A method of controlling the shearing length of double ruler flying shears

A technology of double-footed flying shears and fixed-length lengths, applied in shearing devices, shearing machine control devices, manufacturing tools, etc. tail, ensure safety, and avoid the effect of stacking steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

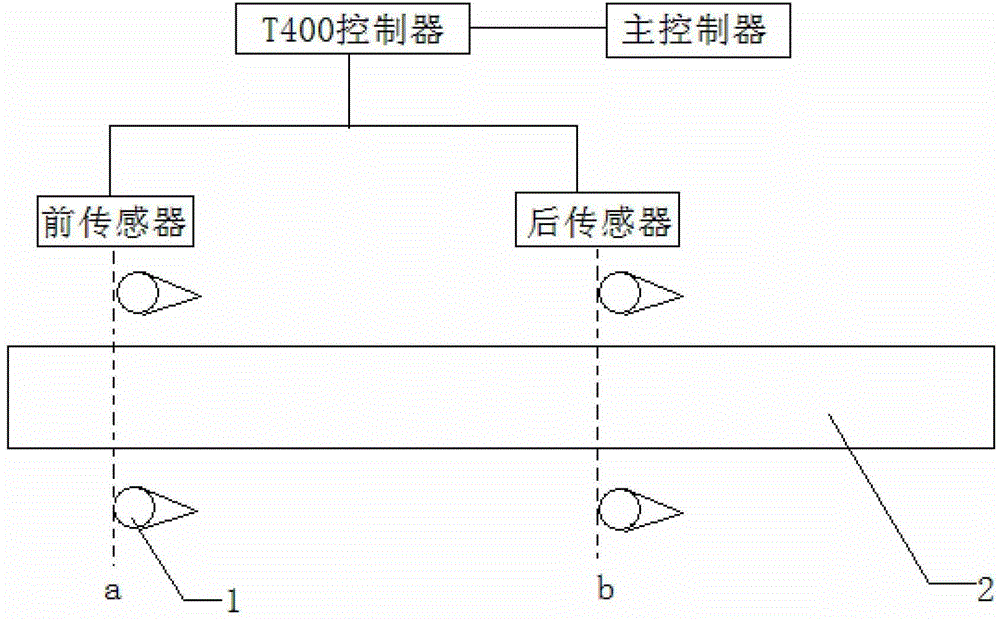

[0019] A device for controlling the cutting length of double-foot flying shears provided in this embodiment, its structural schematic diagram is as follows figure 1 As shown, it includes a rolling mill transmission device 2 and a double-scale flying shear 1 , and the multiple-scale flying shear 1 is arranged on both sides of the rolling mill transmission device 2 .

[0020] It also includes a front sensor, a rear sensor, a T400 controller, a main controller and a weighing device arranged below the rolling mill transmission, the front sensor is arranged at the cutting head of the double-foot flying shear, and the rear sensor It is arranged at the cutting tail of the double ruler flying shear.

[0021] The front sensor and the rear sensor are connected to the T400 controller respectively, and transmit the instantaneous signal of time to the T400 controller; The length of the rolled piece is calculated from the distance between the cutting head and the cutting tail, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com