Overlapping machine

A technology of vertical connection and support device, applied in the direction of conveyor, conveyor objects, stacking of objects, etc., can solve the problems of reducing conveying speed, reducing production line work efficiency, increasing manufacturing cost, etc., to improve work efficiency and ensure production. The rhythm and the process are convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

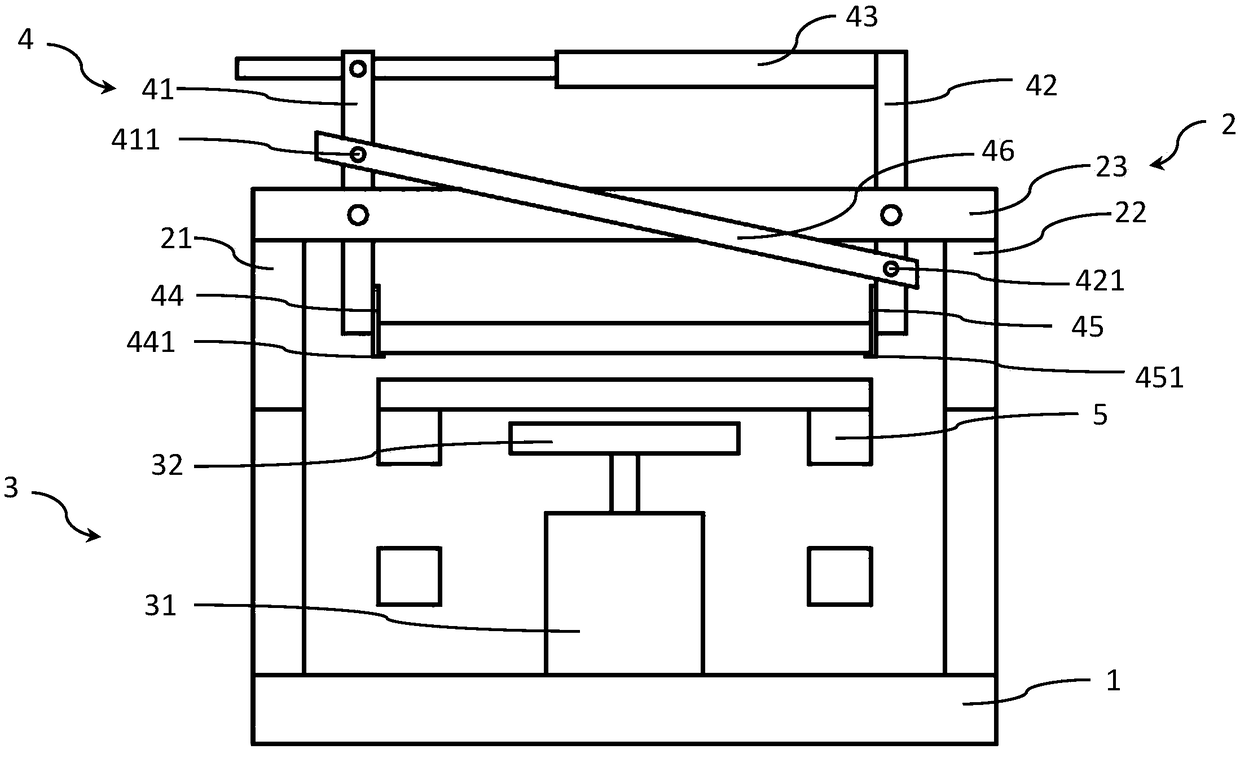

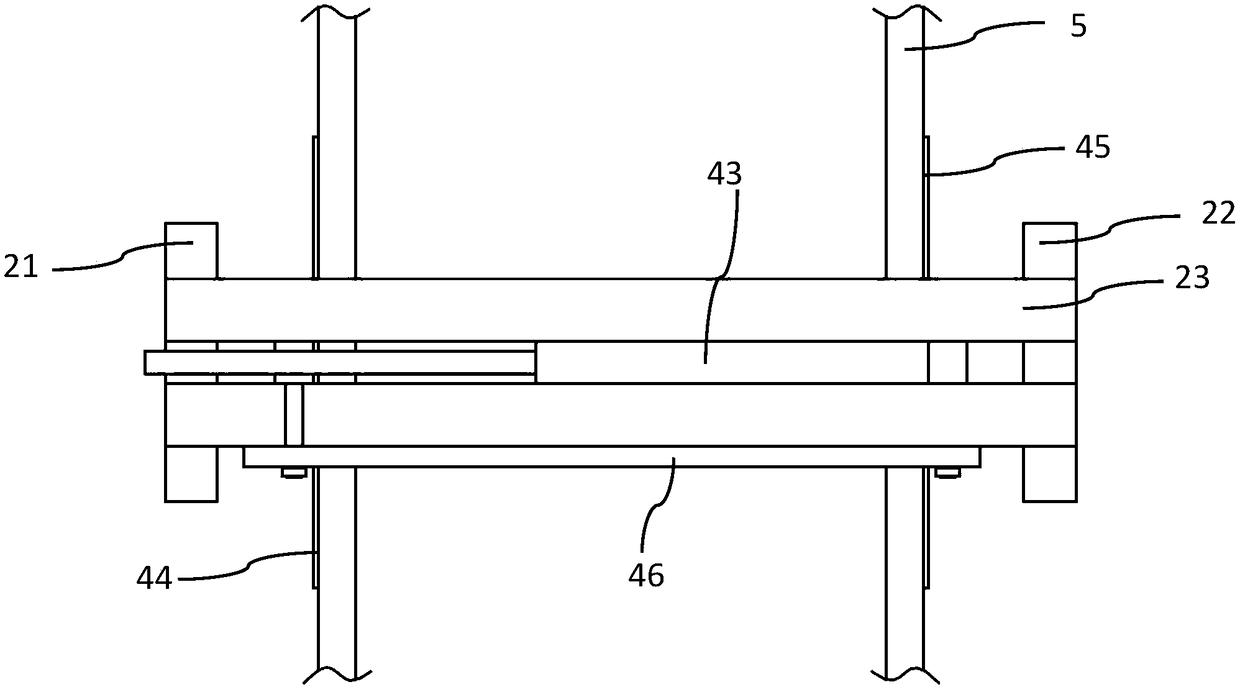

[0018] Such as figure 1 and figure 2 As shown, the present invention discloses a overlapping machine, comprising a base 1, a supporting device 2, a lifting device 3, a clamping device 4 and two conveyor belts 5; the supporting device 2 is arranged on the base 1, and the two conveyor belts 5 are arranged along the The feeding direction is symmetrically arranged in the base 1 , the lifting device 3 is installed on the base 1 , and the lifting device 3 is located between two conveyor belts 5 ; the clamping device 4 is installed on the supporting device 2 . The packaging box containing tiles is pushed to the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com