Forming box mechanism for 3DP printing technology

A molding box and molding machine technology, applied in 3D object support structures, accessories for processing main materials, additive manufacturing, etc., can solve the problems of wasting printed materials, excessive labor and energy, and being easily affected by environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

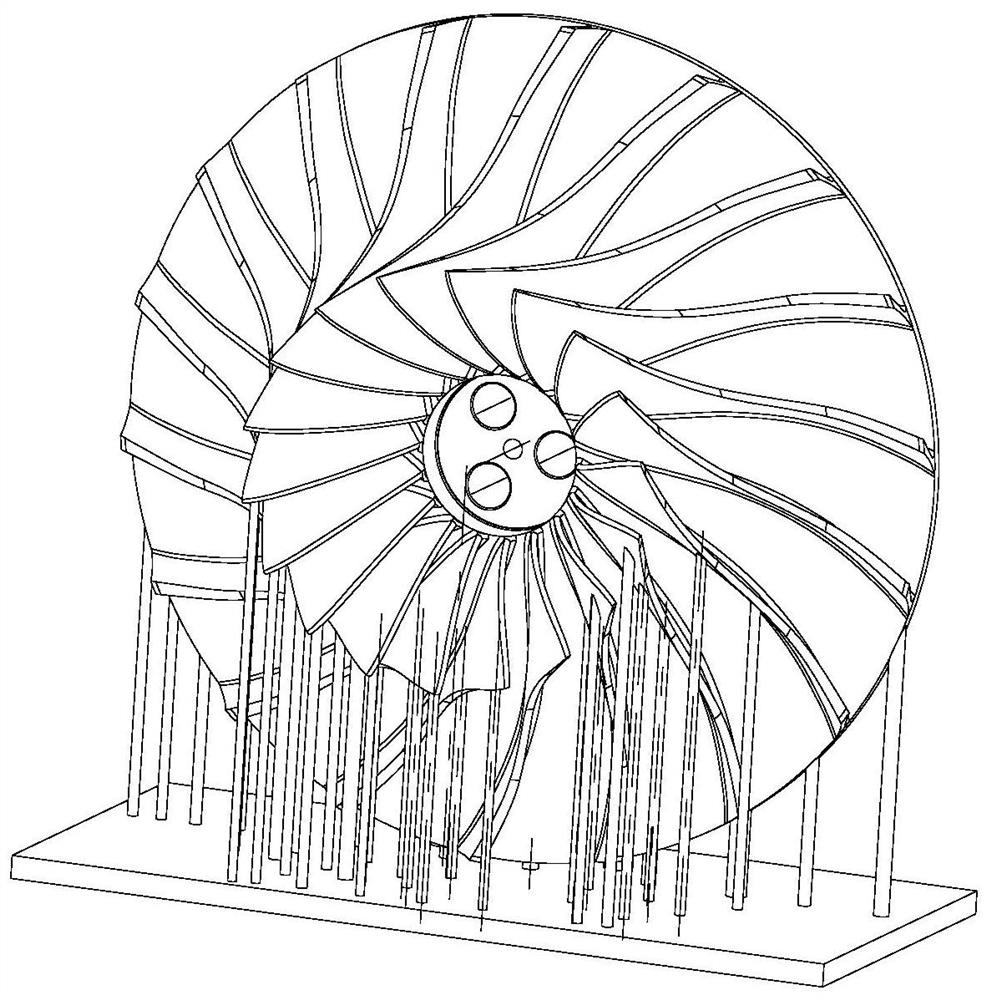

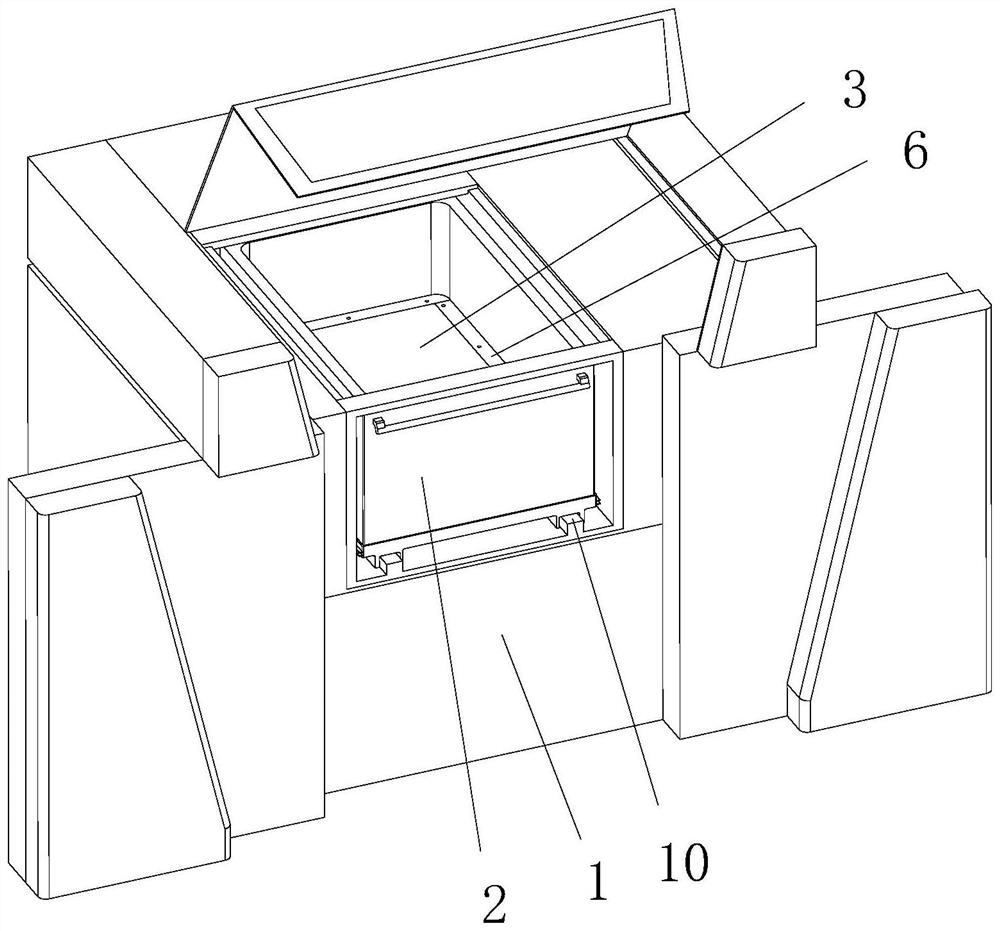

[0017] see Figure 1 to Figure 4 , the embodiment of the present invention includes:

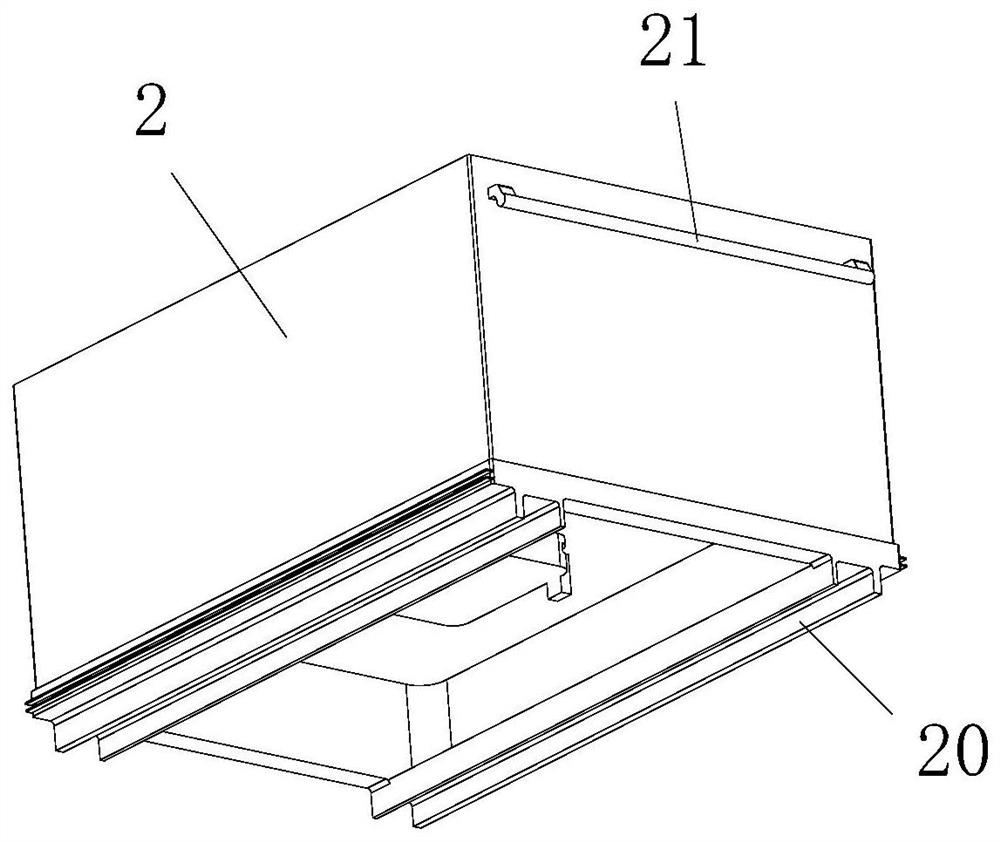

[0018] A forming box mechanism for 3DP printing technology, the forming box mechanism for 3DP printing technology includes a forming frame 1, a forming box body 2, a forming platform 3, a jacking assembly 4, a sealing sponge 5 and a sealing platen 6 , the molding box 2 is slidably inserted on the workbench of the molding frame 1, and the molding platform 3 is housed in the molding box 2, and the molding platform 3 is driven by the jacking assembly 4 to move up and down in the molding box 2, so Sealing grooves are provided around the upper plane of the forming platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com