An automatic production system for road studs

An automatic production and road stud technology, applied in metal processing equipment, threaded products, other household appliances, etc., can solve problems such as large equipment footprint, jamming, and disorderly conveying of road studs, so as to ensure production. Rhythm, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

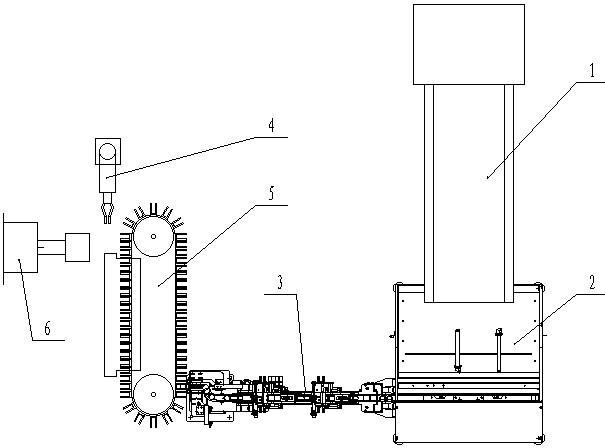

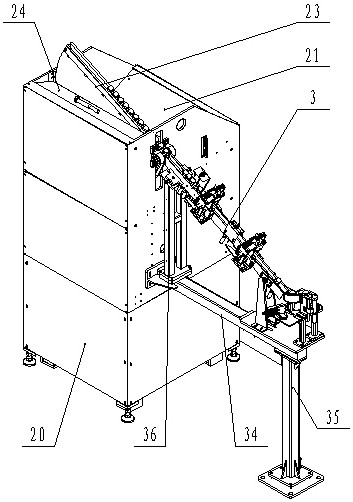

[0056] Such as Figure 1 to Figure 13 As shown, this embodiment discloses an automatic production system for road studs, which includes an automatic feeder for road studs, a heating machine for road studs 5 and a thread rolling machine for road studs 6 .

[0057] The automatic spike feeding machine includes a spike feeding line 1, a ladder feeding machine 2 and a discharge mechanism 3. The spike feeding line 1 is used to transport the spikes to the ladder feeding machine 2, and the ladder feeding The machine 2 sends the spikes to the discharge mechanism 3 in a stepwise feeding manner.

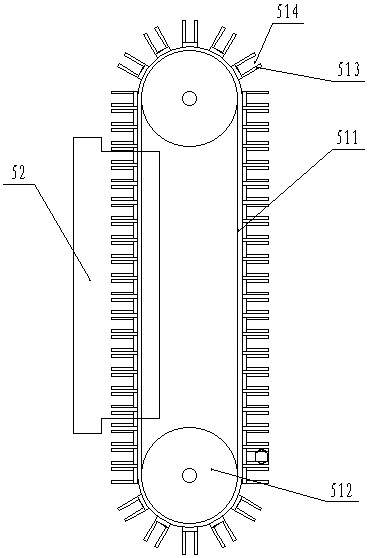

[0058] The spike heating machine 5 is located at the end of the automatic spike feeder, which includes a turntable feeding mechanism and a heating mechanism 52. The turntable feeding mechanism includes a chain ring 511 arranged horizontally, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com