Method for producing clean steel through RH

A technology for cleaning steel and steel grades, applied in the field of metallurgy, can solve the problems of increasing equipment loss and hidden dangers, easy to be welded or blocked, unstable effect, etc., to achieve the effect of low cost, guaranteed production rhythm, and increased operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for RH to produce clean steel, the specific steps are as follows:

[0020] (1) 180t top-bottom combined blowing converter for slag-stop tapping, the tapping temperature is 1694°C, and 150kg of lime particles are added during the tapping process. The hanging tank temperature is 1644°C. After blowing argon for 5 minutes after the furnace, it was transported to the RH station. The RH entered the station to measure the temperature at 1621°C, and the oxygen was fixed at 564ppm. When entering the station, open the main vacuum valve to start forced decarburization. After 20 minutes, decarbonize to the target value, at this time, the fixed oxygen is 371ppm, and the temperature is 1603°C;

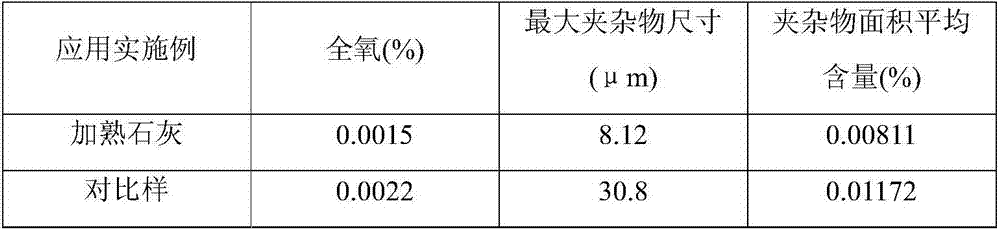

[0021] (2) Add aluminum at one time according to the oxygen activity. The target is to add according to the upper limit of the weight percentage of aluminum + 0.004%. 0.6kg / t of steel, 85kg of slaked lime added; after that, cycle for 5 minutes, temperature measurement and sampling...

Embodiment 2

[0027] A method for RH to produce clean steel, the specific steps are as follows:

[0028] (1) 180t top-bottom combined blowing converter for slag-stop tapping, the tapping temperature is 1698°C, and 170kg of lime particles are added during the tapping process. The hanging tank temperature is 1652°C. After blowing argon for 5 minutes after the furnace, it was transported to the RH station. The RH entered the station to measure the temperature at 1627°C, and the oxygen was fixed at 577ppm. When entering the station, open the main vacuum valve to start forced decarburization. After 20 minutes, decarbonize to the target value, at this time, the fixed oxygen is 361ppm, and the temperature is 1608°C;

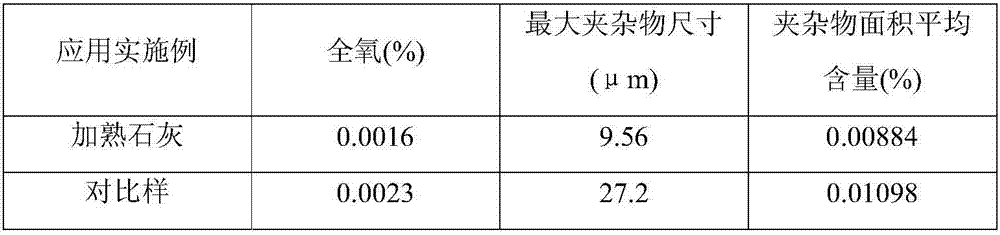

[0029] (2) Add aluminum at one time according to the oxygen activity. The target is to add according to the upper limit of the weight percentage of aluminum + 0.005%. 0.6kg / t of steel, 92kg of slaked lime added; after that, circulate for 5 minutes, measure temperature and take sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com