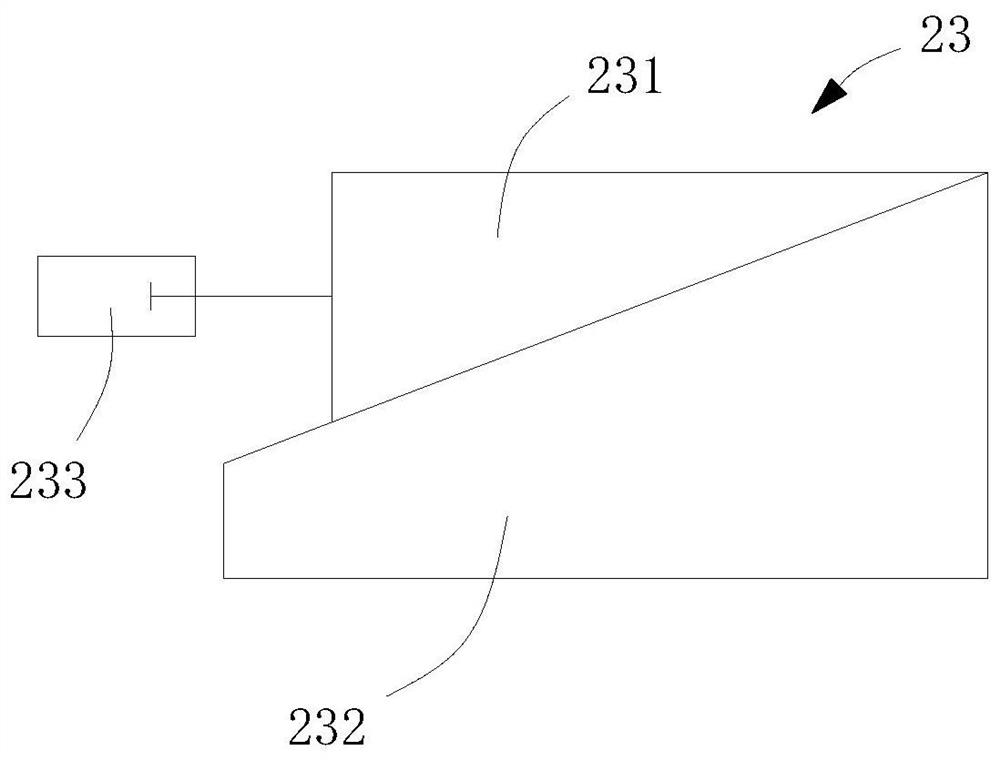

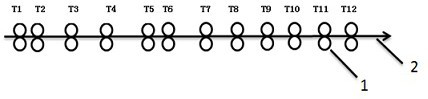

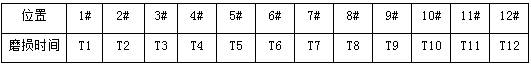

Straightening machine and straightening process thereof

The invention relates to a straightening machine which comprises a lower roller mechanism and an upper roller mechanism which is arranged on the upper portion of the lower roller mechanism and can slide relative to the lower roller mechanism, and the lower roller mechanism comprises a plurality of lower supporting rollers and lower straightening rollers correspondingly arranged on the lower supporting rollers. The upper roller mechanism comprises a plurality of upper supporting rollers and upper straightening rollers correspondingly arranged below the upper supporting rollers, the upper straightening rollers and the lower straightening rollers are arranged in a staggered mode, jacking assemblies are correspondingly arranged on the upper portions of the two upper supporting rollers on the two sides, the positions of the upper supporting rollers on the two sides are driven by the jacking assemblies to change, and then the positions of the corresponding upper straightening rollers are changed. And a straightening gap formed between the inlet and the outlet of the straightening machine is adjusted. The invention further relates to a process for independently straightening the steel plate through the side rollers at the two ends of the straightening machine and a straightening process for independently straightening the head or the tail of the steel plate. The straightening machine improves the finished product rate and the yield of steel plates, enables the heads of the steel plates to be straight, improves the production efficiency and guarantees the production rhythm.

Owner:北京冶自欧博科技发展有限公司

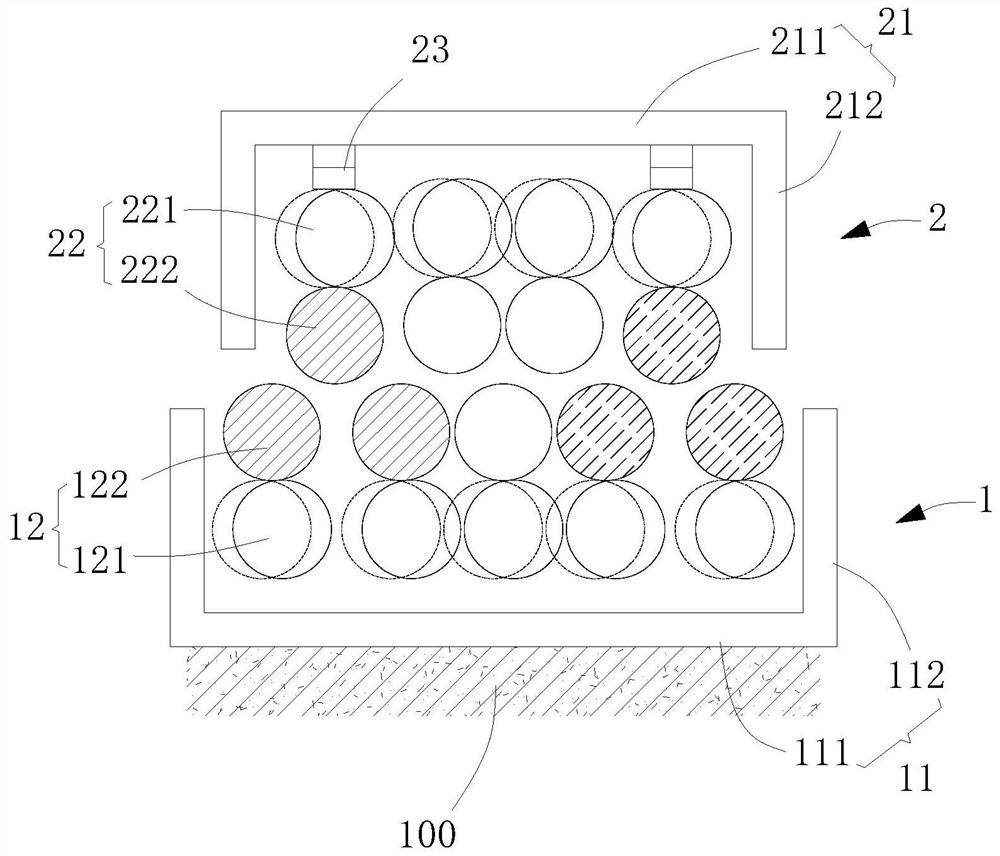

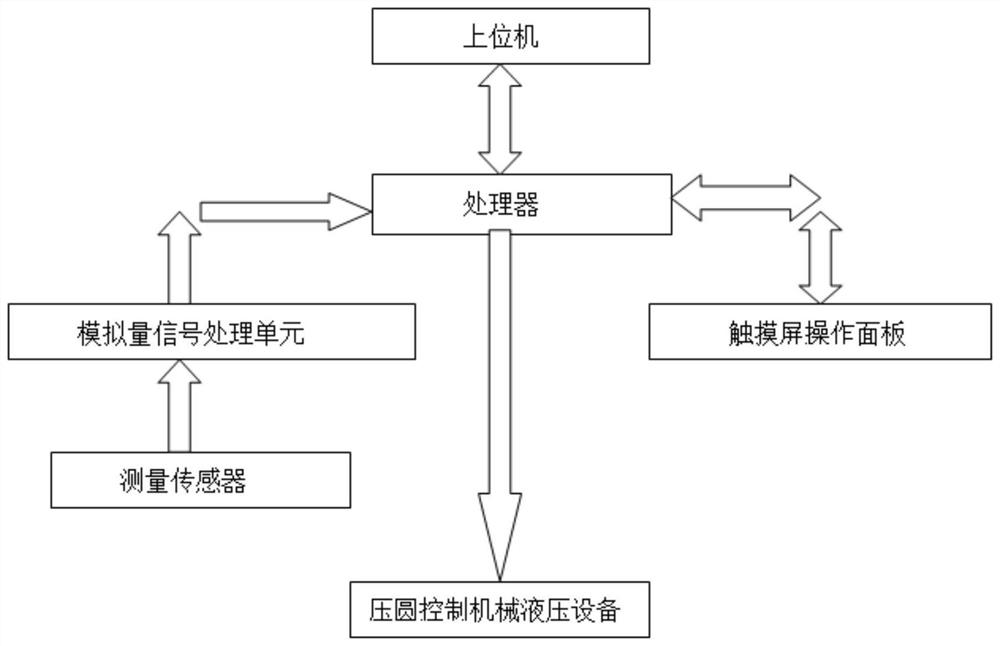

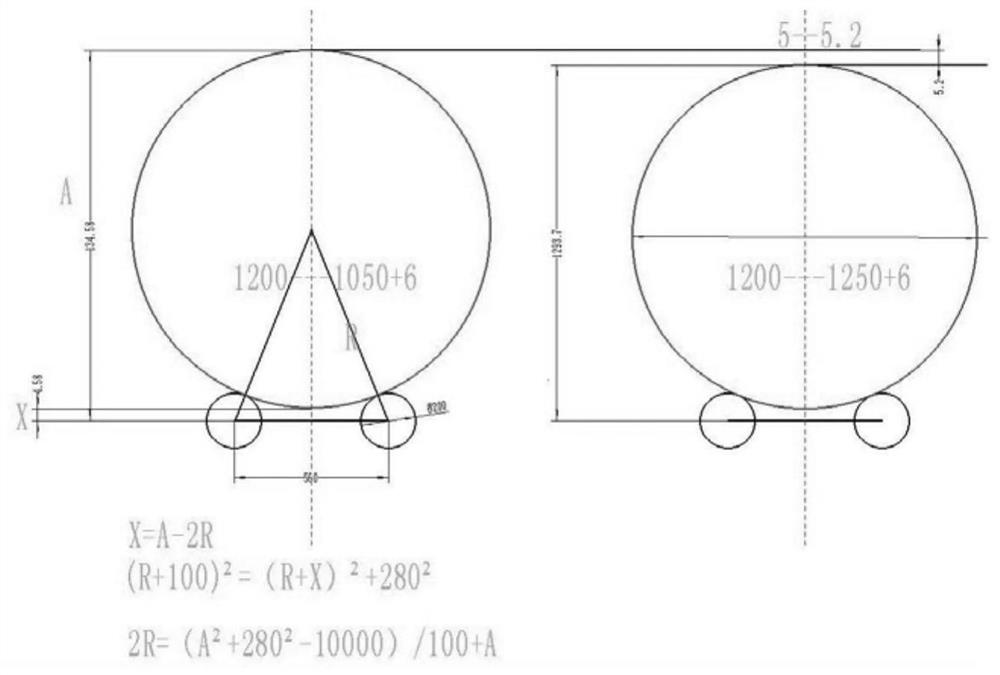

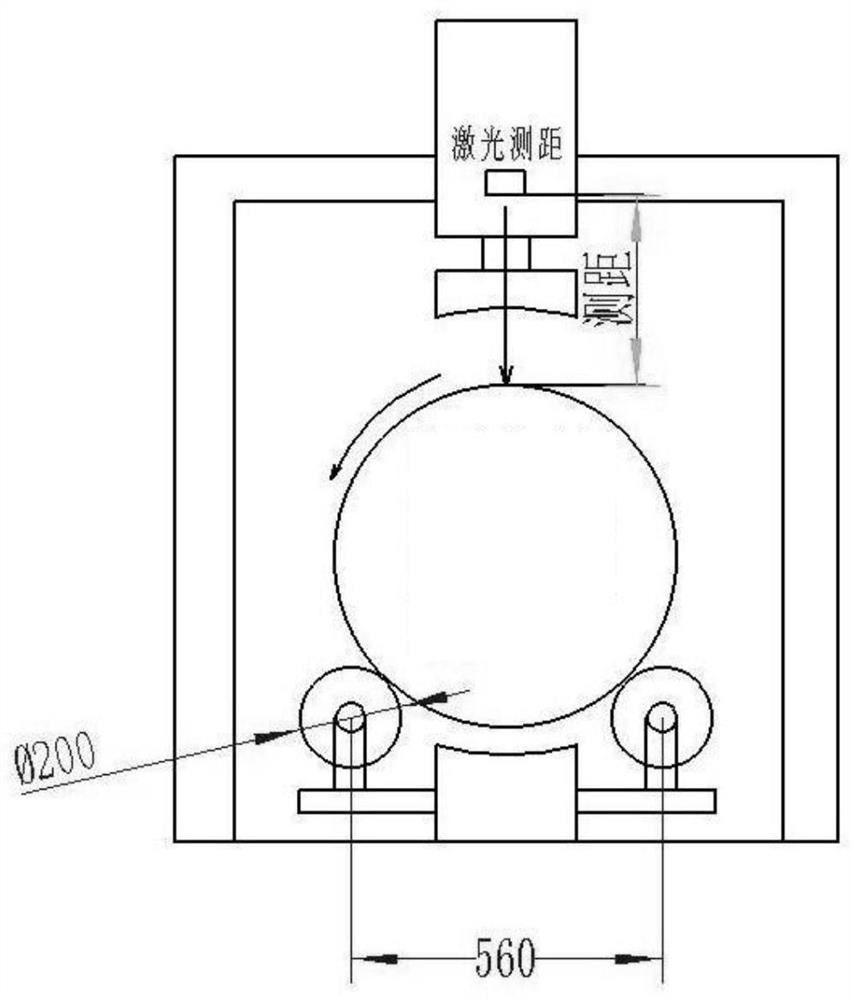

DN400-DN1200 centrifugal nodular cast iron pipe socket ovality detection and correction system

InactiveCN113340256AQuality assuranceAccurate and fast measurementMeasurement devicesProgramme control in sequence/logic controllersEngineeringHydraulic equipment

The invention discloses a DN400-DN1200 centrifugal nodular cast iron pipe socket ovality detection and correction system. The system comprises an upper computer, a processor, a measurement sensor and a touch screen operation panel. The upper computer is connected with the processor and is used for sending an instruction; the touch screen operation panel is connected with the processor and is used for inputting control detection and correction; the measuring sensor is connected with the processor through the analog quantity signal processing unit and is used for testing on site to obtain a stable numerical value; and the processor is connected with the rounding control mechanical hydraulic equipment and is used for obtaining a long axis and a short axis of the ovality of the cast iron pipe by editing a data processing program block according to stable numerical values obtained through field testing, then controlling the cast iron pipe to rotate to the position of the long axis and controlling the rounding equipment to conduct automatic rounding. According to the detection and correction system, automatic roundness correction of the centrifugal nodular cast iron pipe socket is achieved, efficient and accurate measurement and control are achieved, repeated detection and verification can be achieved, the labor intensity of workers is greatly reduced, and the quality of a cast pipe is guaranteed.

Owner:WUHU XINXING DUCTILE IRON PIPES

tmcp type bridge steel plate with small strength difference between the same plates and production method thereof

ActiveCN112359191BHigh strengthImprove toughnessHeat treatment process controlTemperature differenceUltimate tensile strength

The invention discloses a TMCP type bridge steel plate with small strength difference between the same plates and a production method thereof. In the production method, the continuous casting slab is successively processed into a bridge steel plate through the heating process, the rolling process in the recrystallization zone, the head and tail blocking cooling process of the intermediate billet, the rolling process in the non-recrystallization zone, and the cooling process. In the shading cooling process, the intermediate billet is cooled in multiple stages until the intermediate billet is cooled to a final cooling temperature of 860±15°C and the temperature difference between the head, middle and tail of the intermediate billet is ≤30°C; the cooling process of each stage includes: According to the temperature detection results of the entire plate , determine the head and tail low-temperature parts and the shading percentage of the intermediate billet; perform unshielded water cooling on the middle body of the middle billet, and at the same time perform shading cooling on the head and tail low-temperature parts according to the determined shading percentage. The resulting bridge steel plate has a strength difference of less than or equal to 30 MPa, a uniform structure and a good plate shape, reduces head and tail cuts, improves the finished product rate and pass rate, and reduces the short-length rate of the steel plate.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

A method of controlling the shearing length of double ruler flying shears

ActiveCN103331481BReduce failureImprove securityShearing control devicesGreek letter sigmaEngineering

Owner:江苏联峰实业有限公司

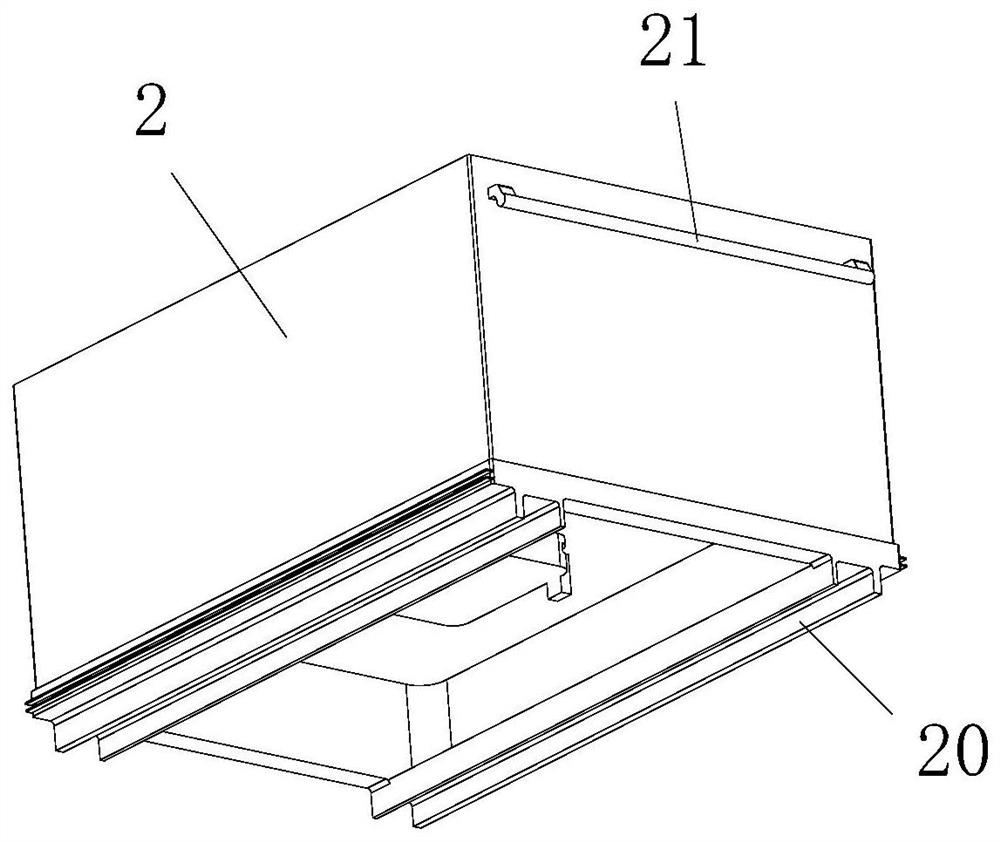

Forming box mechanism for 3DP printing technology

PendingCN113276417AEfficient use ofAvoid wastingManufacturing platforms/substratesManufacturing enclosuresMolding machineWorkbench

The invention discloses a forming box mechanism for a 3DP printing technology. The forming box mechanism for the 3DP printing technology comprises a forming rack, a forming box body, a forming platform, a jacking assembly, a sealing sponge and a sealing pressing plate, the forming box body is slidably inserted into a workbench of the forming rack, the forming platform is arranged in the forming box body, the forming platform is driven by the jacking assembly to move up and down in the forming box body, a sealing groove is formed in the periphery of the upper plane of the forming platform, the sealing sponge is arranged on the sealing groove, the sealing pressing plate for packaging the sealing sponge is arranged on the forming platform, and the sealing sponge is tightly attached to the inner wall of the forming box body. By means of the mode, the forming box mechanism for the 3DP printing technology is compact in structure and ingenious in design, supports products in the layer-by-layer printing process, cancels small cylinder supports on original products, achieves efficient utilization of printing materials, avoids waste of the printing materials, and guarantees printing precision and printing stability.

Owner:维捷(苏州)三维打印有限公司

Overlapping machine

InactiveCN108298326AAchieve stackingImprove work efficiencyConveyorsStacking articlesEngineeringManufacturing line

The invention discloses an overlapping machine. The overlapping machine comprises a base, a supporting device, a lifting device, a clamping device and two conveying belts; the supporting device is arranged on the base; the two conveying belts are symmetrically arranged inside the base in the conveying direction; the lifting device is installed on the base and is positioned between the two conveying belts; and the clamping device is installed on the supporting device. The overlapping machine disclosed by the invention improves the work efficiency of the overall production line and lowers the manufacturing cost.

Owner:重庆市欧华陶瓷(集团)有限责任公司

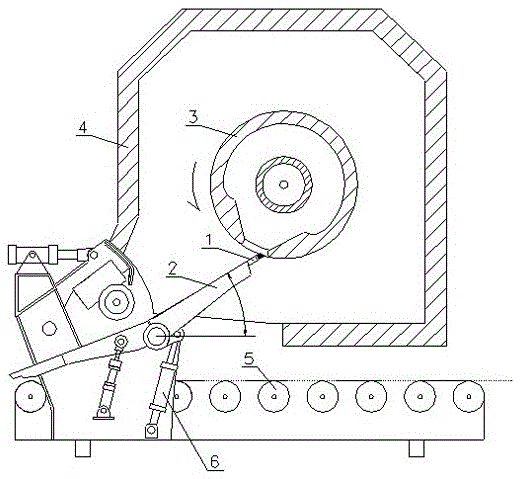

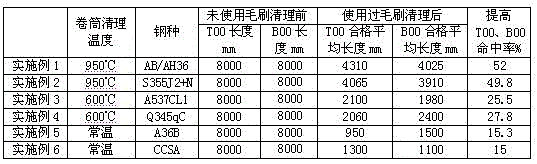

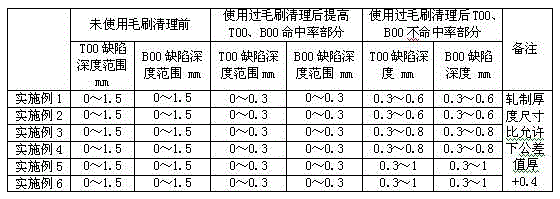

A method for removing nodules on the surface of the reel in the coiling furnace

ActiveCN103706641BReduce consumptionReduce the amount of finishing grindingRolling equipment maintainenceGrinding machinesBristleEngineering

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

An automatic production system for road studs

ActiveCN110340263BFully automatedRealize automated productionMetal-working feeding devicesScrew-threads articlesControl engineeringProcess engineering

The invention discloses an automatic production system of a spike. The automatic production system comprises an automatic spike feeding machine, a spike heating machine and a spike thread rolling machine, wherein the automatic spike feeding machine comprises a spike feeding line, a stepped feeding machine and a discharging mechanism, the spike feeding line is used for conveying the spike to the stepped feeding machine, and the stepped feeding machine conveys the spike to the discharging mechanism in a stepped feeding mode; the spike heating machine is arranged at the tail end of the discharging mechanism of the automatic spike feeding machine, the spike heating machine comprises a rotary disc type feeding mechanism and a heating mechanism, the heating mechanism is arranged on a conveying route of the rotary disc type feeding mechanism, and the spike on the rotary disc type feeding mechanism is heated; a robot gripper is arranged between the spike thread rolling machine and the rotary disc type feeding mechanism, and the robot gripper grabs the spike which passes through the heating mechanism and moves the spike to the spike thread rolling machine to carry out thread rolling operation. According to the automatic production system of the spike, the automatic and systematized production of the spike is realized, and the production efficiency is improved.

Owner:中原利达铁路轨道技术发展有限公司

A method of controlling a tempering machine and an electro-hydraulic servo system for controlling the tempering machine

ActiveCN110038907BAvoid damageImprove surface qualityRoll force/gap control deviceProportional integral differentialWork roll

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Dynamic temperature control system and control method of molten steel process in steelmaking and continuous casting

ActiveCN106363149BReliable end point temperatureGuaranteed production rhythmLiquid steelProduction planning

The invention provides a dynamic temperature control system and control method in the steel-making liquid steel continuous casting process. The dynamic temperature control system comprises an L3 production plan management module, an L3 process temperature computation module, an L3 workstation actual production management module, an L2 workstation production and temperature control module and an L2 actual production management module. The L3 production plan management module is used for generating or adjusting a steel-making continuous casting production plan according to production contract conditions, the actual conditions in the production process of all workstations and the changes of the workstations. The L3 process temperature computation module is used for computing the target temperatures corresponding to all the workstations according to the production plan of the L3 production plan management module. The L2 workstation production and temperature control module is used for conducting process control over temperatures according to the received liquid steel target temperatures, and qualified liquid steel is produced. The L2 actual production management module is used for collecting the actual production of the workstations in the current heat and uploading the actual production to the L3 workstation actual production management module. According to the dynamic temperature control system and control method in the steel-making liquid steel continuous casting process, precise control over the final temperatures of all the workstations can be achieved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

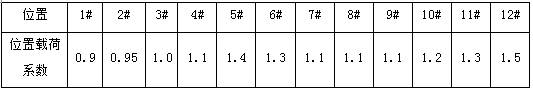

Method for determining wear degree of wringing roller in pickling

ActiveCN112845608AGuaranteed pickling effectGuaranteed production rhythmRoll mill control devicesWork cleaning devicesProcess engineeringMathematical model

The invention relates to a method for determining a wear degree of a wringing roller in pickling, and belongs to the technical field of cold-rolled strip steel pickling. According to the technical scheme of the method, a wringing roller wear time mathematical model is established, and the established mathematical model is utilized in a secondary system to automatically select a length, a running speed, a position load coefficient and a mark load coefficient for producing a current coil; and wear time of the wringing roller at different positions is automatically calculated, when the wear time of the wringing roller reaches a specified value, the wear degree of the wringing roller reaches an optimal state, and periodic replacement can be conducted. The method has the beneficial effects that accurate use tracking of the wringing roller can be effectively realized, accurate control capability of the wear degree of the wringing roller is improved, an accident rate of the wringing roller is reduced by 90% or more, the method plays a great role in pickling quality and stable production of products, and an accurate control problem of the wear degree of the wringing roller is well solved.

Owner:HANDAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com