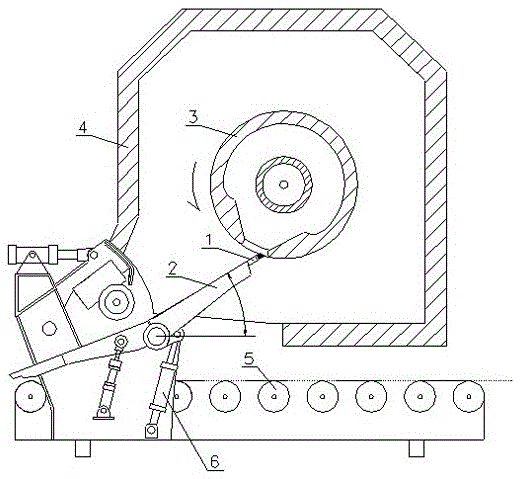

A method for removing nodules on the surface of the reel in the coiling furnace

A technology for coiling furnace and surface cleaning, applied in grinding machines, metal rolling, grinding/polishing equipment, etc., can solve the problems of high follow-up finishing cost, low steel plate yield, high energy consumption, etc., and reduce furnace shutdown. Cooling and opening the cover and manual grinding process, improve the yield and hit rate, and ensure the effect of production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

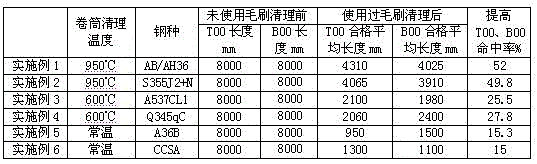

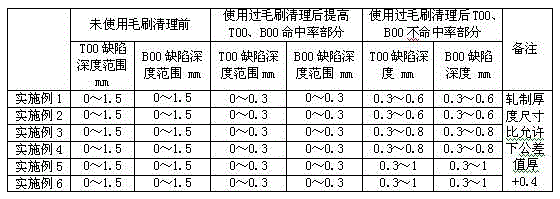

[0025] Embodiments 1 and 2: In this embodiment, the temperature in the coiling furnace is selected to carry out the nodulation removal method on the surface of the reel under the situation of 950 ° C. Before each group of batches of the following batches are rolled, the oxide scale on the surface of the reel is first carried out. The tumor is removed, and the length of T00 and B00 qualified steel plates is counted after re-rolling, and the average qualified length of this batch of rolling is calculated.

Embodiment 1

[0026] Example 1: Choose 1 batch of 10 rolled billets with chemical composition AB / AH36 marine steel, the size of the billet is 150×2640×9630 mm, and the finished product size is 8×2540×185624 mm.

Embodiment 2

[0027] Example 2: Select 1 batch of 12 rolling billets of wind power steel with chemical composition S355J2+N, the billet size is 150×2700×6500mm, and the finished product size is 6.1×2600×164498mm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com